In this section, we will explore the essential elements that make up a powerful and efficient lawn care machine. Understanding the structure and layout of these elements is crucial for maintaining the longevity and performance of your equipment. By gaining insight into how each component interacts within the system, you can ensure smoother operation and faster troubleshooting.

We will provide a detailed breakdown of various mechanical features, highlighting their functions and placements within the framework. This knowledge can be especially helpful when performing routine maintenance or when specific adjustments are necessary to improve overall functionality.

Having a clear view of these integral components allows users to manage and repair their equipment with greater confidence. By identifying the primary mechanisms at work, you will be able to make informed decisions when it comes to replacements or enhancements.

Understanding Key Components of the Z355E

The machine in question incorporates various essential elements that work together to ensure efficient operation. Recognizing these components and their roles is crucial for maintaining peak performance and ensuring a long service life. In this section, we’ll explore the primary features and their functionalities, providing a clearer understanding of how each part contributes to the overall system.

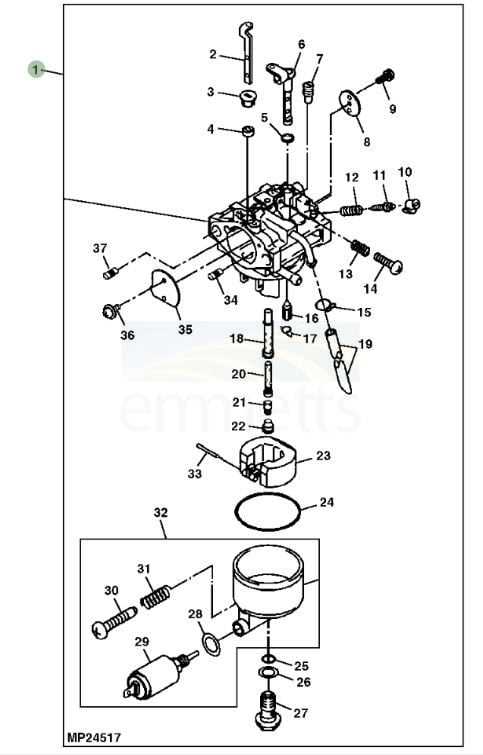

Engine and Transmission Systems

The core of the equipment’s power lies in its engine, which drives the system forward and manages the various tasks. Alongside it, the transmission is responsible for delivering smooth movement and handling. Proper upkeep of these elements is vital for maintaining optimal function, ensuring consistent performance under various conditions.

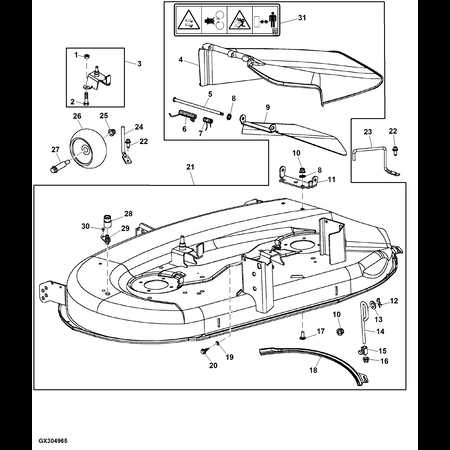

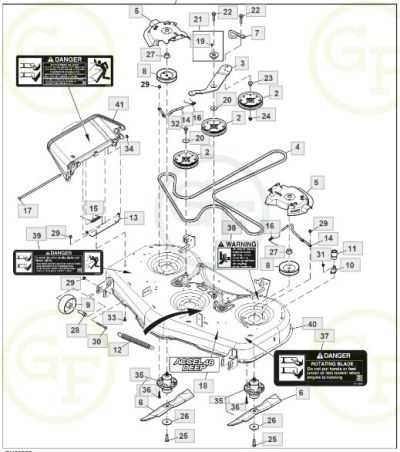

Cutting and Deck Systems

The cutting mechanism and deck are fundamental in achieving precise results. The deck provides stability while the cutting blades ensure even trimming. Both of these systems require regular inspection and maintenance to prevent wear and tear, maximizing operational efficiency.

| Component | Function | ||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Engine | Provides the necessary power for operation

Exploring the Engine Assembly LayoutThe engine assembly is a crucial component in the operation of any machine, consisting of various interconnected parts that work together to ensure efficient functionality. Understanding how these elements are arranged can help with maintenance, repairs, and overall performance optimization. When examining the structure, it’s important to recognize the key components and their roles within the system. Below is a breakdown of some of the critical elements involved:

Each of these elements must function in harmony to deliver the best performance. Regular inspection and proper alignment of these components can prevent mechanical issues and extend the lifespan of the system. Blade System and Cutting Deck Overview

The cutting system of this model features a robust design, ensuring efficient grass trimming and smooth operation across various lawn conditions. The setup integrates multiple components that work together to achieve an even and precise cut. One of the essential elements is the assembly responsible for holding the rotating edges. This part plays a significant role in the overall performance, affecting both the quality of the trim and the machine’s durability over time. Understanding how each element functions can help maintain and optimize the equipment for long-term use.

Maintaining a well-functioning steering system not only enhances control but also prolongs the lifespan of the overall machinery. Regular inspections should be part of standard maintenance practices. Understanding the Electrical System Setup

The electrical configuration of outdoor power equipment is crucial for ensuring efficient operation and reliability. This section will delve into the essential components and their interconnections, highlighting how each part contributes to the overall functionality of the machinery. Key Components of the Electrical Configuration

Common Issues and Maintenance Tips

Wheel and Tire Configuration Details

The arrangement and specifications of wheels and tires play a crucial role in the overall performance and efficiency of any outdoor equipment. Understanding these components can enhance functionality and ensure optimal operation. This section delves into the essential aspects of wheel and tire setups, focusing on their specifications, compatibility, and maintenance requirements. Specifications and Dimensions

Proper specifications are vital for achieving the desired performance. Below are key factors to consider:

Maintenance and CareRegular maintenance is essential to prolong the lifespan of wheels and tires. Consider the following practices:

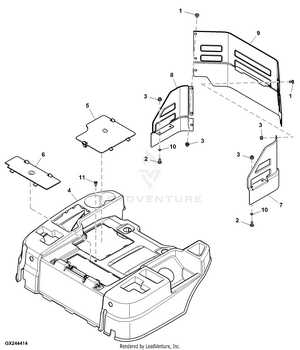

Seat and Control Panel Structure

The design of seating and control mechanisms is crucial for ensuring operator comfort and efficiency during use. This section delves into the configuration and functionality of these essential components, emphasizing their roles in enhancing the overall user experience. The seating arrangement is engineered to provide maximum support and adjustability, allowing users to customize their position for optimal ergonomics. Meanwhile, the control panel is intuitively laid out to facilitate easy access to various functions and settings, promoting seamless operation.

Safety Mechanisms and Related PartsEffective safety features are essential for ensuring operator protection and machinery reliability. These systems are designed to prevent accidents and mitigate risks during operation, enhancing overall user confidence. Understanding the components associated with these safety mechanisms can help maintain functionality and performance.

Accessories and Optional Attachments OverviewThis section provides an insight into various enhancements and optional components that can be integrated with your equipment. These additions can significantly improve functionality and versatility, catering to a wide range of tasks and preferences. Types of Accessories

Numerous enhancements are available to enhance the overall performance. Accessories such as towing kits and attachment mounts allow for seamless integration of additional tools, enabling users to tackle various jobs with ease. Furthermore, mulching kits and bagging systems provide options for maintaining lawns and gardens efficiently. Benefits of Optional AttachmentsIncorporating optional attachments not only expands the operational capabilities but also increases productivity. These tools can be tailored to specific needs, ensuring that the equipment performs optimally for diverse applications. Ultimately, investing in these enhancements leads to improved efficiency and satisfaction in outdoor tasks. |