In any machinery, understanding the core elements that enable its efficient operation is crucial for both maintenance and longevity. A detailed examination of the primary components provides valuable insights into how various mechanisms interact, ensuring optimal performance and minimizing downtime.

Having access to an in-depth look at the structural elements helps users navigate repairs, replacements, and upgrades with ease. With a clear understanding of the interconnections between different modules, troubleshooting common issues becomes more straightforward and cost-effective.

Whether you’re performing routine

Overview of Key Components

The machine is built with several essential elements that work together to ensure its functionality and efficiency. Each component has a specific role, contributing to the overall performance and durability. Understanding these main features can help users maintain and troubleshoot the equipment effectively.

- Engine: The powerhouse of the machine, providing the necessary force to drive various operations.

- Transmission: This mechanism is responsible for transferring power from the engine to the wheels, allowing smooth and controlled movement.

- Cutting Deck: Positioned underneath, this component is crucial for precision cutting and achieving the desired finish on the surface.

- Steering System: Enables the user to guide and maneuver the machine with ease, ensuring accurate direction control.

- Fuel filters

- Air filters

- Pre-filters

- Separator elements

- Fuel Filters: Designed to remove impurities and particles from the fuel before it reaches the engine.

- Air Filters: Prevent dust, dirt, and other airborne particles from entering the intake system, ensuring clean air supply for combustion.

- Pre-Filters: Serve as an initial line of defense, capturing larger contaminants before they reach the main filters.

- Separator Elements: Help in separating fuel from water or other contaminants, which is crucial for maintaining fuel quality.

Engine and Power System Layout

The engine and power system layout is designed to optimize performance and efficiency, ensuring smooth operation and consistent power delivery. By strategically positioning the key components, the machine provides reliable output while minimizing energy loss. This setup supports prolonged use with minimal downtime, enhancing overall functionality.

| Component | Description |

|---|---|

| Engine | A high-capacity engine provides the necessary torque and horsepower, allowing for efficient operation in various conditions. |

| Transmission | The transmission ensures smooth power distribution, offering responsive control and stability during operation. |

| Cooling System | A robust cooling system maintains optimal temperatures, preventing overheating and ensuring sustained performance. |

| Feature | Description |

|---|---|

| Ergonomic Design | Provides support to reduce fatigue during extended use. |

| Adjustable Settings | Allows customization of seat position for optimal comfort. |

| Control Accessibility | Ensures controls are easy to reach and operate, enhancing user experience. |

| Visibility | Offers clear sightlines for better maneuvering and safety. |

Fuel and Air Filtration Components

Effective operation of any engine relies heavily on the efficiency of its fuel and air filtration systems. These components are vital for ensuring that the engine receives clean fuel and air, which are essential for optimal performance and longevity. The filtration mechanisms help prevent contaminants from entering the engine, thereby reducing wear and potential damage.

Key components involved in fuel and air filtration include:

Each component plays a specific role in maintaining the purity of the fluids that enter the engine:

Regular maintenance and replacement of these components are essential to ensure efficient engine performance and prevent potential issues arising from contamination.

Hydraulic System Configuration

The hydraulic system plays a crucial role in the functionality of machinery, facilitating efficient power transmission and enabling various operational tasks. Understanding the configuration of this system is essential for optimal performance and maintenance.

This configuration typically includes several components that work together to ensure the system operates smoothly. Key elements include the hydraulic pump, valves, hoses, and actuators, each serving a specific purpose within the overall system. Proper integration of these components is vital for achieving desired outcomes, such as enhanced maneuverability and precise control.

| Component | Description |

|---|---|

| Hydraulic Pump | Generates hydraulic pressure to drive the system. |

| Control Valves | Regulate the flow of hydraulic fluid to different parts. |

| Hoses and Fittings | Transport hydraulic fluid between components. |

| Actuators | Convert hydraulic energy into mechanical motion. |

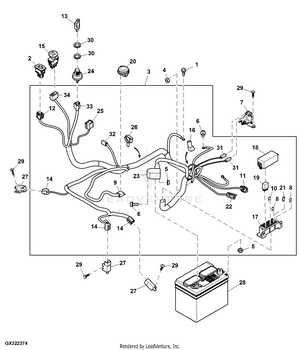

Electrical System and Wiring Setup

The electrical framework in lawn care machinery plays a crucial role in ensuring efficient operation and reliability. Understanding the layout and connections within this system is essential for proper maintenance and troubleshooting. This section will provide insights into the various components involved, their functions, and how they are interconnected to create a seamless electrical setup.

Components of the Electrical System

The electrical system typically consists of several key elements, including the battery, wiring harness, switches, and connectors. Each component serves a specific purpose, such as powering the engine, activating lights, or controlling other essential features. Regular inspection of these parts is important to prevent potential failures and ensure optimal performance.

Wiring Connections and Setup

Proper wiring configuration is vital for the functionality of the equipment. Clear diagrams can assist in understanding the routing of wires and the connection points between components. Ensuring that all connections are secure and free from corrosion will help maintain the integrity of the electrical system, preventing issues that may arise from faulty connections.

Safety and Protection Parts Breakdown

This section provides an overview of essential components designed to enhance safety and ensure the protection of the operator and the machinery during operation. Understanding these elements is crucial for maintaining a secure environment while using the equipment.

Key Safety Features

The equipment incorporates various features aimed at minimizing risks. Emergency shut-off switches allow for quick halting of operations in case of an emergency, while protective guards shield users from moving parts, reducing the likelihood of accidents.

Maintenance and Inspection

Regular maintenance and inspection of safety components are vital for optimal performance. Checking the integrity of safety barriers and ensuring that warning labels are visible can greatly enhance user safety and extend the lifespan of the equipment.

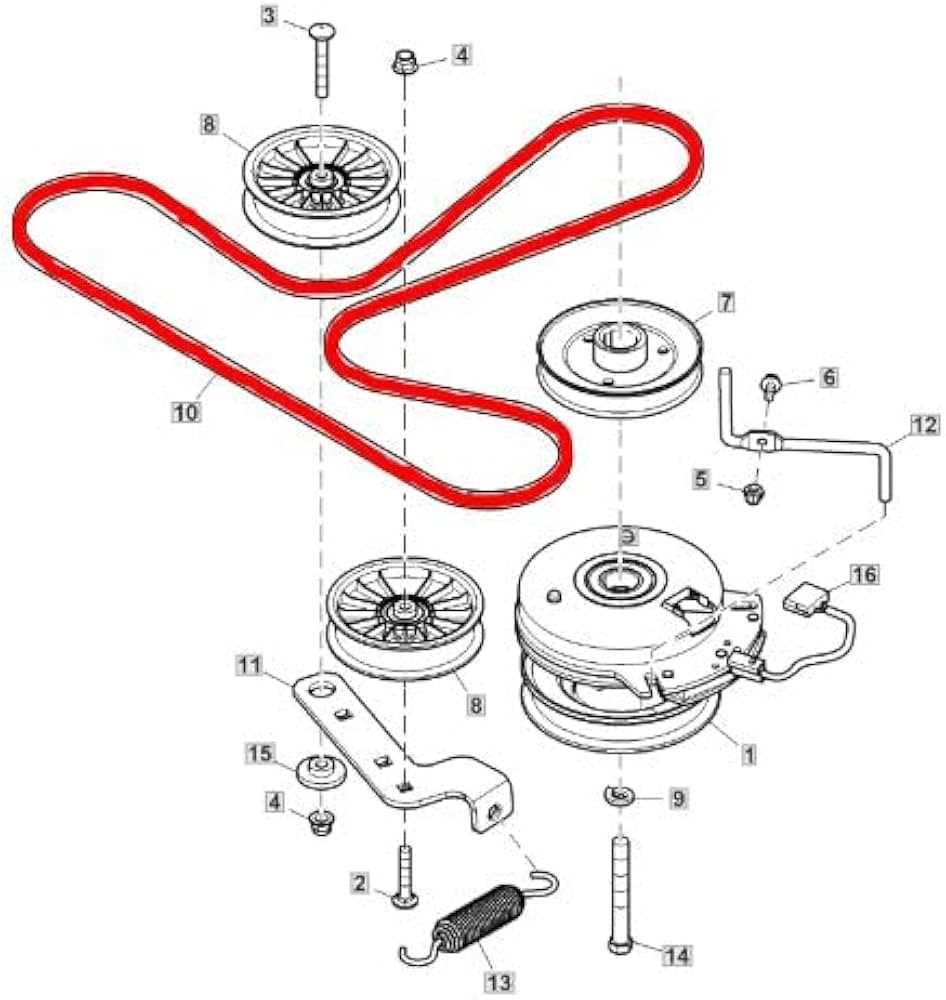

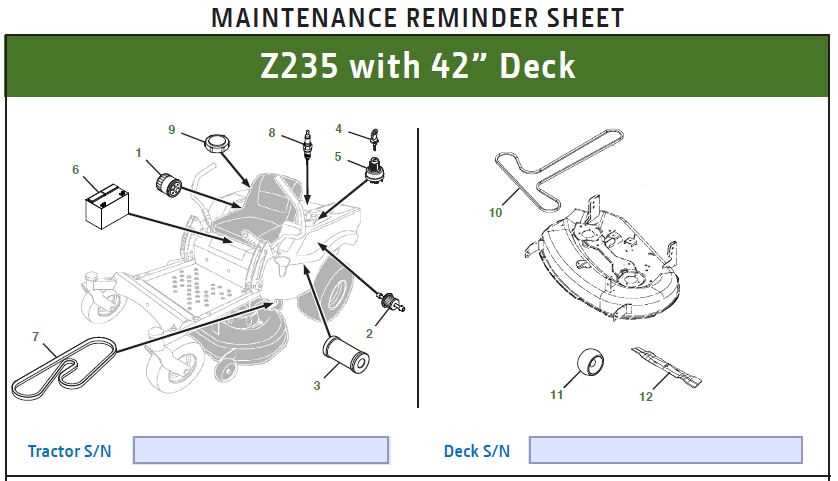

Maintenance Points and Service Parts

Regular upkeep is essential for ensuring optimal performance and longevity of equipment. Understanding the critical areas that require attention, along with the appropriate components needed for servicing, can significantly enhance the functionality and reliability of your machine. This section will outline key maintenance tasks and essential items to consider for effective care.

Essential Maintenance Tasks

Routine inspections and maintenance procedures should be prioritized to prevent potential issues. This includes checking fluid levels, inspecting belts and blades for wear, and ensuring all moving parts are lubricated properly. Additionally, it is vital to clean air filters regularly and monitor tire pressure to maintain operational efficiency.

Necessary Components for Servicing

Having the right components on hand can facilitate smooth maintenance sessions. Essential items may include replacement filters, spark plugs, and blades, which should be regularly updated based on usage. Keeping an inventory of these key elements allows for quick repairs and minimizes downtime during maintenance activities.

Accessories and Optional Attachments Layout

This section provides an overview of the various enhancements and supplementary implements that can be integrated with your equipment. These accessories are designed to improve functionality and versatility, allowing for a tailored experience based on specific needs and preferences.

Types of Accessories

Among the available enhancements, you will find attachments that facilitate different tasks, such as mowing, snow removal, or towing. Each accessory serves a unique purpose, contributing to the overall performance and efficiency of the machinery. Users can select from a range of implements that align with their operational requirements.

Installation Considerations

When adding optional attachments, it is crucial to consider compatibility and installation procedures. Proper alignment and secure fittings are essential to ensure safe and effective operation. It is recommended to consult the user manual or professional guidance for optimal setup and usage.