This section delves into the intricate elements that make up a specific type of lawn maintenance machinery. Understanding these components is essential for effective maintenance and repair, ensuring optimal performance throughout the seasons.

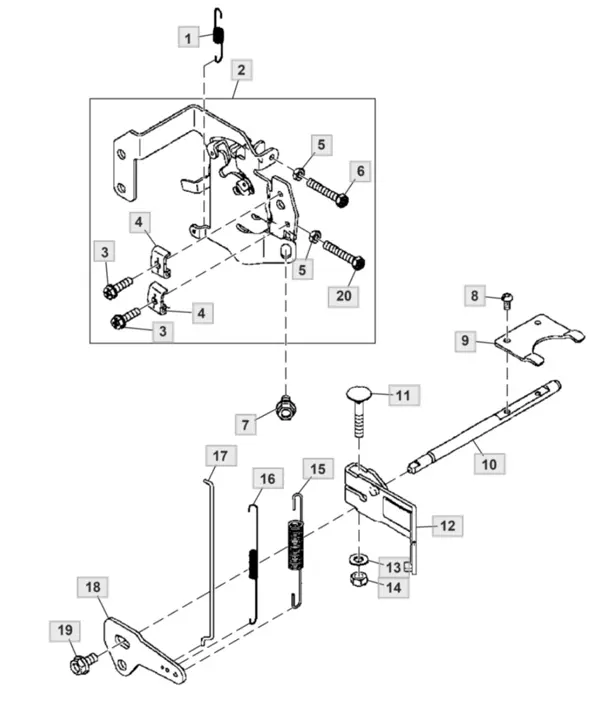

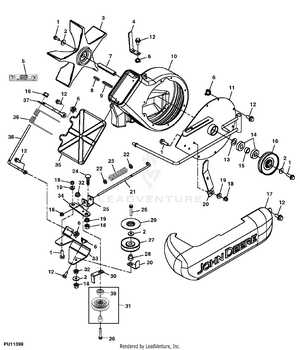

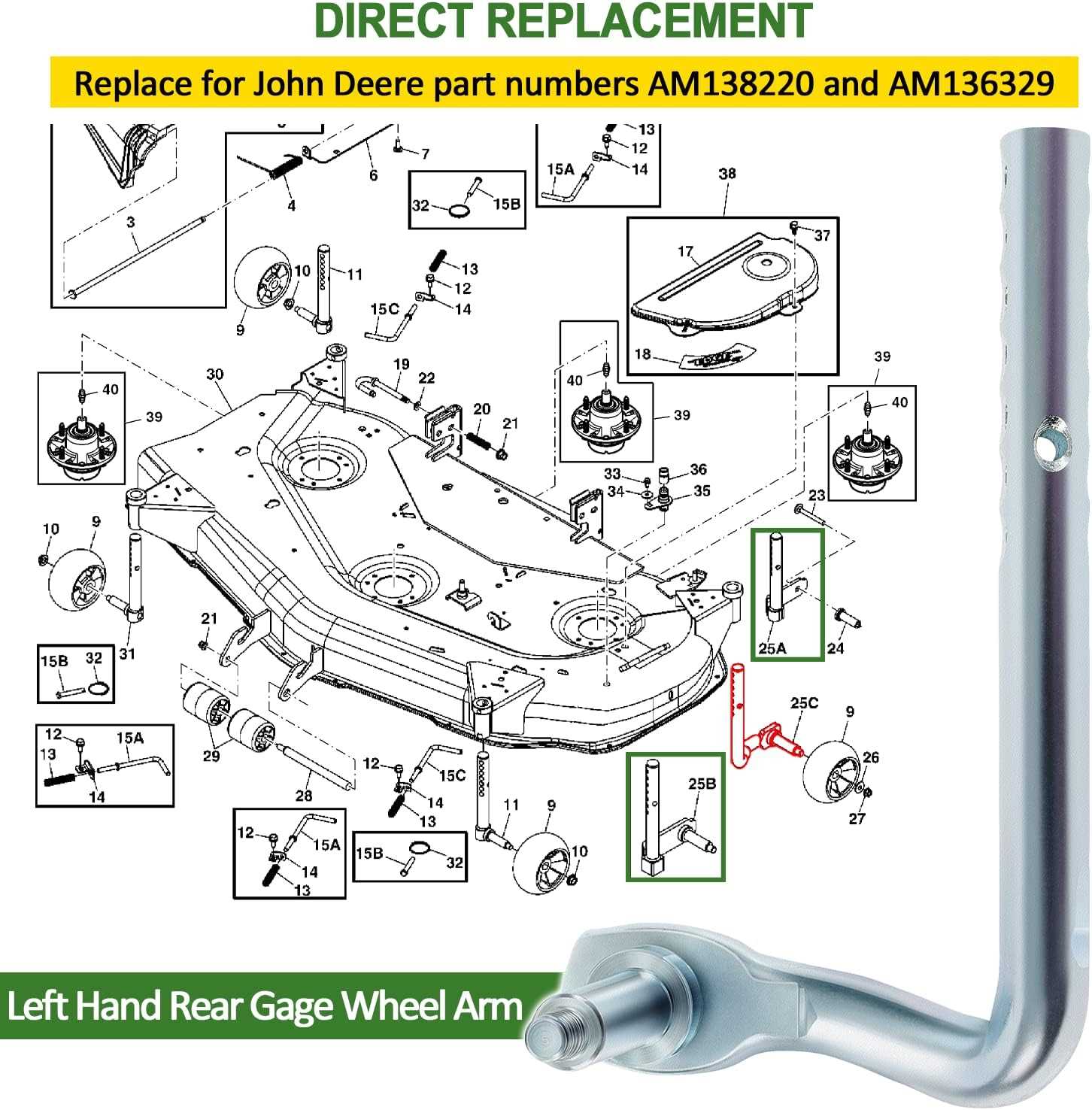

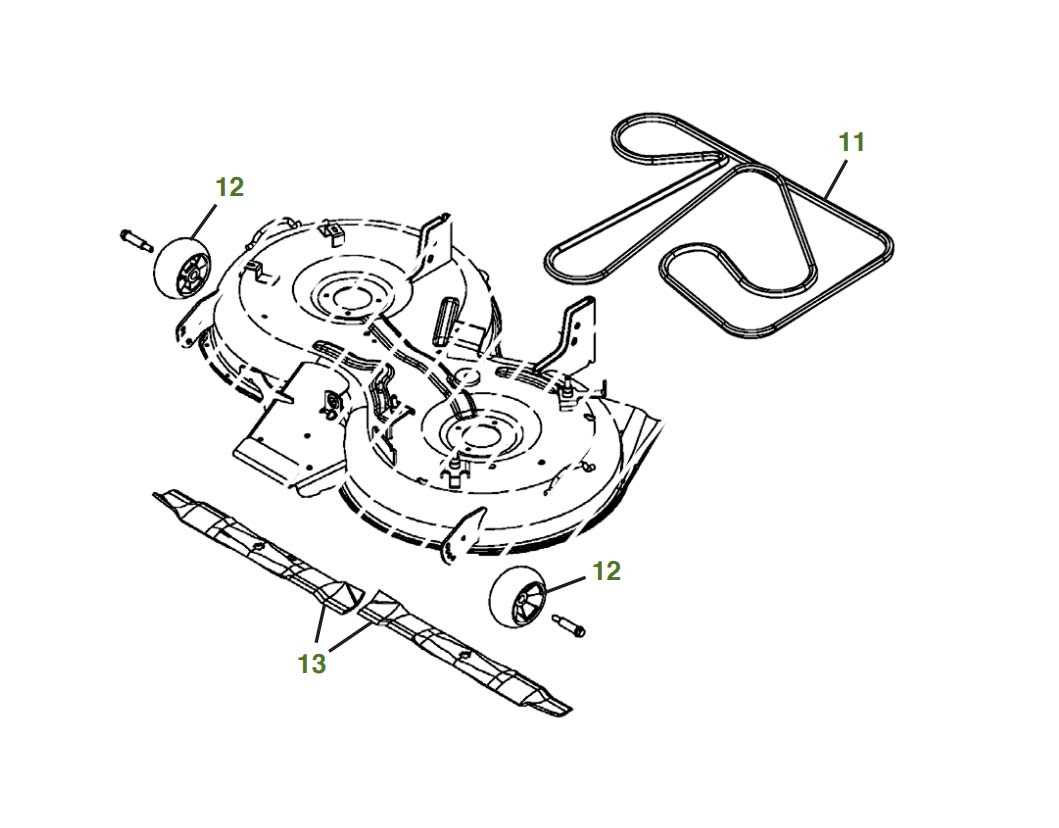

Detailed schematics provide valuable insights into the organization and function of each part. By examining these illustrations, users can identify specific areas that may require attention or replacement, enhancing the longevity and efficiency of their equipment.

Whether you’re a seasoned operator or new to the realm of lawn care machinery, familiarizing yourself with the various elements can greatly improve your troubleshooting skills and overall operational knowledge. Utilizing these resources will empower you to make informed decisions regarding upkeep and enhancements.

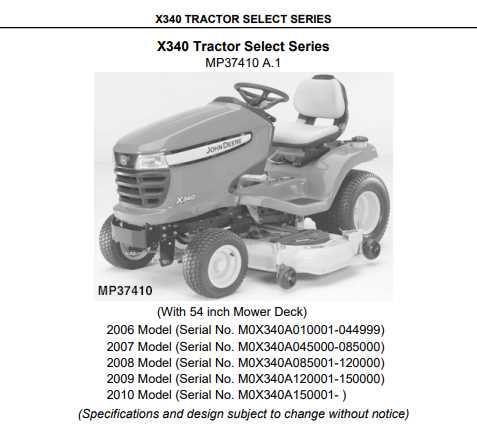

Understanding the X340 Components

This section delves into the essential elements that comprise the machine, providing insights into their functions and interrelations. Familiarity with these components enhances operational efficiency and maintenance awareness, ensuring longevity and performance.

Key Elements of the Machine

Each unit includes various crucial parts, such as the engine assembly, transmission system, and control mechanisms. Understanding how these elements interact allows for improved troubleshooting and optimal performance during use.

Maintenance Considerations

Regular inspection and upkeep of these components are vital for seamless operation. Identifying potential wear and tear early can prevent costly repairs and enhance the overall lifespan of the equipment.

Engine Specifications and Details

This section provides a comprehensive overview of the key characteristics and specifications of the power unit used in the specified model. Understanding these details is crucial for maintenance and optimal performance.

- Type: Air-cooled, four-stroke engine

- Cylinder Configuration: Inline design

- Displacement: Approximately 500cc

- Power Output: Ranges between 18-22 horsepower

- Fuel Type: Regular unleaded gasoline

Regular maintenance of the engine ensures longevity and efficiency. Key components to check include:

- Oil levels and quality

- Air filter cleanliness

- Fuel system integrity

- Cooling system functionality

These specifications contribute to the overall performance and reliability of the equipment, making it suitable for various tasks.

Transmission System Overview

The transmission system is a crucial component in ensuring efficient power transfer from the engine to the wheels. This mechanism plays a vital role in controlling speed and torque, allowing the machine to perform optimally in various conditions.

It typically consists of several key elements, including gears, belts, and pulleys, which work together to adjust the output based on the operator’s requirements. Proper maintenance of this system is essential to prevent wear and ensure longevity, ultimately enhancing overall performance.

Electrical Wiring Schematics Explained

Understanding electrical wiring layouts is essential for troubleshooting and maintenance. These diagrams provide a visual representation of the connections and components within a system, enabling efficient diagnostics and repairs.

| Component | Description |

|---|---|

| Battery | Stores electrical energy for starting and powering the system. |

| Fuse | Protects the circuit by breaking the connection in case of overload. |

| Switch | Controls the flow of electricity by opening or closing the circuit. |

| Relay | Acts as an electrically operated switch to control higher current devices. |

| Ground | Provides a return path for current and enhances safety. |

Deck Assembly and Maintenance Tips

Proper assembly and upkeep of the cutting platform are essential for optimal performance and longevity. Understanding the components and their functions will help ensure smooth operation and reduce wear over time.

Key Components of the Cutting Platform

| Component | Description |

|---|---|

| Blades | Ensure sharpness for effective cutting. |

| Spindle Assembly | Houses the blade and allows for rotation. |

| Deck Shell | Protects internal parts and supports the blades. |

| Anti-Scalp Wheels | Prevent the deck from digging into the ground. |

Maintenance Recommendations

Regularly check and tighten bolts to prevent loosening during operation. Clean the cutting platform after each use to remove grass clippings and debris, which can lead to rust and corrosion. Lubricate moving parts to ensure smooth operation and replace worn blades promptly to maintain cutting efficiency.

Identifying Common Wear Parts

Understanding the components that experience regular wear and tear is essential for maintaining optimal performance of your equipment. Recognizing these elements allows for timely replacements, ensuring efficiency and longevity.

Commonly affected components include:

| Component | Signs of Wear | Recommended Action |

|---|---|---|

| Belt | Cracks, fraying, or slipping | Replace immediately |

| Blades | Dull edges or chips | Sharpen or replace as needed |

| Filters | Clogs or discoloration | Clean or replace regularly |

| Wheels | Uneven wear or cracks | Inspect and replace if necessary |

| Battery | Reduced capacity or corrosion | Test and replace when performance drops |

Fuel System Components Breakdown

This section explores the essential elements of a fuel delivery system, focusing on their functions and interconnections. Understanding these components is crucial for maintaining optimal performance and ensuring the longevity of the machinery.

Key Elements of the Fuel System

The fuel system consists of various parts, including the tank, pump, filter, and injectors. Each element plays a vital role in storing, transferring, and filtering fuel, ensuring that the engine receives the right amount for efficient combustion.

Maintenance Considerations

Safety Features and Mechanisms

When operating a lawn maintenance machine, ensuring user protection is paramount. Various safety features are integrated to minimize risks and enhance operational security. These mechanisms not only safeguard the operator but also contribute to the overall reliability of the equipment.

Emergency Stop System: A crucial element designed to halt the machine’s operation instantly in case of an emergency. This feature ensures that the user can quickly react to unexpected situations, preventing potential injuries.

Safety Interlock: This mechanism prevents the machine from starting unless specific conditions are met, such as the operator being in the correct position. It serves as an essential safety net that reduces the likelihood of accidents caused by improper use.

Protective Guards: Various components are equipped with shields to protect the user from moving parts and debris. These guards are strategically placed to ensure maximum safety without hindering the machine’s performance.

Reflective Markings: Incorporating bright colors and reflective materials enhances visibility, especially in low-light conditions. This feature is vital for ensuring that the operator is seen by others, promoting safer use in shared spaces.

Ordering Replacement Parts Guide

When it comes to maintaining your equipment, acquiring the necessary components is crucial for optimal performance. This section provides guidance on effectively sourcing replacements to ensure longevity and reliability.

Follow these steps to simplify your ordering process:

- Identify the Component: Clearly determine which item needs replacement.

- Check Compatibility: Ensure the selected part is suitable for your specific model.

- Source Trusted Suppliers: Utilize reputable vendors known for quality products.

- Review Specifications: Cross-reference specifications to confirm the correct fit.

- Place Your Order: Follow the supplier’s ordering process, providing necessary details.

Additionally, consider the following tips:

- Keep a record of previous orders for easy reference.

- Ask for assistance from customer service if needed.

- Take note of any warranties that may apply to your purchases.

By adhering to these guidelines, you can streamline the acquisition of necessary components and maintain the efficiency of your equipment.

Troubleshooting Mechanical Issues

Identifying and resolving mechanical problems can enhance the performance and longevity of your equipment. By understanding common symptoms and their potential causes, you can take effective steps to address these challenges.

Here are some common mechanical issues and troubleshooting tips:

- Engine Not Starting

- Check the fuel level and ensure it is sufficient.

- Inspect the battery for charge and connections.

- Examine the ignition system for faults.

- Uneven Cutting

- Verify that the blades are sharp and properly adjusted.

- Inspect the deck for any obstructions or damage.

- Check the tire pressure for consistency.

- Strange Noises

- Listen for unusual sounds while operating and identify their source.

- Examine belts and pulleys for wear or misalignment.

- Check for loose components that may be causing vibration.

By systematically assessing these areas, you can effectively diagnose and resolve mechanical issues, ensuring your equipment runs smoothly.

Maintenance Schedule for Optimal Performance

Regular upkeep is essential for ensuring the longevity and efficiency of your machinery. Adhering to a structured timetable for maintenance tasks can prevent unexpected breakdowns and enhance overall functionality. Below is a comprehensive schedule designed to help you maintain peak performance throughout the operational year.

Routine Maintenance Tasks

| Task | Frequency | Details |

|---|---|---|

| Oil Change | Every 50 hours | Replace with high-quality oil to ensure smooth operation. |

| Filter Replacement | Every 100 hours | Change air and fuel filters to maintain efficiency. |

| Blade Sharpening | Every 25 hours | Keep blades sharp for effective cutting. |

| Belt Inspection | Every 50 hours | Check for wear and replace as necessary. |

Seasonal Maintenance Checks

In addition to routine tasks, it’s important to conduct seasonal checks to prepare for changing conditions. This includes inspecting the entire system and addressing any potential issues before they escalate.