In the realm of modern farming, efficient machinery plays a crucial role in optimizing crop management. Understanding the various elements that comprise such equipment can significantly enhance both functionality and maintenance. This section aims to provide insights into the intricate arrangements of different components used in agricultural machinery, focusing on their roles and interconnections.

Every piece of equipment is a complex assembly designed to perform specific tasks. By exploring the layout and function of these elements, operators can ensure better performance and longevity. Whether it involves liquid distribution systems or mechanical assemblies, a thorough comprehension of these structures is essential for effective operation and troubleshooting.

Furthermore, familiarizing oneself with the various components enables users to identify potential issues before they escalate, leading to reduced downtime and improved productivity. This exploration into the intricacies of agricultural machinery fosters a deeper appreciation for the technology that supports contemporary farming practices.

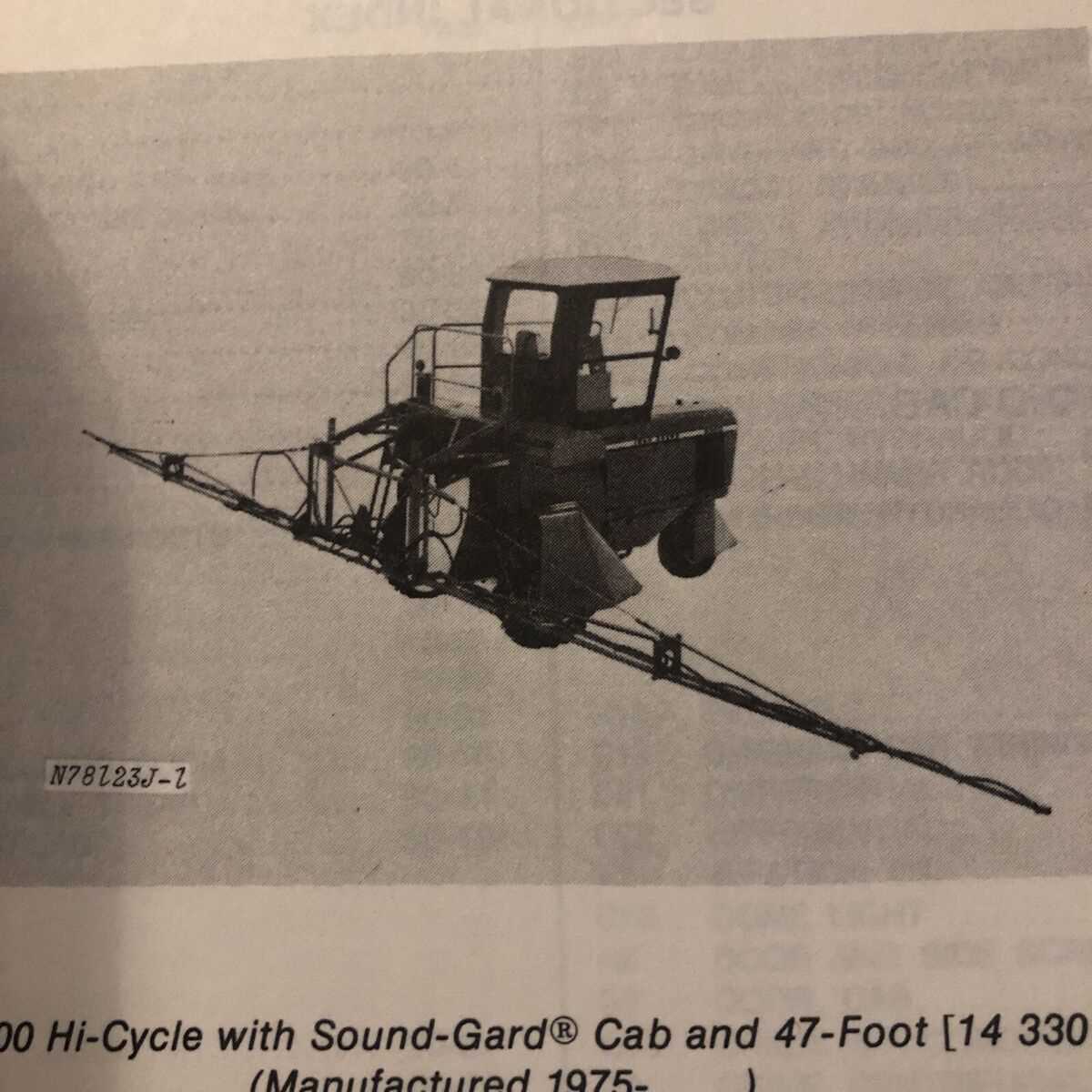

Overview of Sprayer Components

The functionality of an agricultural application system relies heavily on its various elements, each contributing to the overall effectiveness and efficiency of the operation. Understanding these components is essential for optimal performance and maintenance.

Key Elements

At the heart of the system are the mechanisms responsible for liquid distribution. These include pumps that ensure consistent flow and nozzles that facilitate precise application. Additionally, the support structure plays a crucial role, providing stability and ease of maneuverability during field operations.

Maintenance Considerations

Regular upkeep of these components is vital. Inspecting for wear and tear, cleaning filters, and ensuring seals are intact can prevent costly repairs and downtime. By focusing on these areas, operators can enhance the longevity and reliability of their equipment.

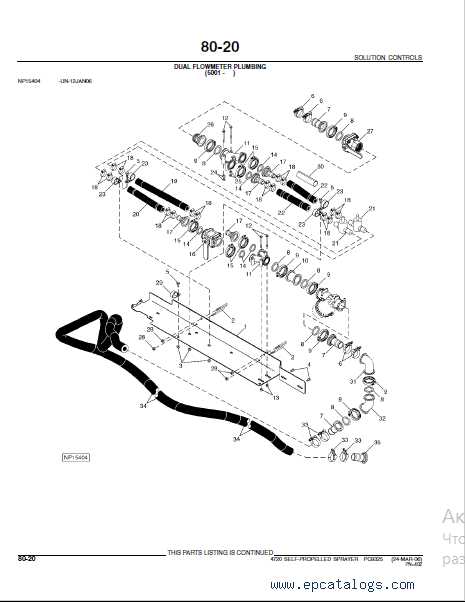

Understanding the Diagrams

Visual representations serve as essential tools for comprehending complex systems. They break down intricate structures into more digestible segments, enabling users to identify components and their interconnections efficiently.

Importance of Visual Aids

- Enhance understanding of assembly processes.

- Facilitate troubleshooting by highlighting critical areas.

- Provide a clear overview of how individual elements interact.

How to Interpret Visual Representations

- Familiarize yourself with the symbols used.

- Identify key sections and components.

- Follow the flow of information to grasp functional relationships.

Common Parts in John Deere Models

In various agricultural equipment, specific components play crucial roles in ensuring efficient operation and maintenance. Understanding these elements is essential for anyone involved in the upkeep of these machines. This section delves into frequently encountered elements across different models, highlighting their functions and importance.

Essential Components

One of the fundamental elements includes the hydraulic system, which facilitates movement and control. Additionally, the fuel delivery system is vital for optimal performance, ensuring that energy is efficiently supplied to the engine. Regular checks and replacements of these components can significantly enhance the longevity and efficiency of the machinery.

Maintenance Tips

Routine inspections are necessary to identify wear and tear in the essential components. Keeping these elements in good condition not only improves functionality but also reduces the likelihood of unexpected breakdowns. Investing time in maintenance can lead to improved productivity and reduced repair costs in the long run.

Identifying Key Features

Understanding the essential elements of agricultural machinery is crucial for optimal operation and maintenance. Recognizing these components can enhance performance and prolong the lifespan of the equipment.

Common Components

- Frame Structure

- Liquid Storage Tank

- Delivery System

- Control Mechanism

- Wheels and Suspension

Functional Attributes

- Capacity: Refers to the volume of liquid that can be stored and applied.

- Efficiency: Indicates how effectively the machine distributes liquids over the target area.

- Durability: Reflects the resilience of materials used in construction, impacting longevity.

- Versatility: The ability to adapt to various agricultural tasks beyond liquid application.

Maintenance Tips for Sprayer Parts

Proper upkeep of your application equipment is essential for optimal performance and longevity. Regular maintenance not only enhances efficiency but also reduces the risk of costly repairs. Here are some valuable suggestions to ensure your machinery remains in top condition.

Routine Inspection

- Check all connections and seals for wear and tear.

- Inspect hoses and tubes for leaks or damage.

- Examine nozzles for clogs or blockages.

Cleaning Practices

- Flush the system after each use to prevent residue buildup.

- Use appropriate cleaning agents that won’t damage components.

- Regularly clean filters to maintain flow efficiency.

Common Issues and Solutions

In the world of agricultural equipment, various challenges can arise during operation. Understanding these problems and their respective solutions is essential for maintaining optimal functionality and performance.

| Issue | Possible Causes | Solutions |

|---|---|---|

| Inconsistent application | Clogged nozzles, improper calibration | Clean nozzles and recalibrate settings |

| Uneven pressure | Faulty pump, leaks in the system | Inspect and repair or replace components |

| Electrical failures | Corroded connections, damaged wiring | Check connections and replace any damaged wires |

| Excessive wear | Poor maintenance, low-quality materials | Perform regular maintenance and use quality parts |

How to Interpret Part Numbers

Understanding the identification codes used for components is essential for accurate replacement and maintenance. These alphanumeric sequences often convey important information about the item, including its specifications and compatibility with various systems.

Decoding the Structure

Typically, the first section of a code may indicate the category or type of the component, while subsequent parts may specify size, model, or version details. Familiarizing yourself with this structure can greatly enhance your efficiency when searching for replacements.

Cross-Referencing and Verification

Utilizing resources such as manuals or manufacturer databases can aid in confirming the correct identification of the components. It’s advisable to double-check the codes to ensure the accuracy of the selected items for your equipment.

Ordering Replacement Components

When maintaining agricultural machinery, sourcing suitable replacement elements is essential for optimal performance. Ensuring the right components are selected not only extends the life of the equipment but also enhances its efficiency in the field.

To facilitate the ordering process, consider the following steps:

| Step | Action |

|---|---|

| 1 | Identify the specific component needed for replacement. |

| 2 | Consult the manufacturer’s specifications to ensure compatibility. |

| 3 | Contact authorized dealers or reliable suppliers for availability. |

| 4 | Place the order and confirm the shipping details. |

| 5 | Track the shipment to ensure timely delivery. |

Following these guidelines will streamline the process and help maintain operational efficiency.

Safety Precautions When Repairing

Ensuring safety during maintenance tasks is crucial for preventing accidents and injuries. Understanding and adhering to safety protocols can significantly reduce risks while working on equipment. This section outlines essential precautions to consider when performing repairs to machinery.

Proper Personal Protective Equipment

Always wear appropriate personal protective gear. This includes gloves, goggles, and steel-toed boots. Each item plays a vital role in safeguarding against potential hazards, such as flying debris, sharp objects, and chemical exposure. Additionally, hearing protection is advisable when working in noisy environments.

Work Area Organization

Maintain a clean and organized workspace. Clutter can lead to accidents and make it difficult to find tools or components quickly. Ensure that all tools are in good condition and stored properly after use. Furthermore, clearly label hazardous materials and ensure that first aid kits are readily accessible. Regularly inspect your surroundings to identify and mitigate any potential hazards.

Tools Required for Maintenance

Effective upkeep of equipment relies heavily on having the right instruments at hand. These essential tools not only facilitate the process but also enhance efficiency and safety during servicing tasks. A well-equipped workspace can significantly impact the longevity and performance of the machinery.

Basic Hand Tools

Having a collection of hand tools is crucial. Items such as wrenches, screwdrivers, and pliers are fundamental for performing routine checks and adjustments. These tools allow for quick and easy access to various components, ensuring that maintenance can be carried out smoothly.

Specialized Equipment

In addition to standard tools, specific equipment tailored for maintenance tasks is invaluable. Diagnostic devices help in identifying issues quickly, while lubrication systems ensure that moving parts operate efficiently. Investing in these specialized tools contributes to effective management and reduces the risk of prolonged downtime.

Comparative Analysis of Models

This section delves into the evaluation of various agricultural machinery variants, focusing on their specifications, functionalities, and operational efficiencies. By examining these differences, users can make informed decisions based on their specific requirements and preferences.

Performance Metrics

Understanding the performance metrics of different models is crucial. Factors such as speed, capacity, and fuel efficiency significantly influence overall effectiveness. Each variant offers unique advantages, which can be pivotal in maximizing productivity in various farming scenarios.

Maintenance and Durability

Another essential aspect to consider is the maintenance needs and durability of the equipment. Some models may require more frequent servicing, while others boast enhanced longevity, leading to reduced downtime and operational costs. Assessing these elements can guide users in selecting the most suitable machinery for their agricultural tasks.

Benefits of Upgrading Components

Enhancing the elements of machinery can lead to significant improvements in performance and efficiency. Upgrading outdated or subpar components ensures that equipment operates at its best, ultimately contributing to higher productivity and reduced downtime.

Improved Performance

One of the primary advantages of component upgrades is the boost in overall functionality. Modern components often feature advanced technology that enables faster processing, better energy efficiency, and enhanced precision. Investing in new elements can lead to smoother operations and superior results, making tasks easier and more effective.

Cost-Effectiveness

Although the initial investment in new components may seem substantial, the long-term savings can be considerable. Upgrading often reduces maintenance costs and the likelihood of unexpected breakdowns. Enhanced reliability means less time spent on repairs, allowing for increased operational capacity and better resource allocation.