The efficiency and performance of a lawn care machine significantly depend on its individual elements. Each component plays a crucial role in ensuring smooth operation and durability. In this section, we will explore the various segments of this equipment, shedding light on how they function together to create an effective mowing experience.

By analyzing the layout and relationships between different parts, users can better comprehend how to maintain and troubleshoot their machines. This knowledge is essential for maximizing the longevity and performance of the equipment. Proper understanding also aids in identifying replacement components when necessary, ensuring the machine remains in top condition.

Additionally, recognizing the roles of each segment empowers operators to make informed decisions during maintenance tasks or repairs. This insight is invaluable for both novice and experienced users alike, ultimately leading to a more satisfying and efficient lawn care experience.

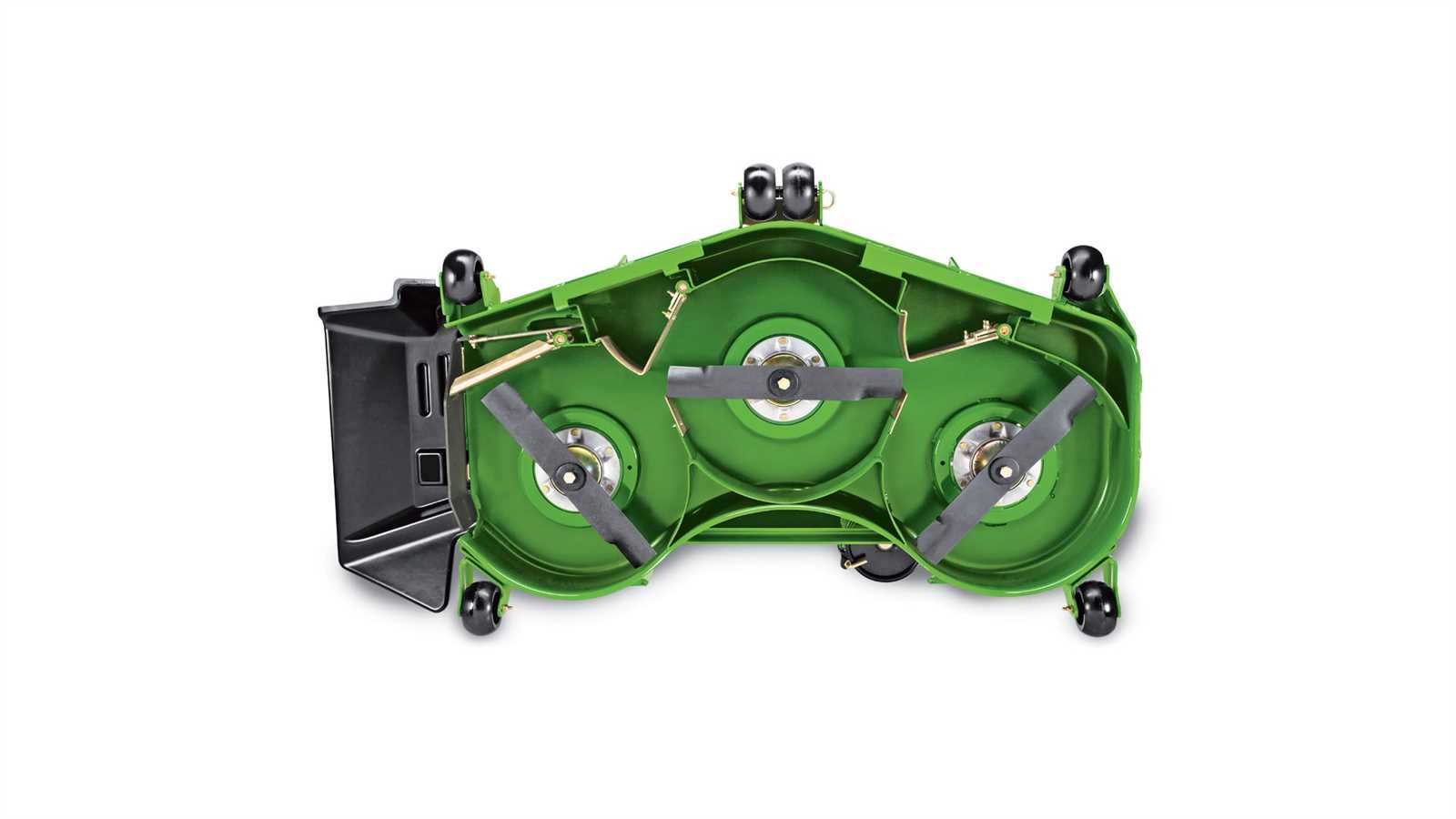

The components of a mowing machine play a crucial role in its overall performance and functionality. Understanding these elements can help users maintain and troubleshoot the equipment effectively. Each part contributes to the machine’s ability to deliver a clean and efficient cut, ensuring that lawns are kept in pristine condition. This section provides an overview of the primary components found in this specific model, highlighting their significance and interrelation.

| Component | Description |

|---|---|

| Engine | The power source responsible for driving the entire machine, providing the necessary energy for operation. |

| Deck | The housing that contains the blades, essential for cutting grass to the desired height. |

| Blades | The sharp tools that rotate to trim the grass, designed for efficient cutting and durability. |

| Wheels | Provide mobility to the machine, allowing for easy navigation across various terrains. |

| Transmission | The system that transfers power from the engine to the wheels, affecting speed and maneuverability. |

| Fuel Tank | Stores the fuel needed for the engine to operate, essential for sustained functionality. |

Key Features of ZTrak 757

This remarkable mowing equipment is designed for efficiency and durability, ensuring optimal performance in various lawn care tasks. Its advanced engineering incorporates innovative technologies that cater to the needs of both professional landscapers and homeowners.

Powerful Engine: The robust motor provides exceptional power, allowing for swift and effective mowing, even in challenging conditions.

Enhanced Maneuverability: Featuring a responsive steering system, this equipment offers remarkable control, enabling users to navigate tight spaces and intricate landscapes with ease.

Durable Construction: Built with high-quality materials, this model is designed to withstand the rigors of frequent use, ensuring longevity and reliability.

Comfortable Operator Experience: The ergonomic design includes a comfortable seat and intuitive controls, making extended mowing sessions more enjoyable and less tiring.

Efficient Cutting Technology: Equipped with advanced cutting systems, this machinery delivers precise results, leaving a well-manicured finish on lawns.

Overall, this mowing solution exemplifies a perfect blend of power, efficiency, and user-friendly design, making it a top choice for those seeking to maintain their outdoor spaces effectively.

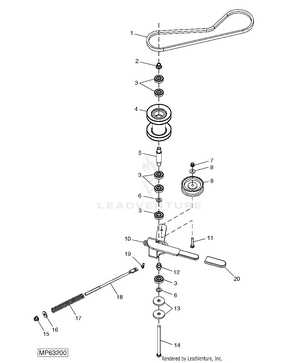

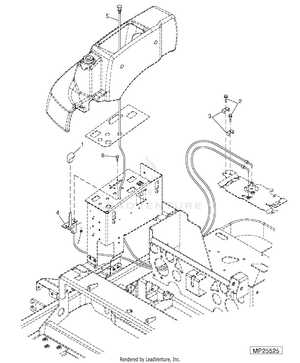

Understanding the Parts Diagram

Familiarizing oneself with the layout of components in any machinery is essential for effective maintenance and repair. A visual representation of these elements aids users in identifying each section, ensuring smoother operation and easier troubleshooting. By grasping how each piece interacts within the whole system, one can enhance performance and longevity.

Key Elements to Note: Typically, such illustrations provide a comprehensive overview of the various sections and individual components. They are often labeled with numbers or letters, making it straightforward to locate specific items when consulting manuals or sourcing replacements. This systematic approach not only facilitates understanding but also empowers users to perform necessary adjustments with confidence.

Application in Maintenance: Understanding this representation is invaluable during repair processes. It allows technicians to reference the schematic accurately while diagnosing issues or replacing faulty elements. Furthermore, this knowledge fosters a proactive attitude towards upkeep, as users can better anticipate potential problems by recognizing wear and tear in specific components.

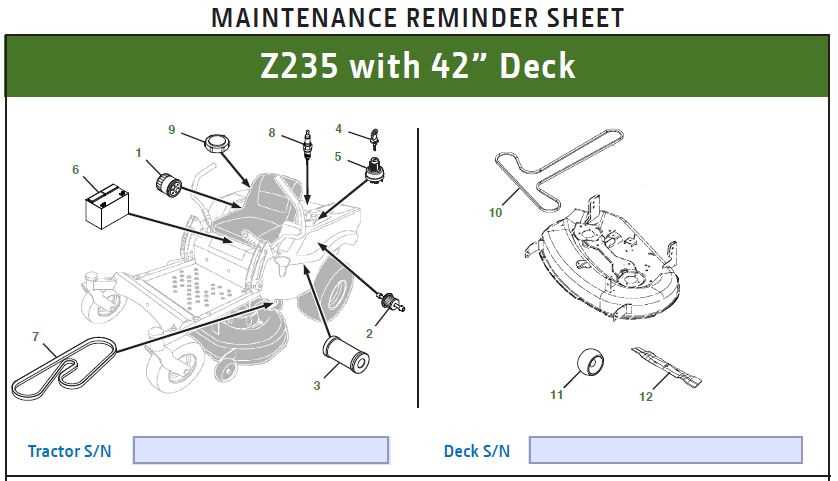

Common Replacement Parts and Accessories

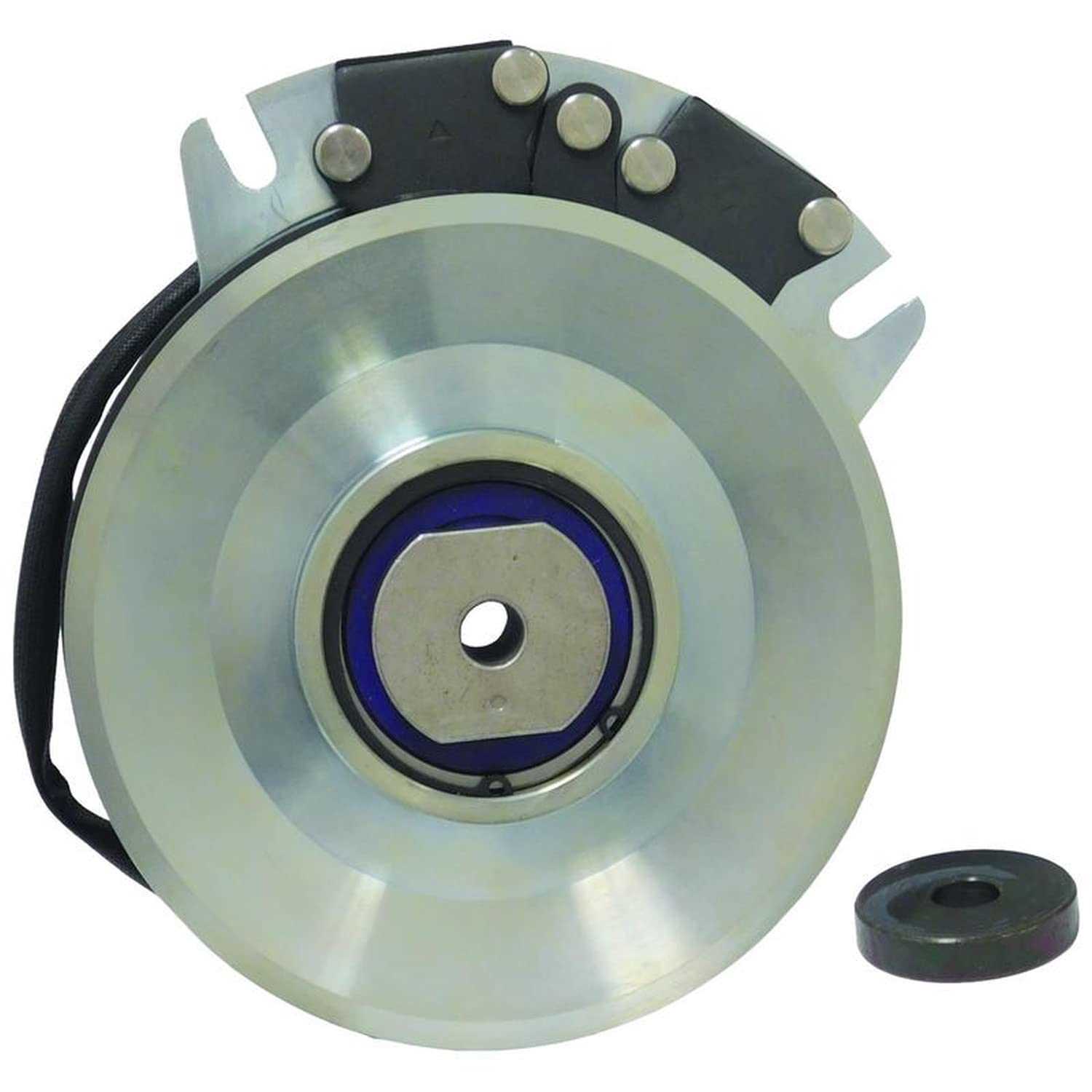

Maintaining equipment is essential for optimal performance and longevity. Various components may require periodic replacement to ensure that the machinery operates efficiently. This section highlights frequently replaced elements and additional items that enhance functionality and user experience.

Key Components for Maintenance

Among the most commonly substituted components are blades, filters, and belts. Blades wear out over time due to regular usage, making them crucial for replacement to maintain cutting efficiency. Filters ensure that the engine runs smoothly by preventing debris from entering, while belts are essential for the effective transfer of power within the system. Regular inspection and timely replacement of these components can prevent costly repairs down the line.

Additional Enhancements and Tools

In addition to essential components, various accessories can improve performance and usability. Items such as mulching kits, grass catchers, and towing attachments provide versatility, allowing users to tailor their equipment for specific tasks. Furthermore, investing in quality maintenance tools ensures that operators can carry out necessary upkeep effectively and efficiently.

Maintenance Tips for ZTrak 757

Proper upkeep of your mowing machine is essential for ensuring its longevity and optimal performance. Regular maintenance not only enhances efficiency but also minimizes the risk of costly repairs down the line. Following a systematic approach to care can significantly extend the lifespan of your equipment.

Regular Inspection

Frequent examination of critical components is vital. Check the blades for wear and tear, ensuring they are sharp and free of debris. Inspect belts and hoses for signs of fraying or damage, as these parts are crucial for smooth operation. Make it a routine to look over fluid levels, including oil and coolant, to keep everything running seamlessly.

Cleaning and Lubrication

After each use, clean the machine to prevent the buildup of grass and dirt, which can lead to corrosion. Utilize a brush or a compressed air system to reach tight spaces. Additionally, regular lubrication of moving parts is important. Applying the right type of lubricant helps reduce friction, thereby improving performance and minimizing wear.

Identifying Essential Repair Tools

Having the right tools is crucial for performing effective maintenance and repairs on machinery. Understanding which instruments are necessary can significantly enhance efficiency and ensure that tasks are completed correctly. A well-equipped toolkit not only streamlines the repair process but also contributes to the longevity and performance of the equipment.

When assembling a toolkit, prioritize versatile and high-quality items. Wrenches and ratchets are essential for loosening and tightening various components. Additionally, having a set of screwdrivers in different sizes and types is vital for accessing screws that secure panels and other parts. Socket sets are particularly useful for applying torque and achieving precise fittings.

Moreover, including pliers and cutting tools will aid in gripping, bending, and cutting materials as needed during repairs. Lastly, safety equipment, such as gloves and goggles, should never be overlooked to protect against potential hazards while working.

How to Read Parts Diagrams

Understanding the visual representations of components can significantly aid in maintenance and repair tasks. These illustrations serve as essential tools for identifying various elements and their relationships within a system. By familiarizing yourself with the conventions used in these visuals, you can enhance your ability to locate and order necessary components effectively.

Key Elements to Consider

- Symbols and Labels: Each illustration includes specific symbols representing various elements. Familiarizing yourself with these symbols will help you decode the information more quickly.

- Legend: Most diagrams feature a legend or key, explaining the symbols used. Referencing this section is crucial for accurate interpretation.

- Groupings: Components may be grouped based on functionality or location. Recognizing these clusters can simplify troubleshooting.

Steps for Effective Interpretation

- Begin by locating the legend to understand the symbols used.

- Identify the main sections and note how components are interconnected.

- Pay attention to any annotations that provide additional details about specific items.

- Use the diagram as a reference when searching for components online or in stores.

Exploring Upgrade Options for Performance

Enhancing the efficiency and functionality of your mowing equipment can lead to significant improvements in overall performance. By considering various upgrade opportunities, users can achieve a more powerful and reliable machine, ensuring that tasks are completed with greater ease and effectiveness. This section delves into several potential enhancements that can elevate your equipment’s capabilities.

| Upgrade Option | Description | Benefits |

|---|---|---|

| Engine Upgrade | Replacing the stock engine with a higher horsepower model. | Increased torque and speed, allowing for faster mowing. |

| Blade Enhancement | Upgrading to high-performance blades designed for specific grass types. | Improved cutting efficiency and a cleaner finish. |

| Suspension System | Installing an advanced suspension system for better ride quality. | Reduced operator fatigue and improved handling on uneven terrain. |

| Fuel System Modification | Incorporating a fuel injection system for better fuel efficiency. | Lower operating costs and improved engine responsiveness. |

| Transmission Upgrade | Switching to a hydrostatic transmission for seamless speed control. | Smoother operation and enhanced maneuverability. |

Safety Precautions During Maintenance

Ensuring a secure working environment is crucial when performing upkeep on equipment. Proper safety measures protect the technician and the machinery from potential hazards. Awareness and adherence to safety guidelines can significantly reduce the risk of accidents and injuries during maintenance tasks.

Personal Protective Equipment

Wearing appropriate personal protective equipment (PPE) is essential. This includes items such as gloves, safety goggles, and sturdy footwear. Utilizing ear protection is also advisable when working with noisy machinery. These safeguards help to minimize exposure to harmful elements and injuries while conducting repairs.

Equipment Safety Checks

Before starting any maintenance procedure, it’s vital to conduct thorough safety checks on the machinery. Ensure that all components are functioning correctly and that safety guards are in place. Disconnecting the power source before beginning work is a fundamental step to prevent accidental starts. Regularly inspecting tools and equipment for defects will further enhance safety during maintenance activities.

Frequently Asked Questions About ZTrak 757

This section aims to address common inquiries regarding the specific model of a well-known mowing machine. Below, you will find answers to frequently posed questions that can help users understand its features, maintenance, and operational tips.

- What type of maintenance is required for this model?

Regular upkeep is essential for optimal performance. Key maintenance tasks include:

- Checking and replacing the oil and filter.

- Sharpening or replacing the cutting blades.

- Inspecting tire pressure and adjusting as needed.

- Cleaning the air filter and checking for debris.

- What are the recommended safety practices?

Ensuring safety while operating this machine is crucial. Recommended practices include:

- Wearing protective gear, such as goggles and gloves.

- Reading the user manual before operation.

- Avoiding slopes that exceed the manufacturer’s guidelines.

- Being aware of surroundings and removing obstacles from the work area.

- How can I troubleshoot common issues?

When facing challenges, consider the following troubleshooting steps:

- If the engine won’t start, check the fuel level and battery connections.

- If the blades do not engage, inspect the switch and related connections.

- If there is uneven cutting, ensure the blades are sharpened and leveled properly.

- Where can I find replacement components?

Replacement components can typically be sourced from:

- Authorized dealerships.

- Online retailers specializing in lawn care equipment.

- Local hardware stores with a gardening section.