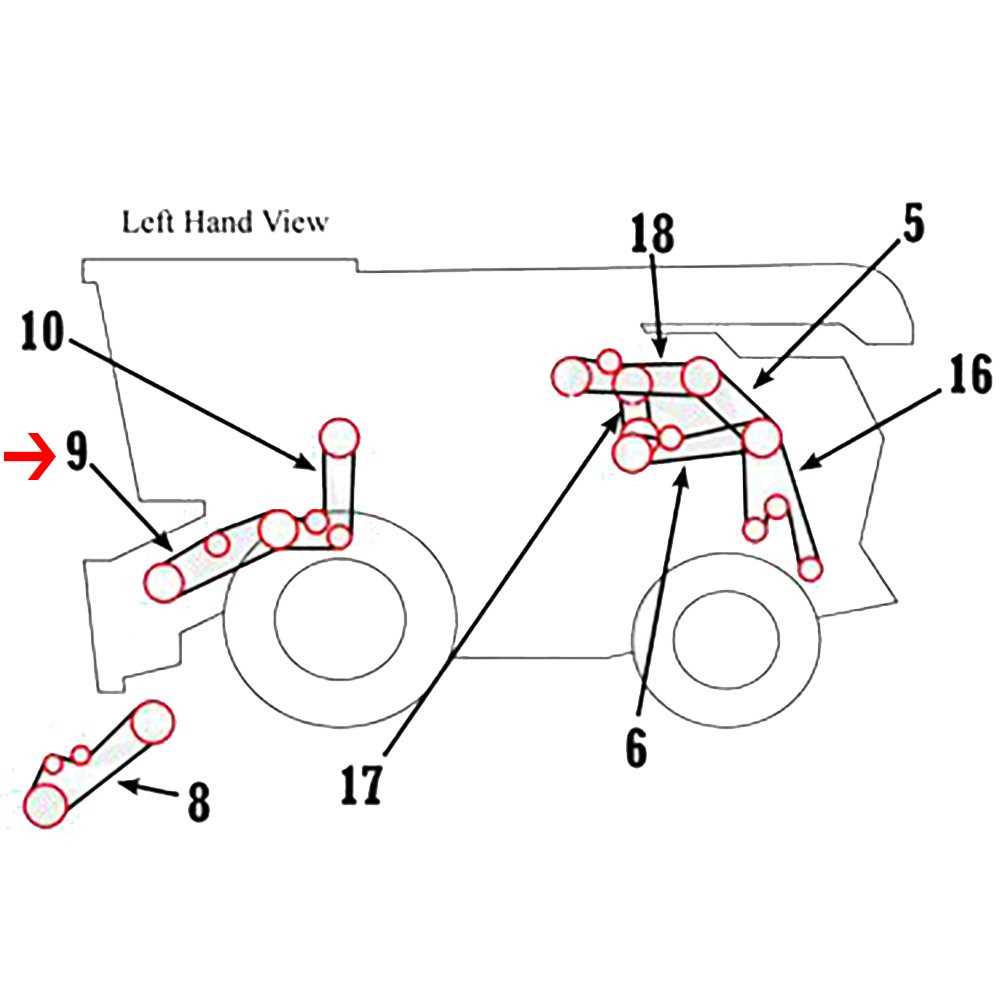

Understanding the intricate design of machinery used in agriculture is crucial for maintaining peak performance. Each element of these advanced machines plays a critical role, contributing to their overall functionality and efficiency. Being able to identify and locate key components is essential for repairs, replacements, and routine maintenance, ensuring long-term productivity.

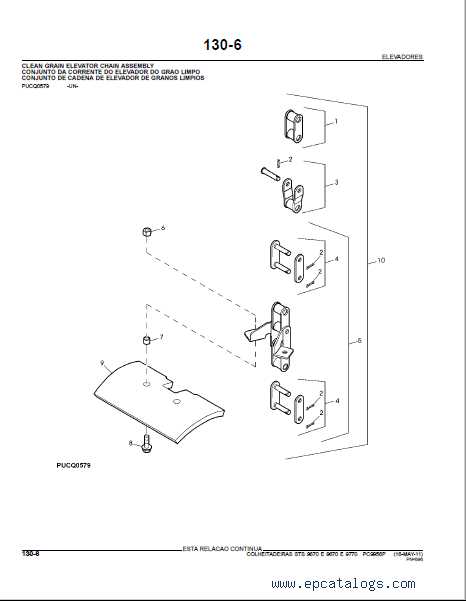

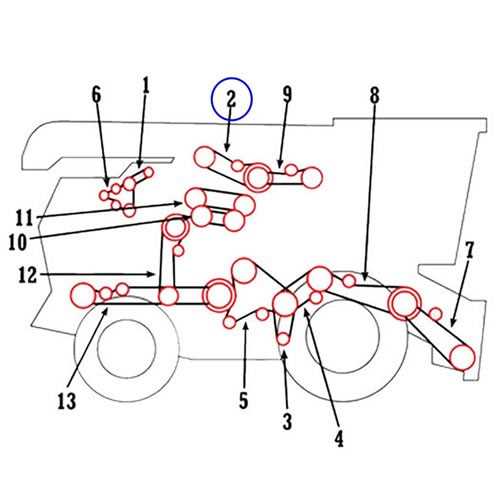

Detailed schematics provide invaluable insights into the internal structure of such equipment, helping operators and technicians navigate the complexity of modern agricultural tools. By studying the layout of various elements, individuals can enhance their ability to troubleshoot issues, streamline maintenance processes, and extend the operational lifespan of the machinery.

In this section, we will explore

Key Components of John Deere 9770

The overall structure of this powerful agricultural machine consists of several integral elements, each designed to ensure efficient operation in various field conditions. From the essential elements responsible for propulsion and movement to the advanced mechanisms that manage harvesting, each component plays a critical role in optimizing performance and reducing downtime.

Power Unit and Drive System

At the heart of the machine lies its power source, delivering the energy needed to perform intensive fieldwork. The drive system works in unison with the power unit, transmitting force to ensure smooth and controlled motion across uneven terrains, making it adaptable for various tasks.

Harvesting Mechanism

The specialized

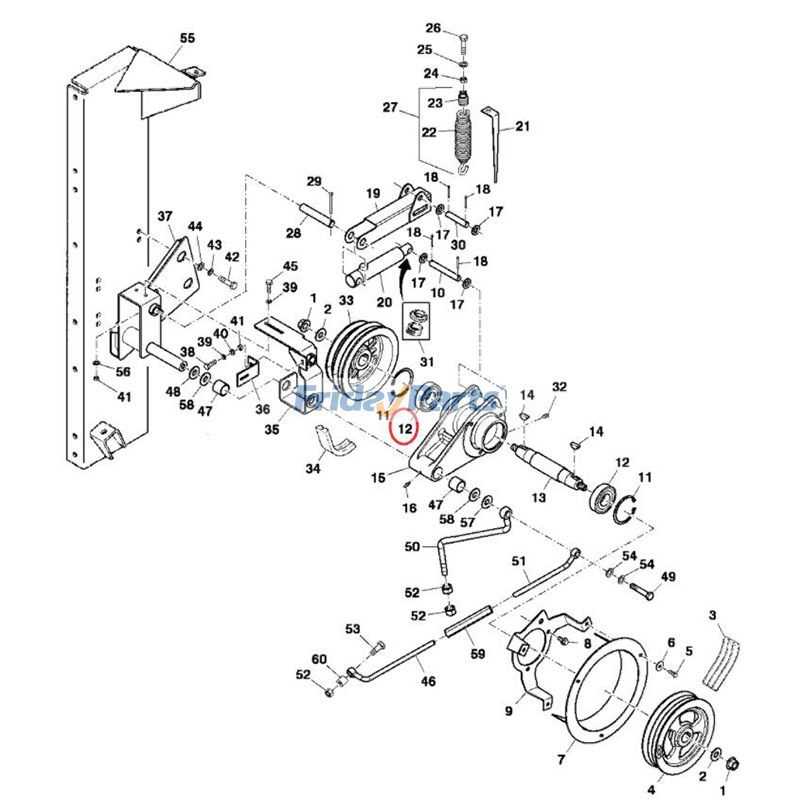

Exploring the Engine System Layout

The engine system serves as the core of mechanical operations, providing the necessary power and efficiency for optimal performance. Understanding its layout allows for better insight into the various interconnected components that drive the overall function. From fuel intake to exhaust, each part plays a critical role in maintaining energy flow and stability during use.

The table below highlights key areas within the system:

| Component | Function | ||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Fuel Injection | Ensures proper delivery of fuel into the combustion chamber for efficient ignition. | ||||||||||||||||||||||||

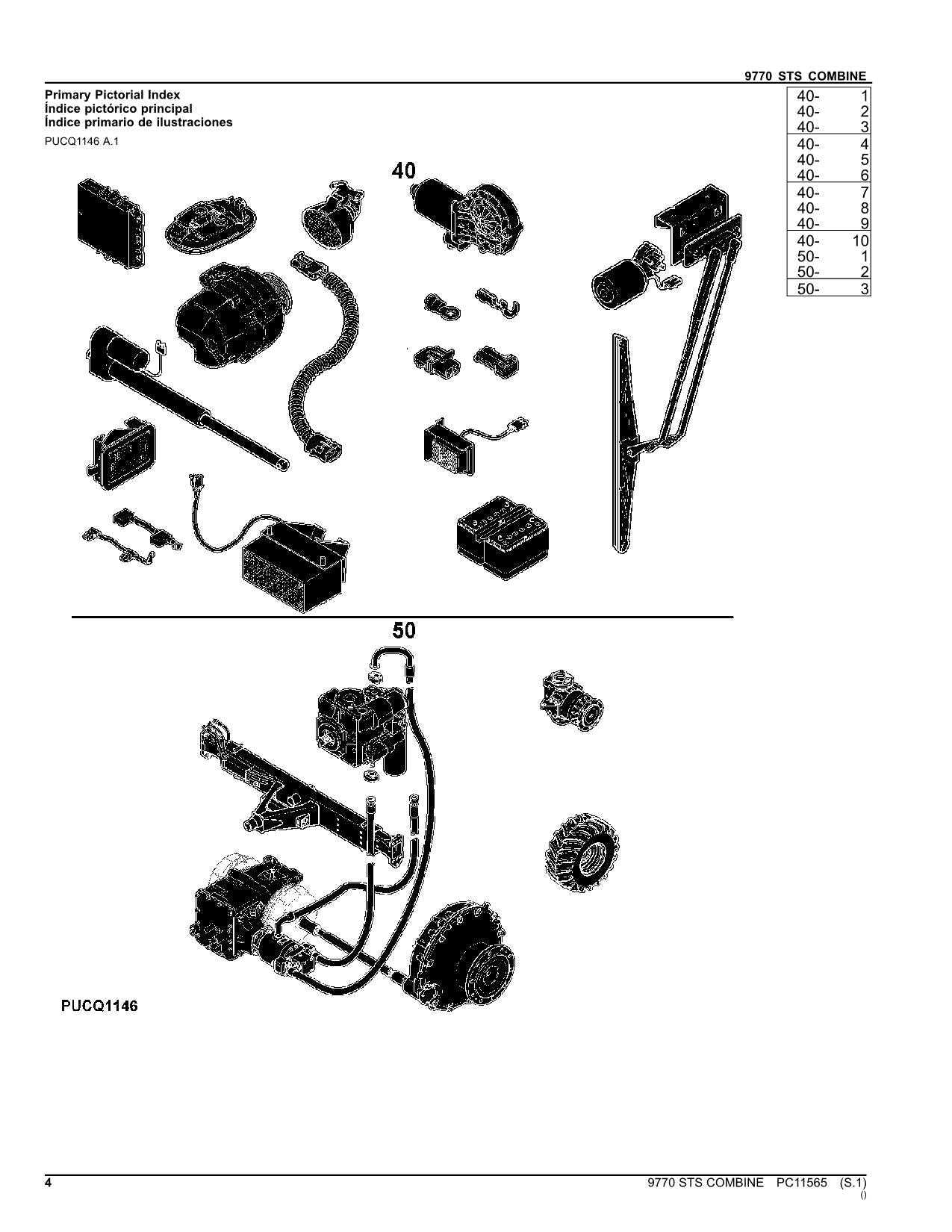

| Hydraulic Systems and Their Functions

Hydraulic systems play a critical role in modern machinery, enabling the transmission of power through fluid pressure. These systems are known for their efficiency and ability to deliver precise control over various mechanical processes. They utilize liquid movement to generate force, which can be applied in multiple areas of operation. Whether it’s lifting, moving, or manipulating heavy equipment, hydraulic technology ensures smooth and reliable performance. Pumping Mechanism is at the heart of hydraulic operation. A pump generates flow, pushing fluid through the system to create the pressure needed for force application. The pump’s role is essential for ensuring consistent energy transfer throughout the system. The valve network serves as the control mechanism, regulating the flow and direction of the fluid. This Detailed View of Electrical Connections

The intricate web of electrical systems in modern machinery is designed to ensure efficient performance, proper energy distribution, and seamless control of various components. Understanding the arrangement of these circuits is essential for troubleshooting, repair, and overall maintenance. This section provides a closer look at the main conductors, connectors, and pathways that allow energy and signals to flow effectively. Main Power DistributionAt the core of the system lies the central power hub, responsible for distributing electricity to various operational units. Key connections within this area include:

Signal Routing and Control

|

| Component | Function |

|---|---|

| Cutting Bar | Enables efficient cutting of the crop at the base. |

| Auger | Transfers cut material toward the center for collection. |

| Reel | Assists in directing the crop into the cutting area. |

| Skid Shoes | Provide support and stability during operation. |

Troubleshooting Issues in Mechanical Assemblies

Mechanical assemblies are intricate systems where various components work together to perform specific functions. When these assemblies encounter problems, it can lead to performance issues, decreased efficiency, or even complete system failure. Identifying the root causes of these issues is crucial for ensuring optimal functionality and longevity of the equipment.

Common Issues and Their Solutions

Understanding typical problems in mechanical structures can facilitate faster diagnostics and repairs. The following table summarizes some frequent issues, potential causes, and suggested remedies:

| Issue | Possible Cause | Recommended Action |

|---|---|---|

| Excessive Vibration | Misalignment of components | Realign the affected parts |

| Unusual Noises | Worn-out bearings | Replace bearings as necessary |

| Inconsistent Performance | Loose connections | Tighten all fasteners and connections |

| Overheating | Insufficient lubrication | Inspect and replenish lubrication |

Preventive Measures

To mitigate the risk of issues arising in mechanical assemblies, regular maintenance and inspections are essential. Implementing a scheduled maintenance plan can help identify potential problems before they escalate, ensuring the reliability and efficiency of the machinery.