In the realm of lawn maintenance machinery, comprehending the various elements and their configurations is essential for effective operation and upkeep. A well-structured overview of individual components provides users with insights into the functionality and assembly of their equipment, enabling them to tackle maintenance tasks with confidence.

By examining the relationships between different parts, users can identify areas that may require attention or replacement. This knowledge is invaluable for ensuring the longevity and efficiency of the machine. Moreover, visual representations can serve as a handy reference for users, simplifying the process of locating and understanding specific components.

Ultimately, gaining familiarity with the arrangement of these essential elements fosters a deeper appreciation of the equipment’s engineering. This understanding not only aids in routine care but also empowers users to make informed decisions regarding repairs and enhancements.

Understanding the L111 John Deere Model

This section explores the features and characteristics of a popular lawn care machinery model renowned for its efficiency and versatility. It caters to both casual homeowners and professional landscapers seeking a reliable solution for maintaining outdoor spaces. Through a comprehensive overview, users will gain insights into the functionality and applications of this specific model, highlighting its importance in the field of garden equipment.

Key Features

- Robust construction for durability

- User-friendly controls for ease of operation

- Powerful engine ensuring optimal performance

- Versatile attachments for various gardening tasks

- Efficient fuel consumption, making it economical

Applications

- Maintaining residential lawns

- Landscaping professional gardens

- Clearing grass and weeds in large areas

- Preparing soil for planting

- Providing precise cutting for a manicured appearance

In summary, this particular model exemplifies a harmonious blend of power and practicality, making it an essential tool for anyone serious about lawn care and maintenance.

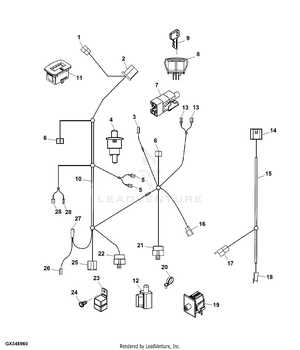

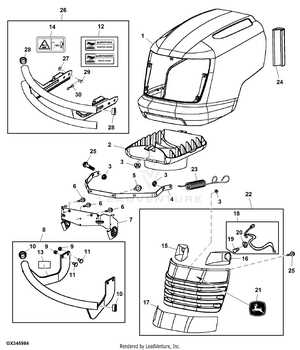

Importance of Parts Diagrams

Understanding the significance of visual representations of components in machinery is crucial for effective maintenance and repair. These illustrations provide users with a clear overview of individual elements, facilitating identification and selection during the servicing process. By offering detailed layouts, they enhance the efficiency of tasks and help prevent errors that may arise from misinterpretation.

Enhanced Troubleshooting

Visual guides play a vital role in diagnosing issues within equipment. By illustrating the relationships and positions of various elements, these resources enable technicians to pinpoint faults more quickly and accurately. This streamlined approach not only reduces downtime but also minimizes the risk of further complications arising from improper handling.

Efficient Repairs

Having access to comprehensive representations significantly aids in the repair process. Users can easily determine the required components and their arrangement, leading to more efficient restoration of functionality. This clarity not only saves time but also ensures that repairs are conducted with precision, ultimately extending the lifespan of the equipment.

Common Issues with L111 Parts

When maintaining and repairing outdoor machinery, several common challenges may arise with various components. Understanding these issues is crucial for effective troubleshooting and ensuring the longevity of the equipment. Recognizing symptoms early can prevent further complications and costly repairs.

Wear and Tear

Over time, specific elements may exhibit signs of fatigue and degradation due to continuous use. This can lead to decreased efficiency and performance. Regular inspections and timely replacements of worn components are essential to maintain optimal functioning.

Compatibility Problems

Using incompatible components can result in various operational issues. It is vital to ensure that each part is suited for the particular model, as mismatches can lead to malfunctioning and even damage to the entire system. Always consult the manufacturer’s specifications to verify compatibility.

Where to Find Replacement Components

When it comes to maintaining your equipment, locating suitable spare components is crucial for ensuring optimal performance. Various resources are available for finding high-quality replacements, whether you’re looking for specific items or general supplies. Understanding where to search can save you time and money while ensuring that your machinery operates smoothly.

One of the best places to start is online marketplaces, which often have extensive selections of components from various manufacturers. You can find competitive pricing and user reviews that can help guide your purchasing decisions. Additionally, specialized retailers focus on specific equipment types, offering knowledgeable staff who can assist with your inquiries.

Local hardware stores and authorized service centers can also be valuable resources. They typically maintain inventories of common items and may be able to order more specialized components. Lastly, online forums and community groups can provide insights and recommendations from fellow users who have experience with similar equipment.

| Resource Type | Examples | Advantages |

|---|---|---|

| Online Marketplaces | Amazon, eBay | Wide selection, competitive prices |

| Specialized Retailers | Local machinery stores | Expert advice, tailored options |

| Authorized Service Centers | Manufacturer-approved outlets | Quality assurance, reliability |

| Community Forums | Online discussion boards | Peer recommendations, shared experiences |

Step-by-Step Repair Guide

This section provides a comprehensive approach to performing repairs on your lawn care equipment. Understanding the procedure can significantly enhance your ability to troubleshoot issues and maintain optimal functionality. The following guide outlines a systematic method to assist you in resolving common problems effectively.

1. Gather Necessary Tools and Materials

Before starting the repair process, ensure you have all essential tools at hand. Common tools include wrenches, screwdrivers, and pliers, along with any replacement components required for the task.

2. Review the User Manual

Consult the equipment’s user manual for specific guidelines related to maintenance and repair. Familiarizing yourself with the recommended procedures will aid in avoiding potential mistakes.

3. Identify the Issue

Carefully examine the equipment to pinpoint the exact problem. Look for signs of wear, leaks, or irregularities that may require attention. A thorough inspection can help you understand what repairs are necessary.

4. Follow Safety Precautions

Ensure that safety measures are in place before beginning any repair work. Disconnect power sources and wear protective gear to prevent injuries during the process.

5. Execute the Repair

Proceed with the repair following the established steps. Replace any damaged parts and tighten connections as needed. Ensure that everything is reassembled correctly to avoid future complications.

6. Test the Equipment

After completing the repair, test the equipment to verify that it operates smoothly. Run it briefly to check for any remaining issues or unusual sounds.

7. Document the Process

Keep a record of the repair process for future reference. Noting down the steps taken and any parts replaced can be invaluable for subsequent maintenance tasks.

Maintenance Tips for Longevity

Ensuring the enduring performance of your equipment requires regular upkeep and attention. By adhering to a consistent maintenance routine, you can enhance the lifespan of your machinery and prevent unnecessary breakdowns. This section outlines essential practices that will help maintain optimal functionality and reliability over time.

Regular Inspections

Conducting routine checks is crucial for identifying potential issues before they escalate. Examine all critical components, including belts, filters, and fluids, to ensure they are in good condition. Addressing minor concerns promptly can save you from costly repairs in the future.

Proper Storage Practices

When not in use, store your equipment in a clean, dry environment to protect it from the elements. Covering the machinery can also shield it from dust and debris, preventing unnecessary wear. Additionally, maintaining a stable temperature and humidity level in the storage area can further enhance the longevity of your equipment.

Identifying Genuine John Deere Parts

When maintaining or repairing equipment, recognizing authentic components is essential for ensuring optimal performance and longevity. Genuine items offer reliability and are designed specifically for particular machines, which enhances functionality and efficiency. Understanding how to differentiate between original and counterfeit alternatives can save time and resources in the long run.

Here are some key characteristics to consider when identifying authentic components:

| Feature | Description |

|---|---|

| Brand Markings | Genuine items often have distinctive logos or trademarks clearly displayed on their surfaces. |

| Quality of Material | Original components are manufactured from high-grade materials, which are durable and resistant to wear. |

| Packaging | Authentic products typically come in branded packaging with detailed labels and identification numbers. |

| Pricing | While original items may be more expensive, significantly lower prices could indicate a counterfeit. |

| Supplier Credentials | Purchasing from authorized dealers or reputable suppliers ensures the authenticity of the components. |

Using Diagrams for Efficient Repairs

Visual representations play a crucial role in streamlining maintenance tasks. By providing clear illustrations of components and their relationships, these tools enable technicians and enthusiasts to identify issues quickly and carry out repairs effectively. Understanding how to interpret these visuals can significantly enhance the repair process, reducing downtime and improving overall efficiency.

Benefits of Utilizing Visuals

- Enhanced Clarity: Diagrams offer a straightforward view of how parts interact, making it easier to locate and assess problematic areas.

- Improved Organization: Visual aids help in organizing repair tasks by illustrating step-by-step procedures.

- Time-Saving: By allowing quick identification of necessary components, these representations can drastically reduce the time needed for repairs.

- Increased Accuracy: Accurate visuals minimize the chances of errors, ensuring that technicians can follow the correct procedures.

Best Practices for Using Visuals in Maintenance

- Familiarize Yourself: Take the time to understand the layout and symbols used in the visual materials.

- Keep Materials Accessible: Store diagrams in an easily reachable location for quick reference during repairs.

- Follow Step-by-Step Instructions: Utilize visuals to guide you through complex procedures, ensuring you don’t miss any critical steps.

- Regularly Update Resources: Ensure you are using the most current visuals, as manufacturers may release updates or changes.

Comparing L111 with Other Models

This section explores the similarities and differences between a specific lawn care equipment model and its counterparts in the market. Understanding how this particular machine stacks up against other variants can provide valuable insights for potential buyers and enthusiasts alike.

In terms of performance, many models offer comparable power and efficiency. However, subtle variations in design and features can lead to distinct user experiences. For instance, some alternatives may prioritize maneuverability, while others might emphasize cutting width or fuel efficiency. These factors can significantly influence a user’s choice depending on their specific needs.

Additionally, when examining durability, it is crucial to consider the materials used in construction. Some units might utilize more robust components, leading to a longer lifespan and reduced maintenance needs. This aspect is often a deciding factor for those looking to invest in a reliable piece of equipment for their lawn care tasks.

Moreover, the availability of aftermarket support and accessories can enhance the functionality of the equipment. Users may find that certain models are better supported by third-party providers, offering a wider range of attachments and enhancements. This can be particularly advantageous for those looking to customize their machines for specific applications.

Ultimately, the choice between various models should align with individual preferences and requirements. By carefully comparing the features, performance, and support options, buyers can make informed decisions that best suit their lawn care needs.

Resources for Technical Support

Accessing reliable support resources is essential for maintaining equipment and ensuring optimal performance. Users often encounter various challenges that require expert guidance and assistance. Numerous platforms and tools are available to help individuals find the information and support they need for efficient troubleshooting and repairs.

Online Forums and Communities

Engaging with online forums and communities can be a valuable way to connect with other users and experts. These platforms offer a space to share experiences, ask questions, and receive advice from knowledgeable individuals. Many members of these communities are willing to assist with troubleshooting and offer insights based on their personal experiences.

Manufacturer’s Support Services

Most manufacturers provide dedicated support services, including customer service hotlines and technical assistance. These resources are designed to help users navigate any issues they may encounter. Accessing official support ensures that the guidance received is accurate and tailored to the specific equipment in question.

Owner Experiences and Feedback

In this section, we explore the insights and opinions shared by users regarding their experiences with a specific lawn care machine. These reflections provide valuable information about the reliability, performance, and ease of use of the equipment. Users often highlight both the positive aspects and any challenges they faced during operation, offering a comprehensive view of their ownership journey.

Many owners express satisfaction with the efficiency and functionality of their machines, noting how they enhance their gardening tasks. Comments often emphasize the device’s ability to tackle various terrains and the smoothness of its operation. Additionally, users appreciate the straightforward maintenance processes that contribute to the longevity of the equipment.

Conversely, some feedback addresses areas for improvement. Common concerns include difficulties encountered with specific components or features, leading to suggestions for enhancements. These insights are invaluable for potential buyers and manufacturers alike, as they underscore the importance of user experience in product development.

Overall, the feedback gathered from owners serves as a crucial resource for understanding the practical aspects of the machine, helping others make informed decisions and enhancing future iterations of the product.