When working with complex machinery, understanding how different elements come together is crucial for both maintenance and repair. This guide provides a detailed look at essential components, helping you navigate through the structure and function of the equipment. Each element plays a key role, ensuring that the system operates smoothly and efficiently.

Recognizing the configuration of specific mechanisms allows for easier identification of potential issues and replacement needs. By exploring various sections of the equipment, you can ensure optimal performance and longevity. Whether you’re performing routine checks or addressing malfunctions, having a clear visual representation of each component’s role is invaluable.

This guide focuses on providing an organized breakdown of the equipment’s internal and external features. You will find detailed information that aids in pinpointing specific elements, allowing you to maintain and improve the machinery with confidence.

Comprehensive Guide to John Deere LX176 Components

Maintaining the efficiency and longevity of any equipment depends on a clear understanding of its essential elements. Knowing the different systems and their functionality can help optimize performance and reduce downtime. In this guide, we will explore various critical elements, providing insight into how they interact and contribute to smooth operation. Whether it’s understanding the internal mechanisms or external fittings, familiarity with these aspects ensures better upkeep and troubleshooting.

Engine System: At the heart of any machine is its power source. This system converts fuel into energy, driving the entire unit forward. It’s crucial to keep this area well-maintained, as it plays a vital role in the overall performance.

Transmission and Drive: The motion of the unit relies heavily on this assembly. It ensures seamless movement, transmitting power from the motor to the wheels, facilitating both forward and reverse motions.

Steering and Control: Maneuverability is critical, and this system allows operators to direct the machine effortlessly. A well-functioning control setup provides smooth turning and responsive handling.

Cutting and Handling Mechanism: The core function of this equipment revolves around its ability to process materials effectively. This section includes blades and other handling tools, ensuring precise operation and optimal results.

Electrical System: The electrical components ensure ever

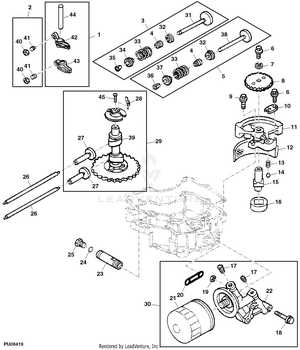

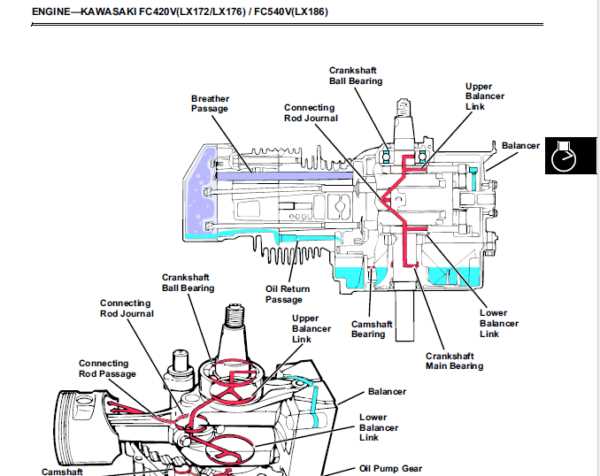

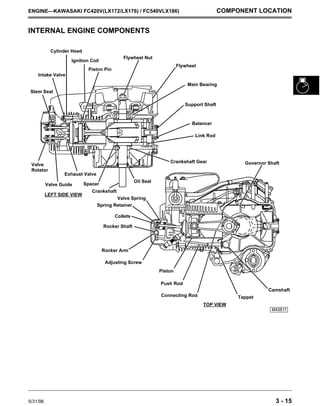

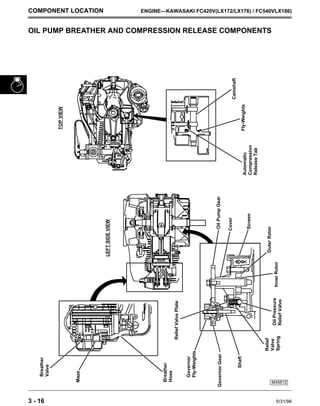

Understanding the Engine Assembly Layout

The structure of the engine is composed of several interconnected elements that work together to ensure optimal performance. To properly maintain and repair these components, it is essential to understand their spatial arrangement and how they interact with each other.

Main Components Overview

In the core of the engine, several vital sections can be identified. These sections include parts responsible for fuel delivery, combustion, and power generation. Each element plays a unique role, contributing to the overall efficiency of the system.

- Fuel Supply System: Delivers the necessary fuel to the internal chambers.

- Combustion Chamber: Where the fuel mixes with air and ignites, generating energy.

- Cooling System: Ensures that the temperature is maintained within operational limits.

- Exhaust Pathway: Allows gases to escape after combustion has occurred.

Understanding Component Connections

The assembly is structured in a way that allows for easy flow of fuel, air, and coolant. Understanding how these systems are interconnected is key for troubleshooting and efficient repair work. The arrangement is also designed to minimize heat buildup and maximize airflow, ensuring longevity and performance.

- Begin by ide

Exploring the Electrical System Schematic

The wiring blueprint of a machinery’s power system provides an essential understanding of how different components connect and interact to ensure proper functionality. By analyzing this layout, one can identify critical paths of energy flow and pinpoint where electrical components such as connectors, relays, and fuses are positioned. This exploration is fundamental to maintaining and troubleshooting the equipment’s overall performance.

- Wiring routes that carry energy between key mechanical units

- Important safety devices like breakers and protection circuits

- Connections that link various control systems and sensors

Gaining familiarity with this map allows for efficient identification of potential issues, whether it’s a malfunctioning switch or a disconnected wire. Understanding how the network operates also facilitates smoother repair processes and helps in making precise adjustments when necessary.

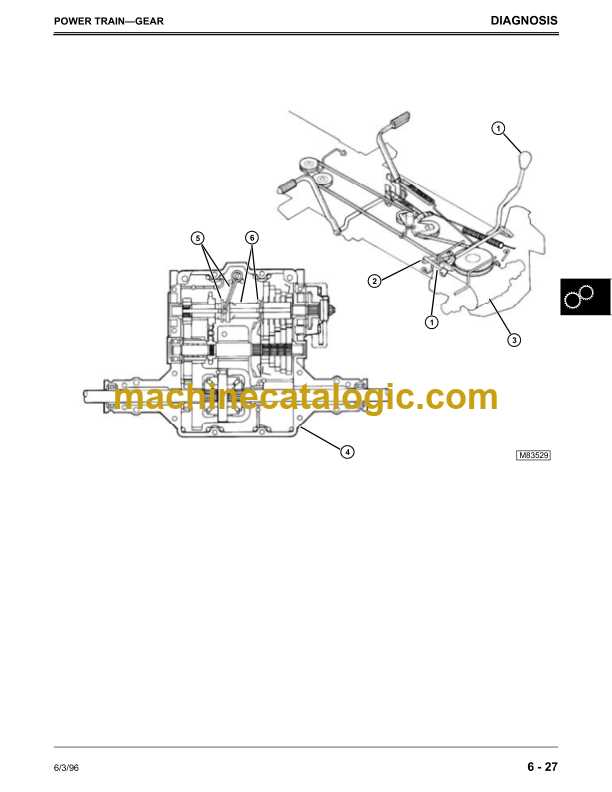

Transmission and Drivetrain Overview

The power transfer system is essential for the movement and control of the machine. It ensures that energy is efficiently distributed from the engine to the wheels, providing the necessary torque for smooth operation. Understanding how these components interact is key to maintaining optimal performance.

- Transmission System: This component governs how power is delivered to the wheels, ensuring smooth acceleration and deceleration. It plays a vital role in managing speed and direction, allowing for a responsive and controlled experience.

- Drivetrain: The connection between the engine and the wheels, this system transfers mechanical energy. It includes various parts that work in harmony to provide movement and traction, especially when navigating uneven terrain.

- Key Functions:

- Controlling speed variations

- Adjusting power flow based on terrain

- Ensuring smooth transitions between different gear settings

Overall, regular inspection and maintenance of these systems are critical to ensuring reliable performance. Addressing issues early on can prevent costly repairs and downtime.

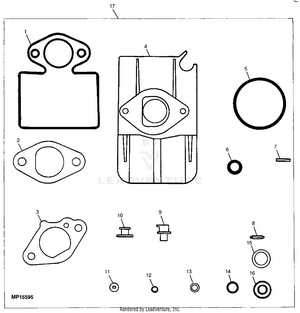

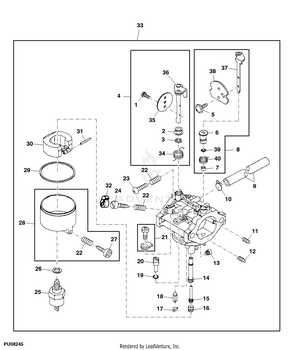

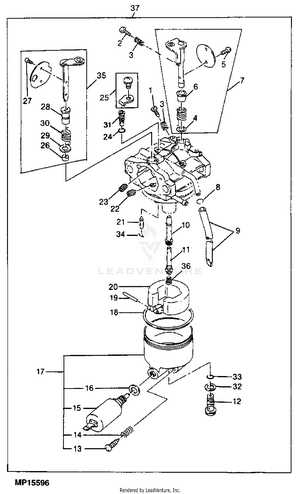

Fuel System Configuration for Optimal Performance

Ensuring efficient fuel delivery is critical for maintaining reliable operation and achieving peak performance in any engine system. A well-designed setup provides consistent energy flow, which improves both power output and fuel efficiency. This section outlines key considerations for configuring the components responsible for fuel distribution and combustion.

- Fuel Delivery Path: The route through which fuel travels needs to be free of obstructions, and all connections must be securely tightened to prevent leaks. Proper line routing reduces the risk of pressure drops and ensures smooth delivery to the engine.

- Filtration System: Effective filtering is essential to remove impurities from the fuel, preventing clogging and damage to sensitive components. A regularly maintained filter improves fuel quality, contributing to smoother engine operation.

- Fuel Injection: An accurately calibrated injector ensures optimal atomization of the fuel, which leads to more efficient combustion. Adjusting the injector settings to match engine load requirements can significantly boost performance.

- Pressure Regulation: Maintaining consistent pressure

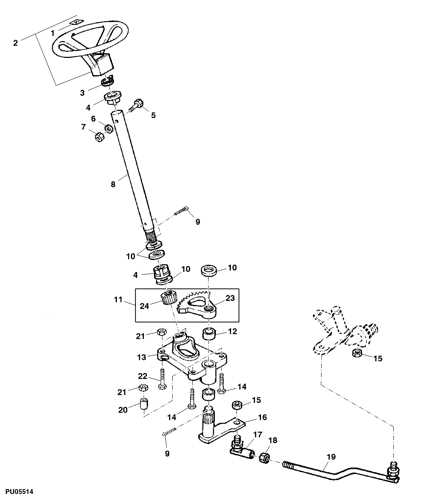

Key Details on Steering Mechanism

The steering system is a critical component in ensuring the maneuverability and stability of lawn care machinery. Understanding its essential elements can significantly enhance operational efficiency and user control. This section delves into the intricate aspects of the steering setup, highlighting its functions and maintenance considerations.

Components of the Steering System

The steering assembly comprises various parts that work together to provide smooth navigation. Key elements include the steering wheel, linkages, and the rack and pinion system. Each component plays a vital role in translating the driver’s inputs into directional movement. Regular inspection of these elements can prevent wear and ensure optimal performance.

Maintenance Tips

Proper upkeep of the steering apparatus is crucial for maintaining safety and functionality. Lubrication of moving parts is essential to reduce friction and wear, while tightening loose connections can prevent misalignment. It’s advisable to consult the user manual for specific maintenance intervals and recommended practices.

Hydraulic Lift System and Its Parts

The hydraulic lift mechanism is an essential feature in various agricultural machines, enabling efficient lifting and lowering of implements. This system relies on fluid dynamics to transmit power, making it a critical component for enhancing functionality and performance in machinery.

Understanding the components of this system is vital for proper maintenance and troubleshooting. Below is a breakdown of the key elements that make up the hydraulic lift system:

Component Description Hydraulic Cylinder Responsible for converting hydraulic pressure into mechanical force, enabling movement. Hydraulic Pump Generates fluid flow, creating the pressure needed for the system to operate effectively. Fluid Reservoir Stores hydraulic fluid, ensuring a constant supply to the system during operation. Control Valve Regulates fluid flow and directs it to various parts of the system, controlling movement. Hoses and Fittings Transport hydraulic fluid between components, maintaining system integrity and efficiency. Proper understanding and regular inspection of these components can significantly enhance the reliability and longevity of the hydraulic lifting mechanism in any machinery.

Brake System Diagram and Functions

The braking mechanism is a vital component of any vehicle, ensuring safety and control during operation. Understanding its layout and functionality is essential for effective maintenance and repair. This section delves into the various elements of the braking system, outlining their roles and how they interact to deliver optimal performance.

Key components of the braking system include:

- Brake Pedal: The primary interface for the operator, allowing for manual activation of the brakes.

- Master Cylinder: Converts the force from the brake pedal into hydraulic pressure.

- Brake Lines: Transport hydraulic fluid from the master cylinder to the brake components.

- Brake Calipers: House the brake pads and apply pressure to the braking surface when engaged.

- Brake Pads: Friction material that contacts the braking surface to slow down or stop the vehicle.

- Rotors: The surface against which the brake pads press to create friction and halt motion.

Each of these elements plays a crucial role in the overall functioning of the braking system:

- The brake pedal initiates the process when the operator applies force.

- This force is transferred to the master cylinder, generating hydraulic pressure.

- The pressurized fluid travels through the brake lines to the calipers.

- Calipers then exert pressure on the brake pads, forcing them against the rotors.

- The friction generated by this contact slows the rotation of the wheels, bringing the vehicle to a stop.

Regular inspection and maintenance of these components are essential to ensure the braking system functions reliably and safely. Understanding the layout and interaction of these parts allows for more efficient troubleshooting and repair, ultimately enhancing the longevity and performance of the entire vehicle.

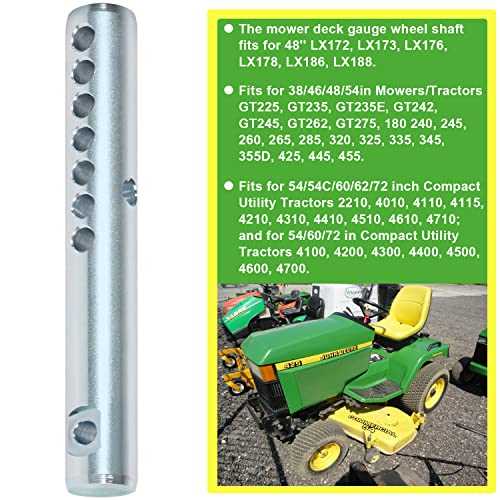

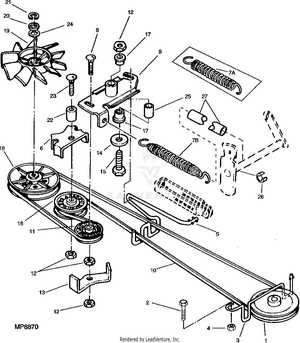

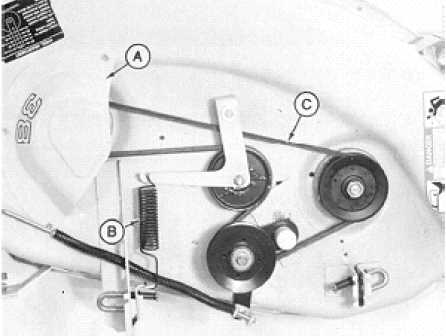

Mower Deck Parts and Attachments

The mower deck is a crucial component of any grass-cutting equipment, designed to provide efficient cutting and even grass distribution. Understanding its various components and attachments can enhance performance and versatility, making lawn care tasks more manageable and effective.

Key elements of the mower deck include the cutting blades, which are responsible for achieving a clean and precise cut. Blade spindles hold the blades in place, allowing for smooth rotation and optimal cutting efficiency. Additionally, deck belts transfer power from the engine to the blades, ensuring that the mower operates seamlessly.

Moreover, various attachments can be integrated with the deck to enhance functionality. These may include mulching kits, which finely chop grass clippings, and bagging systems that collect debris for easy disposal. Understanding the compatibility of these accessories can significantly improve the performance of the mowing machine, catering to specific lawn care needs.

Overall, being familiar with the different components and their roles within the mower deck system enables users to maintain their equipment effectively and achieve desired mowing results.

Troubleshooting Common Issues with Control Systems

Understanding the complexities of control mechanisms is essential for effective maintenance and operation. Various challenges can arise, affecting performance and reliability. This section focuses on identifying typical problems and offers solutions to ensure smooth functionality.

Identifying Symptoms: The first step in resolving issues is to recognize the symptoms of malfunction. Common signs include erratic movements, delayed responses, or complete system failures. Observing these indicators can help narrow down the source of the problem.

Checking Connections: Often, loose or corroded connections can lead to operational failures. Inspect all wiring and connectors to ensure they are secure and free from damage. Regular maintenance can prevent these issues from occurring in the first place.

Power Supply Evaluation: A stable power source is crucial for optimal performance. Verify that the power supply is functioning correctly and that there are no interruptions. Testing with a multimeter can provide insights into voltage levels and help identify deficiencies.

Calibration and Settings: Misconfigured settings can lead to performance discrepancies. Ensure that all parameters are calibrated according to manufacturer specifications. Adjusting these settings can resolve many operational issues.

Component Inspection: If problems persist, inspecting individual components for wear and tear is advisable. Elements such as sensors, actuators, and control units may need replacement or servicing to restore proper functionality.

Consulting Documentation: Referring to the technical documentation can provide valuable insights into troubleshooting procedures. Manufacturer guidelines often include troubleshooting charts that can help identify common issues and their solutions.

Seeking Professional Assistance: When all else fails, consulting a professional technician may be necessary. Their expertise can provide a deeper understanding of complex systems and ensure that issues are resolved effectively.

Cooling System Structure and Components

The cooling mechanism in machines plays a vital role in maintaining optimal operating temperatures, ensuring that the engine runs efficiently and preventing overheating. This system comprises various interconnected elements designed to regulate temperature effectively. Understanding these components is essential for proper maintenance and troubleshooting.

Core Elements of the Cooling Mechanism

At the heart of the cooling setup lies the radiator, which dissipates heat from the engine coolant into the surrounding air. The coolant, a mixture of water and antifreeze, circulates through the engine and radiator, absorbing and releasing heat as needed. A thermostat regulates the flow of coolant, ensuring that the engine maintains a steady temperature during operation.

Additional Components

Supporting the primary functions, a water pump facilitates the movement of coolant throughout the system. Hoses connect various parts, allowing for the seamless transfer of coolant and preventing leaks. Furthermore, fans may assist in increasing airflow over the radiator, enhancing cooling efficiency, especially in demanding conditions.

Examining the Seat and Safety Features

This section focuses on the essential components that enhance comfort and ensure protection while operating riding equipment. Proper seating and safety mechanisms are vital for an efficient and secure experience, contributing to the overall functionality of the machine.

The seating arrangement is designed to provide maximum support during operation. It typically features adjustable elements that cater to various user preferences, ensuring optimal comfort. The materials used are durable, weather-resistant, and easy to clean, making maintenance straightforward. Moreover, these seats often come with integrated safety features, such as seat belts or sensors that monitor occupancy.

Feature Description Adjustable Seat Allows customization for comfort based on user height and preferences. Safety Belts Provides secure fastening to minimize movement during operation. Occupancy Sensors Detects if the seat is occupied, enhancing safety mechanisms. Ergonomic Design Promotes good posture and reduces fatigue during extended use. Weather-Resistant Material Ensures longevity and durability against environmental factors. These features work in tandem to create a secure operating environment. Regular maintenance of the seat and its safety components is crucial for optimal performance and user well-being.

Regular Maintenance Tips for Long-Term Durability

Ensuring the longevity and efficiency of your machinery involves adhering to a consistent upkeep routine. By following a few essential practices, you can prevent potential issues and maintain optimal performance throughout the equipment’s lifespan.

First and foremost, regularly inspecting components for wear and tear is crucial. Check for any signs of damage, rust, or loose connections, as these can lead to more significant problems if left unattended. Additionally, routine cleaning is vital; removing dirt and debris from both the exterior and interior parts helps prevent buildup that can hinder functionality.

Moreover, adhering to a scheduled lubrication routine can significantly enhance performance. Use appropriate lubricants on moving parts to reduce friction and prevent premature wear. Furthermore, replacing filters and fluids at recommended intervals will ensure the machinery operates smoothly and efficiently.

Lastly, keeping the user manual on hand can provide valuable insights into specific maintenance tasks and intervals. This proactive approach will not only enhance the durability of your equipment but also ensure it remains reliable for years to come.