When it comes to maintaining a lawn mower, having a clear understanding of its various elements is essential for efficient repair and upkeep. This section aims to provide insight into the intricate arrangement of a specific model’s structure, helping users identify and locate necessary components for service or replacement.

Visualizing the assembly of this machinery allows for a more comprehensive grasp of its functionality. By exploring the various sections, readers will gain valuable knowledge about how each part interacts within the overall framework. This understanding not only aids in troubleshooting common issues but also enhances the ability to perform routine maintenance with confidence.

In addition, an in-depth look at the layout of these elements can significantly improve the user’s experience when sourcing replacements. Knowing where each component fits within the larger system can streamline the process of identifying potential problems and expedite repairs. Overall, this information serves as a vital resource for both novice and experienced operators alike.

Understanding John Deere LT180

This section delves into the intricacies of a well-known lawn care machine designed for residential use. It highlights the essential components that contribute to its functionality, reliability, and overall performance in maintaining outdoor spaces. Gaining insight into these elements allows users to better appreciate the engineering and design behind this model.

Key Features of the Model

One of the standout attributes of this mower is its powerful engine, which ensures efficient operation across various terrains. Additionally, the user-friendly controls enhance the mowing experience, making it accessible for both seasoned users and novices. The cutting mechanism is designed for precision, allowing for an even finish on lawns of different sizes.

Maintenance Considerations

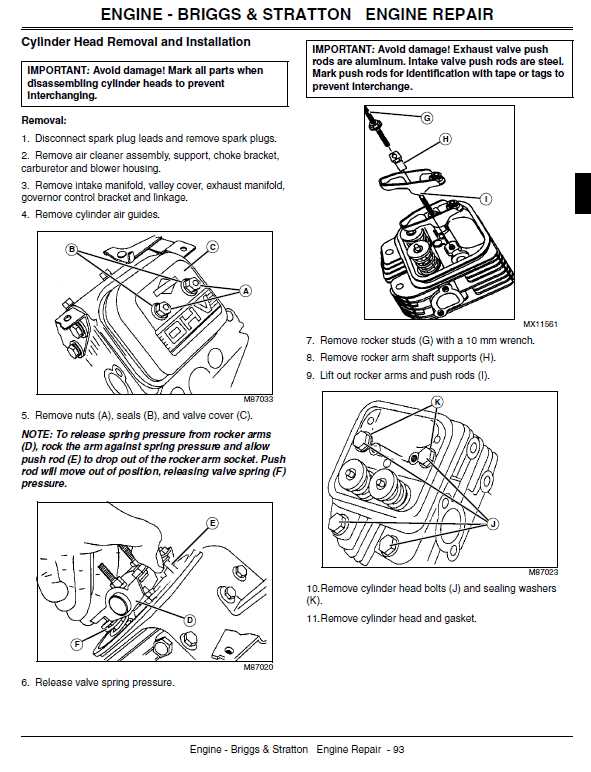

Proper upkeep is crucial for maximizing the lifespan of this equipment. Regular checks on the engine, blades, and fuel system can prevent common issues and ensure optimal performance. Users are encouraged to refer to the service guidelines to familiarize themselves with maintenance routines that will keep the machine running smoothly.

Overview of Lawn Tractor Components

Lawn tractors are essential for maintaining vast outdoor spaces, offering a blend of power and efficiency. Understanding the various elements that comprise these machines can enhance their performance and ensure proper upkeep. This overview delves into the key components that contribute to the functionality and reliability of a typical mowing vehicle.

Chassis and Frame

The chassis serves as the foundational structure of the machine, providing stability and support for all other components. This robust framework is designed to withstand the rigors of outdoor use, ensuring durability and longevity. Attached to the chassis are the wheels and axles, which play a critical role in mobility and maneuverability across different terrains.

Engine and Transmission

The engine acts as the heart of the tractor, generating the necessary power to drive the blades and propel the vehicle forward. Coupled with the transmission system, it enables smooth acceleration and efficient operation. This combination is vital for achieving optimal performance, whether navigating flat lawns or tackling hilly landscapes.

Importance of Parts Diagrams

Visual representations of components within machinery play a crucial role in understanding assembly and maintenance processes. They serve as essential guides for identifying individual elements and their relationships, ultimately facilitating repairs and enhancements.

Benefits of Visual Representations

- Clarity: Simplifies the complexity of intricate machinery, making it easier to locate specific components.

- Efficiency: Speeds up the identification and ordering of necessary components, reducing downtime during repairs.

- Training Aid: Acts as a valuable resource for educating new technicians and operators about machinery layouts and functionalities.

Applications in Maintenance and Repair

- Assists in diagnosing issues by providing a clear view of the assembly and helping pinpoint malfunctioning elements.

- Facilitates proper reassembly by outlining the correct order and placement of individual components.

- Enhances communication among team members, ensuring everyone has a shared understanding of the machinery’s structure.

Key Features of LT180 Model

The featured model stands out in its category due to a combination of performance, versatility, and user-friendly design. This machine is engineered to meet the needs of both residential and commercial users, ensuring reliable operation across a variety of tasks.

Engine and Performance

- Powerful engine for enhanced efficiency

- Optimized fuel consumption for cost savings

- Responsive acceleration for quick task execution

Design and Comfort

- Ergonomic seat for user comfort during extended use

- Intuitive controls for ease of operation

- Durable construction designed for long-term reliability

These characteristics ensure that this model is not only effective but also enjoyable to operate, making it a preferred choice among users. Its blend of functionality and comfort allows for tackling various outdoor tasks with ease.

Common Issues with LT180 Parts

In the realm of outdoor machinery, certain components may frequently encounter problems that can hinder overall functionality. Understanding these common challenges can aid in maintaining optimal performance and prolonging the lifespan of the equipment.

Several factors contribute to the malfunctions of various components. Users often report issues related to wear and tear, improper installation, or inadequate maintenance practices. Recognizing these potential pitfalls can enhance the reliability of the machine.

| Component | Common Issues | Possible Solutions |

|---|---|---|

| Battery | Frequent drainage, difficulty starting | Regularly check connections, replace if necessary |

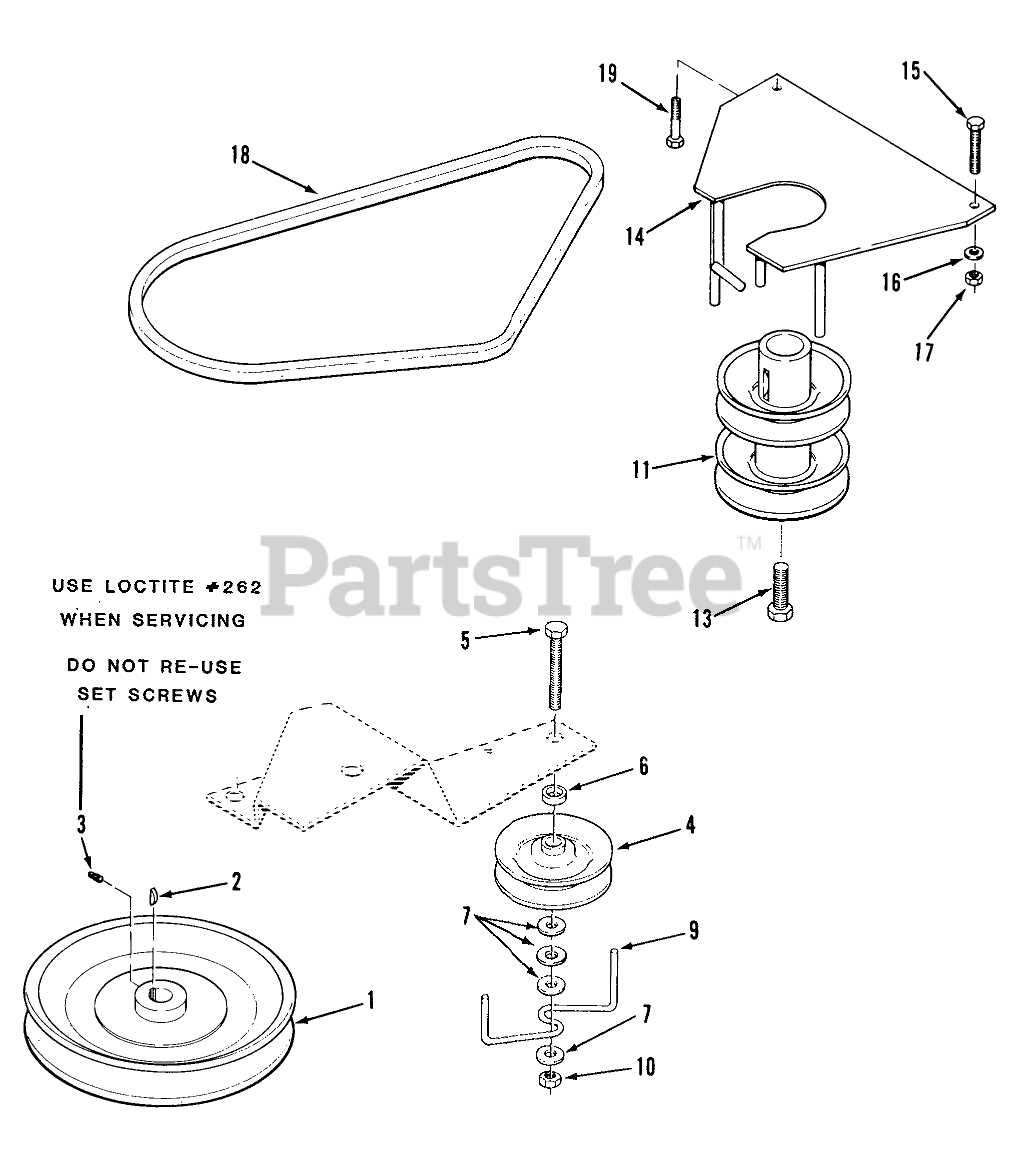

| Belts | Cracking, fraying, slippage | Inspect regularly, replace worn belts promptly |

| Blades | Dullness, chipping, uneven cutting | Sharpen regularly, ensure proper alignment |

| Fuel System | Clogs, leaks, poor performance | Clean fuel lines, replace filters as needed |

| Wheels | Punctures, wobbling, misalignment | Check tire pressure, inspect for damage |

By addressing these prevalent issues promptly and effectively, users can maintain their equipment’s functionality and avoid costly repairs. Regular maintenance and inspections are key to ensuring long-term performance.

Locating Replacement Parts Online

Finding suitable components for your equipment has become increasingly convenient with the rise of online resources. Whether you are looking to enhance performance or replace worn-out items, the internet offers a plethora of options for sourcing the necessary elements. By utilizing specialized websites and online marketplaces, you can efficiently search for what you need without the hassle of traditional shopping methods.

Utilizing Online Marketplaces

Online marketplaces provide a vast selection of components from various sellers. Platforms such as eBay and Amazon allow users to compare prices and find high-quality replacements. Make sure to check seller ratings and reviews to ensure the reliability of your purchase. Many listings will also include detailed descriptions and specifications, making it easier to identify the right fit for your needs.

Manufacturer and Specialty Websites

Another effective approach is visiting the official websites of manufacturers or specialty retailers. These sites often have extensive catalogs, allowing you to search by model or type. In addition, many of these platforms provide diagrams and resources to help you understand compatibility and installation processes. Utilizing these resources can save you time and guarantee that you receive the correct items for your machinery.

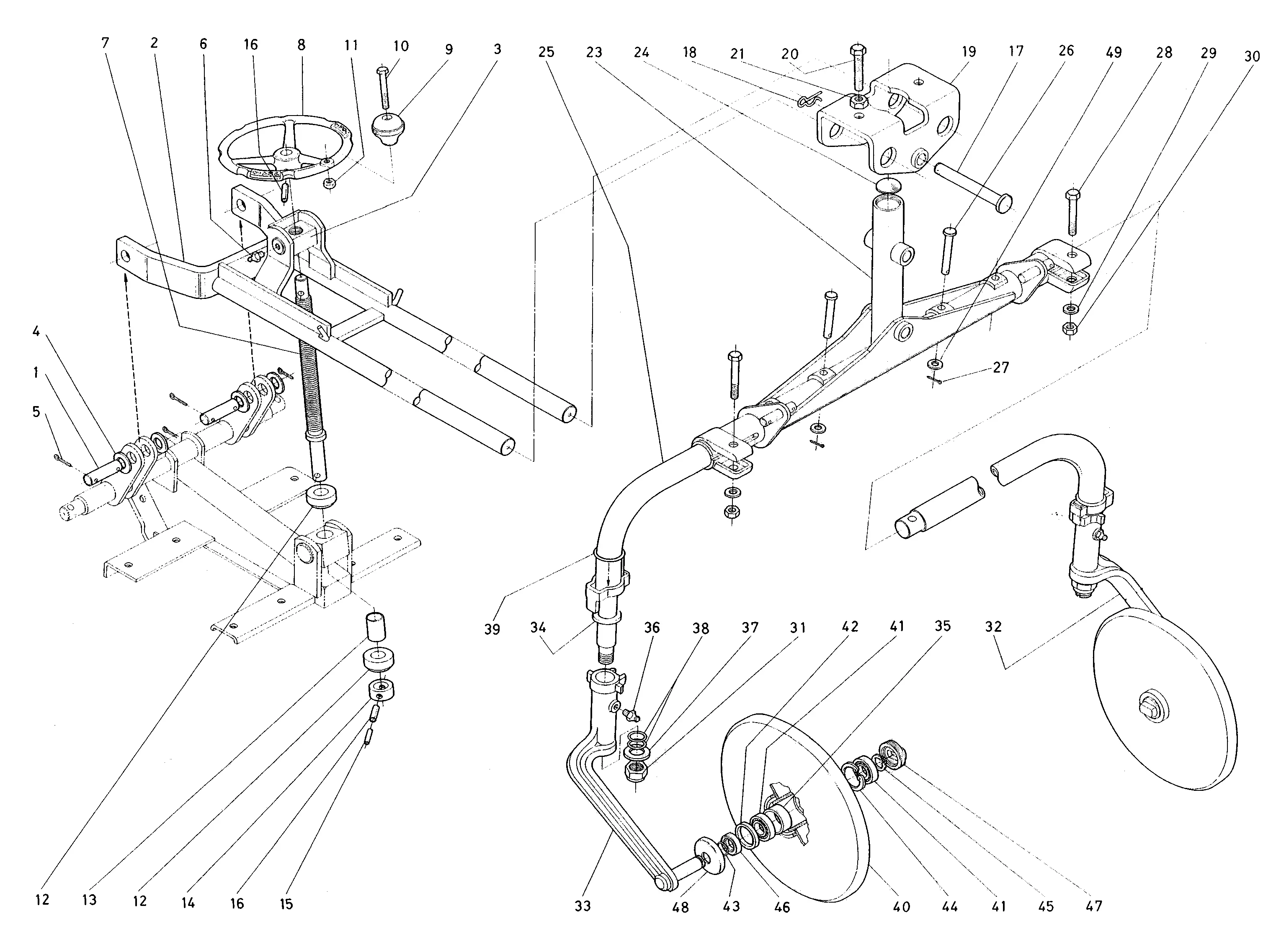

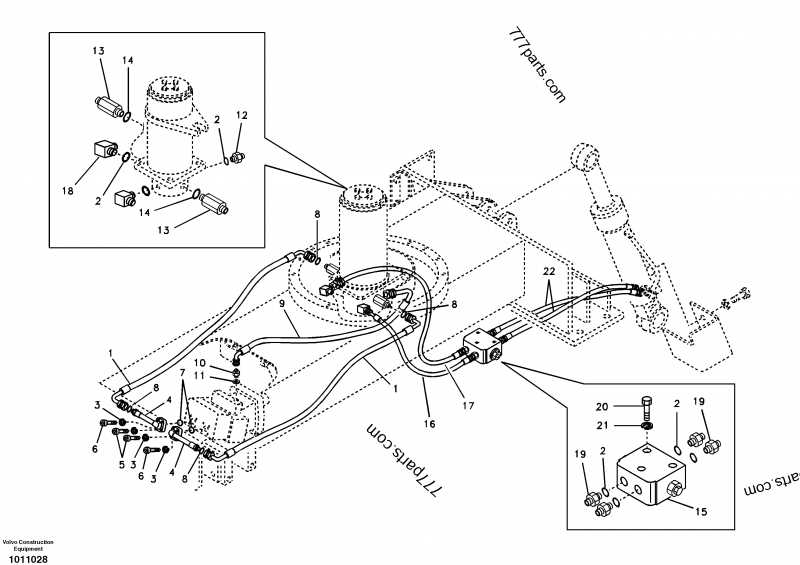

Identifying Parts by Diagram

Understanding the layout and components of machinery is crucial for effective maintenance and repair. Utilizing a visual representation allows operators to pinpoint specific elements within the system, facilitating a more organized approach to servicing. By examining the provided illustration, one can gain insights into the assembly, identify individual components, and comprehend their functions.

To effectively utilize a visual guide, it is essential to familiarize oneself with the various sections depicted. Each labeled section provides a reference point for locating parts and understanding their interrelationships. This systematic method not only simplifies troubleshooting but also enhances overall efficiency during repairs.

When referencing an illustration, pay close attention to any accompanying notes or legends that may clarify component specifications or installation guidelines. Such details can significantly aid in ensuring that replacements or adjustments are executed accurately, thereby prolonging the lifespan of the machinery.

Maintenance Tips for LT180

Regular upkeep is essential for ensuring optimal performance and longevity of your equipment. By implementing effective maintenance strategies, you can prevent potential issues and enhance operational efficiency.

1. Check the Oil Level: Regularly inspect the oil level and quality. Changing the oil as per the recommended intervals will help maintain engine health and performance.

2. Clean or Replace Air Filter: A clean air filter is crucial for proper airflow. Make it a habit to check and clean or replace the filter to avoid engine strain.

3. Inspect the Blades: Dull or damaged blades can affect cutting performance. Regularly sharpen or replace blades to ensure a clean cut and reduce stress on the engine.

4. Battery Maintenance: Keep the battery terminals clean and ensure a secure connection. Check the charge regularly and replace the battery when necessary to prevent starting issues.

5. Tire Pressure Check: Maintaining proper tire pressure is vital for stability and traction. Regularly inspect and adjust the pressure to match the manufacturer’s recommendations.

6. Fuel Quality: Use fresh, high-quality fuel to prevent engine knocking and improve efficiency. If the equipment is not in use for an extended period, consider using fuel stabilizers.

7. Storage Considerations: When storing your equipment for long periods, ensure it is cleaned and protected from the elements. Use a cover to prevent dust accumulation and damage from exposure.

By following these maintenance tips, you can ensure the reliable operation of your equipment and extend its service life.

Tools Needed for Repairs

When tackling maintenance or repair tasks, having the right tools is essential for achieving efficient and effective results. A well-equipped toolkit not only streamlines the process but also enhances safety and accuracy during work. Below is a comprehensive list of necessary instruments and equipment that can assist in various repair endeavors.

Essential Hand Tools

- Wrenches: A set of adjustable and fixed wrenches will help tighten or loosen bolts and nuts with ease.

- Screwdrivers: Both flathead and Phillips head screwdrivers are vital for assembling and disassembling components.

- Pliers: A good pair of pliers is crucial for gripping, bending, and cutting wires or small parts.

- Hammers: A hammer is useful for driving nails or fitting parts together securely.

- Utility Knife: This tool is handy for cutting various materials, including rope, plastic, and packaging.

Specialized Equipment

- Torque Wrench: Ensures that fasteners are tightened to the correct specifications, preventing damage from over-tightening.

- Diagnostic Tools: Devices such as multimeters or code readers can help identify electrical issues and troubleshoot problems.

- Lift or Jack: Essential for safely elevating machinery to access lower components for repair or inspection.

- Safety Gear: Items like gloves, goggles, and ear protection are necessary to ensure personal safety during repair tasks.

Equipping yourself with these tools will enhance your ability to perform repairs efficiently and safely, ensuring that you can handle any challenge that arises.

Comparing LT180 with Other Models

This section explores the distinctions and similarities among various models within the same category of lawn care equipment. By examining features, performance, and user experiences, we aim to provide valuable insights for prospective buyers and enthusiasts.

Performance Metrics

When evaluating different machines, it’s essential to consider factors such as engine power, cutting efficiency, and maneuverability. While some models excel in delivering robust power for larger lawns, others are designed for efficiency in smaller, more intricate spaces. Understanding these performance metrics helps users select the right model based on their specific needs.

Design and Features

In terms of design, various machines offer unique features that cater to different preferences. Some are equipped with advanced comfort systems and user-friendly controls, enhancing the overall experience. Additionally, options for attachments and customization can significantly impact functionality, allowing users to adapt their equipment for diverse tasks.

Frequently Asked Questions about LT180

This section addresses common inquiries regarding a specific model of lawn equipment. Understanding these aspects can enhance user experience and ensure proper maintenance and operation.

What should I consider when maintaining my mower?

Regular upkeep is essential for optimal performance. Key factors include checking the oil level, ensuring the blades are sharp, and inspecting the belts for wear. Additionally, keep the air filter clean and replace it if necessary to maintain airflow.

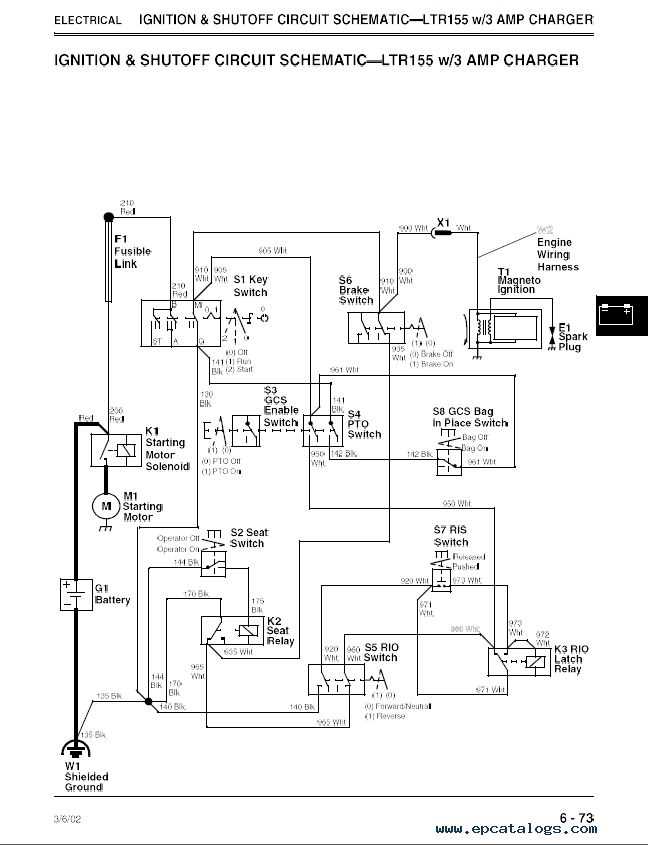

How can I troubleshoot starting issues?

If your mower is having difficulty starting, check the battery for a proper charge. Ensure that all safety switches are engaged, and inspect the ignition system for any faults. If problems persist, consult a professional for further diagnostics.

Best Practices for Parts Replacement

Replacing components in machinery requires careful consideration to ensure optimal performance and longevity. Following established guidelines can prevent unnecessary issues and enhance the overall functionality of your equipment.

Assessing Compatibility

Before proceeding with any replacement, it is essential to verify the compatibility of the new component with your specific model. This can help avoid mismatches that could lead to operational failures.

- Consult the manufacturer’s manual for specifications.

- Cross-reference with reputable sources for part numbers.

- Check online forums or communities for user experiences.

Installation Procedures

Proper installation techniques play a crucial role in ensuring that the new component functions as intended. Adhering to best practices during installation can significantly reduce the risk of future problems.

- Gather all necessary tools before starting.

- Follow step-by-step instructions from reliable sources.

- Perform a thorough inspection of the surrounding area to ensure cleanliness.

- Test the machine after installation to confirm proper operation.

Resources for John Deere Owners

Owning a piece of heavy machinery comes with its own set of challenges and responsibilities. Access to reliable information and quality components is crucial for maintaining efficiency and longevity. This section provides a curated list of resources to assist equipment enthusiasts in finding the necessary tools, support, and community connections to enhance their experience.

Online Forums and Communities

Engaging with fellow machinery owners can offer invaluable insights and shared experiences. Numerous online platforms and discussion boards allow users to exchange knowledge, troubleshoot issues, and share maintenance tips. Participating in these communities not only provides answers but also fosters a sense of camaraderie among users who share similar interests.

Retailers and Supply Stores

Reliable retailers are essential for sourcing high-quality components and accessories. Many vendors offer comprehensive catalogs that include everything from routine maintenance supplies to specialized implements. Establishing a relationship with trusted suppliers can help ensure that equipment owners have access to the best products available, tailored to their specific needs.