When working with large equipment, it is essential to understand the internal systems and how various mechanical elements are connected. A clear breakdown of the framework can greatly simplify maintenance and troubleshooting, making it easier to identify which elements require attention. Having a visual representation of these mechanisms can significantly enhance one’s ability to efficiently manage and operate complex machinery.

In this section, we’ll explore how to interpret various schematics for essential machine elements. These illustrations provide a comprehensive view of key components, allowing users to gain insight into their functions and interactions. With a solid grasp of these connections, it becomes easier to perform repairs or replacements, ensuring long-term reliability and optimal performance.

Whether you are a professional technician or a first-time user, gaining familiarity with these elements can drastically improve your workflow. By analyzing detailed visuals, you can save time and reduce errors, ultimately leading to a smoother operational experience and fewer downtimes.

Overview of John Deere D155 Components

Understanding the key components of a lawn tractor is essential for proper maintenance and operation. Each element plays a vital role in ensuring the machinery functions efficiently, providing long-term reliability and performance. In this section, we will explore the essential structures that make up the tractor, offering insight into how they contribute to its overall functionality.

- Engine Assembly: The powerhouse that drives the equipment, responsible for delivering the necessary torque and horsepower for various tasks.

- Transmission System: A crucial mechanism that transfers power from the engine to the wheels, allowing smooth speed adjustments and control.

- Cutting Deck: Designed to handle mowing duties with precision, the cutting deck houses the blades and other related components.

- Steering and Control: This system ensures the operator can maneuver the machine effectively, offering responsive handling on different terrains.

- Fuel and Cooling

Understanding the Structure of This Equipment

The overall build of this machine is designed for both efficiency and durability, ensuring it performs well in various conditions. Its framework is robust, capable of supporting heavy use while maintaining stability and balance during operation. The carefully engineered design allows for smooth functionality, offering both precision and power where needed. By examining the core components, one can gain insight into how this equipment operates as a cohesive system.

Key elements of the structure include the mechanical system that drives the machine forward, the steering system that offers responsive control, and the chassis that ensures reliable performance even in tough environments. Each element is interconnected, playing a critical role in the overall operation. By understanding these interconnected systems, it becomes clear how the machine is optimized for performance.

Additionally, the attention to

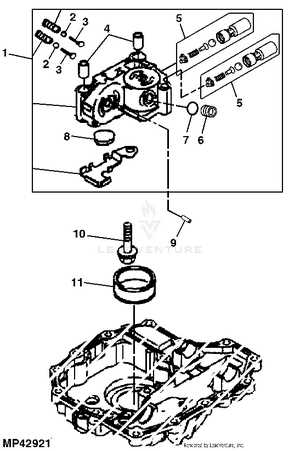

Engine Parts and Their Functions

Understanding the various components of an engine and their roles is essential for ensuring optimal performance and longevity. Each element contributes to the overall efficiency of the machinery, playing a crucial role in the combustion process and power generation.

Component Function Pistons Pistons move up and down within the cylinders, compressing fuel and air for ignition and converting the combustion force into mechanical energy. Cylinder Block The cylinder block houses the cylinders, which form the core of the engine, ensuring smooth functioning by holding the pistons and other essential parts. Crankshaft Transmission System Breakdown

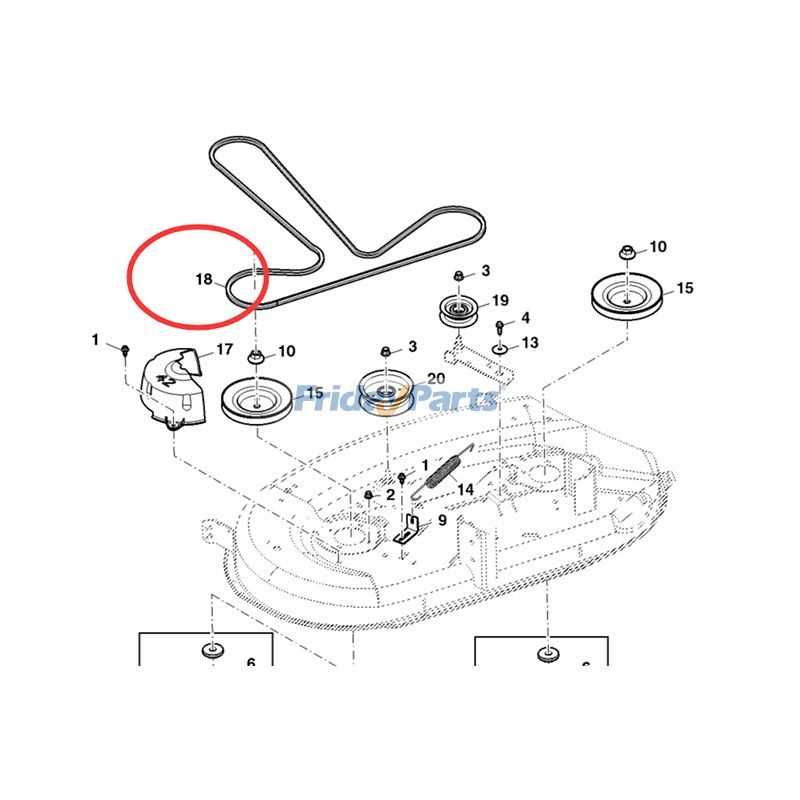

The transmission system plays a crucial role in ensuring smooth operation and efficiency in various machinery. This section offers an overview of the system’s key elements, highlighting how different components work together to manage power distribution and regulate speed. Understanding this mechanism is essential for maintaining optimal performance and diagnosing any issues that may arise over time.

At the heart of the system, the gearbox enables the shifting of gears, allowing adjustments in speed and torque. The transmission belt connects vital sections, ensuring power is transferred seamlessly between the engine and the drive system. Additionally, the hydraulic components within the mechanism contribute to regulating force, further supporting efficient motion

Key Features of the Steering Mechanism

The steering system is a vital component of any vehicle, ensuring smooth navigation and precise control during operation. Understanding the unique elements of this system allows for better handling and a more efficient driving experience, especially when maneuvering through challenging environments.

Adjustable Precision

A key aspect of the steering system is its adjustable precision, allowing for fine-tuning based on different driving conditions. This feature enhances the ease of turning and provides a responsive feel, enabling the operator to handle tight corners with minimal effort.

Durability and Longevity

Built with robust materials, the steering system is designed for long-term durability. Its components resist wear and tear, ensuring consistent performance over time, even in harsh conditions. The system’s reliability minimizes the need for frequent adjustments, contributing to its longevity.

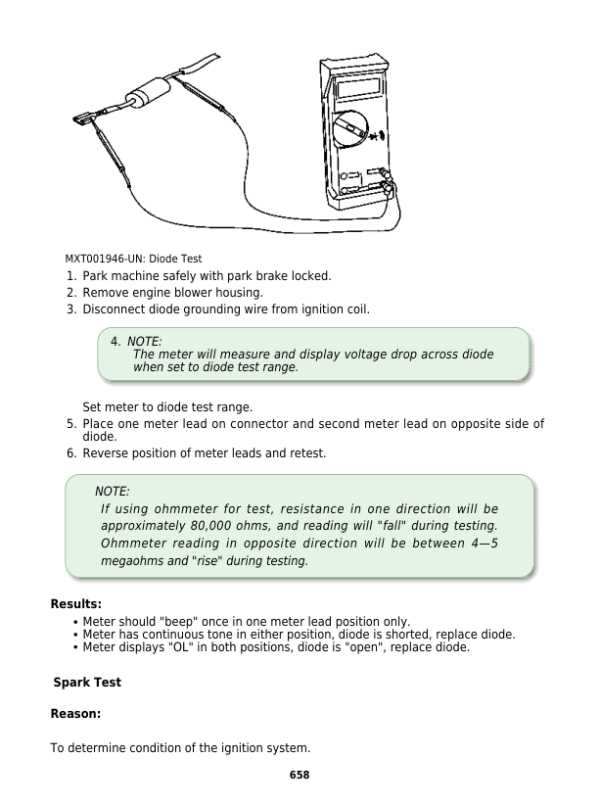

Identifying Electrical System Components

The electrical system of any machinery plays a crucial role in its overall functionality. Understanding the various elements that comprise this system is essential for effective maintenance and troubleshooting. Each component works in unison to ensure that the vehicle operates smoothly, providing power and control to different systems.

Wiring Harness: The wiring harness is the backbone of the electrical system, connecting various components and facilitating communication between them. It consists of a series of wires and connectors that transmit electrical signals throughout the machine.

Batteries: The batteries serve as the primary power source, storing energy and supplying it to the electrical system. Proper identification of the battery type and capacity is vital for ensuring reliable performance.

Fuse Box: The fuse box houses various fuses that protect the electrical components from overloads and shorts. Recognizing the location and function of each fuse is important for troubleshooting electrical issues.

Switches: Various switches control different aspects of the electrical system, from starting the engine to operating lights and accessories. Understanding the function of each switch can greatly aid in diagnosing problems.

Relays: Relays act as electronic switches that control high-power components using low-power signals. Identifying the relays and their specific functions is crucial for effective troubleshooting.

By familiarizing oneself with these components, operators can enhance their ability to maintain and repair the electrical system, ensuring optimal performance of their machinery.

Hydraulic System Overview

The hydraulic system in machinery plays a crucial role in ensuring efficient operation and power transmission. It utilizes fluid dynamics to transfer force and energy, enabling various components to perform their functions effectively. By leveraging pressurized fluid, this system enhances the machine’s capabilities, allowing for smooth movements and precise control.

This system typically consists of several key elements, including pumps, actuators, valves, and hoses. Each component contributes to the overall functionality, working together to create a seamless flow of hydraulic fluid. The pumps generate the necessary pressure, while valves direct the flow to specific areas, ensuring that the actuators can perform their tasks with precision.

Understanding the hydraulic system’s layout and function is essential for maintenance and troubleshooting. Regular checks and servicing of components can prevent potential issues and ensure longevity. Properly maintained hydraulic systems not only improve performance but also enhance the safety and reliability of the machinery.

Brake System Components and Operation

The braking mechanism is a crucial element of any vehicle, ensuring safety and control during operation. It comprises various components that work in unison to provide effective stopping power. Understanding these elements and their functions can enhance maintenance practices and overall performance.

Key Components of the Braking Mechanism

The braking system consists of several vital parts, each playing a specific role in its operation. These include the actuator, friction materials, and hydraulic elements. Below is a brief overview of these components:

Component Description Actuator The device that initiates the braking action, converting driver input into mechanical force. Friction Material Materials that create resistance when pressed against the brake rotor, slowing down the vehicle. Hydraulic System A network that transmits force from the actuator to the friction materials through fluid pressure. Operation Principles

The operation of the braking system relies on the conversion of kinetic energy into thermal energy through friction. When the driver engages the brake, the actuator applies pressure to the hydraulic fluid, which then forces the friction materials against the rotating components. This interaction creates the necessary force to decelerate the vehicle, ensuring safe and controlled stopping.

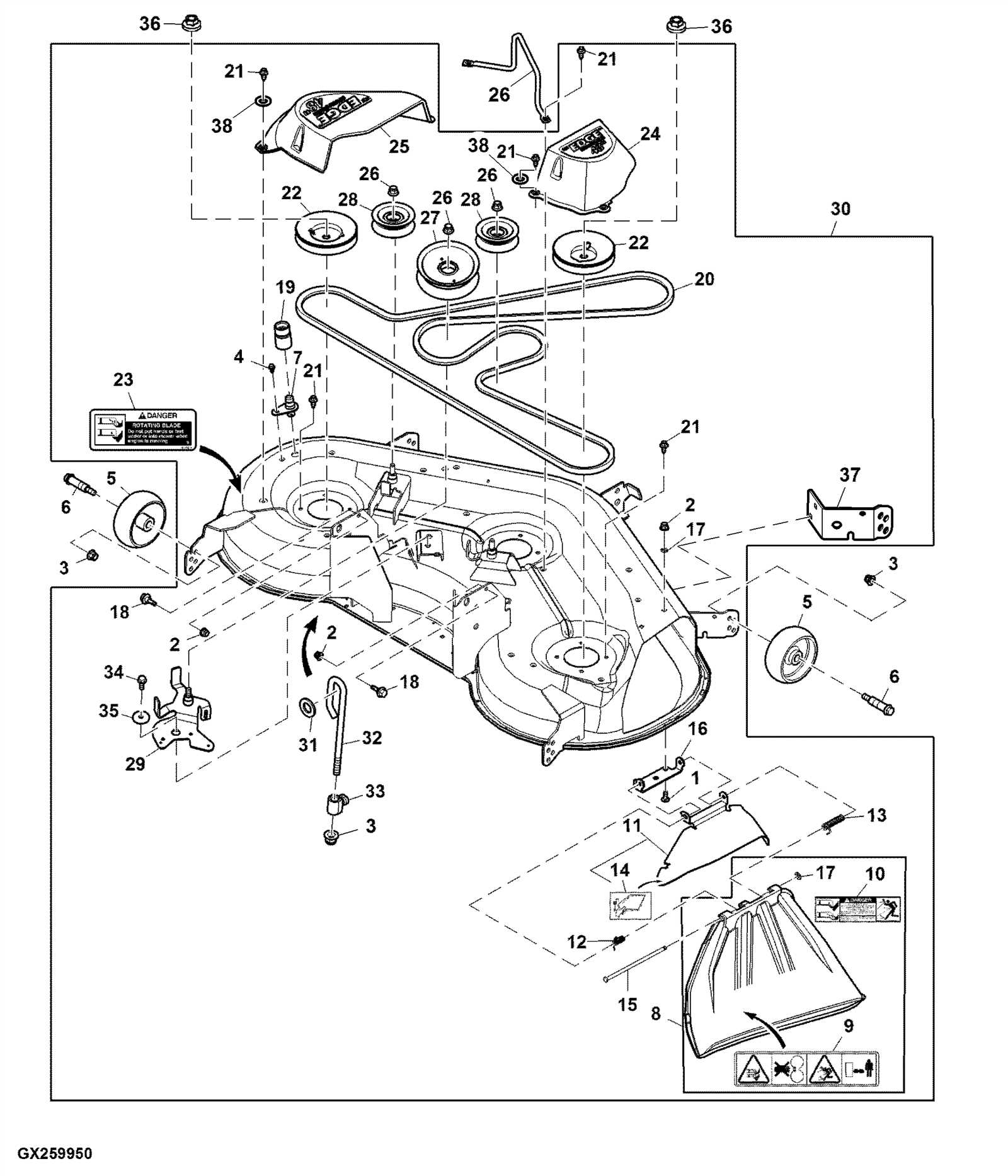

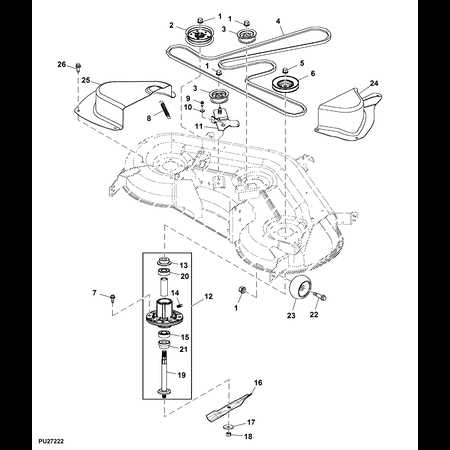

Blade and Mower Deck Assembly

The assembly of the cutting mechanism and mower housing is crucial for the effective operation of your machine. Proper installation and maintenance of these components ensure optimal performance and longevity. This section will guide you through the essential aspects of assembling and maintaining the blade and mower deck.

Assembly Steps

Begin by positioning the mower deck beneath the machine, ensuring it is aligned correctly with the attachment points. Secure the deck using the appropriate fasteners to prevent any movement during operation. Once the deck is in place, install the cutting blades, ensuring they are tightened to the manufacturer’s specifications. This is vital to maintain balance and achieve an even cut.

Maintenance Tips

Regular inspection of the blades and deck assembly is essential for optimal performance. Check for wear and tear, and replace any damaged parts immediately. Additionally, keep the area beneath the deck clean from grass clippings and debris, as this can affect the efficiency of the cutting action. Lubricating the moving parts will also enhance the longevity of the assembly.

Fuel System Parts and Maintenance

The fuel system is crucial for the efficient operation of any engine. Proper maintenance and understanding of its components can significantly enhance performance and longevity. Regular inspection and timely replacement of vital elements ensure that the fuel delivery process remains optimal, preventing potential issues that could affect the overall functionality of the equipment.

Key Components of the Fuel System

Essential elements of the fuel delivery system include the fuel tank, pump, filter, and injectors. Each component plays a specific role in ensuring that fuel is efficiently transported from the tank to the engine. The tank stores the fuel, while the pump moves it through the system. Filters are critical for removing impurities, and injectors are responsible for delivering the fuel into the combustion chamber at the correct pressure and timing.

Maintenance Tips

To maintain the fuel system, it is vital to regularly check for leaks and ensure that all connections are secure. Replacing the fuel filter at recommended intervals helps keep the fuel clean and protects the engine from contaminants. Additionally, keeping the fuel tank filled can prevent moisture buildup, which can lead to corrosion and other issues. Regular inspections and servicing by a qualified technician can help identify and address potential problems before they escalate.

Understanding the John Deere D155 Exhaust System

The exhaust mechanism of a lawn tractor plays a crucial role in managing engine performance and emissions. A well-functioning exhaust system ensures that harmful gases are efficiently expelled, contributing to optimal engine operation and reducing environmental impact. This section delves into the components, functions, and maintenance of the exhaust setup, highlighting its importance for performance and longevity.

Key Components of the Exhaust Mechanism

- Exhaust Manifold: This component collects gases from the engine’s cylinders and directs them to the exhaust pipe.

- Exhaust Pipe: A channel through which gases flow away from the engine, often designed to minimize back pressure.

- Muffler: Reduces noise produced by the engine and helps in quieting the sound of the exhaust gases as they exit.

- Catalytic Converter: If equipped, this part aids in converting harmful gases into less harmful emissions before they are released into the atmosphere.

Maintenance Tips for Optimal Performance

- Regularly inspect the exhaust components for any signs of wear or damage.

- Ensure that connections are secure to prevent leaks.

- Clean the muffler to remove any buildup that may impede gas flow.

- Replace any faulty parts immediately to maintain engine efficiency.

Common Replacement Parts for the D155

Regular maintenance of outdoor machinery involves the timely replacement of various components to ensure optimal performance and longevity. Understanding the essential components that may require replacement helps in maintaining the functionality of the equipment.

Key Components to Monitor

- Blades: Worn or damaged blades can lead to ineffective cutting and should be replaced as needed.

- Filters: Air and oil filters accumulate debris and contaminants over time, requiring regular replacement to maintain engine health.

- Batteries: Old or weak batteries can hinder starting and overall operation, making them a crucial component to check frequently.

Additional Essential Items

- Belts: Frayed or broken belts can disrupt the machinery’s operation, necessitating replacement to ensure smooth functionality.

- Wheels: Tires may wear down or become punctured, affecting traction and performance, which makes timely replacements important.

- Spindles: Damaged spindles can lead to instability in the cutting deck, requiring prompt attention and replacement.

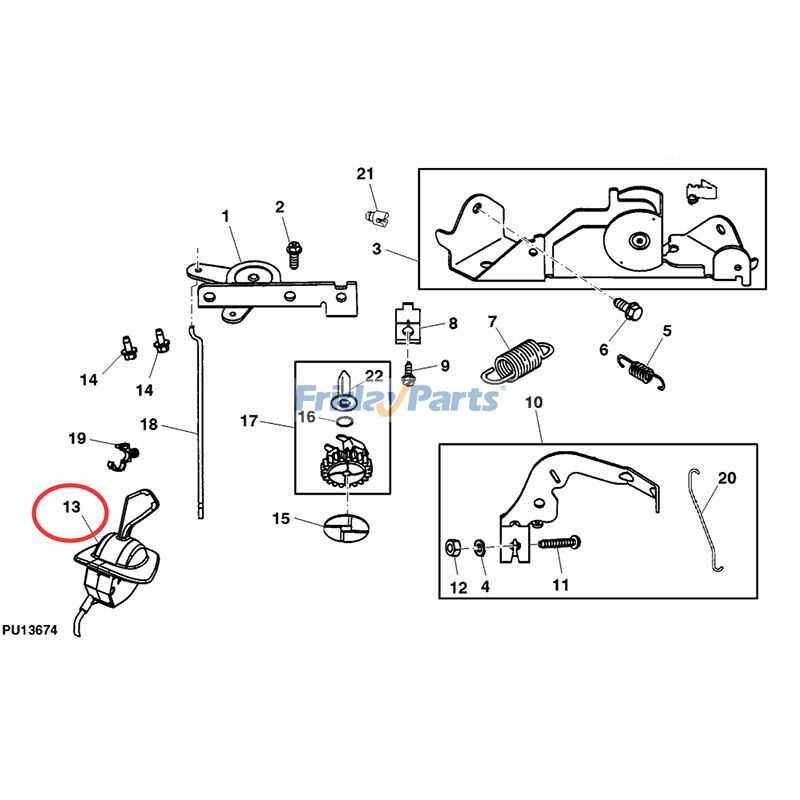

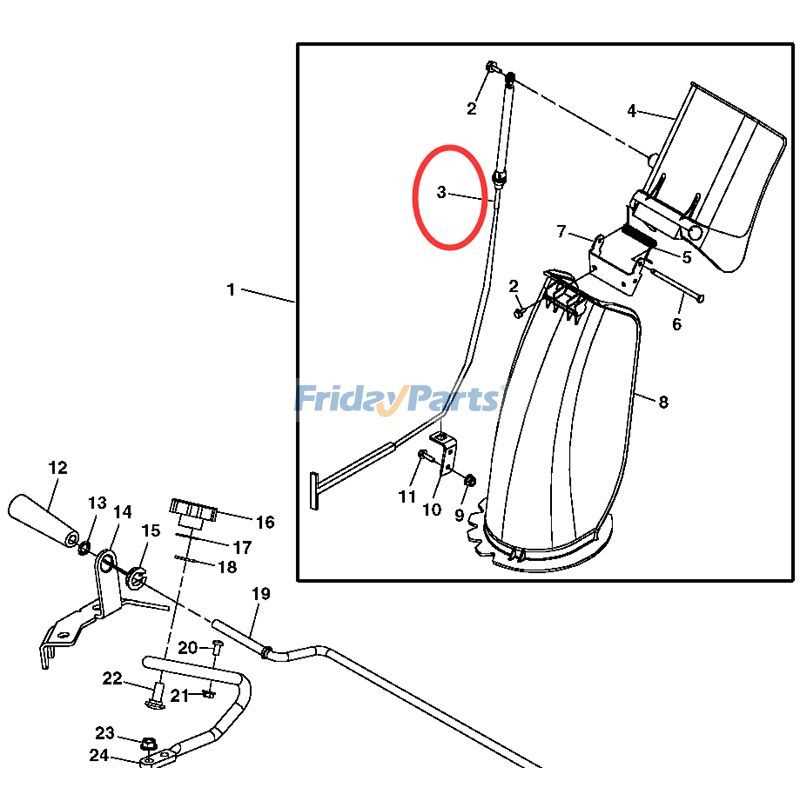

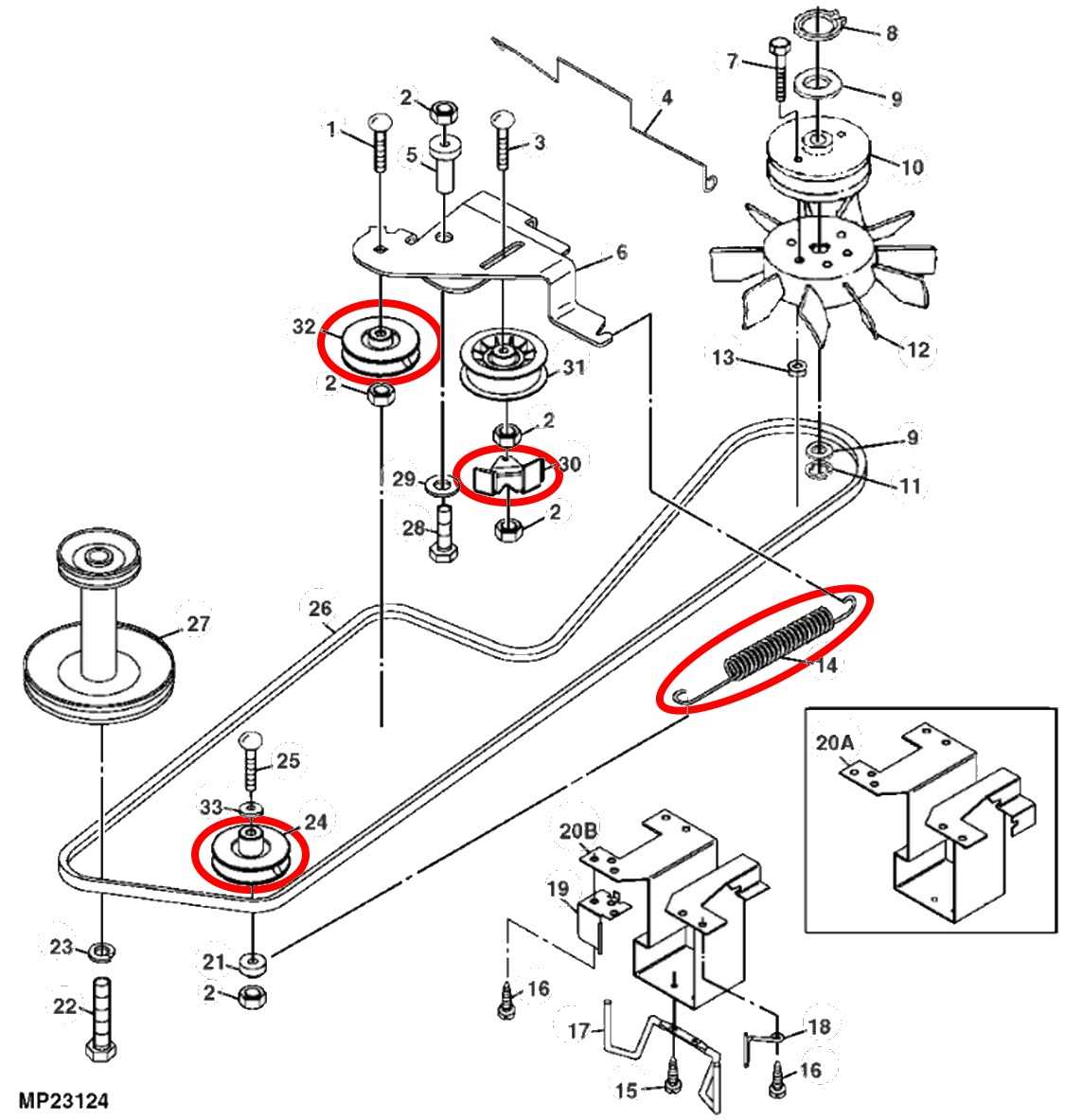

How to Read a John Deere Parts Diagram

Understanding a visual representation of components is essential for effective maintenance and repair. These illustrations provide crucial information on how parts are organized and their specific functions within a machine. Learning to interpret these visuals can enhance your efficiency when servicing equipment.

Here are some key aspects to consider when examining such illustrations:

- Component Identification: Each element is typically labeled with a unique identifier, which correlates to a list of items. Familiarize yourself with these codes for easier reference.

- Connections and Relationships: Pay attention to how different elements connect. Lines or arrows may indicate the relationship between components, helping you understand their interactions.

- Grouping and Sections: Components are often grouped by function or location within the equipment. Identifying these sections can streamline the repair process.

- Scale and Proportion: Take note of the scale used in the illustration. Understanding the size relationship between components can be crucial when ordering replacements or making adjustments.

By mastering these skills, you can improve your understanding of machinery and ensure that you are adequately prepared for any maintenance tasks.