Understanding how various tools are constructed and how their individual elements work together is key to maintaining and repairing them. By gaining insight into the detailed structure, users can easily identify specific features and ensure everything functions as intended. A clear understanding of each part’s role can greatly enhance the longevity of any equipment.

In this guide, we’ll delve into the internal structure of a popular power tool, focusing on its most crucial components. We’ll explore each element’s function and how they contribute to the overall performance. This will provide users with a better grasp of how to maintain their equipment and troubleshoot any issues that may arise.

Through detailed illustrations and descriptions, we will break down the device into its core segments, making it easier to identify, replace, or repair various elements. Whether you’re a professional or an enthusiast, having access to this information will help you handle technical tasks with confidence.

Dewalt DCP580: Detailed Component Overview

This section provides an in-depth look at the key components that make up the handheld planer, offering insights into the functions and roles of each part within the tool’s system. The following breakdown will help users understand how the various elements work together to ensure efficient performance.

Main Assembly Elements

The core structure of the planer includes several interconnected elements, all designed to enhance precision and user control. These parts form the base of the tool, ensuring stability and smooth operation.

| Component | Function | |||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cutterhead | Responsible for material removal, the cutterhead spins at high speed to plane surfaces with accuracy. | |||||||||||||||||||||||||||||||

| Motor |

| Specification | Description |

|---|---|

| Length | Typically ranges from 6 to 10 feet, allowing flexibility during use. |

| Gauge | Commonly 16 or 14 AWG, indicating the thickness of the wire, affecting current capacity. |

| Material | Usually made of rubber or PVC for durability and resistance to abrasion. |

| Connector Type | Standard three-prong design to ensure proper grounding and safety. |

Electrical Components

In addition to the power cord, the electrical system comprises various components that ensure proper operation. Key parts include:

| Component | Function |

|---|---|

| Motor | Converts electrical energy into mechanical energy to perform tasks. |

| Switch | Controls the power flow to the motor, enabling the user to turn the tool on or off. |

| Fuse | Provides overcurrent protection by breaking the circuit in case of a fault. |

| Transformer | Steps down the voltage for tools that require lower operational levels. |

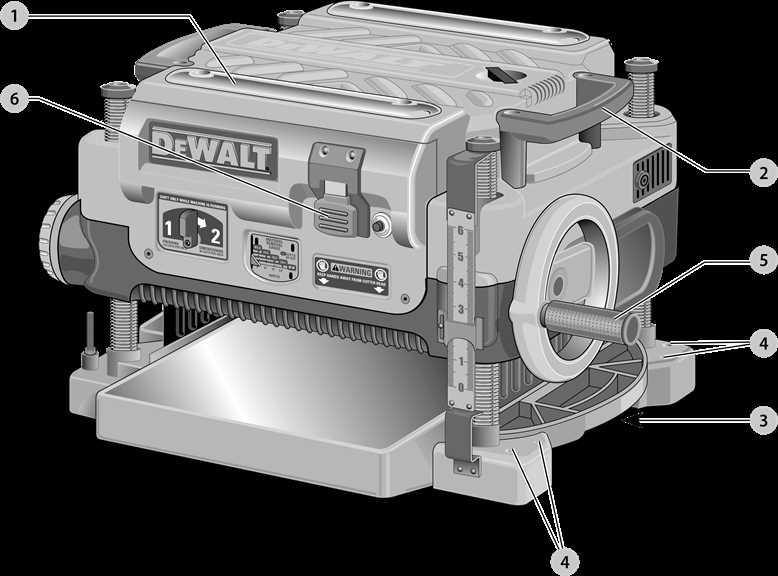

Exploded View of Internal Components

The detailed representation of the internal mechanisms provides valuable insights into the assembly and functionality of the tool. This visual guide serves to enhance understanding of how each element interacts within the system, facilitating maintenance and repair.

Examining the exploded view reveals the intricate arrangement of components, highlighting key parts such as the motor housing, gear assembly, and power switch. Each section is meticulously designed to contribute to the overall performance, ensuring efficiency and reliability in operation.

By studying this illustration, users can identify specific areas for troubleshooting or upgrades. It offers a clear perspective on how to approach disassembly, ensuring that reassembly is straightforward and effective. Understanding the layout not only aids in repairs but also empowers users to maximize the tool’s potential.

Replacement Parts for the DCP580 Planer

When it comes to maintaining your woodworking tool, having the right components is crucial for optimal performance and longevity. Whether you are looking to replace worn-out elements or upgrade specific features, knowing the available options can enhance your experience. This section highlights essential replacements that ensure your device operates smoothly and efficiently.

Below is a table summarizing the commonly needed components along with their functions:

| Component | Description |

|---|---|

| Blade Assembly | Critical for achieving precise cuts, these blades are essential for effective planing. |

| Motor Housing | Protects the internal mechanisms and provides stability to the tool during operation. |

| Power Switch | Facilitates easy control of the machine, ensuring safety and convenience. |

| Depth Adjustment Knob | Allows users to set the desired cutting depth, improving versatility in different tasks. |

| Dust Chute | Helps in efficient dust collection, keeping the workspace clean and safe. |

Having access to quality replacements is vital for sustaining the functionality of your tool. Regular checks and timely replacements can prevent unexpected breakdowns and maintain high efficiency.

Upgrades and Accessories for the DCP580

Enhancing the performance and functionality of your handheld sander can significantly improve your woodworking experience. By integrating various upgrades and accessories, users can tailor their tools to meet specific project needs and optimize their efficiency. Below are some recommended enhancements that can elevate your tool’s capabilities.

Popular Accessories

- Dust Extraction Attachments: Maintaining a clean workspace is crucial. These attachments efficiently capture debris, ensuring better visibility and cleaner results.

- Fine Grit Sanding Discs: For achieving a smooth finish on delicate surfaces, fine grit discs are essential. They provide a polished look without damaging the material.

- Backing Pads: Upgrading to high-quality backing pads can improve the adhesion of sanding discs, providing a more stable sanding experience.

Performance Upgrades

- High-Performance Battery: Opting for a more powerful battery can extend runtime, allowing for longer working sessions without interruptions.

- Variable Speed Control: Installing a speed control feature enables users to adjust the sanding speed, catering to different materials and applications.

- Ergonomic Grip Enhancements: Upgrading to more comfortable grips can reduce fatigue during extended use, making tasks more enjoyable.