The efficient operation of agricultural machinery relies on a comprehensive understanding of its various elements. Familiarity with the arrangement and function of each component can significantly enhance maintenance and performance. This section aims to provide insight into the essential elements that contribute to optimal functionality.

Exploring the configuration of these vital mechanisms not only aids in troubleshooting but also promotes better decision-making when it comes to repairs and upgrades. By grasping how different parts interact, users can ensure their equipment remains in peak condition, thus maximizing productivity during crucial operational periods.

In this guide, we will delve into the intricate layout of these essential implements, highlighting the roles and relationships of each element within the assembly. Whether for maintenance or enhancement purposes, understanding this structure is key to achieving successful outcomes in agricultural practices.

tags: Understanding Baler Components

This section aims to provide a comprehensive overview of the various elements that comprise a typical agricultural machinery model. By breaking down the essential components, readers will gain a clearer understanding of how these individual parts work together to facilitate efficient operation.

1. Overview of Key Elements

Understanding the primary components is crucial for effective maintenance and operation.

2. Functionality of Each Component

Each element plays a specific role in the overall efficiency of the equipment.

3. Maintenance Tips for Longevity

Regular upkeep ensures that each part functions optimally for extended periods.

4. Troubleshooting Common Issues

Identifying and resolving common problems can enhance performance significantly.

5. Upgrading Components for Improved Performance

Investing in higher-quality parts can lead to increased efficiency and productivity.

6. Understanding Safety Features

Awareness of safety mechanisms is essential for safe operation and use.

7. Importance of Proper Installation

Correct installation of components is vital for preventing operational failures.

8. Common Mistakes in Maintenance

Avoiding typical errors can prevent unnecessary repairs and costs.

9. Impact of Environmental Factors

Environmental conditions can affect the wear and tear of various elements.

10. Resources for Further Learning

Additional materials and guides can aid in understanding the machinery better.

11. Future Trends in Machinery Design

Keeping abreast of advancements can inform choices for upgrades and maintenance.

| Component | Description |

|---|---|

| Frame | Supports the entire structure and provides stability. |

| Feeder | Introduces material into the processing area. |

| Drive Mechanism | Transfers power to various moving parts. |

| Compaction System | Forms and compresses materials into bundles. |

| Cutting Mechanism | Processes the material for optimal handling. |

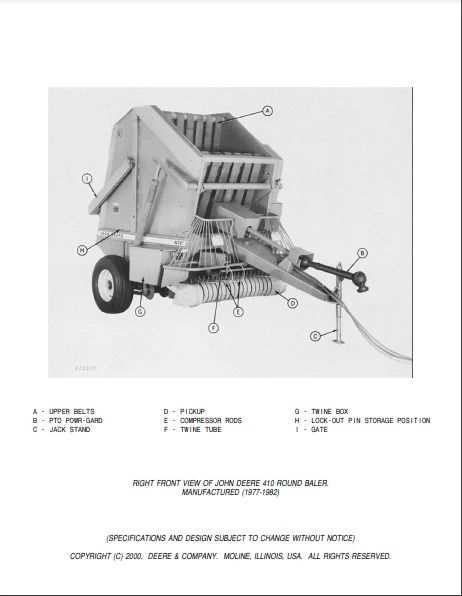

Key Parts of John Deere Balers

This section outlines the essential components found in a renowned brand of agricultural machinery used for harvesting and compacting plant materials. Understanding these elements is crucial for effective operation and maintenance.

Essential Mechanisms

The main mechanisms of this equipment include systems that ensure the efficient gathering, compressing, and tying of harvested materials. These functionalities are vital for achieving optimal performance and reliability during usage.

Maintenance and Replacement

Regular upkeep of the key components is necessary to extend the lifespan of the machinery. Identifying which elements require replacement or adjustment can enhance efficiency and prevent unexpected breakdowns. Utilizing high-quality replacements is recommended to maintain the integrity of the equipment.

Functionality of Each Component

This section delves into the roles and purposes of various elements within the machinery, emphasizing their significance in overall operation. Understanding how each part interacts contributes to a more efficient and effective use of the equipment.

- Feed Mechanism: This element ensures a steady supply of material into the machine, facilitating continuous operation.

- Cutting System: Essential for preparing the incoming material, this system operates to ensure uniform size and readiness for further processing.

- Compression Chamber: Here, the gathered material is compacted, creating dense and manageable bundles for easier handling.

- Baling Twine or Wire System: This mechanism secures the compacted material, preventing it from unraveling during transportation and storage.

- Discharge System: Responsible for releasing finished bundles, this system allows for seamless unloading and further processing.

Each element plays a crucial role, and familiarity with their functionalities aids in better maintenance and troubleshooting, ensuring optimal performance.

Maintenance Tips for Baler Parts

Regular upkeep of machinery components is essential for ensuring optimal performance and longevity. By adhering to proper care practices, operators can minimize wear and prevent unexpected breakdowns.

1. Routine Inspection: Conduct frequent evaluations of the equipment to identify signs of wear, corrosion, or damage. Pay close attention to moving parts and connections.

2. Lubrication: Apply appropriate lubricants to designated areas to reduce friction and heat generation. This practice helps maintain smooth operation and extends the lifespan of the components.

3. Cleaning: Keep all surfaces free of debris and buildup. Regular cleaning helps prevent blockages and ensures that all elements function effectively.

4. Tightening Fasteners: Periodically check and tighten bolts and screws. Loose connections can lead to misalignment and operational issues, impacting efficiency.

5. Follow Manufacturer Guidelines: Always refer to the manufacturer’s recommendations for specific maintenance schedules and procedures. This ensures that all actions taken are appropriate for the equipment.

Common Issues with Baler Components

Understanding frequent problems associated with hay-making machinery is essential for effective maintenance and operation. These issues can arise from various factors, including wear and tear, improper settings, or external conditions. Recognizing these common challenges can help users take preventative measures and enhance the equipment’s performance.

Wear and Tear

Regular usage can lead to deterioration of specific elements, which may result in decreased efficiency. Components such as belts, rollers, and cutting tools are often susceptible to this type of damage. Regular inspections can help identify signs of wear early, allowing for timely replacements and minimizing downtime.

Incorrect Adjustments

Misalignments and improper adjustments can significantly affect the operation of the machinery. If the settings are not calibrated correctly, it can lead to inefficient operation and increased stress on individual components. It’s crucial to consult the manufacturer’s guidelines to ensure all adjustments are accurate and maintain optimal functionality.

How to Identify Baler Parts

Understanding the components of a harvesting machine is essential for effective maintenance and operation. By recognizing each element’s function, users can ensure smooth performance and identify issues promptly.

To accurately distinguish between the various elements, follow these guidelines:

- Familiarize Yourself with the Manual: Always consult the instructional guide specific to the model. This resource typically contains labeled illustrations and descriptions of each component.

- Utilize Online Resources: Various websites offer detailed visual aids and forums where users share experiences and insights. Engaging with these platforms can enhance your understanding.

- Observe Physical Characteristics: Take note of the size, shape, and placement of each component. Some parts may be easily recognizable due to their unique features.

- Consult Professionals: If uncertain, seek assistance from experienced operators or technicians. Their expertise can help clarify any doubts regarding specific elements.

By following these steps, you will develop a better understanding of the machine’s components, facilitating more effective repairs and maintenance.

Importance of Genuine Replacement Parts

Utilizing authentic components for machinery maintenance is crucial for ensuring optimal performance and longevity. High-quality replacements are specifically designed to fit seamlessly with existing systems, minimizing the risk of complications during operation.

Benefits of Authentic Components

- Enhanced Performance: Genuine items contribute to the overall efficiency of equipment, ensuring it operates at peak capacity.

- Durability: Original components are manufactured to withstand the rigors of operation, reducing the likelihood of premature wear and tear.

- Safety: Using verified elements can prevent accidents caused by malfunctions, thereby safeguarding users and operators.

- Warranty Protection: Many manufacturers provide warranties that may be voided if non-genuine parts are installed, highlighting the importance of using the correct replacements.

Cost Considerations

While authentic items may have a higher upfront cost, their durability often leads to lower overall expenses. Investing in quality components reduces the need for frequent replacements and costly repairs in the long run.

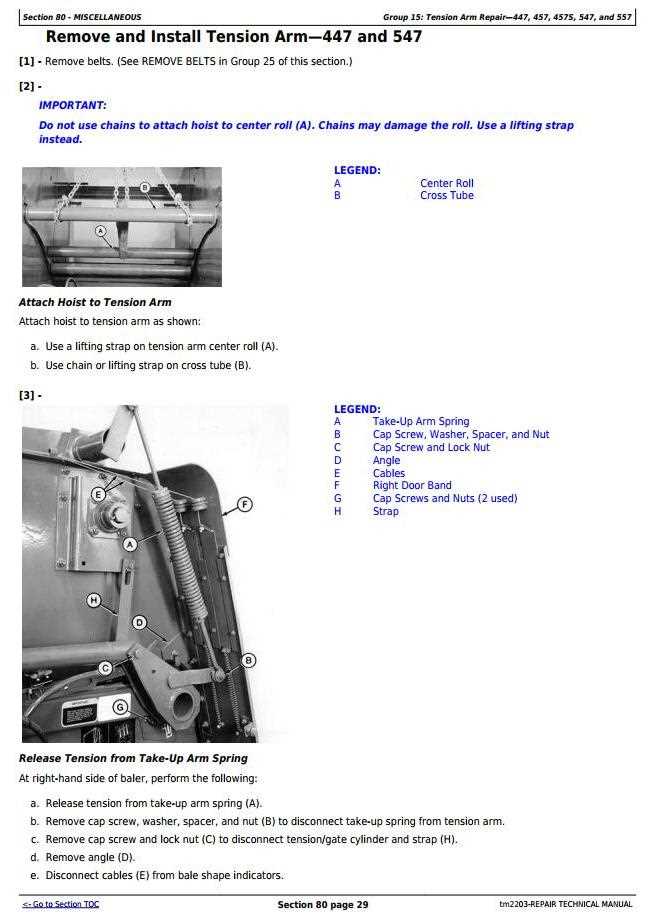

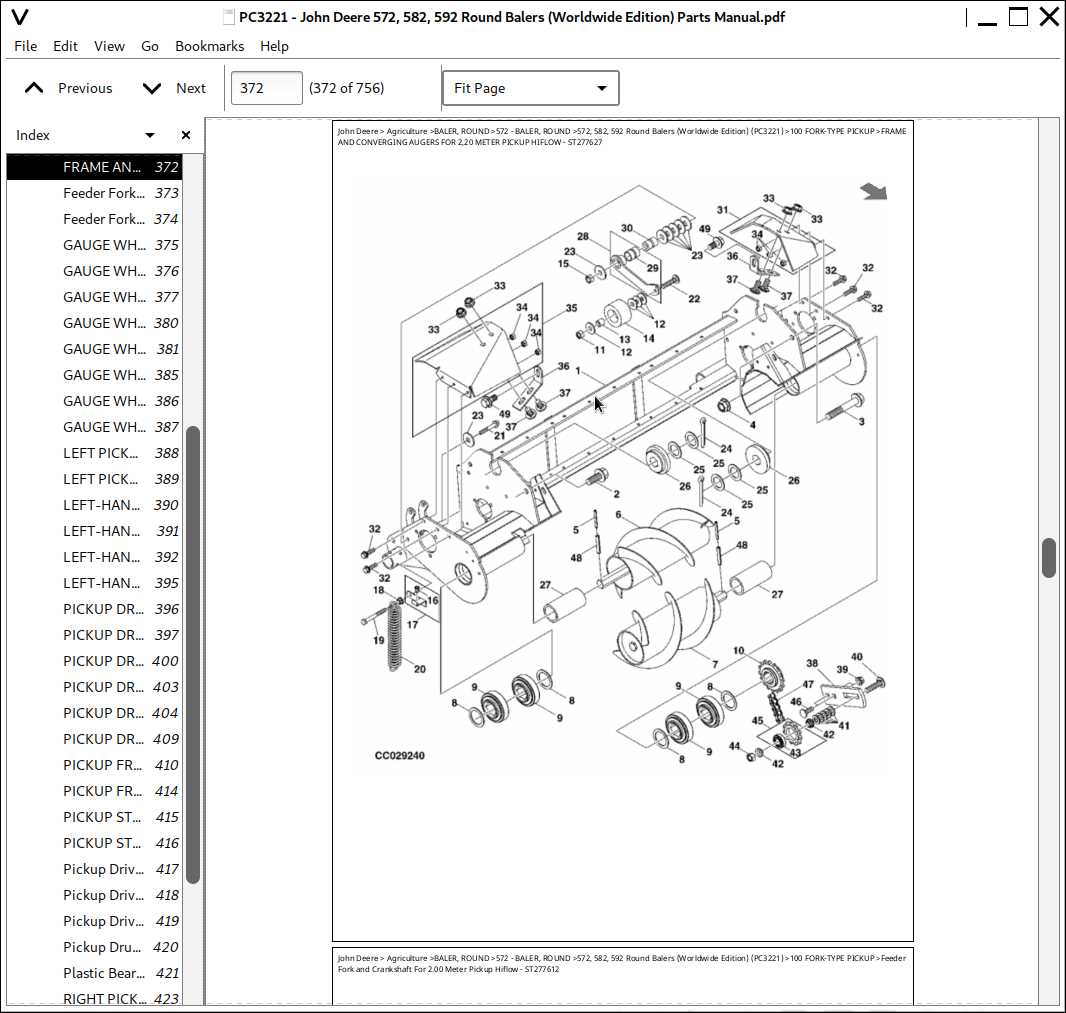

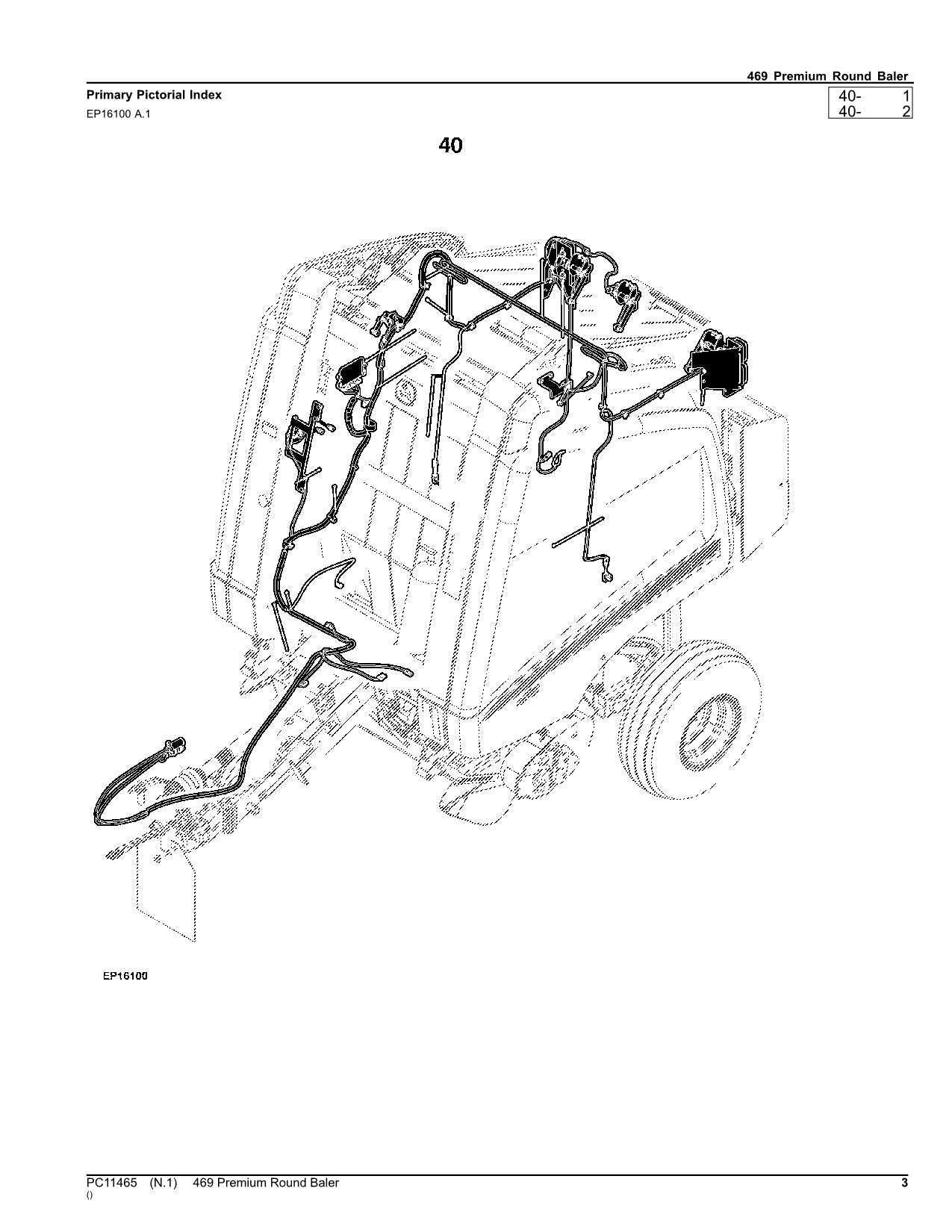

Visual Guide to Baler Diagrams

This section offers an illustrative representation of the mechanisms involved in the compacting process of agricultural materials. By providing visual aids, users can easily grasp the functionality and organization of various components within the machinery.

Understanding the Components

Familiarity with the essential elements enhances the overall efficiency of operation. Below are the primary components typically featured:

- Compression chamber

- Feeding mechanism

- Twine or net wrap systems

- Discharge mechanism

Interpreting the Visuals

When reviewing the illustrations, consider the following tips for better comprehension:

- Focus on the labeling of each part for a clear understanding of its role.

- Compare different visual representations to recognize variations in design.

- Use the guides to troubleshoot or enhance maintenance routines effectively.

Assembly Process for Baler Parts

The assembly of machinery components is a crucial step in ensuring optimal performance and efficiency. This section outlines the essential stages involved in the assembly of these components, focusing on techniques and best practices that promote reliability and functionality.

Key Stages in the Assembly

- Preparation: Gather all necessary components and tools before starting the assembly. Ensure a clean workspace to prevent contamination.

- Component Inspection: Examine each element for any defects or wear. This ensures that only quality parts are utilized in the final assembly.

- Follow Assembly Guidelines: Adhere to specific instructions provided in the user manual. This is essential for proper installation and operation.

Best Practices for Successful Assembly

- Use the correct tools for each component to avoid damage.

- Ensure all fasteners are tightened to the manufacturer’s specifications to maintain structural integrity.

- Conduct a final inspection after assembly to verify that everything is correctly installed and functioning.

Safety Measures for Baler Maintenance

Ensuring a secure environment during maintenance activities is crucial for effective and safe operation. By adhering to specific precautions, individuals can minimize risks and foster a safer workplace. This section outlines essential practices to follow when conducting upkeep on the machinery.

Pre-Maintenance Preparations

- Always wear appropriate personal protective equipment (PPE), including gloves, goggles, and hearing protection.

- Disconnect power sources and ensure that all moving components are stationary before starting any maintenance work.

- Keep the work area tidy and free from clutter to avoid accidents and enhance efficiency.

Ongoing Safety Practices

- Regularly inspect equipment for any signs of wear or damage, addressing issues promptly.

- Follow the manufacturer’s guidelines for maintenance tasks to ensure correct procedures are utilized.

- Utilize tools and equipment specifically designed for maintenance activities to enhance safety and effectiveness.

Upgrades for Enhanced Baler Performance

Improving the efficiency and effectiveness of hay handling equipment can significantly boost productivity and reduce downtime. Various enhancements can lead to better operation and longevity of the machinery, ensuring optimal performance during peak usage times.

Consider implementing the following modifications to elevate the functionality of your equipment:

- Advanced Cutting Mechanisms: Upgrading to high-performance cutting systems can enhance the precision of material handling.

- Improved Feeding Systems: Installing more efficient feeding mechanisms can ensure a consistent flow of material, reducing jams and increasing throughput.

- Enhanced Control Features: Integrating advanced electronic controls allows for more precise adjustments, improving overall operation.

- Durable Wear Parts: Utilizing higher-quality components can reduce maintenance needs and extend the lifespan of critical systems.

- Efficient Hydraulic Systems: Upgrading hydraulic components can improve power delivery and responsiveness, enhancing overall machine performance.

By focusing on these enhancements, operators can significantly increase the overall effectiveness of their machinery, leading to better results and increased satisfaction.

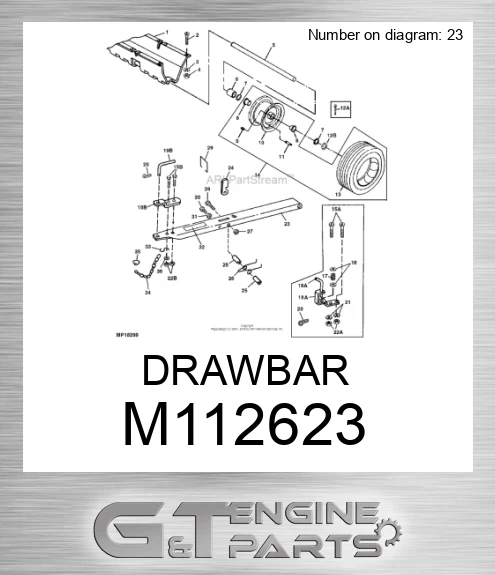

Resources for Baler Parts Lookup

Finding the right components for agricultural machinery can often be a challenging task. Numerous resources are available to assist individuals in locating essential items for their equipment. These sources provide detailed information, ensuring that users can efficiently identify and obtain what they need.

Online Tools and Databases

Several online platforms offer comprehensive databases for users seeking specific equipment components. These tools allow for quick searches based on model numbers or descriptions, facilitating a smoother experience when looking for necessary items.

Local Suppliers and Dealerships

Another valuable option is to connect with local suppliers and dealerships. These establishments often have knowledgeable staff who can provide insights and assist in locating the appropriate components. Engaging with them can lead to discovering additional resources and solutions.

| Resource Type | Description |

|---|---|

| Online Catalogs | Websites featuring extensive lists of items with images and specifications. |

| Manufacturer Websites | Official sites offering detailed information on their products and recommended suppliers. |

| Community Forums | Platforms where users share experiences and solutions regarding equipment maintenance. |

| Trade Shows | Events where manufacturers and suppliers showcase their offerings, providing networking opportunities. |