Modern agricultural machinery is an intricate blend of technology and engineering, designed to improve efficiency and precision on the field. One of the essential elements of such machinery involves various attachments and specialized tools that ensure optimal performance during harvesting. Recognizing and understanding these crucial mechanisms is important for smooth operation and maintenance.

Each machine is composed of multiple elements that work together in harmony, each performing a specific function to deliver a reliable harvest. In this section, we explore the various assemblies and mechanisms that make up these machines, highlighting their role in the overall system. This knowledge will help in identifying key areas to focus on when addressing performance or wear issues.

By gaining a deeper understanding of the individual mechanisms within these machines, you can better manage maintenance, ensure longevity, and maintain productivity throughout the harvesting season. Detailed insights into how each component contributes to the machine’s functionality can assist in making informed decisions during repairs or upgrades.

Understanding the Structure of the 995 Header

The mechanical design of this implement is crucial for efficient performance in a range of field conditions. By examining how its various components interact, operators can gain insights into optimizing its use for harvesting and processing. Each part of the assembly plays a role in enhancing the precision and speed of operations, contributing to a smooth workflow.

Core Components and Their Functions

The primary elements work together to cut and gather crops seamlessly. These include cutting mechanisms, gathering systems, and drive assemblies, all designed to ensure a uniform and consistent process. Each section is engineered to handle specific tasks, which helps the overall system adapt to different terrains and crop types.

Importance of Regular Maintenance

Regular checks and adjustments of this machinery are vital to maintaining its efficiency. Over time, wear and tear can affect the functionality of its components, leading to reduced performance. Keeping up with maintenance schedules ensures that each element functions at its peak, prolonging the machine’s operational lifespan.

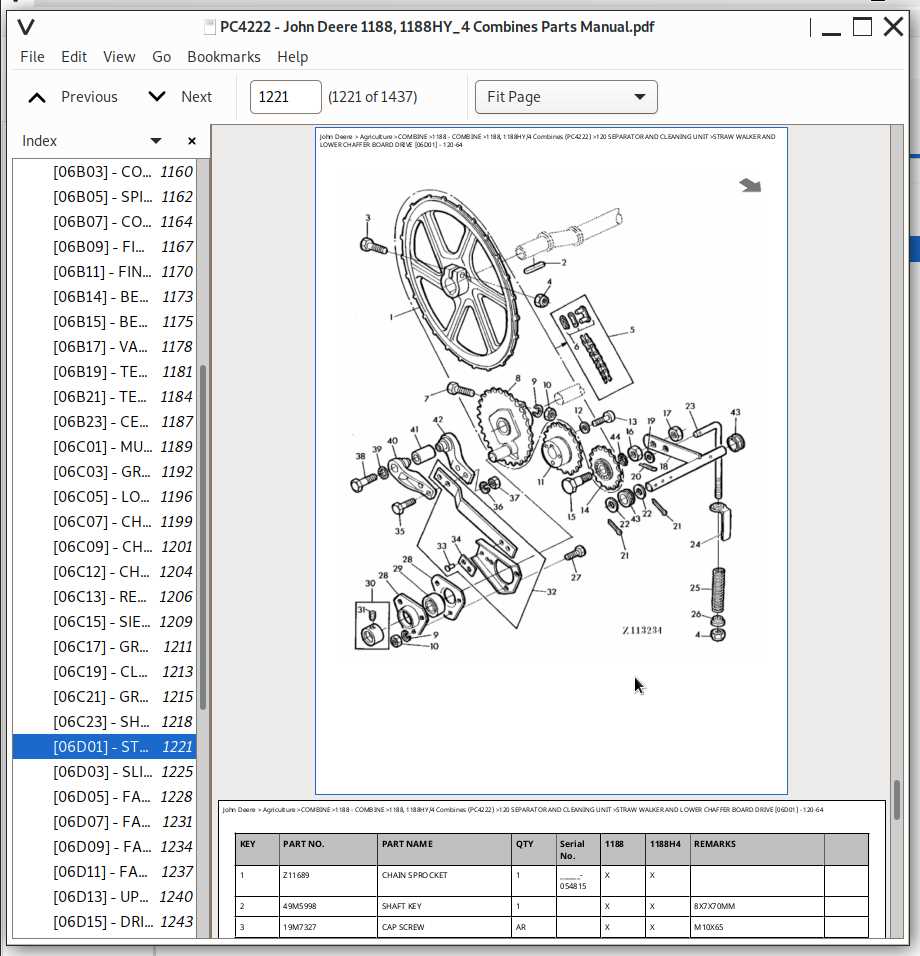

Key Components in the Agricultural Cutting System

In any agricultural cutting equipment, understanding its essential mechanical parts is crucial for effective operation and maintenance. Each section of the machinery is designed to ensure optimal performance in harvesting crops, with every element working together to achieve maximum efficiency and reliability.

Cutting Mechanism: The cutting system plays a vital role in the efficient separation of crops. Precision blades or knives are employed to ensure clean cuts, minimizing damage to the harvested material while maximizing output.

Feeding Assembly: The feeding component helps move the harvested material towards the next stages of processing. Designed to handle various crop types, it ensures smooth and consistent material flow, reducing the risk of clogging and enhancing throughput.

Drive System: The power behin

Common Wear Points in the Header Assembly

In any agricultural cutting equipment, specific areas are more susceptible to wear due to the nature of their operation. These components endure constant motion, friction, and interaction with tough materials, making them prone to damage over time. Understanding where to expect wear can help with maintenance and reduce downtime.

Blade and Cutter Bar Wear

The blades and the cutting bar are among the most stressed components. As they continuously engage with crops, their sharp edges gradually dull, and the entire assembly may become misaligned. Regular inspection and sharpening are essential to prevent inefficiencies and avoid more significant repairs.

- Blades dulling from contact with tough stalks

- Misalignment leading

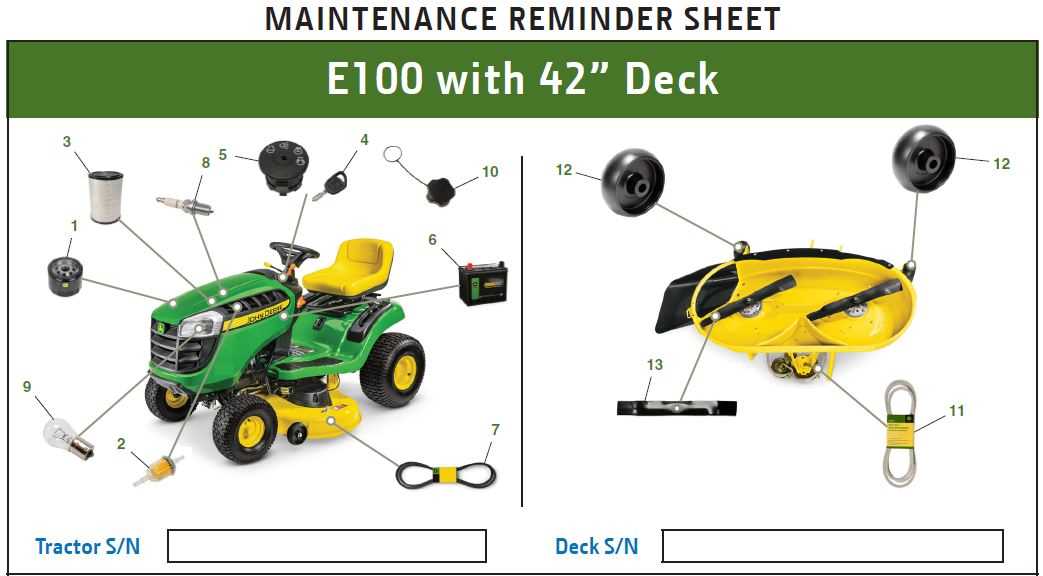

Maintenance Tips for Agricultural Equipment Components

Regular upkeep of key machinery elements ensures optimal performance and prolongs the lifespan of your equipment. Following simple, yet effective strategies can help avoid unexpected breakdowns and ensure smooth operation during the busiest seasons.

Inspect and Clean Frequently

- Check critical connections regularly for dirt, rust, or debris buildup.

- Keep essential mechanisms free from contaminants by cleaning them after every use.

- Lubricate moving parts to prevent wear and tear.

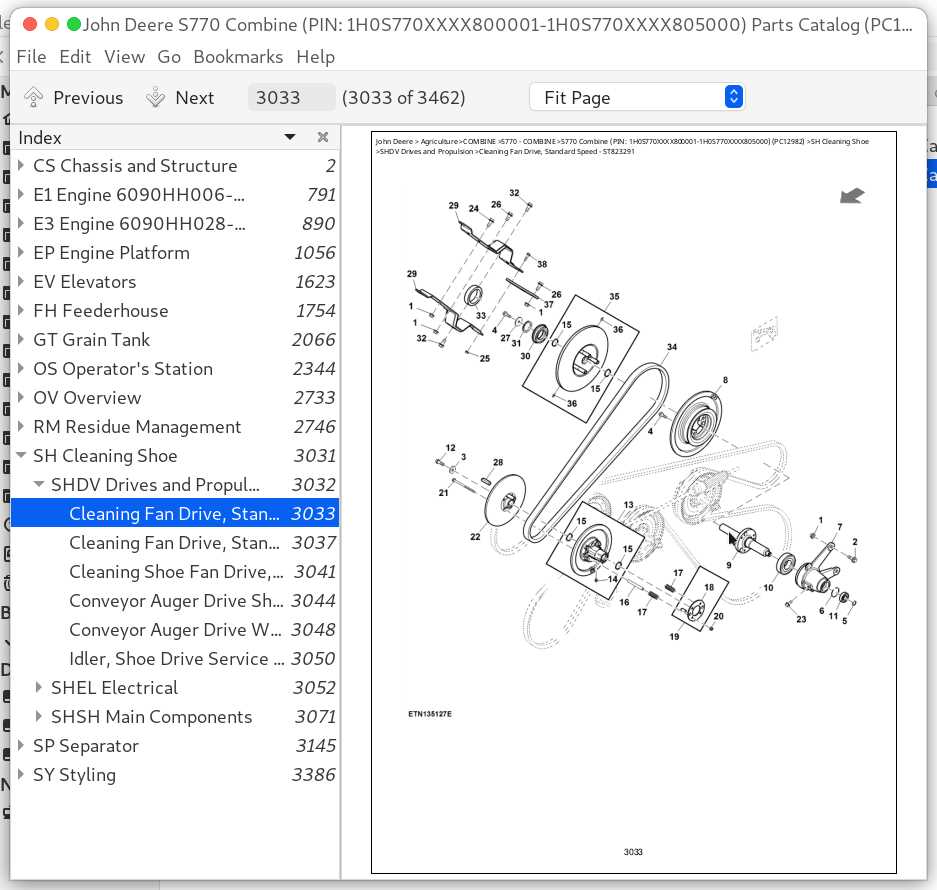

Exploring the Gear and Drive Mechanism

The internal workings of the machinery responsible for movement and power transmission rely heavily on a well-coordinated set of gears and drive elements. These components function together to ensure efficient motion, whether it’s for turning, lifting, or transporting materials. Understanding how these parts interact can help identify any potential points of wear and ensure smooth operation.

Main Components Overview

The system includes several key mechanical elements designed to convert energy into motion. These include the

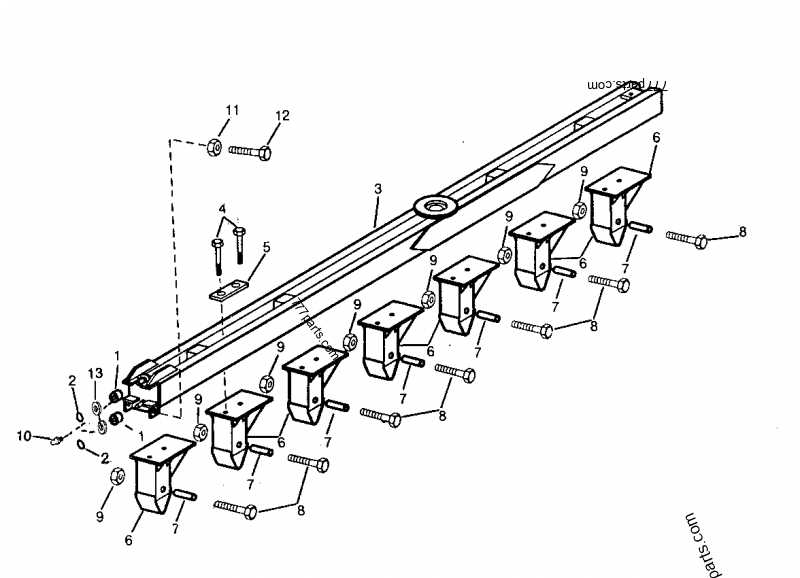

Blade and Cutterbar Setup for Efficient Operation

Proper arrangement of cutting components is essential for maximizing performance and ensuring seamless operation during harvesting. This setup not only influences the quality of the cut but also impacts the overall productivity of the machinery. Attention to detail in the configuration of these elements can lead to smoother operation and reduced wear over time.

Importance of Accurate Alignment

Achieving precise alignment of blades and cutterbars is crucial. Any misalignment can lead to uneven cutting and increased strain on the machine. Regularly checking and adjusting the angles and positions of these components can help maintain optimal performance. Ensure that all fastenings are secure to prevent vibrations that may cause further alignment issues.

Maintenance and Regular Inspections

Routine maintenance plays a significant role in sustaining efficient operation. Regularly inspect blades for signs of wear or damage, and replace them as needed to maintain cutting efficiency. Lubrication of moving parts is equally important, as it minimizes friction and prolongs the life of the equipment. By adhering to a consistent maintenance schedule, operators can avoid unexpected downtime and ensure smooth harvesting operations.

Identifying Hydraulic Systems in the Header

Understanding the role of hydraulic mechanisms within agricultural equipment is crucial for efficient operation. These systems are responsible for facilitating various functions, including lifting, lowering, and adjusting components to optimize performance in the field. By familiarizing oneself with the elements that comprise these systems, operators can enhance their maintenance practices and troubleshoot issues effectively.

Key Components of Hydraulic Mechanisms

Hydraulic systems typically consist of several integral components, including pumps, cylinders, hoses, and valves. Each of these elements plays a significant role in the overall functionality. The pump generates fluid pressure, which is essential for activating the cylinders that perform work. Hoses transport the hydraulic fluid between these parts, while valves control the direction and flow of the fluid, enabling precise adjustments.

Maintenance Considerations

Regular inspection of hydraulic systems is vital to ensure their reliability. Operators should check for leaks, worn hoses, and damaged components to prevent failures during operation. Maintaining clean fluid levels and replacing filters periodically can also prolong the lifespan of these systems. By staying proactive in maintenance, users can avoid costly repairs and ensure optimal performance during critical tasks.

How to Replace Key Moving Parts

Replacing essential components of machinery is crucial for maintaining optimal performance and efficiency. Understanding the steps involved in this process ensures that you can effectively carry out the task while minimizing downtime. This guide provides a clear overview of how to handle the replacement of vital moving elements in agricultural equipment.

Preparation Steps

- Gather necessary tools and replacement components.

- Consult the user manual for specific instructions and safety guidelines.

- Ensure the machine is powered down and secured to prevent accidents.

Replacement Process

- Remove the protective casing or covers to access the moving components.

- Carefully detach the worn-out elements, taking note of their arrangement for reassembly.

- Install the new components, ensuring a snug fit and proper alignment.

- Reattach any covers or casings that were removed during the process.

- Test the machinery to confirm that the replacements function correctly.

Checking for Alignment in the Header Frame

Ensuring proper alignment within the assembly structure is crucial for optimal performance and efficiency. Misalignment can lead to increased wear, reduced functionality, and potential mechanical failures. Regular inspections and adjustments are necessary to maintain the integrity of the equipment.

Importance of Proper Alignment

Maintaining correct positioning is essential for smooth operation. Proper alignment minimizes stress on components and promotes even wear. This not only extends the lifespan of the machinery but also enhances overall productivity. A well-aligned frame contributes to precise cutting and efficient crop handling.

Steps for Checking Alignment

Begin by examining the frame visually for any noticeable discrepancies. Utilize a level tool to ensure the structure is even. If adjustments are needed, loosen the necessary fasteners and make the required changes carefully. Recheck alignment after making adjustments to confirm accuracy. Regular monitoring will help identify potential issues before they escalate.

Troubleshooting Issues in the 995 Header

Addressing challenges related to the harvesting attachment is essential for ensuring optimal performance and productivity. Various issues can arise during operation, affecting efficiency and overall functionality. Identifying and resolving these problems quickly can minimize downtime and enhance the machine’s effectiveness.

Common challenges that operators may encounter include malfunctioning components, irregular performance, and difficulties during attachment operation. Proper maintenance and regular inspections play a crucial role in preventing these issues. Below is a table outlining some frequent concerns and potential solutions:

Issue Possible Causes Recommended Solutions Uneven cutting Worn blades or improper height settings Check and replace blades; adjust height settings accordingly Excessive vibration Loose components or imbalance Tighten all fittings and inspect for balance Power loss Clogged systems or damaged belts Clear any obstructions; inspect and replace belts if necessary Stalling Overheating or fuel supply issues Monitor temperature; ensure proper fuel flow and quality By understanding these typical problems and applying the suggested remedies, operators can maintain high efficiency and prolong the lifespan of their equipment. Regular maintenance checks and attention to detail are vital in preventing operational disruptions.

Cleaning and Storage Recommendations for Longevity

To ensure the durability and optimal performance of agricultural equipment, it is essential to implement effective cleaning and storage practices. Regular maintenance not only extends the life of the machinery but also enhances efficiency during operation. This section outlines key strategies for maintaining your equipment in excellent condition.

Effective Cleaning Procedures

Thorough cleaning after use prevents the accumulation of dirt, debris, and residues that can lead to corrosion and mechanical failure. Here are some recommended steps:

Step Action 1 Remove loose debris using a brush or compressed air. 2 Wash surfaces with water and a mild detergent to eliminate stubborn grime. 3 Inspect all components for wear or damage during cleaning. 4 Dry thoroughly to prevent moisture accumulation. Optimal Storage Conditions

Proper storage is crucial for preventing deterioration. Follow these guidelines to maintain equipment in ideal conditions:

Condition Recommendation Location Store in a dry, covered area to protect from weather elements. Environment Avoid areas with high humidity or extreme temperatures. Position Ensure machinery is positioned on a stable surface to prevent tipping. Inspection Regularly check stored equipment for signs of pests or moisture.