The intricate world of agricultural machinery is built upon a foundation of numerous interconnected elements, each playing a vital role in the overall functionality. Understanding how these components work together is essential for maximizing efficiency and ensuring the longevity of the equipment. By exploring the various sections of these complex machines, operators can gain valuable insights into maintenance and repair processes.

Every agricultural vehicle comprises a variety of essential mechanisms that must be properly understood and maintained. These mechanisms can range from the operational units to the support structures that hold everything in place. Familiarity with these components not only aids in troubleshooting but also enhances the ability to perform repairs with confidence.

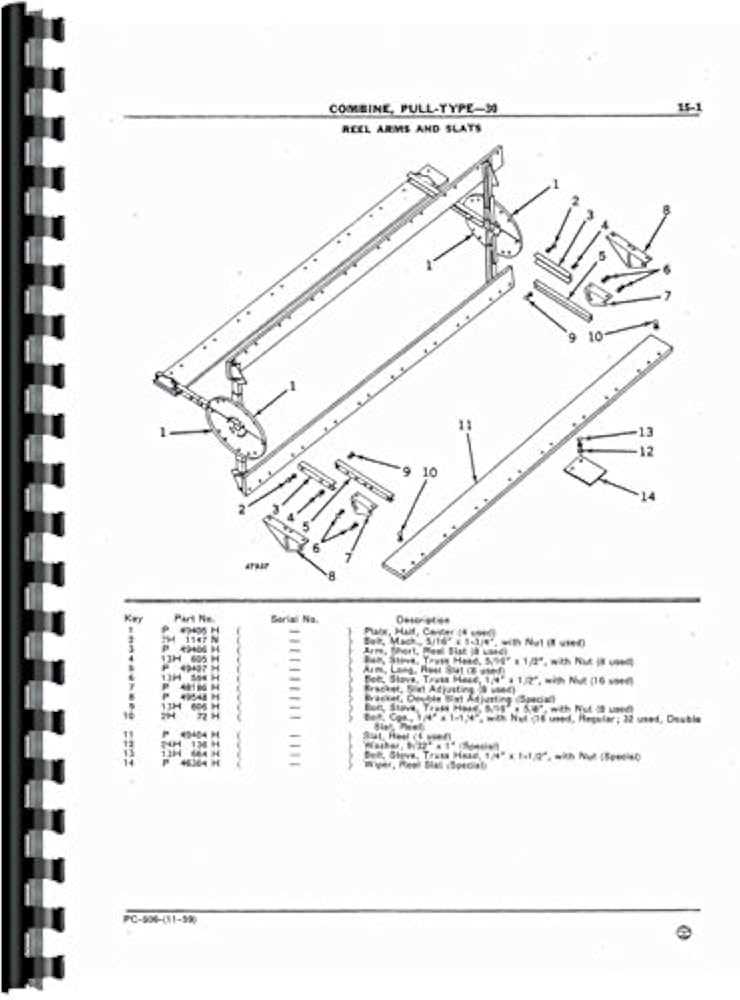

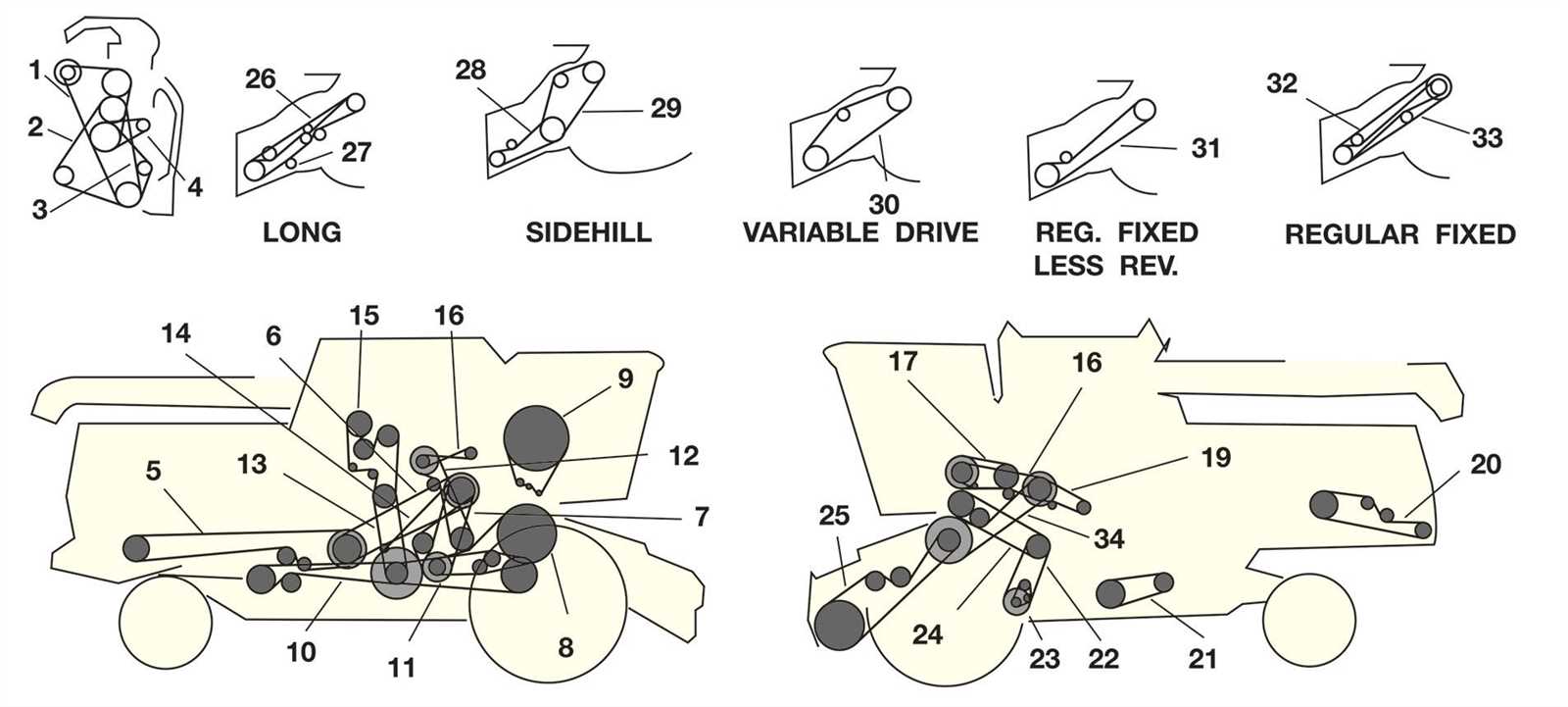

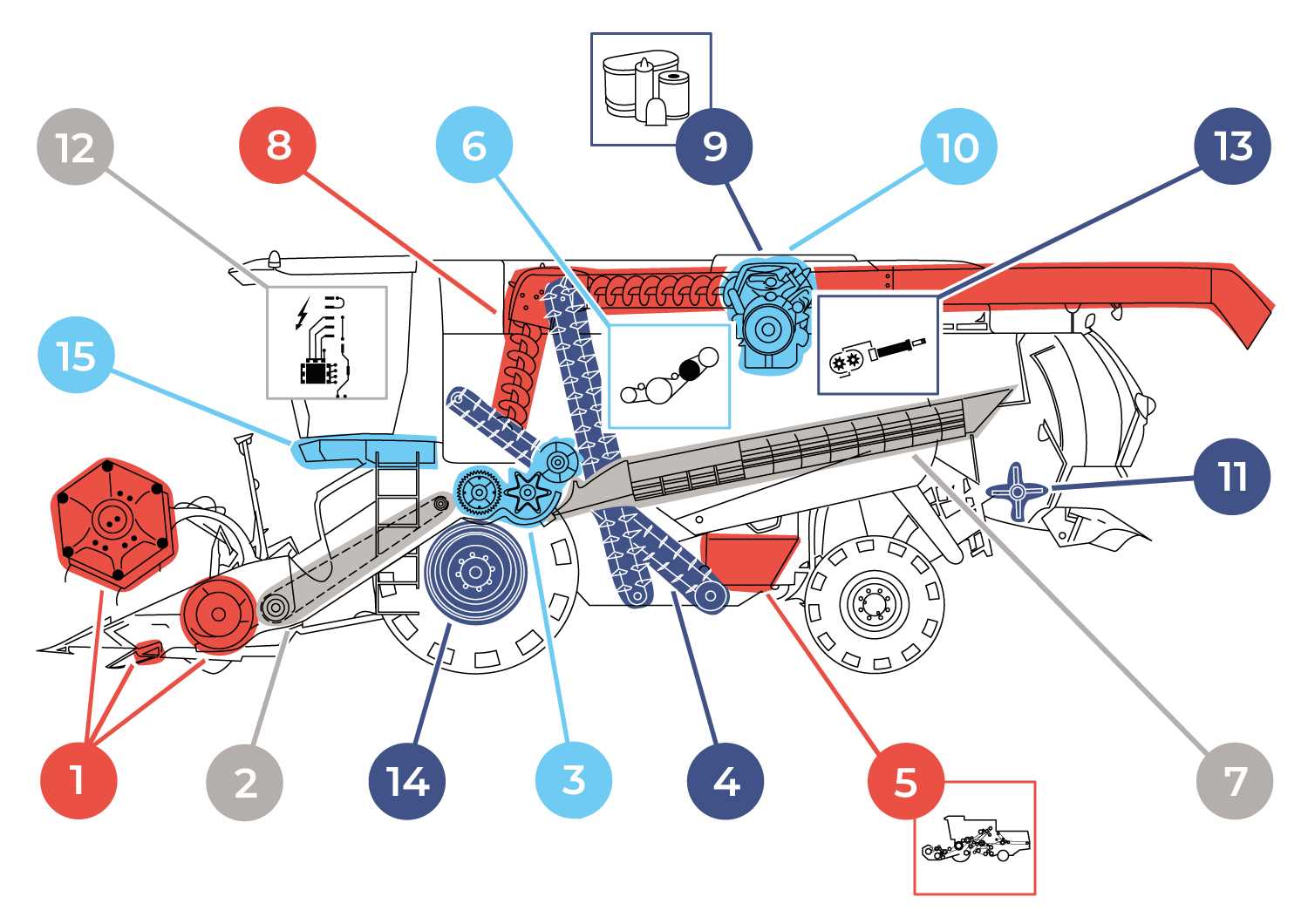

To navigate this intricate landscape, detailed illustrations and representations serve as crucial tools. They provide a visual roadmap, illustrating the relationship between different elements and simplifying the understanding of their functions. By engaging with these resources, operators can develop a deeper appreciation for the machinery they rely on and enhance their operational expertise.

Understanding John Deere Combine Parts

Gaining insight into the components of agricultural machinery is essential for efficient operation and maintenance. This knowledge enhances productivity and ensures longevity in the field.

Key Elements of Harvesting Machinery

Each unit consists of several critical elements that work in harmony. Recognizing these pieces, from the header to the threshing section, can significantly impact performance.

Importance of Regular Maintenance

Regular upkeep of machinery components is vital. Identifying wear and tear early on can prevent costly breakdowns and ensure optimal functioning during harvest season. Investing time in understanding these essentials ultimately leads to better results in the field.

Importance of Accurate Diagrams

Precise illustrations play a crucial role in ensuring the functionality and efficiency of machinery. They serve as essential tools for operators and technicians, providing clarity and facilitating maintenance tasks. With well-structured visuals, users can easily identify components and understand their interconnections, leading to better troubleshooting and repair processes.

Accurate representations reduce the risk of errors during assembly and maintenance, enhancing overall safety and performance. They enable efficient resource allocation and minimize downtime, ultimately contributing to the longevity of the equipment. By relying on reliable visuals, users can streamline operations and foster a more knowledgeable workforce.

Common Parts in Combines Explained

Understanding the essential components of harvesting machinery is crucial for optimal performance and maintenance. Each element plays a vital role in ensuring efficiency during the harvesting process, making it important for operators to be familiar with these key items.

Main Components Overview

Harvesting equipment consists of several primary elements, each contributing to the overall functionality. From the cutting mechanism to the grain handling system, each section is designed to enhance productivity and reduce downtime.

Functionality Table

| Component | Function |

|---|---|

| Header | Cuts crops at ground level for collection. |

| Auger | Transfers harvested material into the machine. |

| Threshing Drum | Separates grain from the stalk and chaff. |

| Grain Tank | Stores collected grain before unloading. |

| Chassis | Provides the structure and mobility for the equipment. |

How to Read a Parts Diagram

Understanding a visual representation of components is essential for effective maintenance and repairs. Such illustrations provide detailed insights into the structure and organization of machinery, enabling users to identify specific elements and their relationships. By mastering the skill of interpreting these visuals, one can streamline troubleshooting and enhance operational efficiency.

Familiarize Yourself with the Legend

Most schematics include a legend or key that explains symbols and color codes. Take the time to review this section, as it can significantly aid in comprehending the layout and function of each element. Understanding these symbols will help you quickly locate parts and understand their roles within the system.

Trace the Connections

Follow the lines and connections depicted in the illustration. These pathways often indicate how components interact with one another. By observing the flow and linkage between parts, you can gain insights into the overall operation and diagnose potential issues effectively. Look for arrows and directional indicators that highlight movement and functionality.

Finding Replacement Parts Easily

Locating suitable components for your machinery can be a straightforward task with the right approach. By leveraging various resources and tools, you can streamline the search process and ensure that you obtain the necessary items quickly and efficiently. Understanding where to look and how to navigate available options will ultimately save you time and effort.

Start by utilizing online databases and manufacturer websites, which often provide detailed catalogs and specifications. Many platforms also offer filtering options that help narrow down your choices based on specific criteria, enhancing your ability to find what you need. Additionally, community forums and discussion groups can be valuable, as they frequently share insights and recommendations from experienced users.

Another effective strategy is to consult with local dealers or service centers, as they can offer personalized assistance and may have parts readily available. Establishing relationships with these professionals can also lead to helpful tips regarding maintenance and compatibility, further simplifying your search for components. By taking advantage of these methods, you can ensure that your equipment remains in top condition with minimal downtime.

Maintenance Tips for Combine Components

Ensuring the longevity and efficiency of agricultural machinery requires regular upkeep and attention to various elements. Proper maintenance not only enhances performance but also prevents costly repairs and downtime. Adopting a systematic approach to caring for each crucial component can significantly extend the lifespan of the equipment.

Start by developing a routine inspection schedule. Regularly check belts, chains, and gears for wear and tear. Look for signs of fraying or damage that could lead to mechanical failure. Additionally, ensure all moving parts are adequately lubricated to reduce friction and prevent overheating.

Cleaning is another vital aspect of maintenance. Debris and residue can accumulate, affecting the functionality of different systems. After each use, take the time to clean out chaff and dirt from critical areas. This not only improves performance but also minimizes the risk of corrosion.

Monitor fluid levels consistently. Hydraulic fluids, engine oils, and coolant should be checked regularly to ensure they are at appropriate levels. Replenishing these fluids as needed is essential for optimal operation and can help prevent major issues down the line.

Lastly, consider investing in quality replacement parts when repairs are necessary. While it might be tempting to opt for cheaper alternatives, using high-quality components will result in better performance and reliability over time. Keeping a stock of frequently used items can also streamline maintenance efforts, reducing downtime during busy seasons.

Identifying Worn Out Parts

Recognizing components that have deteriorated is crucial for maintaining optimal machinery performance. Over time, various elements may wear down, impacting efficiency and leading to potential failures. Regular inspections can help ensure that all elements function smoothly, prolonging the lifespan of your equipment.

Signs of Wear

Common indicators of degradation include unusual noises, vibrations, and decreased functionality. For instance, if a mechanism begins to emit grinding sounds or exhibits excessive movement, it may signify that certain elements need replacement. Regularly monitoring these signs can prevent more significant issues down the line.

Inspection Techniques

To effectively assess the condition of components, employ visual inspections alongside operational tests. Thoroughly examine for cracks, corrosion, or unusual wear patterns. Utilizing checklists during each evaluation can streamline the process and ensure no critical areas are overlooked, allowing for timely maintenance decisions.

Sources for Quality John Deere Parts

When seeking reliable components for your agricultural machinery, it’s crucial to identify trustworthy sources. Quality ensures optimal performance and longevity, making the selection of the right supplier a top priority.

Authorized Dealers often provide the best options, offering original items that guarantee compatibility and durability. These establishments usually have knowledgeable staff who can assist with specific inquiries and recommendations.

Online Retailers have become increasingly popular, presenting a vast selection at competitive prices. It’s essential to choose well-reviewed platforms to ensure authenticity and quality assurance.

Local Workshops can also be valuable resources, as they may have access to refurbished or aftermarket alternatives that can meet your needs effectively. Engaging with these professionals can offer insights into various options and their performance.

Exploring community forums dedicated to machinery can provide firsthand experiences and suggestions from other users, enriching your understanding of available choices.

Comparing OEM and Aftermarket Options

When it comes to sourcing components for agricultural machinery, the choice between original equipment manufacturer (OEM) offerings and alternatives from other manufacturers can significantly impact both performance and cost. Understanding the nuances of each option allows operators to make informed decisions that align with their operational needs and budgetary constraints.

Advantages of OEM Components

Original equipment solutions often come with a promise of quality and compatibility. These products are designed to meet the exact specifications of the machinery, ensuring optimal functionality and reliability. Additionally, OEM options typically benefit from robust warranties and support services, providing peace of mind for users.

Benefits of Aftermarket Alternatives

On the other hand, aftermarket components can offer significant cost savings and increased availability. Many aftermarket suppliers focus on creating competitive solutions that can match or even exceed the performance of OEM items. These alternatives often come with a variety of options, allowing for customization based on specific requirements or preferences.

| Feature | OEM | Aftermarket |

|---|---|---|

| Quality Assurance | High | Varies |

| Cost | Generally Higher | Often Lower |

| Warranty | Comprehensive | Limited |

| Compatibility | Exact Fit | May Vary |

| Availability | Limited to Manufacturer | Widely Available |

In summary, the choice between OEM and aftermarket components hinges on the balance of quality, cost, and specific needs. Evaluating these factors carefully will help operators make decisions that enhance the longevity and efficiency of their machinery.

Assembly Process of Combine Parts

The process of assembling various components in agricultural machinery is crucial for ensuring optimal functionality and efficiency. Each segment must be carefully integrated to create a cohesive unit capable of performing complex tasks in the field. Understanding this procedure can enhance maintenance and troubleshooting efforts, leading to prolonged equipment life and improved performance.

Step-by-Step Integration

Initially, the assembly begins with a thorough inspection of all components to ensure they meet quality standards. Following this, the primary frame serves as the foundation upon which other elements are mounted. Gradually, additional mechanisms, such as harvesting tools and grain handling systems, are attached in a specific order to guarantee proper alignment and balance. Each connection is secured using specialized fasteners, ensuring durability and stability during operation.

Final Adjustments and Testing

After the major components are joined, the final stage involves adjustments and calibration. This step ensures that all moving parts function harmoniously and that settings are optimized for various agricultural conditions. Once adjustments are complete, a series of tests are conducted to verify that the entire system operates as intended, addressing any issues that may arise before the machinery is deployed in the field.

Understanding this assembly process is essential for anyone involved in agricultural operations, as it emphasizes the importance of meticulous craftsmanship and attention to detail in achieving reliable performance.

How Diagrams Improve Repair Efficiency

Visual representations are essential tools that significantly enhance the efficiency of repair processes. By offering a clear overview of components and their relationships, these illustrations streamline the troubleshooting and maintenance efforts.

- Facilitate quick identification of issues.

- Provide a clear roadmap for assembly and disassembly.

- Minimize the risk of errors during repairs.

- Enhance communication among technicians.

Moreover, these visual aids can:

- Accelerate the learning curve for new technicians.

- Allow for more efficient inventory management.

- Improve overall maintenance planning.

Ultimately, leveraging these resources leads to reduced downtime and improved operational efficiency.

Common Mistakes When Using Diagrams

Visual representations are invaluable tools for understanding complex machinery and processes. However, misinterpretations and errors can lead to significant issues during repairs or maintenance. Recognizing common pitfalls can enhance the effectiveness of these graphical aids and ensure accurate implementation.

1. Ignoring Scale and Proportion: One frequent error is neglecting the scale of the illustration. Misjudging the size of components can result in improper fitting or assembly, leading to further complications.

2. Overlooking Annotations: Many users skim over labels and notes provided in the visuals. These annotations often contain critical information that guides proper usage, and failing to read them can lead to misunderstandings.

3. Misinterpreting Symbols: Symbols and icons used in illustrations may not be universally understood. It is crucial to familiarize oneself with the legend or key to avoid confusion and ensure correct interpretation.

4. Focusing Solely on Visuals: Relying exclusively on images without consulting supplementary documentation can lead to incomplete understanding. Combining visual aids with written guides ensures comprehensive knowledge.

5. Skipping Steps: When following a sequence, it can be tempting to bypass steps depicted in the visuals. Each step is often critical to the overall process, and skipping them can compromise the outcome.

By being aware of these common mistakes, users can enhance their proficiency and ensure more accurate results when working with visual guides.

Future Trends in Combine Technology

The agricultural sector is poised for significant advancements as technology evolves, promising enhanced efficiency and sustainability in harvesting operations. Innovations in machinery are set to transform traditional methods, leading to improved productivity and reduced environmental impact.

| Trend | Description |

|---|---|

| Automation | Increased use of autonomous systems for seamless operation and reduced labor costs. |

| Data Analytics | Utilization of big data for informed decision-making and optimized performance. |

| Sustainability | Focus on eco-friendly technologies to minimize carbon footprints and enhance resource efficiency. |

| Precision Agriculture | Integration of sensors and GPS technology for targeted interventions and resource management. |