In the realm of heavy equipment, comprehending the intricacies of machine assembly is essential for effective maintenance and repair. Familiarity with the various components and their interrelations allows operators and technicians to diagnose issues swiftly and ensure optimal performance. This knowledge is invaluable for anyone working with complex machinery, facilitating a smoother workflow and reducing downtime.

The exploration of individual elements within these machines reveals a wealth of information that can aid in troubleshooting and enhancing operational efficiency. By examining detailed illustrations and schematics, users can gain insight into the layout and function of each part. This understanding not only empowers individuals to perform repairs more confidently but also encourages a proactive approach to equipment upkeep.

Ultimately, having access to clear and comprehensive visual representations of machinery components enhances the user’s ability to maintain and optimize their equipment. It equips operators with the tools necessary to engage with their machines on a deeper level, fostering a culture of knowledge and responsibility in the world of heavy machinery.

Overview of John Deere JS38

This section provides a comprehensive look at a specific lawn care machine, highlighting its design, functionality, and features that make it a popular choice among gardening enthusiasts. Understanding its components and overall structure can enhance the user experience and maintenance practices.

Key Features

The equipment boasts an efficient engine, allowing for seamless operation across various terrains. Its ergonomic design facilitates ease of use, while the durable materials ensure longevity and reliability. Versatility is another significant aspect, as it can adapt to different lawn conditions effortlessly.

Maintenance and Care

Proper upkeep is essential for optimal performance. Regular inspections and timely replacements of wear-prone elements can greatly extend the machine’s lifespan. Delving into maintenance practices not only enhances efficiency but also assures the ultimate care of the equipment.

Understanding Parts Diagrams

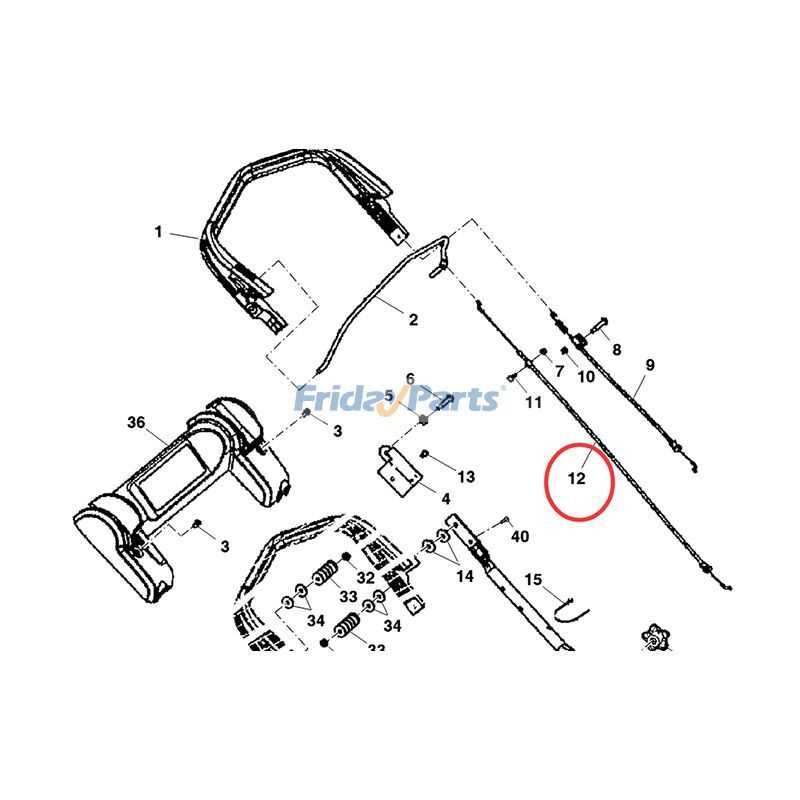

When it comes to machinery maintenance, visual representations of components play a crucial role in ensuring effective repairs and replacements. These illustrations serve as essential tools for users, helping them identify individual elements and their respective functions within a system. By decoding these visuals, one can enhance their understanding of equipment assembly and disassembly.

Visual aids offer a clear snapshot of how different parts interact, facilitating a smoother repair process. Each element is typically labeled with numbers or codes, allowing for easy cross-referencing with manuals or catalogs. This clarity reduces the likelihood of mistakes during maintenance, which can lead to costly errors.

Moreover, studying these illustrations not only aids in the immediate task at hand but also builds a foundation for future troubleshooting. As users become more familiar with the layout and components, their confidence in managing repairs grows, ultimately extending the lifespan of the equipment. Understanding these visual guides is a fundamental skill for anyone involved in machinery upkeep.

Key Components of the JS38 Mower

The functionality of a modern lawn care machine relies on several crucial elements working in harmony. Each component plays a significant role in ensuring efficient operation, durability, and ease of use. Understanding these parts can enhance maintenance practices and overall performance.

| Component | Description |

|---|---|

| Engine | Powers the mower and determines its cutting efficiency. |

| Blade | Responsible for cutting grass; its sharpness and design affect the quality of the cut. |

| Deck | Encloses the blade and provides structural support; influences cutting width and height. |

| Wheels | Facilitate movement and maneuverability; size and tread pattern affect traction. |

| Handle | Allows the operator to guide the machine; often adjustable for comfort. |

| Chassis | The framework that houses various components; contributes to stability and durability. |

| Fuel System | Delivers fuel to the engine; includes the tank and lines, affecting performance and efficiency. |

| Exhaust System | Channels emissions away from the engine; crucial for engine cooling and reducing noise. |

Understanding these key elements not only aids in maintenance but also enhances user experience, ensuring the lawn care machine performs at its best.

Where to Find Replacement Parts

Finding suitable components for your machinery can be a straightforward process with the right resources. Various avenues are available to ensure you obtain high-quality items that will keep your equipment running efficiently.

Online Retailers offer a vast selection of components, often at competitive prices. Websites specializing in agricultural equipment frequently provide detailed catalogs, allowing you to delve into specific models and compatibility.

Local Dealerships serve as valuable resources, providing genuine components and expert advice. They often have knowledgeable staff who can assist in identifying the ultimate parts needed for repairs.

Salvage Yards can be a cost-effective alternative. Many offer a range of used items that are still in good condition, making it a viable option for those looking to save money while maintaining functionality.

Forums and Community Groups can also be beneficial. Engaging with other enthusiasts can lead to recommendations and tips on where to find specific components, enhancing your search experience.

Common Issues with JS38 Parts

When maintaining equipment, users often encounter various complications that can affect performance and longevity. Identifying these frequent challenges can streamline the repair process and enhance efficiency.

- Wear and Tear: Components may deteriorate over time, leading to decreased functionality.

- Misalignment: Parts not properly aligned can cause operational issues, resulting in unusual noises or reduced efficiency.

- Corrosion: Exposure to moisture can lead to rust and degradation, particularly in metallic components.

- Contamination: Dirt and debris can obstruct vital areas, impacting overall performance.

- Improper Installation: Incorrectly fitted parts can result in a range of operational problems, including increased wear.

Regular inspection and timely maintenance can mitigate these issues, ensuring optimal performance and extending the life of the equipment.

Maintenance Tips for Longevity

Regular upkeep is essential for extending the lifespan of your equipment. By implementing a few straightforward practices, you can enhance performance and prevent premature wear and tear. Understanding the importance of maintenance not only saves money but also ensures optimal functionality over time.

Firstly, always refer to the manufacturer’s guidelines for scheduled service intervals. Adhering to these recommendations can prevent potential issues. Additionally, routinely check and replace fluids, filters, and belts to keep everything running smoothly. Clean components regularly to avoid dirt accumulation, which can hinder performance.

Moreover, inspecting for signs of wear and addressing them promptly is crucial. This proactive approach helps avoid costly repairs down the line. Lastly, storing your equipment in a sheltered environment can protect it from harsh weather conditions, further contributing to its durability.

How to Read Parts Diagrams

Understanding schematics is essential for anyone involved in machinery maintenance or repair. These visual representations provide critical information about components and their relationships, enabling users to identify parts quickly and effectively. Familiarizing yourself with the structure and symbols used in these illustrations can significantly streamline the process of sourcing and replacing components.

Components of a Schematic

To effectively interpret these illustrations, it’s important to recognize several key elements:

- Symbols: Each component is represented by a specific symbol, often accompanied by labels to indicate their function.

- Numbers: Unique identifiers are typically assigned to each item, which correlate with a list of parts or components.

- Connections: Lines and arrows indicate how various parts are connected or interact with each other.

Tips for Effective Interpretation

- Familiarize with Common Symbols: Spend time learning the most frequently used symbols in the industry to reduce confusion.

- Cross-reference with a List: Always have the corresponding parts list available to ensure accuracy in identifying each component.

- Use a Magnifying Tool: If the illustration is detailed, consider using a magnifying glass for clearer visibility of small text or symbols.

By mastering these techniques, you can enhance your ability to navigate these crucial resources, leading to more efficient repairs and maintenance tasks.

Identifying OEM vs Aftermarket Parts

When maintaining machinery, distinguishing between original and alternative components is crucial for ensuring optimal performance and longevity. Understanding the differences can significantly impact both the efficiency of your equipment and your budget.

Understanding OEM Components

Original equipment manufacturer items are produced by the same company that makes the machine itself. These components are designed to meet specific quality standards, ensuring compatibility and reliability. Using OEM parts often guarantees that the performance and durability of the equipment will be maintained.

Evaluating Aftermarket Options

Alternative items are produced by third-party manufacturers and may offer a more affordable solution. However, not all aftermarket products are created equal. It’s essential to research the reputation of the manufacturer and to read reviews to ensure the quality and reliability of these options. While they can provide cost savings, the trade-offs in performance or lifespan must be considered.

Benefits of Using Genuine Parts

Opting for authentic components significantly enhances the performance and longevity of your machinery. These original items are designed to meet the specific standards set by the manufacturer, ensuring seamless compatibility and reliability.

Quality Assurance

Authenticity guarantees that each piece has undergone rigorous testing, resulting in superior quality compared to aftermarket alternatives. This level of assurance translates to reduced maintenance issues and enhanced operational efficiency.

Cost-Effectiveness

Investing in genuine items can lead to long-term savings. While the initial purchase price may be higher, the durability and performance can prevent frequent replacements and costly repairs, making it the ultimate choice for smart budgeting.

Popular Upgrades for the JS38

Enhancing your equipment can significantly improve performance and longevity. Upgrades not only boost efficiency but also provide a better user experience. Here are some popular modifications that enthusiasts often consider.

- Improved Blades: High-performance blades can enhance cutting efficiency and reduce wear.

- Air Filters: Upgrading to premium air filters ensures better airflow and engine performance.

- Fuel System Enhancements: Opting for better fuel lines and filters can improve fuel efficiency and engine responsiveness.

- Handlebar Grips: Upgrading grips can provide greater comfort and control during use.

- Wheels: Switching to larger or more robust wheels can enhance maneuverability and stability.

These enhancements can elevate functionality and make maintenance easier, ultimately leading to a more satisfying user experience.

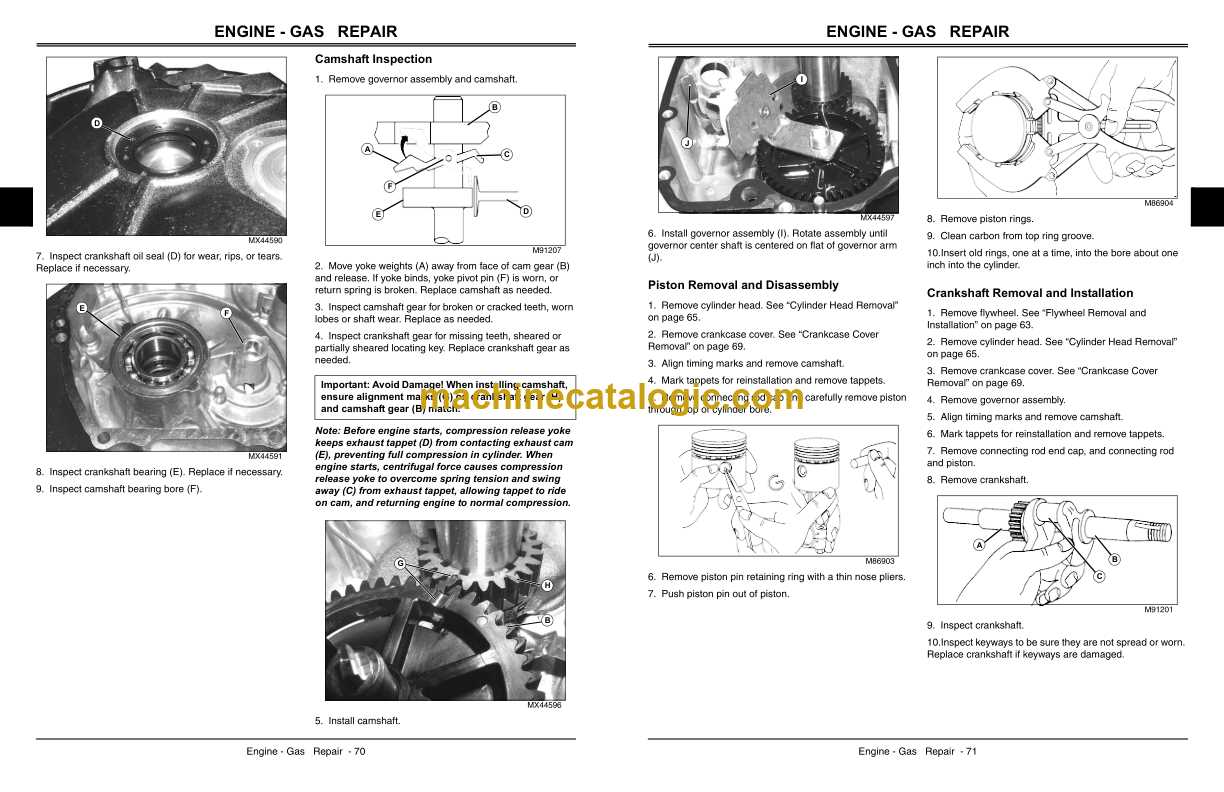

DIY Repairs for the JS38 Mower

Performing maintenance on your lawn equipment can save both time and money while ensuring optimal performance. This section explores various repair techniques that can be tackled at home, empowering you to address common issues without professional assistance. From simple adjustments to more intricate fixes, these guidelines will help you maintain the longevity of your machine.

Begin with routine checks, such as inspecting the blades for dullness and ensuring all components are securely attached. Sharpening blades not only enhances cutting efficiency but also promotes healthier grass growth. Additionally, replacing spark plugs and air filters can significantly improve engine performance.

For those facing engine troubles, troubleshooting the fuel system is essential. Verify that the fuel is fresh and clean, as old or contaminated fuel can lead to performance issues. If your machine won’t start, examining the ignition system and battery connections may reveal the culprit.

When it comes to wheels and drive systems, ensuring proper tension in belts and chains is crucial. Adjusting these components can eliminate slippage and improve handling. Regularly cleaning the deck and undercarriage prevents grass buildup, which can hinder performance and lead to corrosion.

By mastering these essential repair techniques, you can enhance your machine’s efficiency and extend its lifespan, all while enjoying the satisfaction of a job well done.

Community Resources and Support

Access to reliable information and assistance is essential for enthusiasts and professionals alike. Engaging with a network of knowledgeable individuals can significantly enhance understanding and troubleshooting skills related to various equipment.

Online Forums: Participating in dedicated forums allows users to share experiences, seek advice, and find solutions to common challenges. These platforms foster collaboration and knowledge exchange among peers.

Local Workshops: Attending community workshops or training sessions can provide hands-on experience and practical skills. These gatherings often feature experts who can offer valuable insights into maintenance and operation.

Resource Guides: Many organizations publish comprehensive guides that outline best practices, safety protocols, and troubleshooting techniques. These documents serve as excellent references for both new and seasoned users.

Support Networks: Joining local clubs or associations can create a sense of camaraderie and support. Members often benefit from shared resources, events, and collective expertise, enhancing their overall experience.