In the realm of agricultural equipment maintenance and repair, detailed visual representations play a crucial role in understanding the intricate workings of machinery. These visual aids provide comprehensive insights into the configuration and assembly of essential components.

Visual guides serve as indispensable resources for technicians and enthusiasts alike, offering a detailed look at the intricate assembly of machinery. They provide a visual roadmap that highlights the placement and interconnection of various parts, aiding in both diagnostics and assembly.

By delving into schematic diagrams, users gain a deeper understanding of the mechanical intricacies that drive agricultural machinery, empowering them to navigate maintenance and repairs with precision and efficiency.

Understanding the John Deere LA120 Structure

In this section, we delve into the intricate design and configuration of the John Deere LA120, exploring its composition and internal framework. We examine how each component integrates to form a cohesive unit, highlighting the structural integrity and functional aspects of this machinery.

The architecture of the John Deere LA120 encompasses various elements that contribute to its robustness and operational efficiency. Key structural components interact harmoniously, ensuring durability and reliability in diverse operational conditions.

Our exploration focuses on the interplay between different sections, emphasizing their roles and contributions within the overall framework. This analysis sheds light on the mechanical synergy that defines the John Deere LA120, underscoring its engineering excellence and design precision.

Essential Components of the LA120 Mower

The functionality of a riding mower depends on several key elements working together efficiently. Each component plays a specific role in ensuring smooth operation, allowing the machine to handle various tasks related to maintaining green spaces. Understanding the main elements helps in both routine maintenance and troubleshooting potential issues.

Key Mechanical Parts

- Engine: The heart of the machine, responsible for powering all movements and actions.

- Transmission: A crucial part that allows for speed control and forward or reverse motion.

- Blades: These sharp tools are used for cutting grass evenly, ensuring a clean finish.

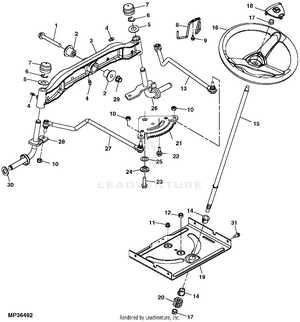

- Steering Mechanism: Provides precise control over direction, helping to navigate obstacles.

Additional Features

- Cutting Deck:

How to Identify Key Parts in Your LA120

Understanding the essential components of your equipment is crucial for maintaining its efficiency and prolonging its life. Familiarizing yourself with the core sections and their functions will help you quickly spot any issues and address them before they escalate.

First, observe the engine assembly. This area houses the heart of the machine, providing power to all other mechanisms. It’s important to note the arrangement of various connectors, belts, and filters that ensure smooth operation.

Next, focus on the transmission area, which is responsible for delivering power from the engine to the wheels. Identifying the placement of gears, levers, and control units here will be helpful during maintenance checks.

Lastly, examine the control system. This includes the steering and braking mechanisms, as well as any hydraulic systems involved. Understanding how these interact can help you navigate any operational concerns.

Maintenance Tips for the John Deere LA120

Proper care and routine upkeep are essential to ensure smooth performance and longevity of any equipment. By following a few simple practices, you can keep your machine running efficiently and avoid unnecessary issues. Regular attention to key areas can prevent costly repairs and improve overall functionality.

- Inspect the Filters: Air and fuel filters play a crucial role in keeping the engine clean. Check and replace them periodically to ensure optimal airflow and prevent contamination.

- Check Fluid Levels: Regularly monitor the oil, coolant, and hydraulic fluid levels. Refill or replace these fluids as needed to avoid overheating or engine damage.

- Sharpen the Blades: Dull cutting edges can lead to uneven results and strain the engine. Sharpening or replacing the blades will maintain cutting efficiency.

- Clean the Deck: Grass buildup under the deck can hinder airflow and reduce cutting performance. Clean it after every use to ensure proper operation.

- Tire Pressure: Uneven tire pressure can affect the balance and handling of the machine. Check the pressure regularly to ensure smooth movement.

Consistent maintenance will extend the life of your equipment and enhance its reliability during every use.

Common Issues with LA120 and Their Solutions

Many lawn tractors face challenges over time that can impact performance and longevity. Identifying and addressing these problems early can help ensure smooth operation and extend the machine’s lifespan. This section covers typical concerns users encounter and offers practical advice on how to resolve them efficiently.

Engine Struggles to Start

If the engine is having trouble starting, it could be related to a dirty air filter, faulty spark plug, or issues with fuel flow. Cleaning or replacing the air filter and checking the spark plug for wear are simple first steps. If the problem persists, inspecting the fuel lines for clogs or leaks may be necessary.

Poor Cutting Performance

Inconsistent or uneven cuts are common when blades become dull or damaged. Regularly sharpening or replacing the blades ensures clean and efficient mowing. Additionally, checking the deck for debris buildup and making sure it’s level can help improve cutting performance.

Exploring the Electrical System of the LA120

The electrical system in this model plays a crucial role in powering various functions and ensuring smooth operation. It consists of several interconnected components that work together to provide reliable energy flow, ignition, and overall functionality. Understanding how these elements operate can help maintain optimal performance and troubleshoot any issues that may arise.

Key Components of the Electrical Setup

Among the essential elements, you will find a power source, wiring network, and control mechanisms. The power source delivers energy to start the machine, while the wiring ensures the flow of electricity across various areas. Control mechanisms manage the distribution and regulation of energy, ensuring every part functions properly.

Troubleshooting Electrical Issues

When issues occur within the system, it’s important to check connections, inspect the condition of the power source, and ensure the control units are functioning as expected. Regular maintenance and timely adjustments can prevent common failures, keeping the equipment running efficiently.

Best Practices for LA120 Mower Blade Care

Maintaining the cutting tools of your lawn equipment is crucial for ensuring efficient operation and extending its lifespan. Proper upkeep of these components can result in a smoother and cleaner cut, reducing strain on the engine and improving overall performance.

- Regular Cleaning: After each use, remove any grass buildup or debris from the blades. This prevents rust and maintains sharpness.

- Sharpen Blades: Sharpen the blades every 25 hours of use or whenever the cutting seems uneven. Dull edges can tear grass, making it vulnerable to disease.

- Inspect for Damage: Check the blades for cracks, bends, or excessive wear. Damaged blades should be replaced immediately to avoid damaging the mower or the lawn.

- Balance the Blades: After sharpening, ensure the blades are balanced. Unbalanced blades can cause vibrations and uneven cuts, leading to potential equipment damage.

- Use Proper Tools: Always use the correct tools for removing and installing blades. Tighten bolts securely to avoid accidents while in operation.

Following these best practices helps keep your lawn maintenance equipment in optimal condition, ensuring a consistent, healthy cut for your lawn.

Troubleshooting the Engine of John Deere LA120

When dealing with issues related to the engine, it’s important to approach the situation methodically. Identifying the cause of malfunction can prevent further damage and ensure the system runs smoothly. Common concerns usually revolve around poor performance, irregular sounds, or difficulties starting. By carefully assessing key components, you can pinpoint the source of the issue and proceed with the appropriate solution.

Starter problems often arise when there’s insufficient power reaching the system. Check the battery connections and ensure they’re clean and tight. If the battery itself is weak or dead, it may need replacing. Additionally, inspect the starter motor for wear or potential damage.

If the engine stalls frequently, it could be related to fuel supply issues. Clogged filters, contaminated fuel, or a malfunctioning fuel pump might be at fault. Clearing any blockages or replacing faulty parts can restore smooth operation.

Finally, overheating could be caused by insufficient airflow or cooling system issues. Check for debris blocking air intake, or inspect the coolant level to ensure it’s adequate. A lack of proper ventilation can also be caused by dirty or damaged parts that need cleaning or replacement.

Transmission and Drive System Overview

The transmission and drive system plays a crucial role in ensuring smooth movement and power distribution in any vehicle. It manages the energy flow from the engine to the wheels, enabling effective motion control and speed adjustments. A well-functioning transmission setup is essential for achieving optimum performance and longevity.

Main Components

This section covers the primary elements involved in the system, including the power transmission mechanism and the drive assembly. Each part works in sync to maintain stability, control, and power transfer during operation. Here’s an outline of the core elements:

Component Function Gearbox Modifies torque and speed for optimal driving efficiency. Drive Belt Transfers power between components for seamless operation. Axle Distributes power to the wheels, ensuring balanced movement. Hydraulic System Supports smooth transmission shifting and vehicle control. Understanding the function of each component is key to maintaining an efficient and reliable drive system. Proper care of these elements ensures prolonged durability and consistent performance.

Fuel System Components in the LA120 Diagram

The fuel system plays a critical role in ensuring smooth and efficient operation. It is responsible for delivering the necessary power by providing fuel to the engine. Understanding the layout of the system helps in maintaining its performance and preventing common issues. This section focuses on the key elements involved in transporting fuel to the engine, ensuring optimal combustion and functionality.

Fuel Tank: The tank serves as the primary storage for the liquid that powers the engine. It must be well-sealed and free of contaminants to avoid clogging or damage.

Fuel Lines: These pipes are essential in guiding the fuel from the storage to other components. Any blockage or leaks here could significantly affect performance, so regular inspections are important.

Fuel Filter: Positioned between the tank and the carburetor, the filter removes impurities, ensuring only clean fuel reaches the engine. Replacing it periodically helps in maintaining efficiency.

Carburetor: This part mixes the fuel with air in precise proportions, crucial for smooth operation. Proper adjustment and cleaning are vital for the best engine performance.

Maintaining these components is essential for the overall longevity and reliability of the machine. Regular checks and timely replacements will prevent most fuel-related issues.

Upgrading or Replacing Essential Components

Maintaining or improving the efficiency of your equipment often involves evaluating key elements that may have experienced wear or simply no longer meet performance expectations. Whether you’re aiming to enhance the functionality or just need to swap out some of the original units, making the right choice can ensure the longevity and optimal performance of your machine.

Benefits of Replacing Worn Components

As machinery ages, some parts naturally degrade due to use. By proactively replacing these essential components, you reduce the risk of breakdowns and improve overall efficiency. Upgrading can also introduce newer technologies, improving both performance and ease of use.

Component Possible Upgrade Benefit Transmission