Proper maintenance of lawn machinery is essential for ensuring its longevity and smooth operation. Knowing the inner workings and how different elements connect allows you to address potential issues before they escalate. This guide will provide insights into the various elements, helping users navigate through each section with ease.

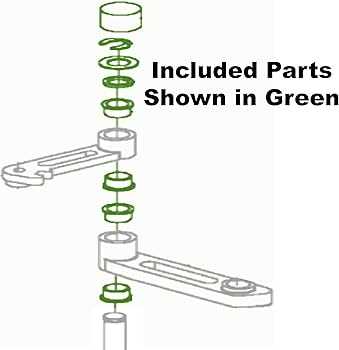

Mechanical assemblies often consist of numerous components that work in harmony to deliver efficient performance. When familiarized with the layout, users can better identify the location and function of specific elements, facilitating easier repairs and replacements. A clear visual representation can be incredibly useful in understanding how each section functions as part of the whole machine.

For any user, from beginners to seasoned operators, grasping the design of key components is invaluable. Whether you are conducting routine inspections or troubleshooting mechanical issues, having a thorough understanding of the structure can significantly reduce downtime and increase productivity.

Key Components Overview of a Popular Zero-Turn Mower

Understanding the essential elements of a zero-turn lawnmower is crucial for efficient maintenance and optimal performance. This section provides an overview of the fundamental systems that ensure smooth operation and durability over time.

Engine: The heart of the machine, powering all critical functions, requires regular inspection and proper care to ensure reliability and longevity. It converts fuel into mechanical energy, driving the mower and its attachments.

Transmission: This system controls the movement, ensuring smooth and precise direction changes. Its efficient function is key to navigating tight spaces and achieving superior maneuverability.

Cutting Deck: Responsible for trimming grass, this section houses the blades and determines the quality of the cut. A well-maintained cutting deck ensures even and clean results.

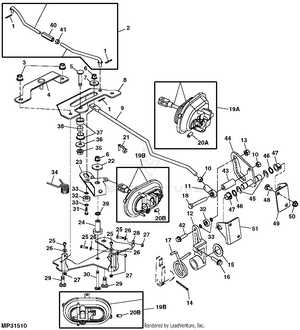

Steering and Control Mechanisms: These components allow for responsive handling. Ensuring they remain in optimal condition is vital for safety and ease of use during operation.

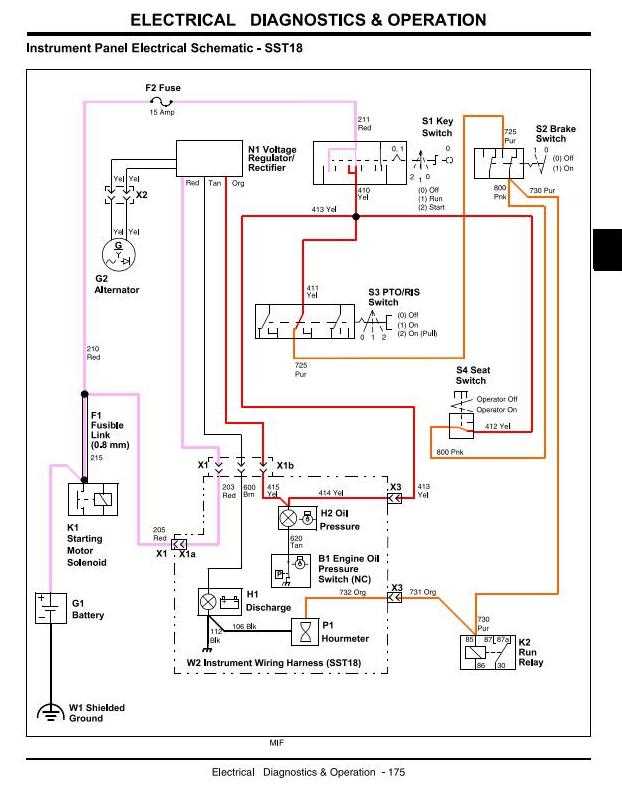

Electrical System: Powering everything from the ignition to the lights, the electrical setup requires periodic checks to prevent malfunctions and maintain consistent performance.

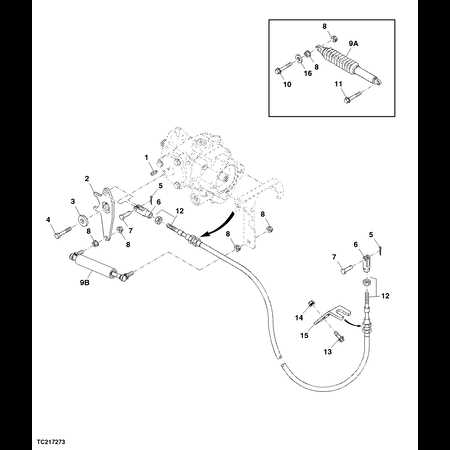

Drive System Breakdown for the SST18

The drive system plays a crucial role in ensuring smooth and efficient movement. Understanding the core components and their interactions is key to maintaining peak performance. This section outlines the main elements involved in the operation, helping you grasp how different parts work together to propel the machine forward.

| Component | Function | ||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Transmission | Transfers power from the engine to the wheels, controlling speed and direction. | ||||||||||||||||||||||

| Drive Belt | Connects the engine to the transmission, facilitating power flow. | ||||||||||||||||||||||

| Hydraulic Pump | Ensures smooth and responsive control of the machine’s movement. | ||||||||||||||||||||||

| Axle Assembly | Steering Mechanism Overview for Maintenance

A functional steering system is crucial for the smooth operation of any vehicle, and regular inspection of its components is essential to ensure reliability. The system is composed of several interconnected elements that work together to control the direction and provide stability. Maintaining these parts is important to prevent unexpected failures and ensure that the steering remains responsive. Key areas to focus on include the control arms, linkages, and bearings. Regular checks and lubrication of these elements help prevent wear and tear. By ensuring these components are properly maintained, the steering will stay precise and easy to operate. Adjustment of alignment is also a vital part of the process. Misalignment can lead to inefficient handling and accelerated wear on other mechanical systems. Keeping the steering aligned will reduce strain on other parts, ensuring smoother performance. Electrical Wiring Layout and ConnectionsUnderstanding the electrical system’s structure is essential for maintaining and troubleshooting any equipment. This section provides an overview of the key wiring connections and components that ensure the proper functioning of the machine’s electrical elements. Main Electrical CircuitsThe primary circuits include various wiring routes responsible for powering different functions. These circuits connect critical parts of the machine, such as the ignition system, lights, and sensors. Ensuring these circuits are properly connected and maintained is crucial for smooth operation.

Key Connection PointsThe electrical layout relies on well-established connection points. These include wiring harnesses, switches, and terminals that link the various components of the system.

Fuel System Configuration in John Deere SST18

The fuel system plays a crucial role in ensuring optimal engine performance, delivering the necessary energy supply for efficient operation. Proper configuration and maintenance of this system contribute to the longevity of the machine and its reliable functionality. This section explores the key components and their functions, providing a comprehensive overview of how the system operates. Main Components of the Fuel System

The primary components involved in the fuel delivery process include the fuel tank, fuel lines, and carburetor. Each of these parts works in unison to maintain a steady flow of fuel to the engine. The fuel tank stores the fuel, while the lines transport it to the carburetor, where it is mixed with air for combustion.

Understanding the Engine Components Layout

Analyzing the configuration of engine elements is crucial for optimal performance and maintenance. Recognizing the arrangement and interaction of various components can enhance both the understanding and functionality of the power unit, leading to improved efficiency and longevity. Key Components OverviewThe main constituents of an engine include the cylinder block, pistons, crankshaft, and valves. Each of these elements plays a significant role in the overall operation. The cylinder block serves as the engine’s core, housing the cylinders where combustion occurs. Pistons move within these cylinders, transforming fuel energy into mechanical energy. The crankshaft then converts this linear motion into rotational motion, powering the machinery. Valves control the flow of air and fuel into the combustion chamber, as well as the exit of exhaust gases. Significance of Proper ArrangementA precise arrangement of these components is vital for efficient operation. Misalignment or improper setup can lead to increased wear and tear, reduced power output, and potential engine failure. Regular maintenance and inspections help ensure that the layout remains optimal, allowing for smooth operation and extending the life of the engine. Cooling System Diagram and Parts OverviewThe cooling mechanism of a machinery unit is crucial for maintaining optimal operating temperatures and preventing overheating. This section provides an in-depth look at the components involved in the cooling process, outlining their functions and interconnections. Core Components: The central elements of the cooling system include the radiator, water pump, thermostat, and hoses. Each part plays a vital role in circulating coolant throughout the engine, absorbing heat, and ensuring efficient performance. Cooling Flow: Coolant travels from the radiator to the engine through hoses, where it absorbs heat. The water pump facilitates this flow, while the thermostat regulates the temperature by controlling the coolant’s path. This harmonious interaction ensures that the engine remains within the desired temperature range. Maintenance Considerations: Regular inspections of the cooling system are essential. Checking for leaks, ensuring hoses are in good condition, and monitoring coolant levels can help prevent significant failures and extend the lifespan of the unit. Transmission System Breakdown and Key ComponentsThe transmission system is a crucial part of any vehicle, responsible for transferring power from the engine to the wheels. Understanding its structure and functionality helps in diagnosing issues and performing maintenance effectively. This section will explore the essential elements that make up the transmission assembly, providing insights into their roles and interconnections. Major Components of the Transmission System

Transmission Fluid and Its ImportanceTransmission fluid plays a vital role in maintaining the system’s efficiency and longevity. It lubricates moving parts, facilitates heat dissipation, and ensures smooth shifting. Regular checks and changes of the transmission fluid are essential for optimal performance. Understanding the breakdown of the transmission system and its key components is essential for effective maintenance and repair. Proper knowledge of these elements contributes to the overall functionality and reliability of the vehicle. |