In the realm of outdoor equipment, a comprehensive grasp of the various elements that contribute to effective operation is essential. Each component plays a vital role in ensuring that the machine runs smoothly, efficiently, and safely. By delving into the specifics of these elements, users can enhance their maintenance routines and extend the lifespan of their devices.

For enthusiasts and professionals alike, visual representations of machinery can be invaluable. Such illustrations not only clarify the function of each part but also assist in identifying issues when they arise. Whether it’s for routine upkeep or troubleshooting, having a clear overview can significantly streamline the process.

By familiarizing oneself with the intricate details of these components, individuals can make informed decisions about repairs and replacements. This knowledge empowers users, enabling them to tackle challenges with confidence and maintain optimal performance throughout the seasons.

Understanding John Deere LT170

This section delves into the nuances of a well-regarded lawn maintenance machine, focusing on its design, functionality, and the components that contribute to its efficiency. Whether you’re a homeowner or a professional, understanding the intricacies of this equipment can enhance your experience and performance.

Key features of this mower include:

- Robust engine options for reliable power.

- Intuitive controls for ease of use.

- Durable construction for longevity and resilience.

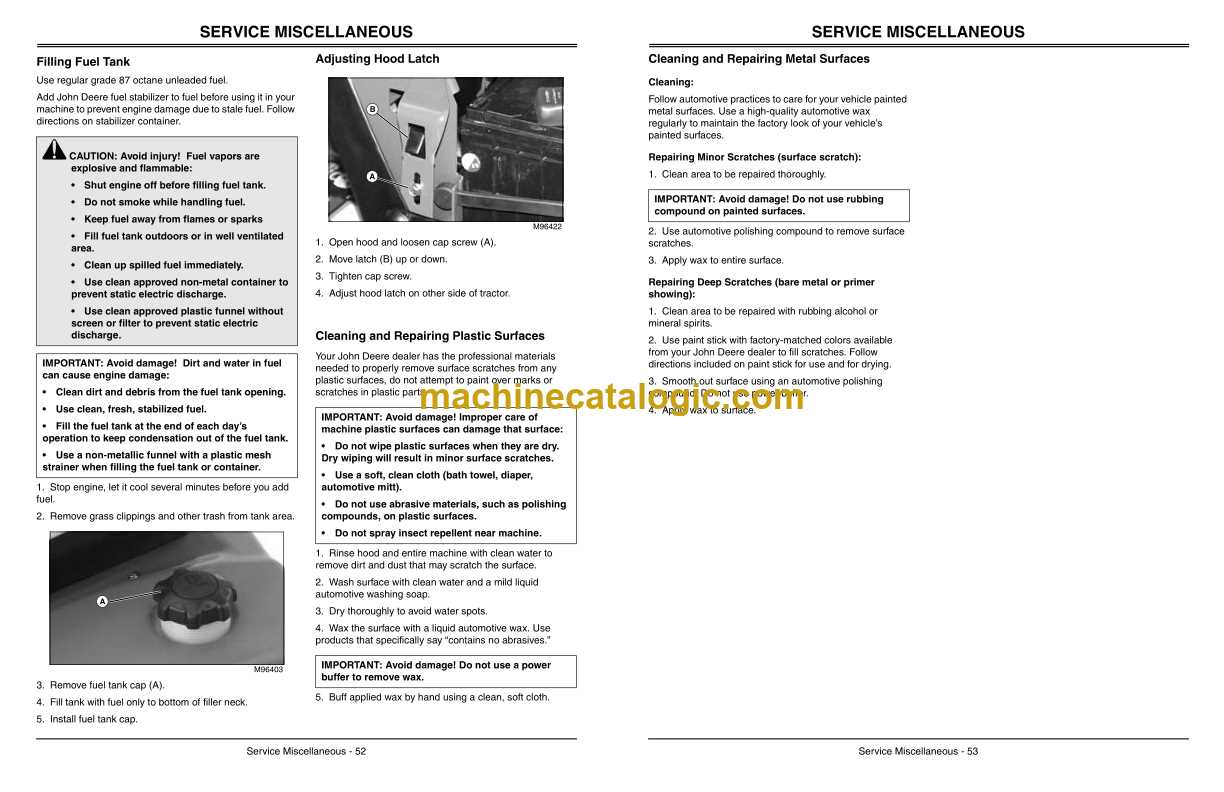

Regular maintenance is essential for optimal performance. Here are some important aspects to consider:

- Routine oil changes to keep the engine running smoothly.

- Blade sharpening to ensure clean cuts.

- Inspection of belts and hoses for wear and tear.

Understanding the various components and their functions can significantly impact the lifespan of your machine. Familiarity with these elements allows for informed decisions regarding repairs and upgrades.

Essential Components of the LT170

Understanding the key elements of this popular riding mower is crucial for efficient maintenance and optimal performance. Each component plays a vital role in the overall functionality and reliability of the machine, ensuring a seamless experience for users.

Engine: The powerhouse of the mower, the engine provides the necessary energy for operation, enabling it to tackle various terrains with ease.

Transmission: This mechanism facilitates smooth power transfer from the engine to the wheels, allowing for better maneuverability and control during use.

Deck: The cutting deck is essential for achieving a clean and even cut, designed to handle various grass types and lengths effectively.

Wheels: Properly sized and designed, the wheels support stability and traction, crucial for navigating slopes and uneven ground.

Controls: User-friendly controls ensure that operators can easily adjust settings and maneuver the mower, enhancing overall usability.

Each of these components contributes to the ultimate performance of the machine, making it essential for users to understand their functions and maintenance needs.

How to Access Parts Diagrams

To effectively navigate the world of equipment maintenance, understanding how to locate visual references for components is essential. These resources can provide clarity on the various elements that comprise machinery, making repairs and replacements more manageable.

Step 1: Begin by visiting the manufacturer’s official website, where you can often find a dedicated section for service resources. This area typically houses a wealth of information.

Step 2: Utilize the search function to input the specific model you are interested in. This will help you quickly narrow down the relevant materials.

Step 3: Look for downloadable manuals or visual aids that detail the assembly of the equipment. Many manufacturers offer PDF formats for easy access.

Step 4: Explore community forums and user groups online. Enthusiasts and professionals often share insights and resources that can lead you to valuable references.

Step 5: For in-depth exploration, consider reaching out to customer support. They can guide you to the exact resources needed for your specific machinery.

By following these steps, you can efficiently delve into the visual references required for successful equipment upkeep and repair.

Common Issues with LT170 Parts

When dealing with various components of a popular lawn mower model, several challenges can arise. Understanding these common problems can help users maintain their equipment more effectively and prevent costly repairs. Here, we will explore frequent concerns that owners encounter.

1. Wear and Tear

Over time, various elements of the machine may experience degradation. This can result in diminished performance or even failure. Common signs of wear include:

- Fading of belts

- Cracking of wheels

- Rust on metal components

2. Compatibility Issues

Another significant concern is the compatibility of replacement items. Not all parts are interchangeable, and using incorrect components can lead to further complications. To avoid this:

- Check the model specifications carefully.

- Consult the manufacturer’s guidelines for suitable replacements.

- Ensure that aftermarket options are reliable and fit correctly.

Addressing these issues proactively can enhance the longevity and functionality of your equipment, ensuring it runs smoothly for years to come.

Where to Buy Replacement Parts

Finding reliable sources for components can be crucial for maintaining your equipment efficiently. Various outlets provide options for high-quality items, ensuring you can keep your machinery in optimal condition. It’s essential to explore both local and online avenues to suit your specific needs.

| Source Type | Description | Pros | Cons |

|---|---|---|---|

| Local Dealers | Authorized retailers often carry genuine items. | Expert advice, immediate availability. | Higher prices. |

| Online Marketplaces | Platforms like eBay and Amazon offer a variety of choices. | Competitive pricing, wide selection. | Variable quality, longer shipping times. |

| Specialty Websites | Dedicated sites focus on specific brands and equipment. | Expertise, often exclusive items. | Limited to specific brands. |

| Salvage Yards | Used components can be found at lower costs. | Cost-effective, sustainable options. | Inconsistent quality, no warranty. |

Maintenance Tips for Longevity

Ensuring the long-lasting performance of your machinery requires a dedicated approach to upkeep. Regular maintenance not only enhances efficiency but also prevents costly repairs and extends the lifespan of your equipment. Here are essential tips to keep your machine running smoothly.

Routine Inspections

Conducting regular inspections is crucial for identifying potential issues before they escalate. Here are key areas to focus on:

- Check fluid levels: oil, coolant, and hydraulic fluids.

- Inspect belts and hoses for wear and tear.

- Examine tires for proper inflation and tread wear.

Scheduled Servicing

Implement a servicing schedule based on manufacturer recommendations. This can include:

- Changing the oil and filters at regular intervals.

- Cleaning or replacing air filters to ensure optimal airflow.

- Sharpening blades to maintain cutting efficiency.

By adhering to these practices, you can significantly improve the reliability and longevity of your equipment.

Identifying Original Equipment Manufacturer Parts

Recognizing components produced by the original equipment manufacturer is essential for ensuring compatibility and reliability in machinery. These elements are designed specifically for certain models, providing optimal performance and durability.

Why Choose OEM Components?

Opting for original parts guarantees that your equipment operates as intended. OEM items often come with better warranties and are rigorously tested to meet quality standards. This choice can ultimately save time and resources in maintenance.

How to Identify OEM Components

To distinguish genuine components, check for identifiable markings, serial numbers, or specific packaging. Additionally, consulting the equipment manual can provide crucial information regarding the correct specifications and compatibility of the parts needed.

Comparing Aftermarket vs. OEM Parts

When it comes to machinery maintenance, choosing the right components can significantly impact performance and longevity. There are two main categories to consider, each with its own advantages and disadvantages.

Aftermarket components are produced by third-party manufacturers, while OEM components are made by the original equipment producer. Here’s a breakdown of their characteristics:

- Cost: Aftermarket options are generally more affordable, which can be appealing for budget-conscious users.

- Quality: OEM products often guarantee superior quality and compatibility, as they are specifically designed for the machinery.

- Availability: Aftermarket alternatives may offer a wider variety, while OEM components can sometimes be limited to specific suppliers.

- Warranty: OEM parts usually come with a warranty, providing additional security for users.

Ultimately, the choice depends on individual preferences, needs, and financial considerations. It’s essential to delve into both options before making a decision.

Tools Needed for Repairs

When undertaking maintenance or repair tasks, having the right equipment is essential for achieving effective results. Proper tools not only simplify the process but also enhance safety and efficiency, allowing for a smoother workflow.

Commonly required implements include wrenches and sockets for loosening and tightening bolts, screwdrivers for fastening and removing screws, and pliers for gripping and manipulating various components. Additionally, specialized tools like torque wrenches may be necessary to ensure proper tension on fasteners, while diagnostic equipment can help identify issues quickly.

Furthermore, having a well-stocked toolbox with basic hand tools, along with safety gear such as gloves and goggles, ensures that repairs can be conducted safely and effectively. Investing in quality tools can make a significant difference in the longevity and performance of the machinery.

Step-by-Step Repair Guide

This section provides a comprehensive guide for effectively troubleshooting and repairing your equipment. By following these outlined steps, you can enhance the longevity and performance of your machine, ensuring it operates smoothly for years to come.

Tools and Materials Needed

- Wrenches and sockets

- Screwdrivers (flat and Phillips)

- Pliers

- Replacement components

- Lubricants and cleaning agents

- Safety goggles and gloves

Repair Steps

- Assess the Issue: Begin by thoroughly examining the machinery for any visible signs of wear or damage.

- Gather Necessary Tools: Collect all required tools and replacement parts to ensure a smooth repair process.

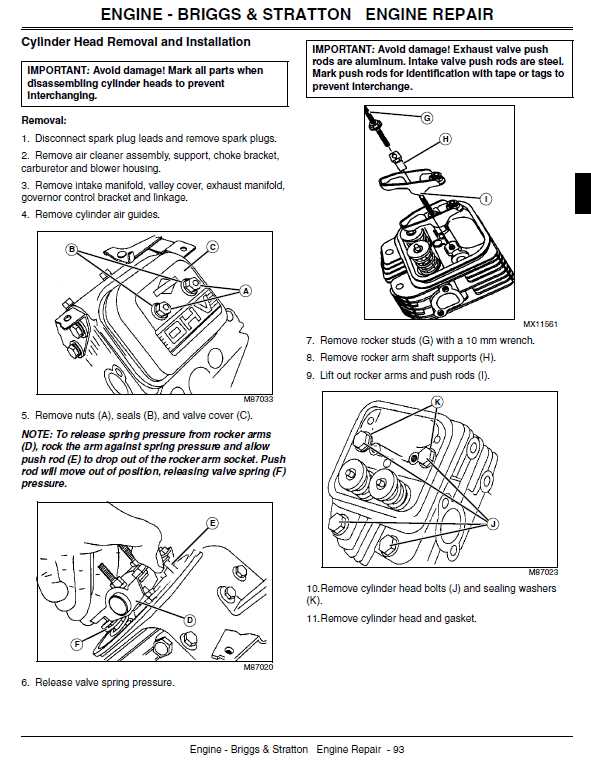

- Disassemble Affected Areas: Carefully remove the components that need attention, taking note of their arrangement for reassembly.

- Inspect and Replace: Evaluate each part for functionality. Replace any defective items with new ones.

- Reassemble the Equipment: Follow your earlier notes to put everything back in its original configuration.

- Test the Repair: Once reassembled, power on the machine to verify that the issue has been resolved.

By adhering to this structured approach, you can effectively address any mechanical challenges, ensuring optimal performance and reliability.

Customer Reviews on LT170 Parts

This section delves into user experiences regarding components for a specific lawn care machine. By analyzing feedback from various customers, we aim to provide insights into quality, durability, and overall satisfaction with these essential items.

Positive Feedback

- Many users appreciate the durability of the replacements, noting they often last longer than expected.

- Several customers highlighted the ease of installation, making maintenance straightforward.

- Consumers frequently mention excellent customer service when inquiring about specific items.

Areas for Improvement

- Some reviewers reported discrepancies in part compatibility, suggesting clearer specifications could help.

- A few customers expressed concerns over shipping times, wishing for quicker delivery options.

- There were mentions of occasional price fluctuations, leading to dissatisfaction among budget-conscious buyers.

Overall, customer feedback emphasizes the importance of both quality and service when selecting components for this lawn care machine. Engaging with user experiences can help prospective buyers make informed decisions.