Utility vehicles serve as versatile machines, adept at handling a variety of tasks across different terrains. These robust vehicles are designed for both recreational and agricultural purposes, providing functionality that can be tailored to meet specific needs. Knowing the intricate layout of these vehicles is essential for effective maintenance and repair.

In this section, we will explore the various elements that comprise these utility machines. By gaining a comprehensive understanding of their structure and assembly, users can enhance their operational efficiency and ensure longevity. Each component plays a vital role, and recognizing their placement and interrelationships is crucial for troubleshooting and upgrades.

Whether you’re a seasoned user or new to utility vehicles, familiarizing yourself with the organization of these components will empower you to make informed decisions. This knowledge not only aids in regular maintenance but also supports the vehicle’s performance in diverse working environments.

To ensure the longevity and efficiency of your utility vehicle, regular upkeep is essential. Adhering to systematic maintenance practices will enhance functionality, prevent unexpected failures, and ensure a smooth operation. This section outlines fundamental strategies to keep your vehicle in top condition.

Regular Inspection and Cleaning

- Conduct routine checks for wear and tear on critical components.

- Clean the exterior and interior to prevent debris buildup that can affect performance.

- Inspect fluid levels and replace any that appear contaminated or low.

Scheduled Service Intervals

- Follow the manufacturer’s recommended service schedule for optimal results.

- Replace filters and fluids at prescribed intervals to maintain peak efficiency.

- Address any signs of malfunction immediately to prevent further damage.

Common Repairs and Replacements

In any utility vehicle, certain components may require attention over time due to wear and tear. Understanding the typical repairs and replacements can help maintain optimal performance and extend the lifespan of the vehicle. This section outlines the most frequent issues that users encounter and offers insight into resolving them effectively.

Battery and Electrical Systems

One of the most common areas needing service involves the electrical systems, particularly the battery. Regular checks are essential to ensure the battery remains charged and functions properly. Signs of a failing battery include difficulty starting the engine or dimming lights. Replacement is straightforward and can restore the vehicle’s reliability.

Brakes and Suspension

Another critical aspect to monitor is the braking and suspension systems. Worn brake pads can compromise safety and should be replaced as soon as they show signs of wear. Similarly, inspecting the suspension components for damage or wear ensures a smooth ride and better handling. Timely maintenance in these areas contributes to overall vehicle performance.

How to Access the Parts Diagram

Accessing the schematic for vehicle components is essential for efficient maintenance and repair. Understanding how to navigate to these resources can greatly enhance your ability to locate specific elements within the assembly.

Online Resources

Many manufacturers offer online platforms that host comprehensive schematics. Here’s how to find them:

- Visit the official website of the manufacturer.

- Navigate to the support or resources section.

- Look for downloadable files or interactive tools related to the vehicle model.

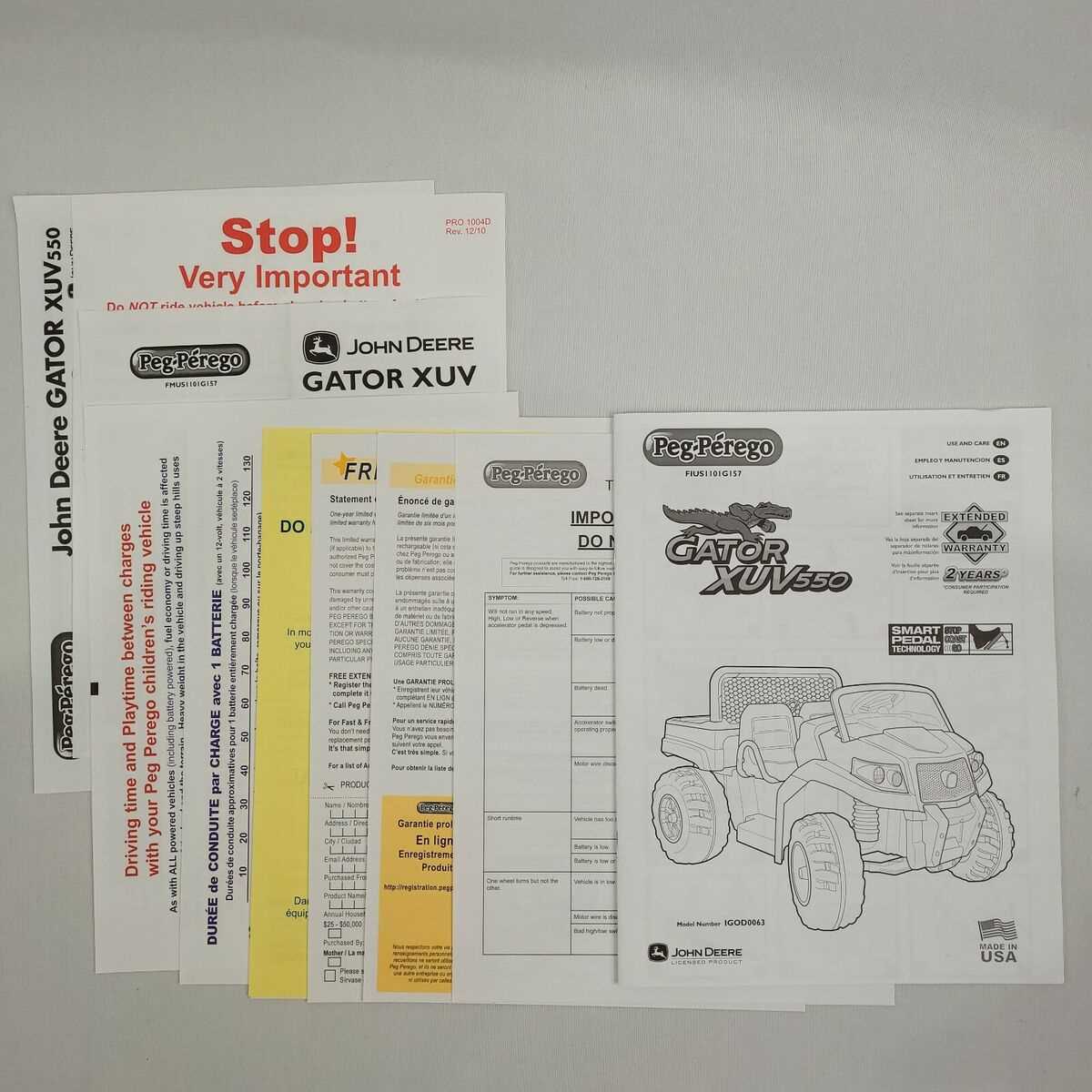

Owner’s Manual

Your vehicle’s owner manual often includes valuable information about its components. To utilize this resource:

- Locate the manual that came with your vehicle.

- Refer to the index or table of contents for schematic references.

- Follow the instructions to understand the layout and functionality of each component.

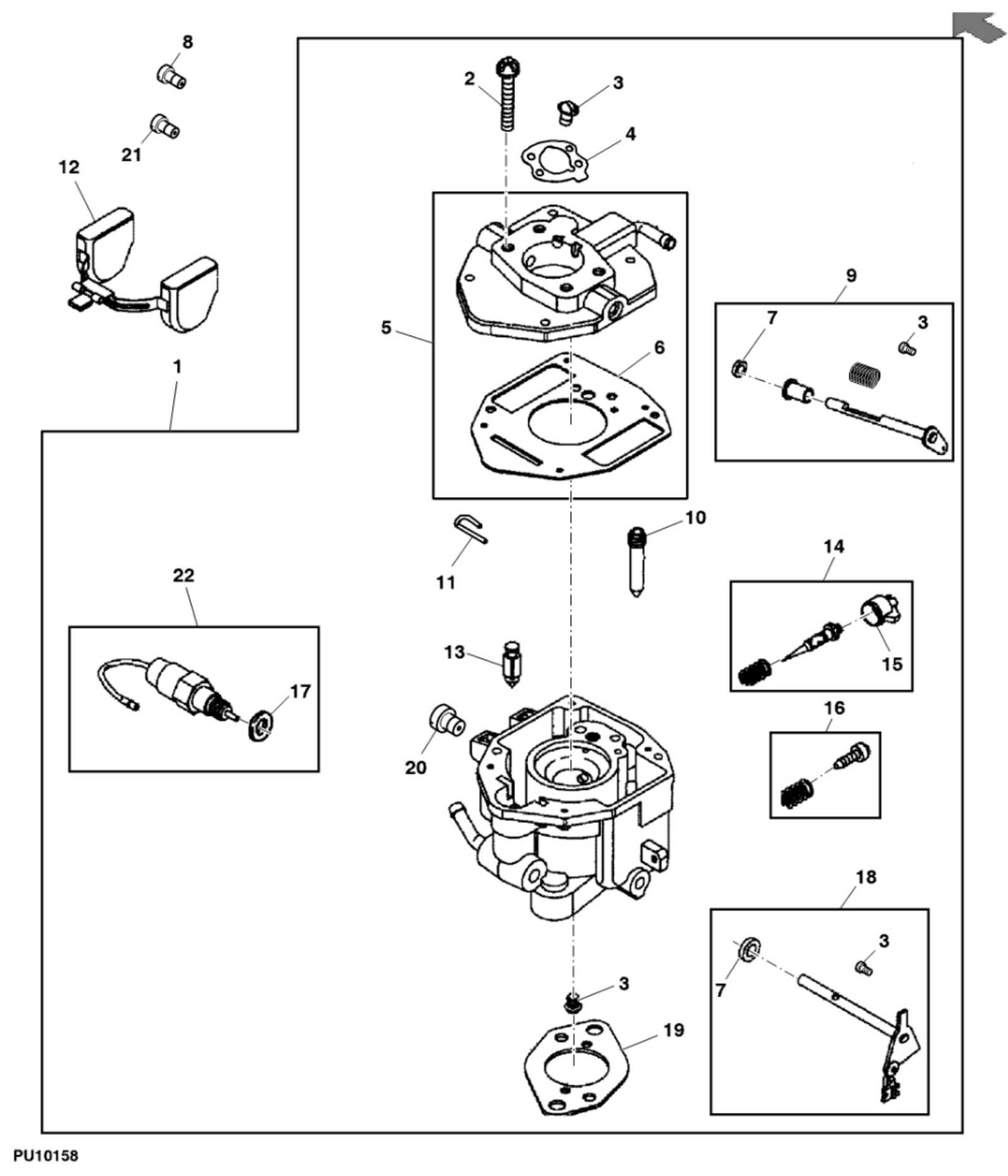

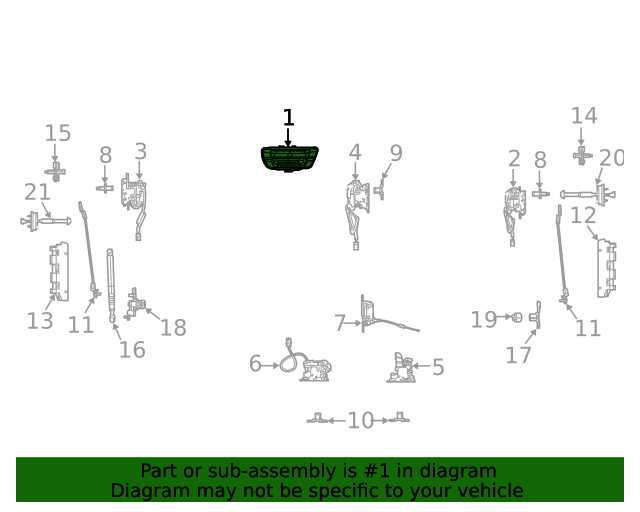

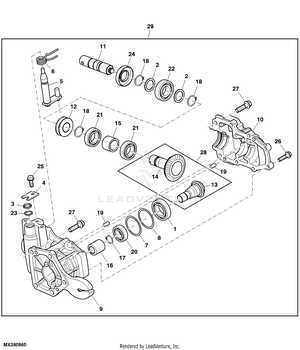

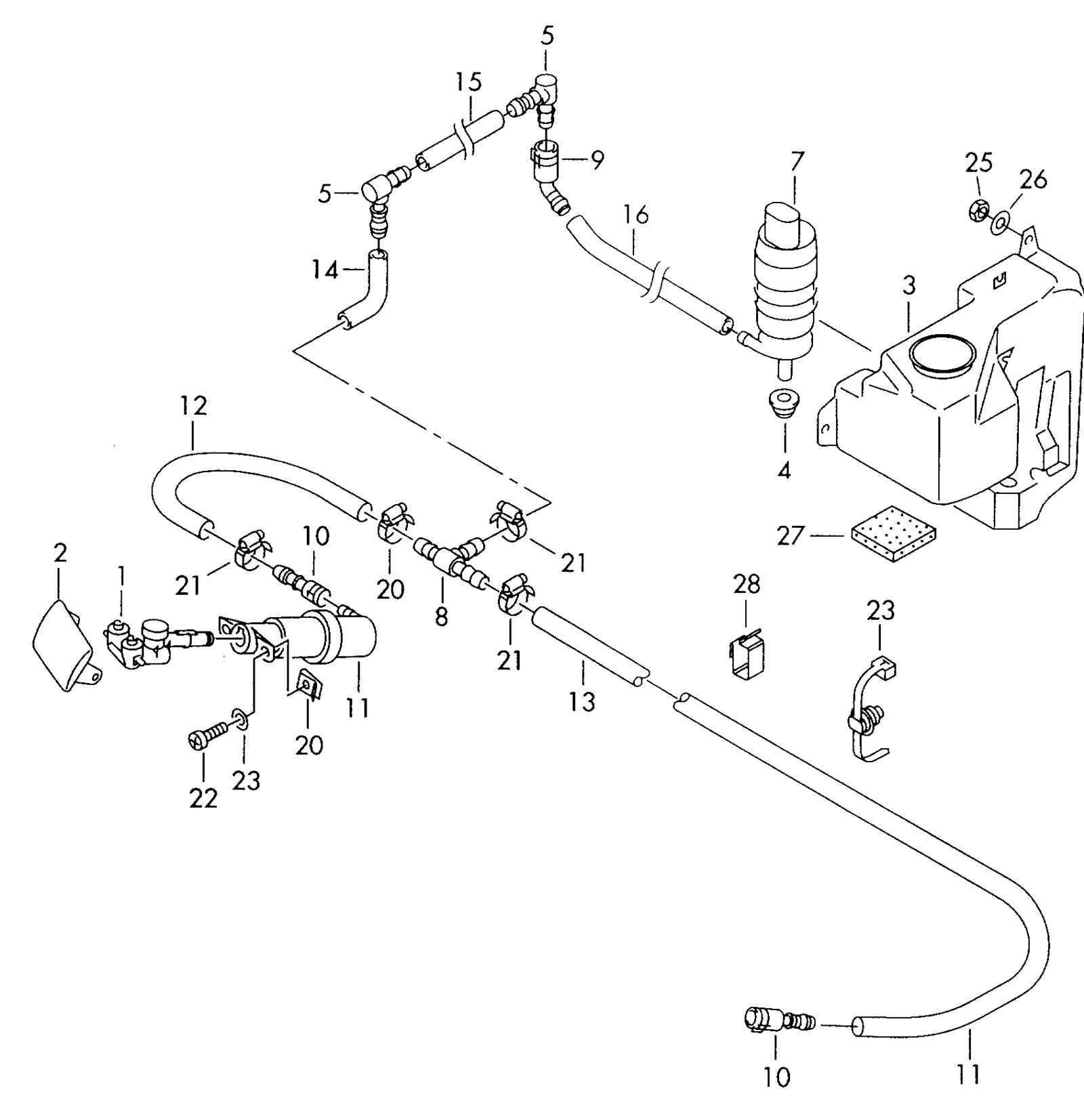

Identifying Components by Number

Understanding the specific elements of a vehicle is crucial for effective maintenance and repair. Each component is assigned a unique identifier, allowing users to easily locate and reference them. This systematic approach simplifies the process of sourcing replacements or performing upgrades, ensuring that the right pieces are used for optimal performance.

Importance of Accurate Identification

Precise identification of each element is vital to avoid errors during repairs. Using the correct identifier can save time and reduce costs by eliminating the need for trial and error. Additionally, it helps in maintaining the overall functionality of the vehicle, enhancing its longevity and reliability.

Utilizing Resources for Identification

Various resources, such as manuals and online databases, are available to assist in the identification process. These tools provide comprehensive lists and illustrations, making it easier for users to find the exact components they need. Familiarizing oneself with these resources can significantly enhance the efficiency of maintenance tasks.

Upgrades for Enhanced Functionality

To maximize the performance and versatility of your utility vehicle, consider a variety of enhancements that can elevate its capabilities. These improvements not only increase efficiency but also contribute to a more enjoyable driving experience.

Suspension System: Upgrading the suspension can provide better handling and comfort on rough terrains. Enhanced shock absorbers and springs can significantly improve ride quality and stability, allowing for smoother navigation over uneven surfaces.

Storage Solutions: Adding storage accessories, such as cargo boxes or racks, can greatly increase the utility of your vehicle. This allows for better organization and easy transport of tools, equipment, or recreational gear, making every outing more efficient.

Lighting Enhancements: Improved lighting options, including LED lights and spotlights, enhance visibility during nighttime or low-light conditions. This not only ensures safer operation but also expands the functionality for work or recreational activities after dark.

Performance Tuners: Consider integrating performance tuners to optimize engine output. These devices can help achieve better fuel efficiency and increased power, making your vehicle more responsive and effective for various tasks.

By investing in these enhancements, you can transform your vehicle into a more powerful and adaptable tool, ready to tackle any challenge with ease.

Comparing OEM and Aftermarket Parts

When maintaining or upgrading equipment, the choice between original manufacturer components and alternative options is critical. Each category offers unique advantages and disadvantages, influencing overall performance, reliability, and cost-effectiveness. Understanding these differences is essential for making informed decisions that align with specific needs and budget constraints.

Original manufacturer components, often referred to as OEM, are designed and produced by the equipment’s manufacturer. These components typically provide:

- Guaranteed compatibility with the equipment.

- Quality assurance and reliability based on strict manufacturing standards.

- Extended warranty options, offering peace of mind for users.

On the other hand, alternative components may offer a more cost-effective solution. They come with their own set of benefits, including:

- Lower initial investment, making repairs or upgrades more affordable.

- A wider selection, providing options that may not be available through the manufacturer.

- Potential for improved performance through innovative designs.

Ultimately, the decision between OEM and alternative components should consider factors such as budget, the specific application of the equipment, and personal preferences for quality and performance. Each option has its merits, and understanding these can lead to better maintenance choices and enhanced operational efficiency.

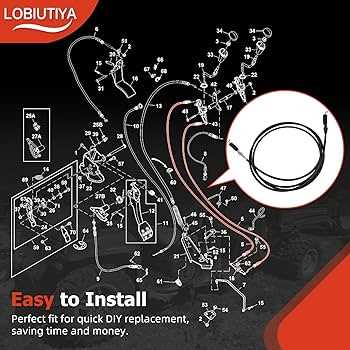

Tips for Efficient Installation

Proper setup of components is crucial for optimal performance and longevity of your vehicle. This section provides essential strategies to enhance the installation process, ensuring each element functions seamlessly within the system.

Preparation and Organization

Before beginning the installation, it’s vital to gather all necessary tools and components. Create a checklist to ensure nothing is overlooked, and organize the workspace to facilitate easy access to each item. Consider the following table for essential tools:

| Tool | Purpose |

|---|---|

| Wrench Set | For securing bolts and nuts |

| Screwdriver Set | For fastening screws |

| Pliers | For gripping and bending components |

| Torque Wrench | For applying precise torque to fasteners |

Step-by-Step Approach

Adopting a methodical, step-by-step approach can greatly improve efficiency. Follow the manufacturer’s guidelines meticulously, as these instructions are tailored for optimal assembly. Additionally, enlist a helper if possible, as an extra set of hands can simplify the process, especially when aligning parts accurately.

Resources for Parts and Support

When seeking components and assistance for your utility vehicle, it’s essential to access reliable resources. This section outlines various avenues to help you locate necessary items and support services effectively.

Utilizing a combination of online platforms, local dealers, and community forums can enhance your search for the right solutions. Consider the following options:

- Official Websites: Manufacturer websites often provide extensive catalogs and support documentation, making it easier to find specific components.

- Authorized Dealers: Local dealerships can be invaluable sources for genuine components and expert advice tailored to your vehicle.

- Online Marketplaces: Various e-commerce platforms allow users to compare prices and find both new and refurbished items.

- Community Forums: Engaging with fellow enthusiasts in online communities can yield tips and recommendations for sourcing components.

- Repair Manuals: Comprehensive guides and manuals may offer insights into installation and maintenance procedures.

By leveraging these resources, you can ensure that your utility vehicle remains in optimal condition, receiving the appropriate support and components as needed.