Utility vehicles are designed for rugged terrain and demanding tasks, making them indispensable in agricultural, industrial, and recreational settings. These machines rely on a multitude of intricate systems working together seamlessly to ensure optimal performance. Understanding the layout and functionality of each individual component is key for maintaining and troubleshooting these vehicles efficiently.

The inner workings of such machines consist of a wide array of interconnected parts, each playing a vital role in mobility, safety, and functionality. To ensure smooth operation, a comprehensive understanding of how these elements fit together and interact is crucial. This detailed examination provides an in-depth look at the key components that make up the structure of these durable vehicles, offering valuable insights for both maintenance professionals and enthusiasts alike.

By delving into the technical specifics, it becomes easier to identify common issues and address them proactively. This approach not only improves the vehicle’s lifespan but also enhances its overall efficiency in various environments. Whether you’re an owner or a technician, having access to a clear overview of the vehicle’s setup is an essential resource for optimal upkeep and performance.

Overview of John Deere Gator TX 4×2 Parts

Understanding the essential components of an all-terrain utility vehicle is crucial for maintaining its functionality and optimizing performance. Every vehicle in this category is made up of several key systems that work in unison to provide reliable service. These systems include the engine, transmission, suspension, and steering mechanisms, all of which require periodic attention to ensure smooth operation over various types of terrain.

These rugged machines are designed to handle tough conditions, and each element, from the frame to the wheels, plays an important role in overall efficiency. When considering repairs or upgrades, it’s vital to know the specific functions of each part and how they interact with the rest of the vehicle. A clear understanding of these elements helps in troubleshooting issues, conducting regular maintenance, and improving the vehicle’s longevity.

With proper knowledge of the internal and external components, operators can ensure that their utility vehicle remains in top condition, ready for any challenging task that may come its way. Regular inspection and replacement of worn-out parts are necessary for peak performance and safety.

Understanding the Gator TX 4×2 Components

When it comes to maintaining and optimizing utility vehicles, knowing the key elements that make up its structure is essential. These components work together to ensure smooth operation, whether it’s for heavy-duty tasks or recreational activities. Each part plays a crucial role in ensuring the vehicle’s reliability, longevity, and performance under various conditions. Understanding how these components interact can help in troubleshooting, maintenance, and upgrading the vehicle.

The vehicle consists of several major systems, each with specific parts contributing to overall functionality:

- Powertrain: This includes the engine, transmission, and drivetrain, all of which are responsible for transferring power from the engine to the wheels. Efficient power transfer is key for handling rough terrain.

- Suspension: Essential for stability and comfort, the suspension system absorbs shocks and bumps, improving the ride quality and control on uneven surfaces.

- Steering: The steering mechanism controls the direction of the vehicle. It’s vital for precise maneuvering, especially in tight spaces.

- Braking System: The brakes ensure safety by providing reliable stopping power, with components like pads, discs, and hydraulics working together to manage speed and control.

- Electrical System: This includes the battery, wiring, and lighting. It’s responsible for powering the vehicle’s accessories, as well as providing essential functions like ignition and lighting.

- Frame and Chassis: The frame is the vehicle’s skeleton, supporting all other components and ensuring structural integrity under heavy loads.

- Wheels and Tires: These are the contact points with the ground and are designed for traction, durability, and smooth handling, especially on rugged terrains.

By understanding these different elements, users can better manage the upkeep of their vehicle, ensuring it remains in top working condition for any task at hand.

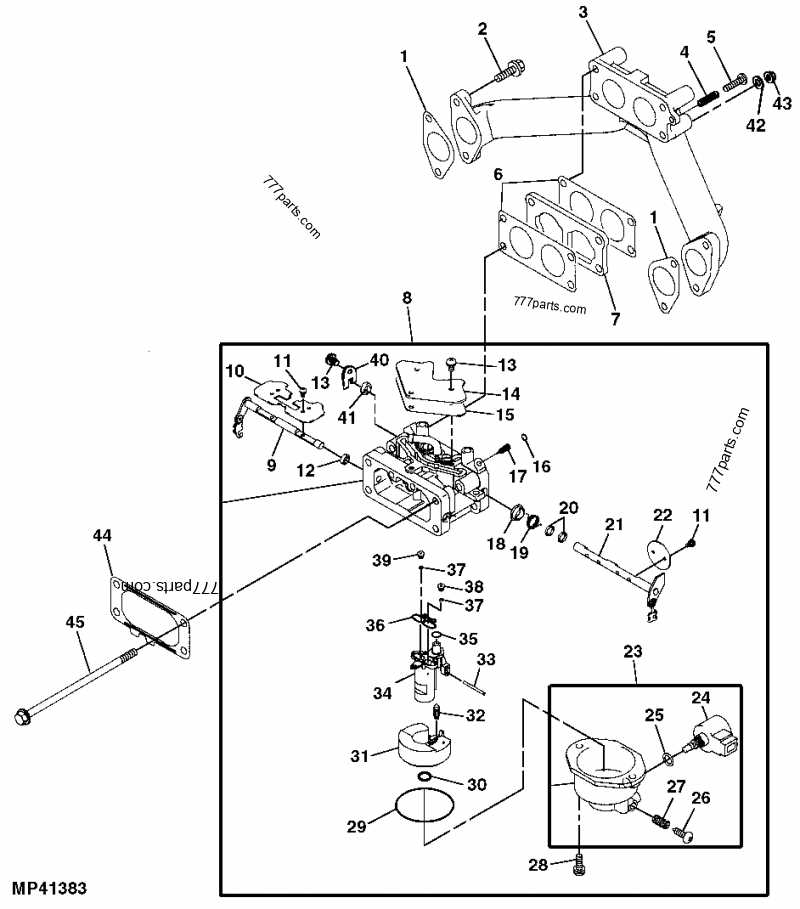

Key Features of the Parts Diagram

Understanding the layout of individual components in a utility vehicle is essential for proper maintenance and repairs. A detailed visual representation of these components allows users to easily identify each part and its role in the overall system. This clarity helps ensure accurate replacement and troubleshooting when needed.

Visual Clarity and Detailed Labels

One of the primary advantages of such a visual guide is the clarity it provides. Each component is illustrated in a way that highlights its placement within the vehicle. Clear labels and markings help users quickly locate the parts they need without confusion.

- Component location identification

- Easy-to-read labels and part numbers

- Color-coding for different system areas

Enhanced Maintenance and Repair Efficiency

With a well-organized illustration, the time spent on diagnosing issues and performing maintenance can be significantly reduced. Users can follow the visual representation step-by-step, ensuring no part is missed and that all connections are properly checked during repair or assembly.

- Accurate identification of worn or damaged components

- Streamlined repair process by reducing guesswork

- Facilitates correct installation of new parts

How to Identify Gator TX 4×2 Parts

Identifying the individual components of your utility vehicle is essential for proper maintenance and repairs. Each part plays a crucial role in ensuring smooth operation and extending the lifespan of the machine. By understanding the layout and functionality of the key elements, you can more effectively troubleshoot issues and replace worn-out items when necessary.

Start by familiarizing yourself with the overall configuration of your vehicle. This includes recognizing the major systems, such as the drivetrain, suspension, and braking mechanisms. Once you have a general understanding, proceed with the identification of specific components through the following steps:

- Consult the user manual: The manual often includes a comprehensive list of components, making it easier to match parts based on visual clues.

- Look for part numbers: Many parts are labeled with unique identification numbers that can be cross-referenced with the manufacturer’s database.

- Examine visual characteristics: Each part typically has distinct features, such as size, shape, and material, which can aid in distinguishing one from another.

- Check online resources: Many manufacturers provide online databases or websites with detailed information, including images and specifications.

- Use a parts catalog: These catalogs often present a detailed breakdown of the vehicle’s components, organized in sections that correspond to their function.

By following these steps, you will be able to confidently identify each element of your machine and ensure its continued performance and reliability.

Importance of Accurate Parts Identification

Correctly identifying components is essential for the efficient maintenance and operation of any machine. Without proper recognition of each element, repairs can become more complicated, leading to unnecessary downtime and increased costs. Misidentifying a specific item can result in incompatible replacements or installation errors, which may affect the overall performance and lifespan of the equipment.

Ensuring precise identification also plays a key role in minimizing the risk of further damage. When the wrong component is used, it can place strain on other interconnected systems, ultimately leading to more extensive and costly repairs. Additionally, accurate identification allows for timely service, reducing the likelihood of unexpected breakdowns and keeping the machine running smoothly for longer periods.

Furthermore, understanding each part’s role and specification helps to streamline the procurement process. It ensures that replacement components are sourced from reliable suppliers, reducing the chances of receiving substandard or counterfeit items. This not only guarantees a higher quality of repair but also boosts the overall operational efficiency of the equipment.

Common Repairs and Parts Replacement Tips

Maintaining the longevity and functionality of utility vehicles requires regular attention to wear and tear. Over time, components can degrade, requiring timely repairs or replacements. Understanding the most common issues and how to address them can significantly reduce downtime and improve performance. In this section, we will discuss frequent repairs and useful advice for replacing key elements of the vehicle.

Frequent Repairs

- Battery Issues: Batteries often lose their charge or fail due to age or environmental factors. Regularly check the battery terminals for corrosion and ensure the connections are tight. If the battery doesn’t hold a charge, replacement might be necessary.

- Tires and Wheels: Tire wear is inevitable with regular use. Inspect tires for proper inflation and tread depth. If you notice uneven wear, it may indicate alignment issues or the need for balancing.

- Brakes: Worn brake pads or fluid leaks can cause diminished braking performance. Regularly inspect brake components and replace worn-out pads or fluid to maintain safety.

- Suspension: Shocks and struts may degrade over time, leading to a rougher ride. Check for signs of damage or leakage and replace as needed.

Replacement Tips

- Use Quality Components: Always opt for high-quality replacement parts that match the vehicle’s specifications to ensure optimal performance and safety.

- Regular Maintenance: Schedule periodic inspections and maintenance to address potential issues before they become major problems. This can include checking fluid levels, cleaning air filters, and examining belts and hoses for wear.

- Consult the Manual: Always refer to the vehicle’s manual for specific instructions and guidelines on repair procedures and compatible components.

- Professional Assistance: For complex repairs or when in doubt, it is recommended to consult a professional technician who has experience with utility vehicle maintenance.

Maintenance Guide for Gator TX 4×2

Proper maintenance is crucial for ensuring the long-term performance and reliability of your utility vehicle. Regular checks and upkeep help to prevent premature wear, improve safety, and maintain optimal functionality. This guide outlines essential tasks to keep your machine running smoothly, ensuring that it remains in top working condition throughout its lifespan.

- Engine Care: Regularly inspect the engine for signs of wear or leaks. Ensure that the oil is changed at recommended intervals and that the air filter is clean to optimize performance. Check coolant levels and look for any signs of overheating.

- Battery Maintenance: Inspect the battery regularly for corrosion on terminals and ensure it’s securely fastened. Clean the terminals and check the charge level to avoid starting issues.

- Tire and Wheel Maintenance: Regularly inspect tires for wear, damage, or uneven pressure. Maintaining proper tire pressure ensures better traction and handling, reducing strain on the vehicle.

- Brake System: Check the brake pads and fluid levels frequently. Ensure that the braking system is functioning properly to guarantee safe operation.

- Suspension and Steering: Inspect the suspension components for wear and replace any damaged parts. Ensure that the steering system is tight and free from excessive play.

- Transmission and Drive Belts: Check for proper operation of the transmission and drive belts. Replace worn-out belts promptly to prevent unexpected failures.

Following these maintenance practices regularly will help extend the life of your utility vehicle and ensure that it operates efficiently in all conditions. Always refer to the owner’s manual for specific guidelines and intervals for maintenance tasks.

Where to Find Genuine John Deere Parts

For those seeking high-quality components to maintain their equipment, finding authentic replacements is essential. Genuine items ensure optimal performance, longevity, and reliability, avoiding potential issues that could arise from substandard alternatives. Whether for routine upkeep or specialized repairs, sourcing the right materials is crucial for maximizing efficiency and minimizing downtime.

One of the best ways to obtain these original components is by visiting an authorized dealer or service center. These locations offer a broad selection of reliable items that are specifically designed for your machine. Additionally, the experts at these outlets can provide valuable advice, ensuring you select the correct options for your needs.

Another reliable source is the official online platform of the manufacturer, where you can explore a catalog of available replacements and make purchases with confidence. Many authorized websites also allow for easy searching based on model specifications, which simplifies the process of finding the right match.

For more personalized assistance, local repair shops that specialize in equipment maintenance may also stock genuine items or be able to order them for you. By consulting with professionals in the field, you can ensure that you’re using products that will maintain the optimal functionality of your machinery.

In all cases, it is important to check for authenticity to avoid counterfeit or incompatible components that could compromise the performance or safety of your equipment.

Step-by-Step Guide to Parts Diagram Navigation

Understanding how to efficiently explore an equipment breakdown is essential for identifying and sourcing the right components. Navigating through a detailed visual reference allows you to pinpoint specific elements and their relationships within the machine, streamlining both repair and maintenance processes. This guide will walk you through the key steps in using such a reference, making it easier to find what you need quickly and accurately.

Follow these steps to master the navigation process:

- Start with the Overview: Familiarize yourself with the general layout. Begin by identifying major sections of the equipment such as the engine, transmission, and chassis. This gives you a clear understanding of the overall structure before diving into finer details.

- Locate the Section of Interest: Once the major components are understood, focus on the specific part you need. Most references will organize components by their function, so look for categories that match the area you’re working on, such as electrical, mechanical, or hydraulic systems.

- Identify the Components: Each part will typically be labeled with a unique identifier. Make sure to note these part numbers or visual markers as you go along. Cross-reference them with the manufacturer’s list to ensure accuracy.

- Use Exploded Views: Exploded views provide a clear illustration of how parts fit together. This is especially useful when disassembling or reassembling the equipment. Pay attention to these detailed visualizations to avoid mistakes.

- Consult the Legend or Key: Some references include a legend or key that explains symbols, part numbers, and other notations used in the diagram. Be sure to consult this if any part of the illustration is unclear.

- Cross-Reference with Documentation: Double-check the information by cross-referencing the visual guide with the equipment’s manual or other technical documents to ensure compatibility and correct identification of components.

By following these steps, you can effectively navigate through technical illustrations and identify the parts needed for your repairs or upgrades with ease and confidence.

Common Issues and Troubleshooting Tips

Operating utility vehicles can sometimes present challenges that require attention to maintain optimal performance. Understanding typical problems and how to address them can prevent unnecessary downtime and extend the lifespan of the equipment. Below are some common issues owners may encounter and practical solutions to resolve them.

- Engine Won’t Start:

When the engine fails to start, the first step is to check the battery for charge. Inspect the connections to ensure they are secure and free of corrosion. Additionally, verify the fuel is fresh and the fuel lines are clear. If the issue persists, the ignition system or starter motor may need to be inspected.

- Poor Acceleration:

Insufficient power or poor acceleration can often be traced back to air or fuel delivery issues. Check the air filter and replace it if clogged. Ensure fuel injectors or carburetors are clean, and that there is no debris obstructing the intake system. Also, examine the spark plugs to make sure they are functioning properly.

- Unusual Noises:

Unusual sounds coming from the vehicle can indicate mechanical issues. Grinding or whining noises may signal problems with the drivetrain or transmission. Inspect the gears and differential for wear or damage. Lubricating moving parts regularly can also help prevent friction-related noises.

- Electrical Problems:

If the lights or other electrical components malfunction, the issue could be with the fuse, wiring, or the electrical connections. Check for blown fuses or loose wires. Inspect the battery voltage to ensure it is within the proper range. In some cases, a faulty alternator could be causing electrical failures.

- Overheating:

Overheating may be due to a blocked radiator or insufficient coolant. Make sure the cooling system is filled to the correct level and that there are no obstructions in the radiator or air vents. It’s also important to inspect the cooling fan to ensure it’s functioning correctly.

Regular maintenance and early detection of these common issues can prevent costly repairs and improve the overall efficiency of your vehicle. Always refer to the user manual for specific troubleshooting steps and safety precautions.

Benefits of Using Official John Deere Parts

When it comes to maintaining and repairing heavy-duty machinery, opting for genuine components ensures optimal performance and longevity. Using high-quality, manufacturer-recommended elements can make a significant difference in the overall efficiency and safety of your equipment. These authentic parts are designed with precision to meet exact specifications, delivering the best possible results for your vehicle’s operation.

Durability and Reliability

One of the primary advantages of choosing genuine components is their unmatched durability. Built to last, these parts are crafted from superior materials that provide exceptional resistance to wear and tear. This leads to fewer breakdowns, minimizing downtime and reducing the need for frequent repairs. Reliability is critical when working in challenging environments, and authentic parts guarantee that your machinery can handle demanding tasks over the long term.

Perfect Compatibility

Official components are engineered to fit seamlessly with your equipment, ensuring perfect compatibility. Using these parts eliminates the risk of poor performance or even potential damage caused by ill-fitting substitutes. When everything works together as intended, the overall efficiency of the machine is greatly enhanced, giving you peace of mind that your vehicle is performing at its best.