In the realm of outdoor machinery, having a clear grasp of the various components is crucial for effective maintenance and repair. Every piece of equipment consists of numerous parts, each playing a specific role in ensuring optimal performance. Familiarity with these elements not only enhances the user experience but also prolongs the lifespan of the machine.

As operators delve into the intricate world of machinery, visual representations become invaluable tools. These illustrations serve as guides, illuminating the relationships between different sections and aiding in the identification of individual elements. With a comprehensive overview, users can tackle issues with confidence, streamline repair processes, and make informed decisions regarding replacements.

Moreover, understanding the layout and function of each component can significantly impact operational efficiency. By recognizing how various parts interact within the system, operators can anticipate potential problems and address them proactively. This knowledge fosters a deeper appreciation for the equipment, transforming routine tasks into opportunities for learning and growth.

Understanding the John Deere Z920M

This section explores the intricate details of a renowned lawn care machine designed for efficiency and performance. With its robust features, it stands out in the landscaping industry, offering users exceptional maneuverability and power.

Key Features: The equipment boasts a powerful engine that ensures smooth operation across various terrains. Its cutting system is engineered for precision, allowing for clean and even results. Additionally, the user-friendly controls enhance the overall experience, making it accessible for both novices and seasoned operators.

Maintenance Tips: Regular upkeep is essential for longevity. Checking fluid levels, inspecting blades, and cleaning the chassis will contribute to optimal performance and reliability. Understanding these elements can ultimately lead to a more rewarding ownership experience.

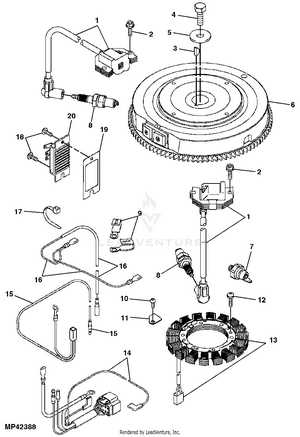

Importance of Parts Diagrams

Understanding the components of machinery is essential for effective maintenance and repair. Visual representations serve as crucial tools for technicians and operators alike, enabling them to identify and locate specific elements quickly. These illustrations not only streamline the process of assembly and disassembly but also enhance overall efficiency in troubleshooting.

Clarity is a key benefit of these visuals. They provide a straightforward way to comprehend complex systems, making it easier to pinpoint where issues may arise. By breaking down intricate mechanisms into manageable sections, users can approach repairs with greater confidence.

Additionally, having access to detailed visuals fosters a deeper understanding of the equipment. Users can familiarize themselves with the functionality of various components, which can lead to more informed decision-making when it comes to maintenance schedules and operational practices.

In conclusion, these illustrations are invaluable resources that enhance both the knowledge and efficiency of those working with machinery. Their role in simplifying communication and understanding cannot be overstated.

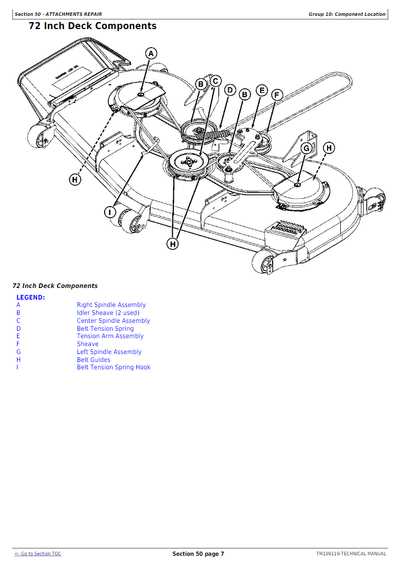

Key Components of Z920M Mower

Understanding the essential elements of a high-performance mowing machine is crucial for effective maintenance and operation. Each component plays a significant role in ensuring the overall functionality and efficiency of the equipment.

The cutting deck serves as the heart of the mower, providing the necessary mechanism for precise grass trimming. Equipped with sharp blades, it facilitates a clean cut while enhancing the machine’s maneuverability.

The engine, a vital source of power, drives the entire system, delivering reliable performance under various conditions. Its efficiency directly impacts the mower’s speed and productivity.

Transmission systems are critical for transferring power from the engine to the wheels, allowing for smooth operation across different terrains. A well-designed transmission ensures optimal speed control and responsiveness.

Lastly, the control panel offers the operator an interface to manage various functions, enhancing user experience and safety during operation. Each element is interlinked, contributing to the machine’s ultimate performance.

How to Read Parts Diagrams

Understanding the visual representations of components can significantly enhance your maintenance and repair experience. These illustrations serve as a valuable tool for identifying and locating individual elements within a complex assembly.

To effectively interpret these visuals, consider the following steps:

- Familiarize Yourself: Spend time getting to know the layout and symbols commonly used in these visuals.

- Identify Key Sections: Break down the illustration into manageable parts to focus on specific areas.

- Refer to Legends: Always check for accompanying legends or notes that explain various symbols and references.

- Cross-Reference: Use additional resources or manuals to verify and clarify any uncertainties.

By mastering these techniques, you can confidently navigate the intricacies of these essential tools, ultimately leading to more efficient repairs and maintenance tasks.

Common Issues with Z920M Parts

Understanding the frequent challenges associated with components of specific models is crucial for efficient maintenance and operation. Identifying these common issues can help users minimize downtime and extend the lifespan of their machinery. Below are some prevalent problems and considerations related to these essential elements.

Frequent Malfunctions

Many users encounter various malfunctions that can hinder performance. These issues often stem from wear and tear or improper maintenance practices. Addressing them promptly can prevent further complications.

Wear and Tear Indicators

Regular inspection is vital to catch signs of deterioration early. Some common indicators of wear include unusual noises, decreased efficiency, and visual damage. It’s important to keep a keen eye on these signs to ensure optimal operation.

| Issue | Symptoms | Possible Solutions |

|---|---|---|

| Overheating | Unusual heat, reduced power | Check fluid levels, clean filters |

| Vibration | Excessive shaking, noise | Inspect for loose components, balance parts |

| Leakage | Fluid spots, decreased levels | Replace seals, check connections |

Where to Find Replacement Parts

Finding quality components for machinery can significantly enhance performance and longevity. Various sources provide access to essential elements, catering to both original and aftermarket options. Understanding where to seek these supplies is crucial for maintaining optimal functionality.

Authorized dealers often stock genuine items, ensuring compatibility and reliability. Visiting these outlets allows for professional assistance and expert advice. Alternatively, online retailers offer a vast selection, often at competitive prices, making them a convenient option for many users.

Local repair shops can also be invaluable resources, as they frequently carry common components or can order specific items. Additionally, forums and community groups dedicated to machinery enthusiasts may provide leads on where to obtain rare or discontinued elements.

Maintenance Tips for Z920M

Proper upkeep of your equipment ensures longevity and optimal performance. Regular attention to various components can prevent issues and enhance efficiency.

Regular Inspections: Conduct thorough checks on all moving parts and systems to identify wear and tear early. This proactive approach can save time and resources in the long run.

Oil Changes: Frequent oil changes are essential to maintain engine health. Follow the manufacturer’s recommendations for intervals and types of oil to use.

Cleaning: Keep the exterior and undercarriage clean. Removing dirt and debris helps prevent rust and promotes better airflow, which is vital for cooling.

Sharpening Blades: Dull blades can lead to poor cutting performance and increased strain on the engine. Regularly sharpen and inspect blades for damage.

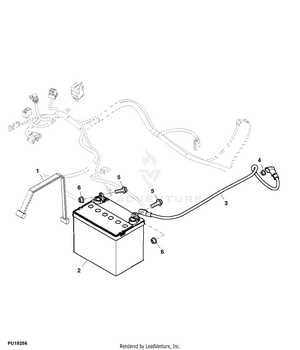

Battery Maintenance: Check battery connections and clean terminals to ensure efficient power supply. Replace batteries as needed to avoid starting issues.

Storage Practices: When not in use, store the equipment in a dry, sheltered area. Consider using covers to protect it from dust and weather elements.

Benefits of Genuine John Deere Parts

Utilizing authentic components for machinery maintenance ensures optimal performance and longevity. These items are designed specifically to fit and function seamlessly, providing peace of mind for users.

| Benefit | Description |

|---|---|

| Reliability | Genuine components are tested for quality, ensuring they perform consistently. |

| Longevity | These items are built to last, reducing the need for frequent replacements. |

| Compatibility | Authentic parts are engineered for specific models, ensuring perfect fit and function. |

| Warranty Protection | Using original components often helps maintain warranties on the machinery. |

Comparing Z920M to Other Models

When evaluating different models within the same category, it’s essential to consider various factors such as performance, efficiency, and overall design. This comparison aims to highlight the unique features and advantages that one model may offer over others, allowing users to make informed decisions based on their specific needs.

Performance Metrics

Performance can vary significantly between models, influencing operational efficiency and user experience. Below is a comparison of key performance metrics for several popular alternatives.

| Model | Horsepower | Cutting Width | Weight |

|---|---|---|---|

| Model A | 22 HP | 54 inches | 500 lbs |

| Model B | 25 HP | 60 inches | 550 lbs |

| Model C | 24 HP | 58 inches | 520 lbs |

Features and Specifications

In addition to performance, various features can enhance usability and comfort. Understanding these aspects helps users identify the ultimate fit for their requirements.

Upgrading Your Z920M Mower

Enhancing your mowing machine can significantly improve its performance and longevity. Whether you’re looking to boost efficiency or simply want to enjoy a smoother operation, there are various modifications and enhancements that can make a noticeable difference. Understanding the options available will help you make informed decisions tailored to your needs.

Performance Enhancements

One of the most impactful upgrades involves improving engine efficiency. Consider options like high-performance air filters and upgraded exhaust systems, which can lead to better airflow and increased power output. Additionally, installing a new blade set can enhance cutting precision and reduce strain on the engine, ensuring a cleaner cut and a healthier lawn.

Comfort and Usability Improvements

Upgrading the comfort features can transform your mowing experience. Installing a cushioned seat can provide better support during long sessions, while adding ergonomic controls can enhance usability. Accessories like cup holders and storage compartments can also make your time on the mower more enjoyable and convenient.

By investing in these upgrades, you can ensure that your mowing machine meets your specific needs and maintains peak performance for years to come.