When maintaining a reliable lawn tractor, understanding the key elements that ensure its efficient operation is crucial. Every machine is made up of numerous interconnected systems, each playing a vital role in its overall performance. Whether focusing on the engine, transmission, or cutting mechanisms, having a clear understanding of how everything fits together can make a significant difference in keeping the equipment running smoothly.

Each piece of this equipment is designed with precision to meet specific needs, and recognizing these individual units can help in troubleshooting or optimizing your machine. Knowing the specific function of different mechanical and electrical elements will not only enhance repair processes but also extend the lifespan of the tractor.

By exploring detailed visual guides, users can get a closer look at how these mechanical parts interact. Such insights are indispensable for both experienced technicians and DIY enthusiasts alike, offering a way to simplify complex systems and make maintenance more straightforward.

John Deere LT133: Essential Component Overview

The focus of this section is to provide a detailed insight into the key mechanical elements that ensure the smooth and efficient operation of this model. Understanding these critical components is vital for maintenance and performance optimization.

Engine: The heart of the machine, responsible for powering the vehicle and ensuring consistent output. Proper care and regular checks of this part are necessary to avoid operational issues.

Transmission: This system plays a crucial role in translating engine power into movement. It controls speed and maneuverability, making it a pivotal aspect for those who need precision and reliability.

Cutting Deck: The cutting mechanism is designed to ensure precision and efficiency when working with large areas. Regular maintenance is essential to maintain its sharpness and effectiveness.

Electrical System: This part includes the battery, ignition system, and various sensors. It ensures that the machine starts reliably and operates with proper electrical feedback to all

Engine Parts Breakdown for John Deere LT133

The core of this equipment lies in the performance and reliability of its motor components. Each element within the motor is designed to work in harmony, ensuring efficient operation and long-term durability. Understanding the layout and the function of the engine’s internal structure is key to maintaining its performance over time.

Key Components of the Engine

The main elements of the motor include the cylinder, carburetor, and cooling system. These are critical for optimal combustion and heat management, ensuring smooth operation during extended use. Additionally, the ignition system and fuel lines play vital roles in starting and powering the equipment efficiently.

Engine Component Overview

| Component | Function | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cylinder Block |

| Component | Description | Function |

|---|---|---|

| Fuel Tank | Storage unit for fuel | Holds and supplies fuel to the pump |

| Fuel Pump | Mechanical or electric device | Moves fuel from the tank to the engine |

| Fuel Filter | Screen or filter element | Removes impurities from the fuel |

| Injector | Spray nozzle | Delivers fuel into the combustion chamber |

Maintenance Tips

Regular maintenance of the fuel system is essential to prevent issues such as clogging or fuel leaks. Inspecting the fuel filter and replacing it as necessary will enhance the efficiency of the system. Additionally, keeping the fuel tank clean and ensuring that the fuel is of high quality can significantly improve performance.

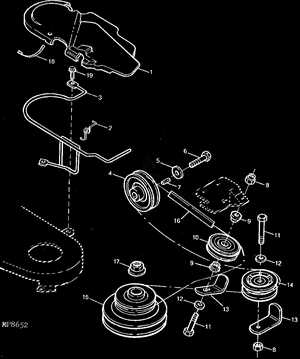

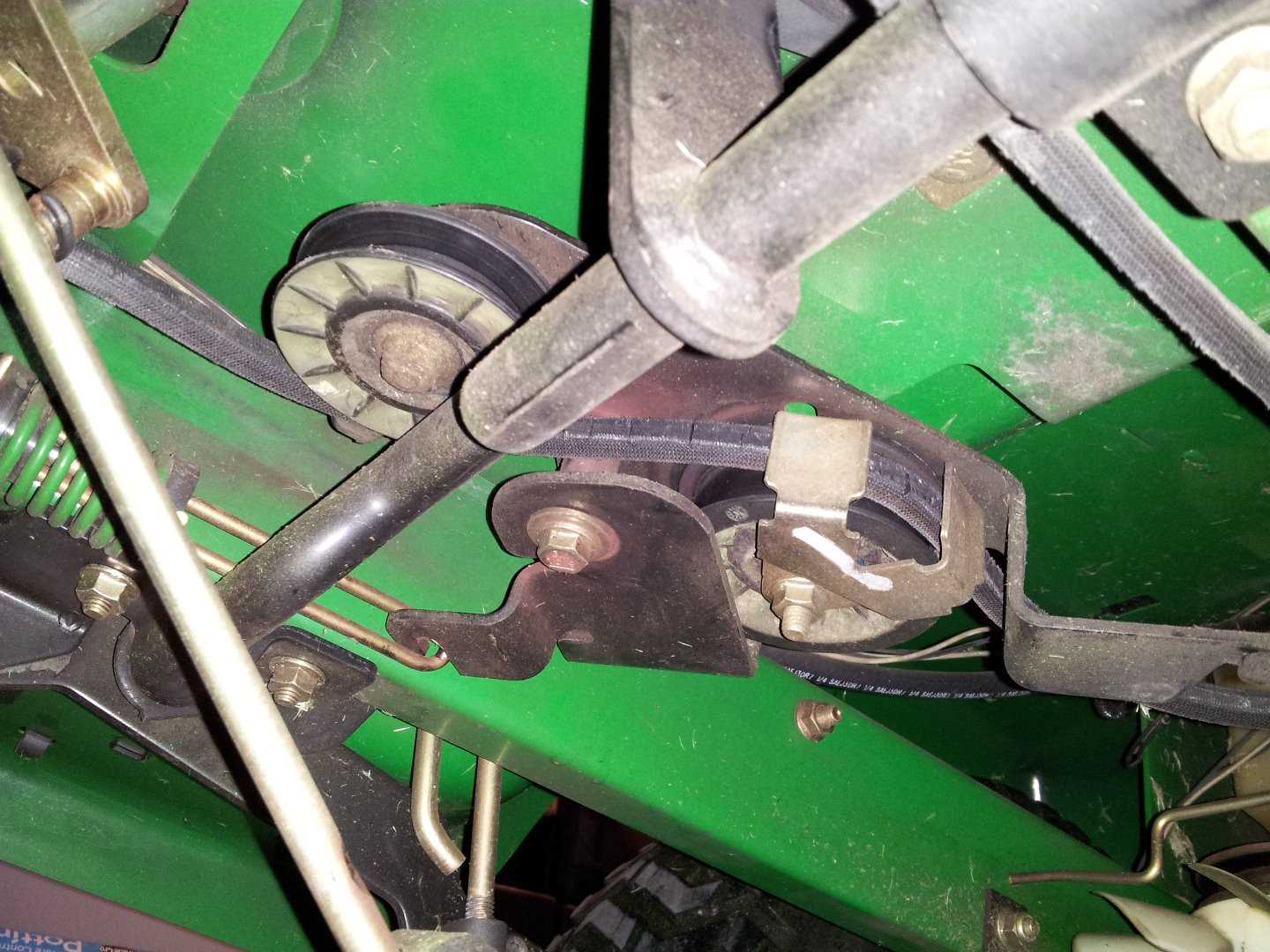

Brake and Clutch Mechanisms of the LT133

The braking and clutch systems in lawn equipment play a crucial role in ensuring smooth operation and control. These mechanisms allow for efficient stopping and starting, providing safety and ease of use during various tasks. Understanding their components and functionality can significantly enhance the user experience and maintenance procedures.

The braking system typically consists of various elements that work together to bring the machine to a halt when needed. Components such as brake pads, discs, and actuators interact to create the necessary friction for stopping. Regular inspection and timely replacement of worn-out parts are essential for optimal performance.

On the other hand, the clutch mechanism enables the operator to engage and disengage the drive system smoothly. This function is vital for controlling the power transfer from the engine to the wheels, allowing for better maneuverability. Maintaining the clutch, including checking the adjustment and condition of components like springs and plates, ensures reliable operation.

In conclusion, both braking and clutch systems are integral to the functionality of lawn equipment. Proper maintenance and understanding of these mechanisms not only improve performance but also enhance safety for the operator.

Rear Axle and Differential Parts Explained

The rear axle and differential assembly plays a crucial role in the overall functionality of lawn equipment, particularly in facilitating movement and power distribution. Understanding the components that make up this assembly is essential for maintenance and repair, ensuring optimal performance on various terrains.

The rear axle serves as the central shaft for the wheels, providing support and stability while allowing rotation. It is typically constructed from durable materials to withstand heavy loads and impact. The axle connects to the wheels, transmitting torque from the engine and enabling the vehicle to navigate smoothly.

At the heart of this assembly is the differential, which allows the rear wheels to rotate at different speeds, particularly during turns. This mechanism is vital for maintaining traction and control, preventing tire slippage. The differential consists of several key components, including gears, bearings, and a housing that protects these elements from debris and damage.

Regular inspection and maintenance of the rear axle and differential can help identify wear or damage early, ensuring that the machinery remains in peak condition. Proper lubrication and timely replacement of worn components are essential practices for extending the life of this critical assembly.

Understanding the LT133 Cooling System

The cooling mechanism in small engines is crucial for maintaining optimal performance and preventing overheating. A well-functioning system ensures that the engine operates efficiently, thereby prolonging its lifespan and enhancing reliability. This section delves into the key components and functionality of the cooling system designed for this model, highlighting its significance in the overall operation.

Key Components of the Cooling Mechanism

The cooling system consists of several essential parts that work together to dissipate heat generated during operation. Key components include the radiator, cooling fan, and various hoses that transport coolant. The radiator serves as the primary heat exchanger, where coolant absorbs heat from the engine and releases it to the atmosphere. The fan assists in enhancing airflow, ensuring that the coolant maintains an optimal temperature.

Importance of Regular Maintenance

Routine maintenance is vital for the cooling mechanism’s efficiency. Regular checks on coolant levels, hose integrity, and fan functionality can prevent potential issues such as overheating or engine damage. Additionally, flushing the cooling system periodically helps remove any debris or buildup, ensuring smooth operation. Proper care not only enhances performance but also contributes to the longevity of the engine.

Seat and Control Panel Components of LT133

The seating arrangement and control interface are crucial elements in ensuring comfort and functionality for users. These components not only enhance the operator’s experience but also facilitate efficient control over the machine’s operations.

Key components of the seating area include:

- Seat Cushion: Provides comfort during operation.

- Backrest: Supports the operator’s back, promoting good posture.

- Seat Mounting Bracket: Secures the seat in place, ensuring stability.

Regarding the control interface, several essential elements contribute to user interaction:

- Steering Wheel: Enables precise maneuverability.

- Throttle Control: Adjusts engine speed for optimal performance.

- PTO Switch: Engages and disengages attachments as needed.

- Indicator Lights: Provide visual feedback on machine status.

Understanding these components is vital for proper maintenance and effective operation, ensuring the machine remains reliable and user-friendly.