The intricate network of machinery utilized in modern agriculture plays a crucial role in enhancing efficiency and productivity. Understanding the various elements that constitute these machines can significantly aid operators in ensuring optimal performance and maintenance. This section delves into the essential components of a specific model, providing clarity on their functions and interrelations.

In-depth knowledge of the individual segments not only facilitates effective troubleshooting but also empowers users to make informed decisions regarding replacements and upgrades. Each element serves a unique purpose, contributing to the overall functionality of the equipment. By examining the layout and connections of these components, operators can develop a comprehensive understanding of their machinery.

Furthermore, having a clear visualization of the various parts and their arrangement can streamline repair processes and enhance the user experience. Whether for routine maintenance or emergency repairs, familiarizing oneself with the configuration of these components is invaluable for any agricultural professional.

Understanding John Deere 990 Components

In the realm of agricultural machinery, comprehending the various elements that constitute a specific model is crucial for effective maintenance and operation. Each component plays a significant role in ensuring the overall functionality and efficiency of the equipment. By gaining insights into these individual parts, operators can enhance performance and longevity, facilitating smoother workflows.

Central Mechanisms: The heart of the machinery lies in its core mechanisms, which drive the operational capabilities. These components are designed to withstand rigorous usage while maintaining optimal performance levels.

Auxiliary Features: Additional features enhance the primary functions, offering operators greater versatility and efficiency. Understanding how these features integrate with core systems allows for improved handling and productivity in the field.

Maintenance Practices: Regular upkeep of these elements is essential for maximizing the machine’s lifespan. Recognizing signs of wear and implementing timely maintenance measures can prevent costly repairs and ensure consistent performance.

Parts Interconnectivity: A thorough understanding of how these elements work together is vital. Each part relies on others to function correctly, highlighting the importance of proper assembly and alignment for optimal operation.

Overview of the 990 Model

This section provides a comprehensive insight into a prominent agricultural machinery model known for its efficiency and reliability. With advanced engineering and robust design, this equipment has become a favored choice among farmers and professionals in the industry. Understanding its features and components is essential for maximizing performance and ensuring longevity.

Key Features

Renowned for its durability and versatility, this machinery integrates cutting-edge technology that enhances productivity. The model is equipped with various enhancements that cater to diverse farming needs, making it an indispensable asset in modern agriculture.

Applications

This equipment is widely utilized in various agricultural tasks, including tillage, planting, and harvesting. Its adaptability allows it to excel in different soil conditions and crop types, ensuring optimal results for users. Furthermore, the efficient operation reduces downtime and maintenance costs, contributing to overall productivity.

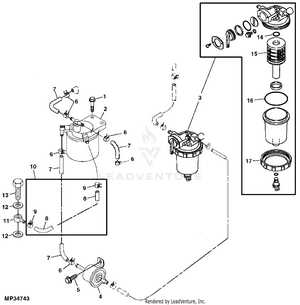

Essential Parts for Maintenance

Proper upkeep of agricultural machinery requires a thorough understanding of critical components that ensure optimal functionality. Regular inspection and replacement of these elements contribute significantly to the longevity and performance of the equipment.

| Component | Description | Function |

|---|---|---|

| Engine Oil Filter | Filters impurities from engine oil | Maintains clean oil circulation |

| Air Filter | Removes dust and debris from intake air | Ensures efficient combustion |

| Fuel Filter | Filters contaminants from fuel | Prevents engine damage |

| Belt Drive | Transfers power from the engine to attachments | Ensures efficient operation |

| Hydraulic Fluid | Fluids used in hydraulic systems | Facilitates movement and operation of implements |

Common Issues and Solutions

When operating complex machinery, users may encounter various challenges that affect performance and reliability. Recognizing these issues early can prevent further complications and ensure smooth operation.

Overheating is a frequent concern that can lead to severe damage if not addressed promptly. This issue often arises from inadequate lubrication or cooling system malfunctions. Regularly checking fluid levels and ensuring proper airflow can mitigate this risk.

Another common problem is starting difficulties, which can stem from battery failure or fuel system blockages. To resolve this, inspect the battery’s condition and connections, and ensure the fuel lines are clear and functional.

Uneven wear on components can significantly impact efficiency. This often results from misalignment or improper adjustment. Routine inspections and calibrations can help identify and rectify such discrepancies before they escalate.

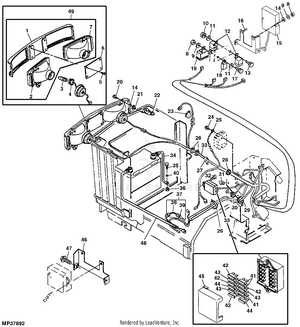

Finally, electrical malfunctions may disrupt operation. These issues can range from faulty wiring to defective sensors. Conducting thorough electrical checks and maintaining clean connections can help prevent these problems.

Where to Find Replacement Parts

Locating suitable components for machinery maintenance is crucial for ensuring optimal performance and longevity. Various resources are available for those seeking to replace specific elements, whether for routine upkeep or repair needs. Below are some recommended avenues to explore when searching for high-quality substitutes.

Authorized Dealers and Retailers

Authorized distributors offer a reliable source for genuine components. These retailers are often equipped with knowledgeable staff who can assist in identifying the correct items based on model specifications. Furthermore, purchasing from recognized sellers guarantees the authenticity of the parts.

Online Marketplaces

Numerous online platforms provide an extensive selection of replacement items. These sites enable users to compare prices, read reviews, and ensure compatibility with their equipment. It’s essential to verify the seller’s reputation before making any purchases to avoid counterfeit or substandard products.

| Source | Description | Advantages |

|---|---|---|

| Authorized Dealers | Official retailers of specific brands. | Genuine products and expert assistance. |

| Online Marketplaces | Various websites offering numerous options. | Price comparisons and customer reviews. |

| Local Mechanics | Service providers who may stock parts. | Immediate access and installation services. |

Importance of Using Genuine Parts

Utilizing authentic components is crucial for maintaining the efficiency and longevity of machinery. Original items are designed to meet specific standards, ensuring compatibility and optimal performance. This commitment to quality can significantly enhance the reliability of equipment, reducing the likelihood of unexpected failures.

Enhanced Performance: When machines are equipped with original components, they operate at their best. Authentic parts are engineered to fit precisely, providing improved functionality and efficiency. This can lead to better fuel consumption and overall productivity.

Long-Term Cost Savings: While it may be tempting to choose cheaper alternatives, investing in genuine components often proves more economical in the long run. Imitation items can lead to frequent breakdowns and costly repairs, negating any initial savings.

Warranty Protection: Many manufacturers offer warranties that are contingent upon the use of original components. Utilizing non-genuine items may void these warranties, leaving users responsible for any repair costs. Ensuring that only authentic parts are used safeguards the investment in equipment.

Safety Assurance: Authentic components undergo rigorous testing to meet safety standards. By opting for genuine parts, users can trust that their machinery adheres to these regulations, minimizing the risk of accidents or injuries caused by faulty equipment.

In summary, the choice of genuine components is vital for anyone seeking to maintain their machinery’s performance and reliability. The benefits of enhanced efficiency, cost savings, warranty protection, and safety make this choice a clear priority for responsible equipment management.

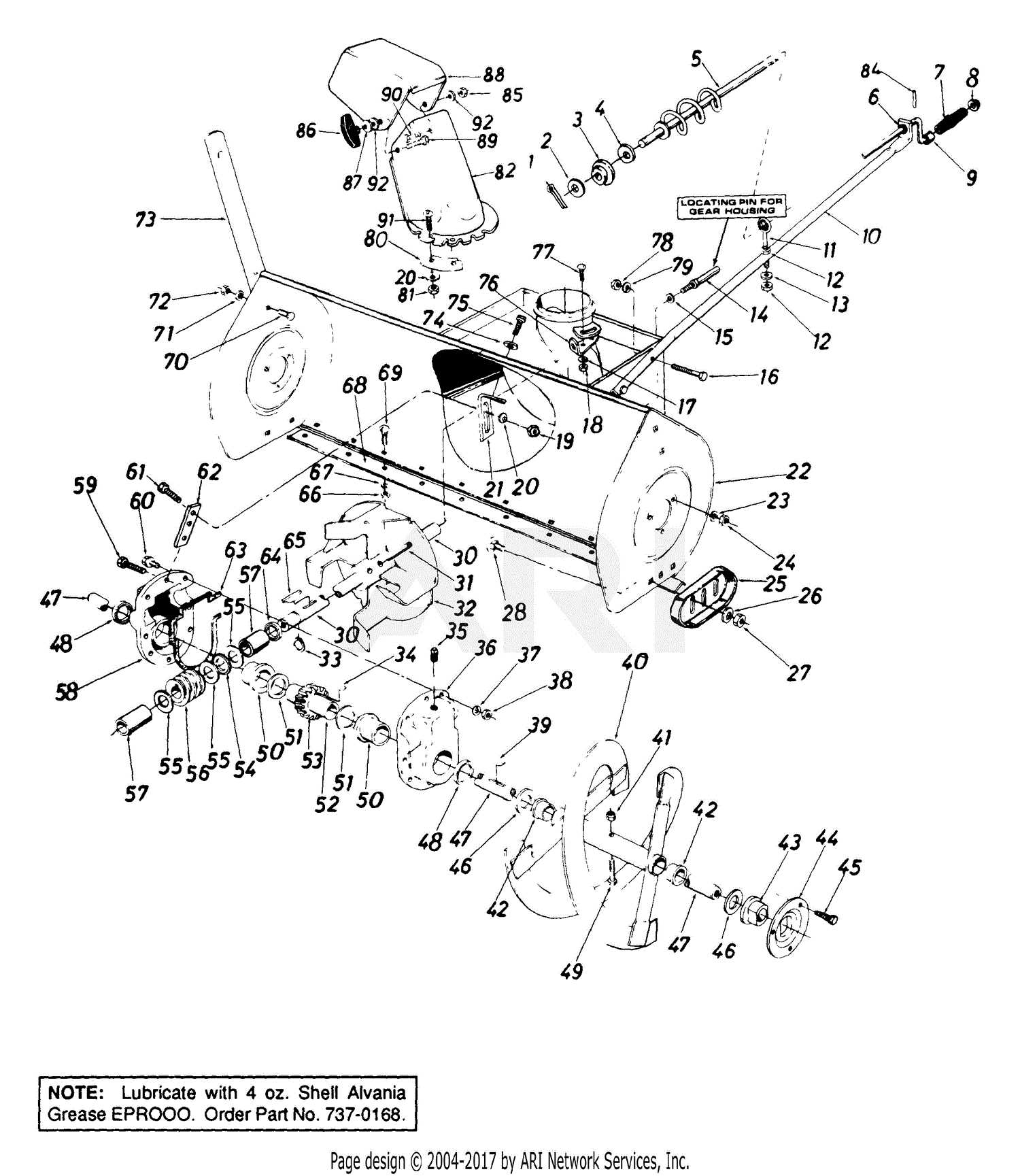

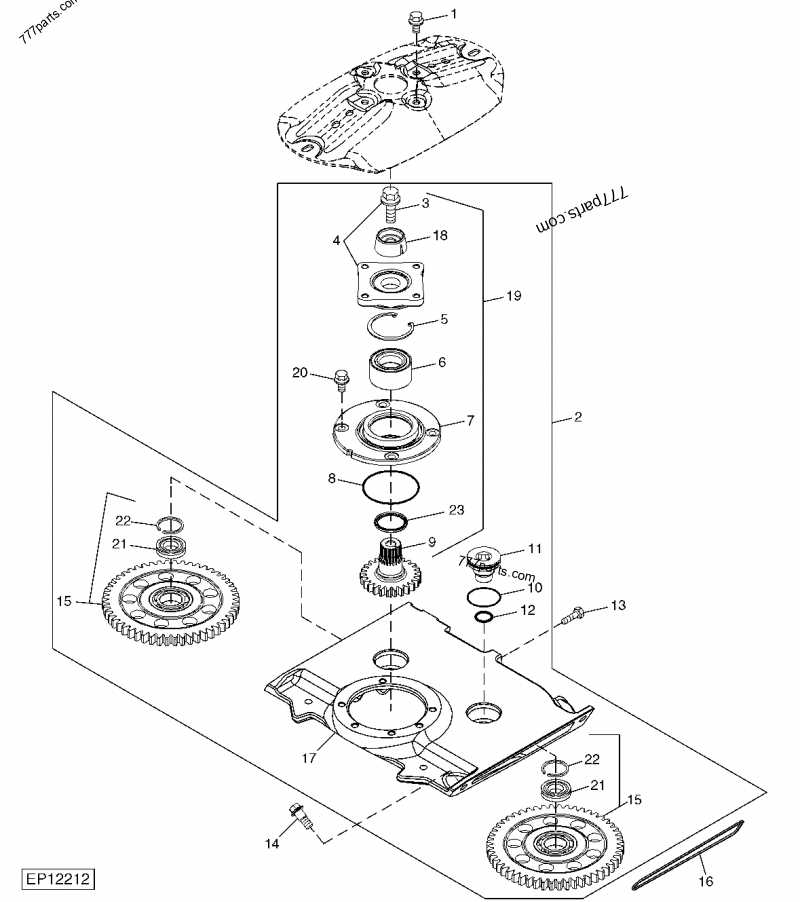

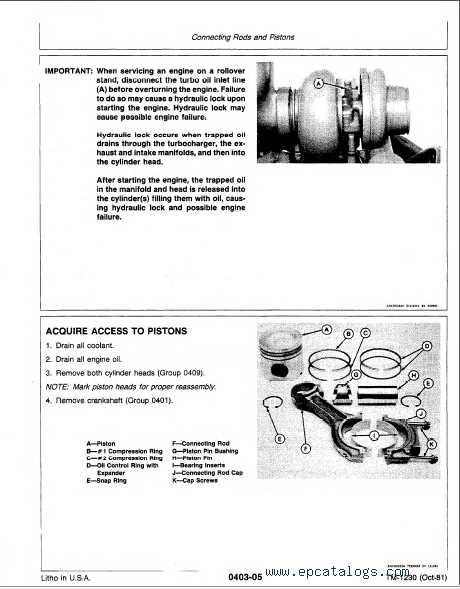

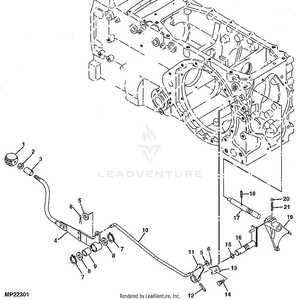

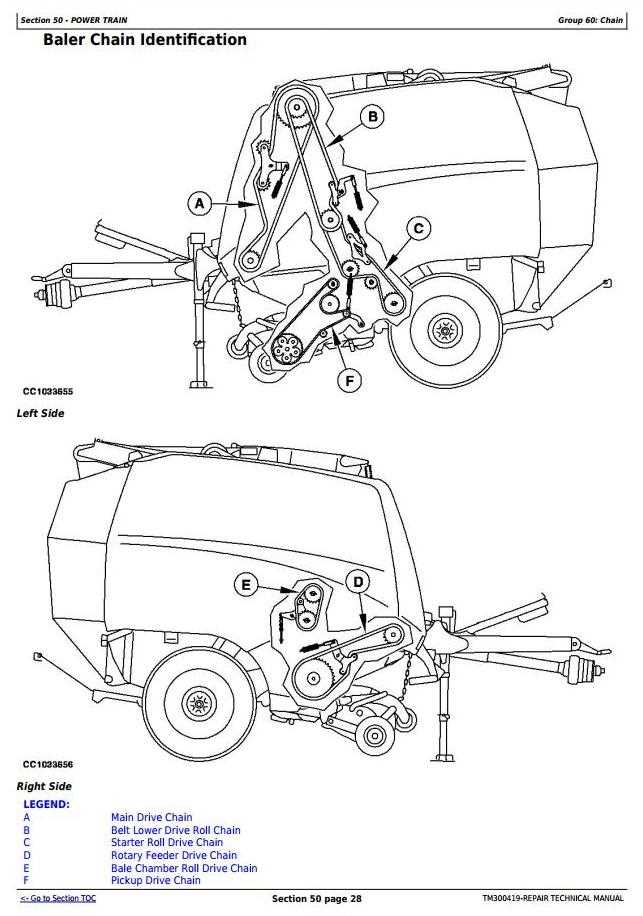

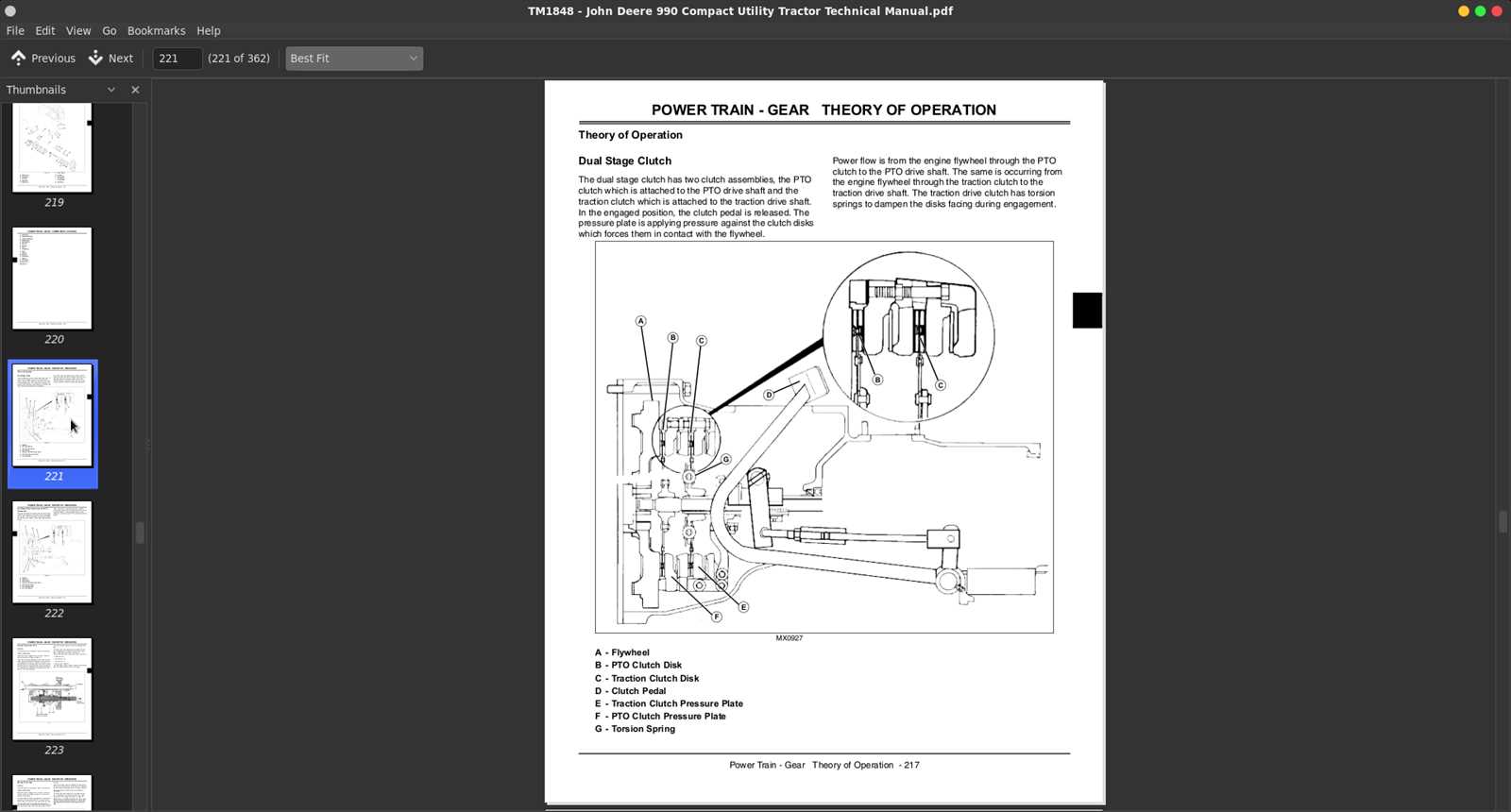

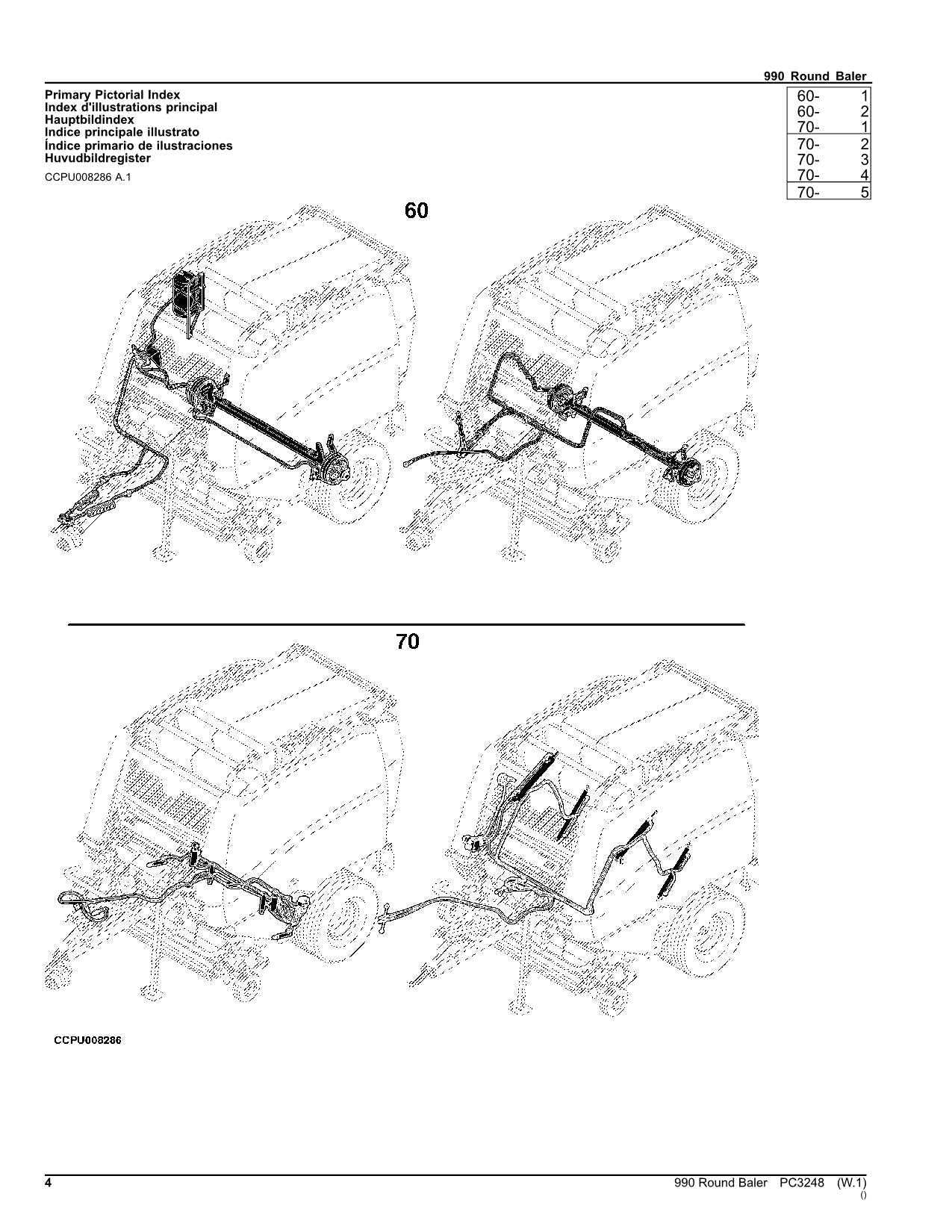

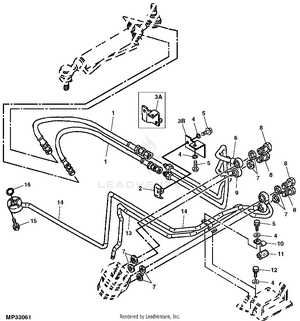

How to Read Parts Diagrams

Understanding illustrations that depict components is essential for effective maintenance and repairs. These visuals serve as a guide to identify individual elements and their arrangement within a system. Grasping the layout can streamline the process of locating and replacing items, ensuring optimal functionality.

Start by familiarizing yourself with the overall layout, noting how different sections are organized. Each element is typically numbered or labeled, making it easier to cross-reference with a list of specifications. Pay attention to the connections and relationships between components, as this will aid in understanding how they interact with one another.

Next, take note of any symbols or color coding used, as these often indicate specific features or functions. Being aware of these details enhances comprehension and assists in identifying compatible replacements. Lastly, always refer to the accompanying documentation for additional insights and instructions that may clarify any uncertainties.

Upgrading Your John Deere 990

Enhancing the performance and functionality of your agricultural machinery can significantly improve efficiency and productivity. Upgrades can range from minor adjustments to major modifications, depending on your specific needs and the tasks at hand. By selecting the right components and technologies, you can elevate the capabilities of your equipment and ensure it meets modern operational demands.

Choosing the Right Enhancements

When considering improvements, it’s essential to evaluate which aspects of your machinery require attention. Upgrading the engine for increased power output or incorporating advanced transmission systems can lead to better performance. Additionally, investing in modern attachments or accessories can expand the versatility of your equipment, allowing it to tackle a wider variety of tasks with ease.

Installation and Maintenance Tips

Proper installation and ongoing maintenance of new components are critical for maximizing the benefits of any upgrade. Always consult manufacturer guidelines and seek professional assistance if needed to ensure that modifications are executed correctly. Regular maintenance checks will help in identifying potential issues early, ensuring that your machinery remains in top condition and continues to perform at its best.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your equipment involves a combination of regular upkeep and mindful practices. By adopting a proactive approach to maintenance, you can minimize wear and tear, enhance performance, and avoid costly repairs. This section highlights essential strategies to keep your machinery running smoothly over time.

Routine Inspections

Conducting regular checks on various components is crucial. Look for signs of wear, leaks, and other issues that may arise during operation. By identifying problems early, you can address them before they escalate into significant repairs.

Proper Lubrication

Maintaining adequate lubrication is vital for reducing friction and preventing damage. Use the recommended lubricants for your equipment, and follow the specified intervals for application. Proper lubrication contributes to the efficient functioning of moving parts, enhancing overall performance.

Comparing 990 with Other Models

This section explores the distinctions and similarities between this particular agricultural machinery and its counterparts in the same category. By examining various features, functionalities, and specifications, users can gain insights into how this model stands in comparison to others available in the market.

One notable aspect is the engine performance, which varies significantly across different machines. While some may prioritize power, others focus on fuel efficiency, catering to specific user needs. Additionally, the range of attachments compatible with each model can influence operational versatility, making it essential to consider the intended application when choosing the right equipment.

Furthermore, the design and ergonomics play a crucial role in user experience. Certain models may offer enhanced comfort and ease of use, thereby affecting productivity during long working hours. Evaluating these attributes alongside maintenance requirements can provide a comprehensive understanding of which machinery will best suit individual operational demands.

Resources for DIY Repairs

Engaging in do-it-yourself maintenance can be a rewarding experience, enabling enthusiasts to take charge of their machinery. Having the right resources at hand is essential for successful repairs and upgrades. Various platforms offer valuable information, ranging from manuals to community forums, ensuring that individuals can tackle their projects with confidence.

| Resource Type | Description | Where to Find |

|---|---|---|

| User Manuals | Detailed guides that outline maintenance procedures and troubleshooting steps. | Manufacturer’s website or local dealerships |

| Online Forums | Communities where users share experiences, advice, and solutions to common issues. | Dedicated machinery forums or social media groups |

| Video Tutorials | Visual guides demonstrating repair techniques and maintenance practices. | YouTube or DIY websites |

| Parts Retailers | Suppliers offering components and accessories for repairs and enhancements. | Online marketplaces or specialized retailers |