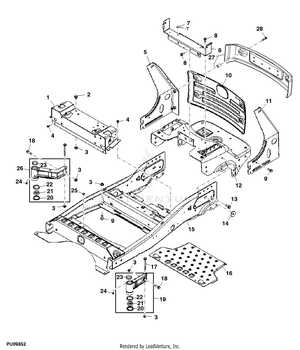

Maintaining a smooth and efficient operation of your lawn care equipment relies heavily on understanding its core elements. Knowing how the various mechanisms work together can significantly improve performance and prolong the lifespan of your machine. In this guide, we will explore the essential elements that make up a high-performance zero-turn mower, offering insights into the functionality and proper upkeep of these crucial components.

Each piece of the equipment plays a vital role in ensuring optimal cutting precision and maneuverability. From the engine that drives the machine forward to the blades that provide clean and efficient cutting, all components must function in harmony. We’ll delve into the structure of the mower’s system, providing a detailed look at how these elements contribute to both everyday usage and long-term durability.

By understanding the detailed layout of this machine’s inner workings, you can enhance your ability to troubleshoot issues, perform maintenance, and ensure peak efficiency. Whether you’re looking to improve your knowledge or simply seeking guidance for repairs, this overview will serve as a valuable resource in keeping your mower in top condition.

Component Overview for Z710A Mower

The mower is built with a variety of essential components that work together to ensure optimal performance and efficiency. Each element plays a specific role in maintaining smooth operation, durability, and ease of use, making it a reliable machine for landscaping tasks.

- Engine: A powerful engine is the core, delivering the necessary energy for the entire system. Its reliability and strength ensure high performance during extended use.

- Transmission: This part handles the power transfer from the motor to the wheels, ensuring smooth movement and control across different terrains.

- Cutting Deck: The deck is designed for precision and efficiency in cutting, providing consistent results while reducing the time spent on each task.

- Blades: Sharp and durable, these are the components that directly impact the quality of the cut, and they are engineered for longevity and performance.

- Fuel System: A robust system that ensures the engine receives a consistent fuel supply, contributing to both power output and fuel efficiency.

- Steering: This system provides precise control, making the machine easy to maneuver around obstacles and tight spaces.

- Wheels:

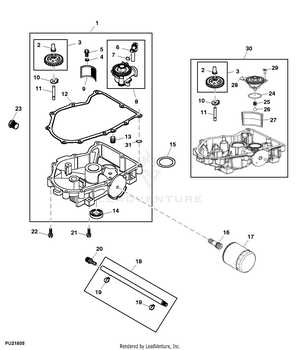

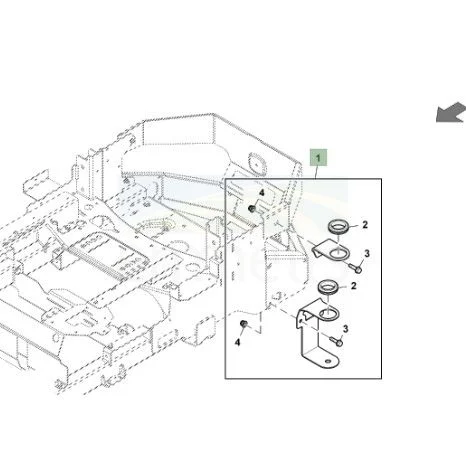

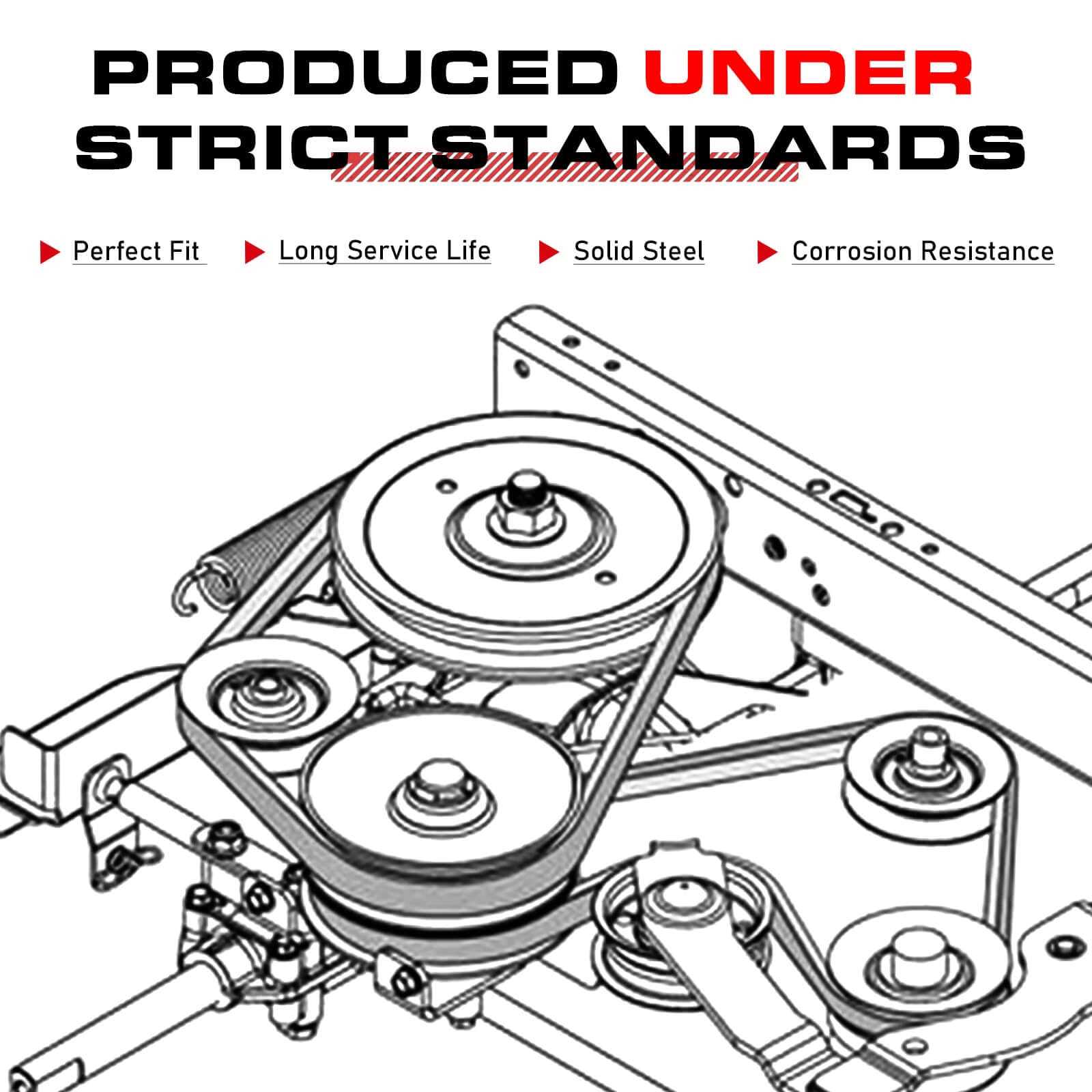

Understanding the Z710A Mower Deck Assembly

The mower deck is a crucial component of any riding lawn equipment, ensuring efficient grass cutting and a smooth finish to the lawn. Understanding how the deck assembly operates is essential for maintaining optimal performance, as this system directly influences the cutting precision and durability of the machine.

Key Components of the Deck

The deck assembly includes various interconnected elements designed to work together for seamless operation. Blades, pulleys, and spindles are integral parts that must be kept in sync for accurate cuts. Ensuring that these components are properly aligned and maintained can prevent uneven cutting or damage to the lawn surface.

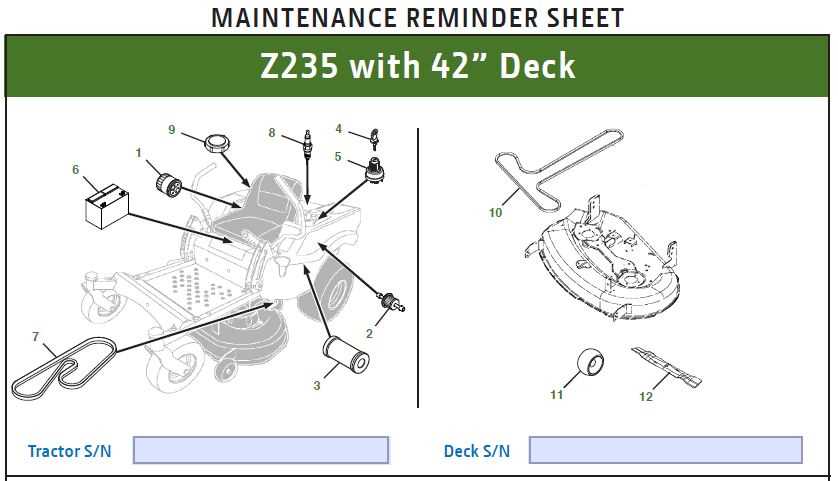

Proper Maintenance and Care

To keep the mower deck functioning at its best, regular inspections and adjustments are necessary. Pay attention to the condition of the belts, blades, and bearings. A well-maintained assembly not only extends the life of the equipment but also enhances cutting efficiency. Cleaning the underside of the deck and sharpening the blades at appropriate intervals are simple yet effective ways to ensure long-term reliability.

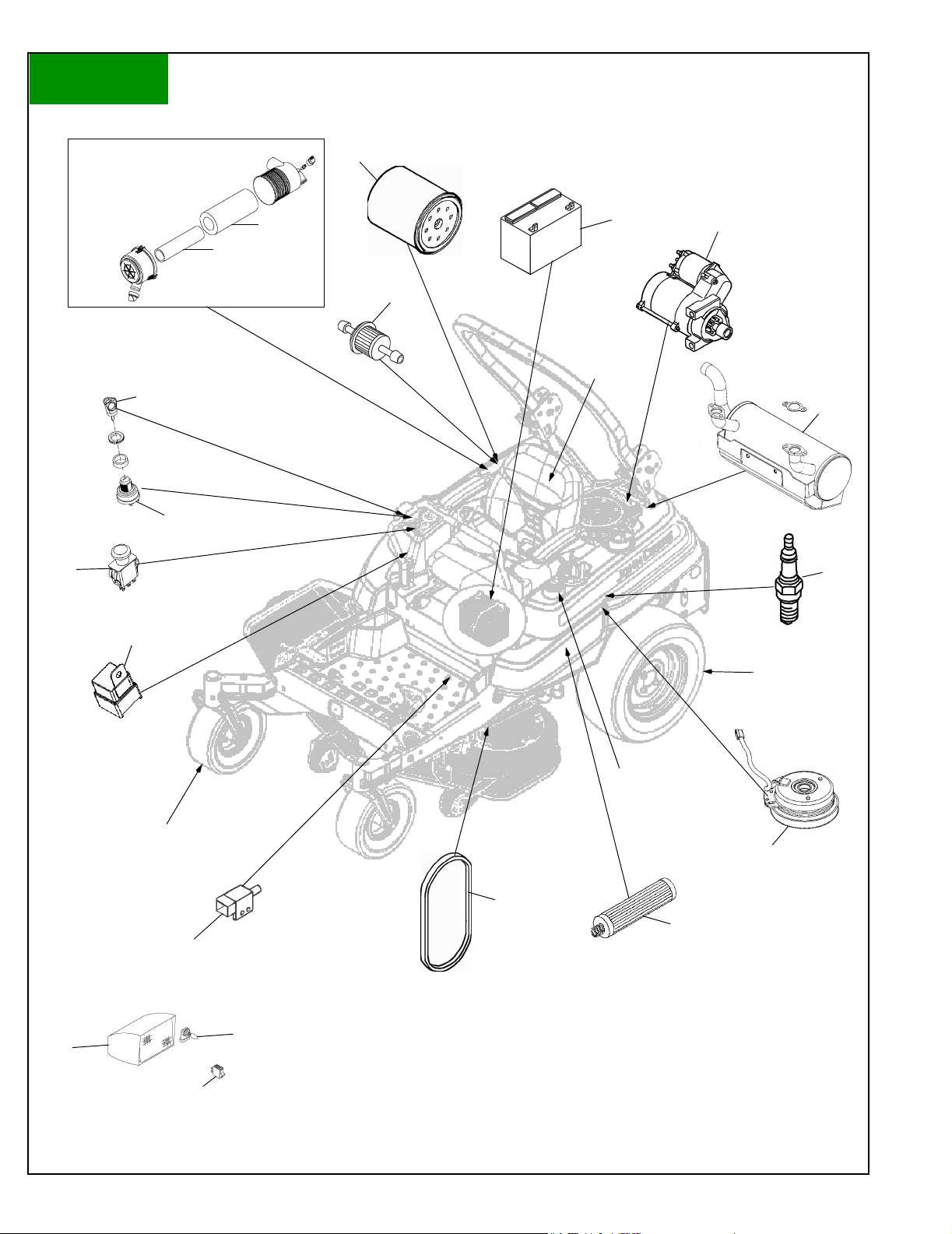

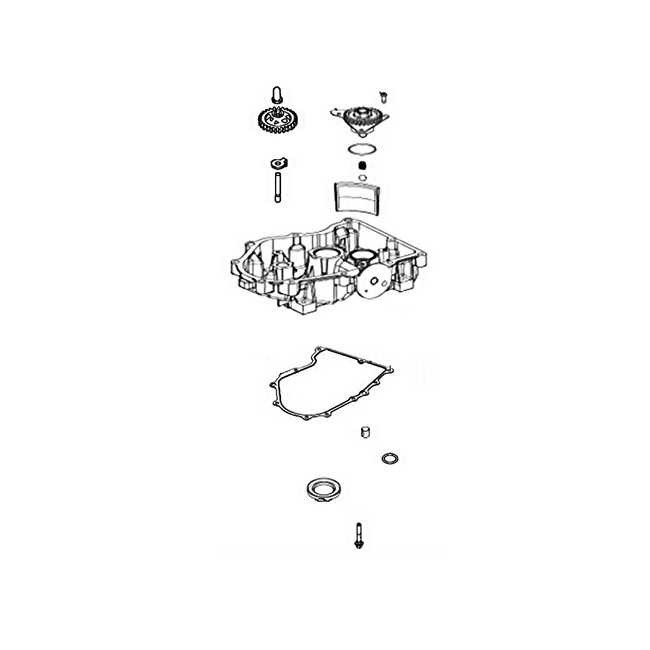

Engine Components for John Deere Z710A

The heart of any high-performance mowing machine relies heavily on a well-engineered motor system. Understanding the key elements that make up this system is crucial for efficient operation and long-term maintenance. In this section, we break down the essential elements of the power unit, offering a clear overview of the components that ensure optimal functionality.

- Air Filter: Essential for keeping debris and dust out of the internal mechanisms, prolonging engine life.

- Spark Plugs: Crucial for igniting the fuel-air mixture, ensuring a smooth start and consistent performance.

- Fuel Pump: Responsible for delivering the right amount of fuel to the motor, ensuring an uninterrupted power supply.

- Cooling System: A system of fans or coolants to prevent overheating during extended use, maintaining efficiency.

- Oil Filter: Keeps the lubricating fluid clean, reducing wear on moving parts and extending the motor’s lifespan.

Transmission Parts in the Z710A Model

The transmission system plays a crucial role in ensuring the smooth operation of any zero-turn mower, facilitating the efficient transfer of power from the engine to the wheels. Understanding the key components involved in this mechanism is essential for maintaining peak performance and longevity.

Key Components of the Transmission System

The drive mechanism includes several vital elements, each contributing to the overall efficiency. These components, from fluid reservoirs to gears, work together to ensure that the machine runs smoothly even under heavy loads. Regular maintenance of these parts ensures long-lasting functionality and prevents potential breakdowns.

Component Function Hydraulic Pumps Facilitates movement by converting mechanical energy into fluid power. Axles Transmits power from the motor to the wheels, enabling motion control. Gears Regulate speed and torque, providing the right balance for different terrains. Fluid Reservoir Stores hydraulic fluid, essential for the cooling and operation of the system. Common Wear Parts in the Z710A

Over time, certain components in any heavy-duty machinery are prone to wear and tear due to regular use. Identifying these elements early helps maintain peak performance and reduces costly downtime. Regular checks and timely replacements are essential for ensuring smooth operation.

Blades: The cutting edges are often the first to show signs of deterioration. Dull or damaged blades can lead to uneven cuts and additional strain on the engine.

Belts: Drive belts endure significant stress during operation, and cracks or fraying can lead to reduced efficiency or sudden failure, disrupting productivity.

Bearings: These small but crucial parts handle rotational movement, and excessive wear can result in vibrations or noise, indicating they need attention.

Filters: Regular replacement of air and fuel filters is critical to prevent contaminants from causing engine damage or performance issues.

Tires: Constant exposure to different terrains can cause the tires to lose tread or develop punctures, reducing stability and traction.

Maintaining these frequently worn components ensures a longer lifespan and greater efficiency for your machine.

How to Replace Z710A Blades

Replacing the cutting blades on your lawn mower is essential for maintaining a healthy lawn. Dull or damaged blades can lead to uneven cuts, which may stress your grass and promote disease. This guide will walk you through the steps to safely and effectively replace the blades, ensuring optimal performance of your equipment.

Tools and Materials Needed

- New blades compatible with your mower

- Socket wrench or ratchet set

- Safety gloves

- Protective eyewear

- Grease or lubricant

Step-by-Step Replacement Process

- Ensure the mower is turned off and cool to the touch. Disconnect the spark plug wire to prevent accidental starting.

- Lift the mower using a jack or ensure it is stable on a flat surface.

- Locate the blade attachment points beneath the mower deck. Use the socket wrench to remove the bolts securing the old blades.

- Carefully detach the worn blades from the mower. It is advisable to wear gloves to protect your hands from sharp edges.

- Position the new blades in place, ensuring they are aligned correctly. Secure them with the bolts and tighten them firmly.

- Reattach the spark plug wire and lower the mower back to its normal position.

- Test the mower to ensure that it operates smoothly with the new blades.

Regular maintenance and timely blade replacements will enhance your mower’s efficiency and prolong its lifespan.

Electrical System of the Z710A

The electrical framework of this mower model plays a crucial role in ensuring efficient operation and functionality. Its components work in harmony to deliver power to various systems, enabling seamless performance for users. A well-designed electrical layout not only enhances the machine’s capabilities but also contributes to its overall reliability and longevity.

This system comprises several essential elements, including the battery, wiring harness, switches, and fuses. Each component is integral to the machine’s operation, providing power to the ignition system, lighting, and other electrical accessories. Proper maintenance and understanding of this framework are vital for troubleshooting and ensuring optimal performance.

Maintaining the Z710A Fuel System

Ensuring optimal performance of your machinery involves regular upkeep of the fuel delivery mechanism. This crucial aspect plays a significant role in the overall efficiency and longevity of your equipment. By focusing on key maintenance practices, you can prevent potential issues and enhance the reliability of your engine.

Begin by routinely inspecting the fuel filter for blockages and replacing it as necessary. A clean filter is vital for preventing contaminants from entering the fuel system. Additionally, examine fuel lines for any signs of wear or leakage. Promptly addressing any damage will safeguard against fuel loss and ensure a steady supply to the engine.

Moreover, it is essential to keep the fuel tank clean and free of debris. Periodically empty the tank and inspect it for any rust or sediment buildup. Keeping the fuel tank in pristine condition not only enhances performance but also prolongs the lifespan of the entire fuel system.

Finally, always use high-quality fuel that meets the manufacturer’s specifications. Using subpar fuel can lead to clogs and reduced engine efficiency. By prioritizing these maintenance tasks, you can ensure that your machinery operates smoothly and efficiently for years to come.

Z710A Control Panel and Levers Diagram

This section focuses on the interface and control mechanisms utilized in the Z710A model, highlighting their layout and function. Understanding these components is crucial for effective operation, maintenance, and troubleshooting.

Control Mechanisms Overview

The control interface comprises various elements designed for ease of use and precision. Each lever and button serves a specific purpose, facilitating efficient handling of the machinery. Familiarity with these controls enhances operator confidence and improves overall performance.

Key Components

Component Description Throttle Lever Regulates engine speed and power output. Ignition Switch Engages the engine start sequence. Brake Pedal Activates the braking system for safe stopping. Steering Control Enables directional movement of the equipment. Hydraulic Control Lever Controls the operation of hydraulic attachments. Troubleshooting the John Deere Z710A

Addressing issues with lawn care machinery requires a systematic approach to identify and resolve common problems. Whether dealing with performance issues, starting difficulties, or mechanical failures, understanding the equipment’s functionality is essential for effective repairs.

Performance Issues: If the equipment is underperforming, check the fuel system for clogs or leaks. A contaminated fuel filter can hinder efficiency, so ensure it is clean and replace it if necessary. Additionally, inspect the air filter; a dirty filter restricts airflow, impacting overall power.

Starting Difficulties: When the machine fails to start, assess the battery condition. Corroded terminals or a drained battery may be the culprit. Ensure connections are secure and clean. If the starter motor is unresponsive, it may require inspection or replacement.

Mechanical Failures: Unusual noises during operation could indicate a mechanical issue. Check belts and pulleys for wear or damage. Regularly lubricate moving parts to prevent excessive wear. Additionally, examine the blades for dullness or nicks; sharpening or replacing blades will enhance cutting performance.

Electrical Problems: If lights or other electrical components malfunction, inspect wiring for damage or disconnections. Testing fuses is also crucial, as a blown fuse can disrupt functionality. For persistent issues, consult the owner’s manual for detailed wiring diagrams and troubleshooting tips.

By systematically examining each component and understanding the machinery’s functions, operators can efficiently troubleshoot and maintain their equipment, ensuring optimal performance throughout the mowing season.

Where to Buy Z710A Spare Parts

Finding high-quality replacements for your lawn care equipment is essential for maintaining its performance and longevity. Whether you need components for routine maintenance or specific repairs, knowing where to source these items can make all the difference. This section explores various options for acquiring the necessary elements for your machine.

Authorized Dealers

One of the most reliable places to find genuine replacements is through authorized dealers. These retailers often carry an extensive selection of original equipment manufacturer (OEM) components, ensuring compatibility and quality. Additionally, purchasing from authorized sellers often comes with a warranty, giving you peace of mind.

Online Marketplaces

In today’s digital age, online marketplaces provide a convenient option for finding replacement items. Websites specializing in lawn care machinery or general online retailers offer a vast array of components. Always check reviews and seller ratings to ensure you’re getting quality products. Don’t forget to compare prices across different platforms to secure the best deals.

Local Repair Shops can also be valuable resources. Many shops not only offer repair services but also stock commonly needed replacements. Establishing a relationship with a local technician can provide insights into the best options for your specific needs.

In conclusion, exploring various avenues for obtaining the right components will help keep your equipment running smoothly. From authorized dealers to online options, you have numerous resources at your disposal to ensure your machine remains in top condition.

Enhancing Performance with OEM Parts

Utilizing original equipment manufacturer components is essential for maintaining optimal functionality and longevity of your machinery. These meticulously crafted pieces ensure compatibility and precision, leading to improved efficiency and reliability in operation. Investing in high-quality replacements allows users to maximize the performance of their equipment while minimizing the risk of malfunctions.

One of the primary benefits of choosing authentic components lies in their ability to uphold manufacturer specifications. This adherence not only enhances operational performance but also supports the overall health of the machine. Users can expect consistent results, which are critical for achieving desired outcomes in various tasks.

Moreover, OEM components are often backed by warranties, providing an extra layer of assurance. This guarantee enables operators to work with peace of mind, knowing that their investment is protected. Additionally, using original parts often leads to lower maintenance costs over time, as they are designed for durability and efficiency.

Below is a comparison of various types of replacement components, highlighting their advantages:

Component Type Benefits OEM Components Perfect fit, high durability, warranty protection, enhanced performance Aftermarket Components Lower cost, varying quality, potential compatibility issues Rebuilt Components Cost-effective, may not meet original specifications, shorter lifespan In conclusion, prioritizing original components over alternatives significantly contributes to the efficiency and reliability of your machinery. By choosing authentic replacements, operators can ensure that their equipment performs at its best, providing long-term benefits and reducing the likelihood of future repairs.