When it comes to maintaining a high-performing lawn care machine, having a clear overview of its various elements is crucial. This section will explore the intricate assembly of a well-regarded mower, emphasizing how each component contributes to its overall functionality.

By examining the specific sections and their relationships, enthusiasts and professionals alike can better appreciate the engineering that drives exceptional performance. A detailed study of these mechanisms will enhance your ability to troubleshoot and optimize your equipment.

Moreover, familiarizing yourself with these essential parts can lead to more efficient repairs and upgrades, ultimately maximizing the machine’s lifespan. This guide serves as a valuable resource for those aiming to delve deeper into the inner workings of their favorite lawn care tool.

Understanding John Deere Z930M Parts

This section explores the essential components of a specific lawn maintenance machine, focusing on their roles and functionalities. Understanding these elements is crucial for effective maintenance, repair, and overall performance enhancement of the equipment.

Key Components Overview

Each piece of machinery consists of various integral elements that contribute to its operational efficiency. Familiarity with these components aids in recognizing potential issues and facilitates timely interventions.

| Component | Description |

|---|---|

| Engine | Powers the machine and drives its performance. |

| Transmission | Controls the speed and torque of the machine. |

| Deck | Houses the cutting blades and determines cutting height. |

| Wheels | Support movement and stability across various terrains. |

Maintenance and Care

Regular upkeep of these vital components ensures longevity and optimal functionality. Implementing a consistent maintenance schedule can prevent costly repairs and enhance the overall user experience.

Overview of Z930M Components

This section provides a comprehensive look at the essential elements that constitute a high-performance lawn care machine. Understanding these components is vital for ensuring optimal functionality and maintenance.

Key Features

At the heart of this equipment lies a robust engine that powers its impressive cutting capabilities. Coupled with advanced transmission systems, these features allow for seamless operation and maneuverability in various terrains.

Maintenance Essentials

Regular upkeep of critical elements, such as the blades and fuel system, is crucial for longevity. Proper care not only enhances performance but also reduces the risk of unexpected breakdowns, making it an ultimate priority for any operator.

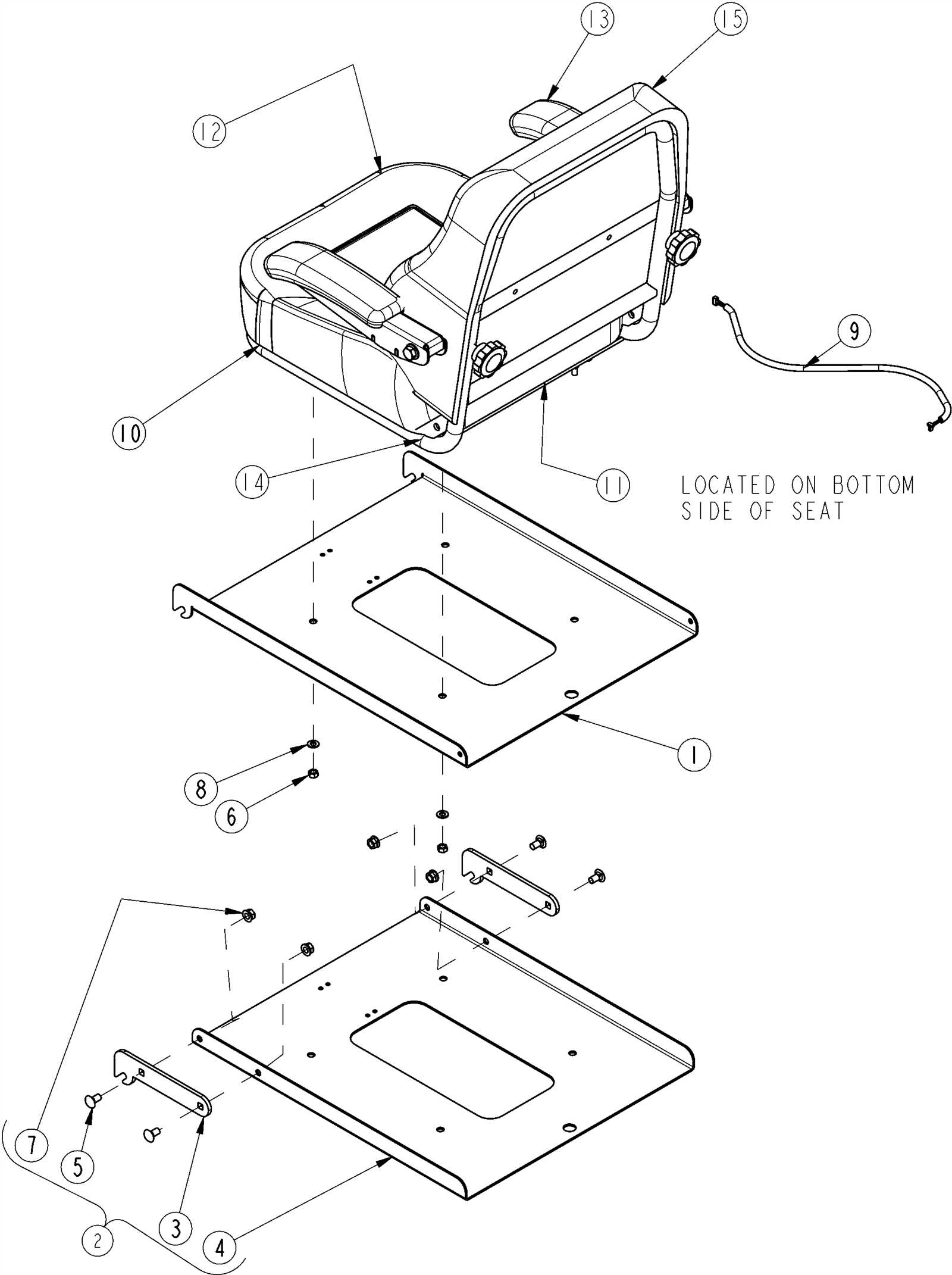

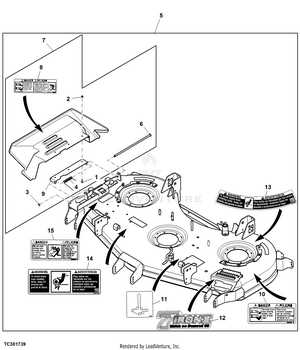

Importance of Accurate Parts Diagrams

Having precise visual representations of components is crucial for effective maintenance and repair tasks. These illustrations not only enhance understanding of complex machinery but also facilitate efficient troubleshooting and assembly. When users can easily identify each element, it minimizes errors and accelerates the repair process.

Enhanced Understanding

Clear visual guides provide valuable insights into the structure and function of various elements within equipment. This understanding allows operators and technicians to perform tasks with greater confidence, reducing the likelihood of mistakes that can lead to costly downtime.

Efficiency in Repairs

Utilizing accurate visual references streamlines the repair workflow. When individuals can quickly locate and identify specific components, they save time and effort. This efficiency not only boosts productivity but also contributes to a safer working environment, as there is less chance of misplacing or mishandling parts.

Key Features of Z930M Mowers

The cutting-edge design of these mowers provides unparalleled performance and efficiency, making them a top choice for landscaping professionals and enthusiasts alike. Each model boasts advanced functionalities that enhance usability and effectiveness in various mowing conditions.

Robust Engine Performance: Equipped with a powerful engine, these mowers deliver consistent power and reliability, ensuring optimal operation even in tough environments.

Precision Cutting Deck: The innovative cutting deck design allows for exceptional grass handling and a clean finish, promoting healthier lawns with every pass.

User-Friendly Controls: Ergonomically designed controls facilitate ease of use, enabling operators to maneuver with confidence and precision.

Durability: Built with high-quality materials, these mowers are engineered to withstand rigorous use, ensuring longevity and dependability in the field.

Adjustable Features: Customizable settings allow users to tailor the mowing experience to their specific needs, enhancing efficiency and comfort.

Common Parts and Their Functions

This section explores various essential components commonly found in lawn maintenance equipment, highlighting their roles in ensuring optimal performance and efficiency.

| Component | Function |

|---|---|

| Blades | Responsible for cutting grass and maintaining a clean lawn appearance. |

| Fuel Filter | Prevents impurities from entering the engine, promoting smooth operation. |

| Battery | Supplies electrical power to start the engine and run accessories. |

| Drive Belt | Transfers power from the engine to the cutting mechanism, enabling movement. |

| Wheels | Facilitate mobility and maneuverability across different terrains. |

How to Read Parts Diagrams

Understanding visual representations of components is crucial for effective maintenance and repairs. These illustrations provide an organized way to identify various elements, their functions, and how they fit together within a system. Familiarity with these visuals enhances the efficiency of locating and replacing items when needed.

Begin by examining the legend or key, which typically explains the symbols and color coding used. This section is vital for deciphering the meanings behind the visuals. Next, observe the layout, noting how different components are grouped and their spatial relationships, which can give insights into assembly and disassembly processes.

Pay attention to the numbering or labeling associated with each part, as this information is essential for ordering replacements or seeking assistance. Additionally, consider the additional notes or tips that may accompany the illustrations, offering guidance on specific tasks or common issues.

Finally, practice is essential. Regularly referring to these visuals while working on equipment will enhance your ability to quickly interpret and utilize them effectively, ultimately improving your overall repair experience.

Identifying Replacement Parts Easily

Understanding the components of your machinery is essential for effective maintenance and repair. Knowing how to recognize and source the necessary elements can save time and ensure optimal performance. This section aims to simplify the process of finding the right substitutes when needed.

One effective approach is to familiarize yourself with the layout and function of each component. Utilizing visual aids, such as charts or illustrations, can provide clarity and help pinpoint what you’re looking for. Additionally, keeping a record of part numbers or descriptions can streamline the ordering process.

Consulting reputable resources, whether online databases or professional guides, can also enhance your ability to locate the correct items quickly. Engaging with community forums or manufacturer support can yield valuable insights and recommendations. Ultimately, an organized and informed approach will facilitate smoother repairs and upkeep.

Maintenance Tips for Z930M Models

Regular upkeep is essential for ensuring optimal performance and longevity of your equipment. Implementing a structured maintenance routine not only enhances efficiency but also prevents costly repairs down the line. Below are some key practices to consider for maintaining your model effectively.

| Maintenance Task | Frequency | Tips |

|---|---|---|

| Oil Change | Every 50 hours | Use high-quality oil to improve engine performance. |

| Blade Sharpening | Every 25 hours | Ensure blades are sharp for clean cuts. |

| Air Filter Cleaning | Every 100 hours | Check for dirt and debris to maintain airflow. |

| Tire Inspection | Monthly | Ensure proper inflation and check for wear. |

| Belt Inspection | Every 50 hours | Look for signs of wear and proper tension. |

Where to Find Genuine Parts

Locating authentic components for your equipment is essential for ensuring optimal performance and longevity. Various sources offer reliable options for acquiring high-quality replacements that match the original specifications.

Authorized Dealers

Visiting authorized retailers is one of the most effective ways to secure genuine items. These establishments typically have access to a comprehensive inventory and can provide expert advice on compatibility and installation.

Online Marketplaces

Numerous online platforms specialize in selling original items. Ensure you choose reputable websites that guarantee authenticity and provide customer reviews to assist in your decision-making process. Research before purchasing to avoid counterfeit products.

Cost Factors for Z930M Components

Understanding the various elements influencing the pricing of machinery components is essential for effective budgeting and maintenance planning. Several key aspects contribute to the overall expense, including material quality, manufacturing processes, and market demand.

| Factor | Description |

|---|---|

| Material Quality | High-grade materials often lead to increased durability and performance, resulting in higher costs. |

| Manufacturing Techniques | Advanced production methods may enhance precision and longevity, impacting the price significantly. |

| Supply and Demand | Market fluctuations can drive costs up or down based on the availability of components and buyer interest. |

| Brand Reputation | Established brands may command higher prices due to perceived reliability and customer loyalty. |

Upgrades and Accessories Available

Enhancing your equipment can significantly improve its performance and versatility. A range of options is available to cater to various needs, ensuring that your machine operates at its ultimate potential.

- Performance Enhancements

- Comfort Accessories

- Safety Features

- Storage Solutions

- Seasonal Attachments

Consider these upgrades:

- Engine upgrades for increased power.

- Comfort seats for longer working hours.

- Rollover protection systems for added safety.

- Toolboxes for organized storage.

- Snow removal attachments for winter tasks.

Choosing the right accessories can transform your equipment into a multifunctional powerhouse, ready for any challenge.

Troubleshooting Common Issues

Addressing common problems in outdoor power equipment is essential for maintaining optimal performance and longevity. Understanding the typical symptoms and potential causes can help users quickly identify and resolve issues, ensuring efficient operation.

One frequent issue is difficulty starting the machine. This may stem from a drained battery, faulty ignition system, or fuel delivery problems. Checking the battery charge, inspecting connections, and ensuring proper fuel flow can often resolve the matter.

Another common concern is uneven cutting. This can be attributed to dull blades, improper deck height, or wheel alignment. Regularly sharpening blades and adjusting the cutting deck can significantly improve performance and achieve a uniform cut.

Overheating is also a critical issue that requires attention. Potential causes include low oil levels, blocked cooling fins, or a malfunctioning cooling system. Regular maintenance checks and oil level inspections are vital to prevent overheating and potential damage.

Lastly, unusual vibrations can indicate underlying mechanical problems. Loose components, worn bearings, or unbalanced blades are common culprits. Conducting routine inspections and tightening any loose parts can help maintain stability and reduce vibrations during operation.

Resources for Further Information

For those seeking additional insights and details on maintenance and repair components for their equipment, a variety of resources are available. These materials can provide valuable guidance, from technical specifications to user manuals, ensuring optimal performance and longevity of your machinery.

Online Resources

Numerous websites offer comprehensive information, including forums and official manufacturer pages. These platforms often include FAQs, instructional videos, and troubleshooting tips.

Books and Manuals

Investing in service manuals and repair guides can be beneficial. These printed resources typically provide in-depth explanations of various assembly components and maintenance procedures.

| Resource Type | Description | Link |

|---|---|---|

| Manufacturer Website | Official information, specifications, and support. | Visit |

| Online Forums | User discussions and shared experiences. | Visit |

| Service Manuals | Detailed guides for repair and maintenance. | Visit |