Maintaining and troubleshooting your machinery requires a comprehensive understanding of its individual elements. Each component plays a vital role in the overall functionality and efficiency of the device. By familiarizing yourself with these parts, you can enhance performance and ensure longevity.

Visual aids are invaluable for grasping the relationship between various sections of the equipment. They not only simplify the assembly process but also assist in identifying potential issues. A well-structured representation can serve as a guide, making repairs and replacements more manageable.

Whether you are an experienced technician or a hobbyist, having access to a detailed visual reference is essential. It empowers you to approach repairs with confidence and precision, ultimately leading to improved operation and satisfaction.

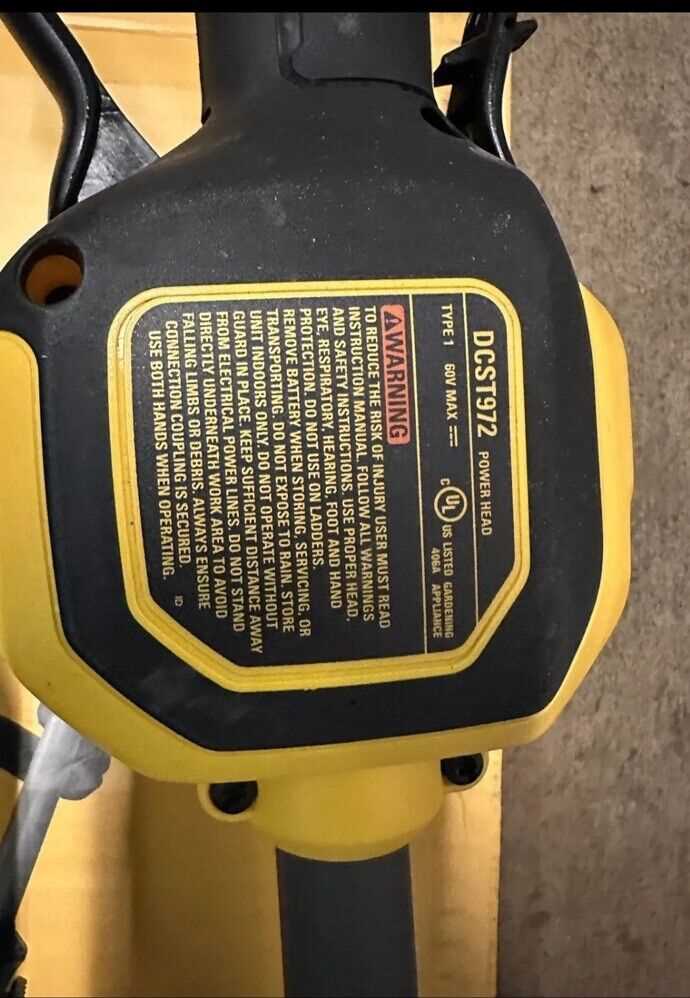

Key Features of the Model

This model stands out in its category, offering exceptional performance and reliability for a variety of tasks. Users can expect a robust design that enhances usability and effectiveness, making it an excellent choice for both professional and home use.

Powerful Motor: Equipped with a high-performance motor, this tool delivers impressive cutting capabilities, ensuring efficiency in all applications.

Lightweight Design: The ergonomic structure minimizes user fatigue during prolonged use, allowing for greater control and precision.

Versatile Functionality: This model is designed to handle a wide range of cutting tasks, making it a versatile addition to any toolkit.

Easy Maintenance: With user-friendly features, maintaining this tool is straightforward, ensuring it remains in optimal condition for years to come.

Durable Construction: Crafted from high-quality materials, this tool is built to withstand rigorous use, providing long-lasting reliability and performance.

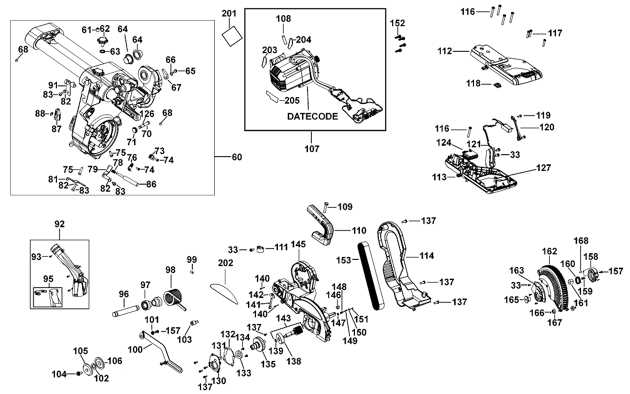

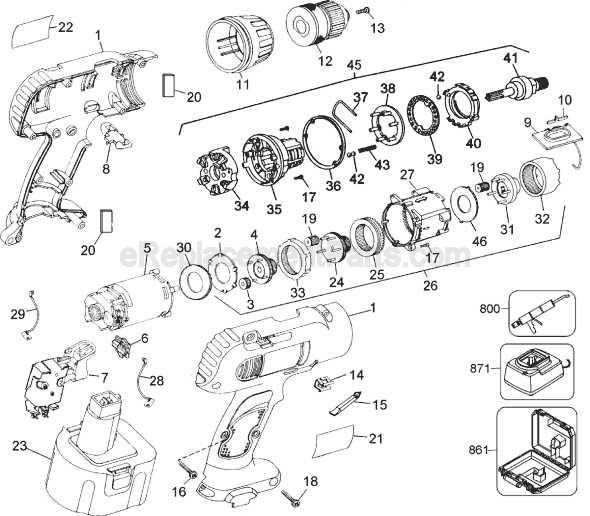

Understanding the Parts Diagram

Comprehending the layout of components is essential for effective maintenance and repairs of any machinery. A detailed representation of individual elements provides insight into their arrangement and interconnections, facilitating troubleshooting and assembly tasks. This section will explore the significance of these visual aids and how they enhance users’ understanding of their tools.

The Importance of Visual Representations

Visual representations serve as crucial references, offering clarity on the relationship between different components. They allow users to quickly identify parts, making it easier to determine what needs replacement or repair. Moreover, these illustrations help in understanding the assembly process, ensuring that each component is correctly positioned for optimal performance.

Key Features of Component Layouts

Understanding key features in these representations can significantly enhance user experience. Common elements include:

| Feature | Description |

|---|---|

| Labels | Indicate specific elements for easy identification. |

| Lines | Show connections and relationships between different parts. |

| Legend | Explains symbols or colors used for clarity. |

By familiarizing oneself with these features, users can navigate the complexities of their equipment with confidence and proficiency.

Importance of Proper Maintenance

Regular upkeep of tools and equipment is essential for ensuring optimal performance and longevity. Neglecting maintenance can lead to reduced efficiency, increased wear, and potential safety hazards. Adopting a consistent maintenance routine helps in identifying issues before they escalate, ultimately saving time and costs in repairs.

Proper care not only enhances functionality but also improves user safety. Well-maintained devices are less likely to malfunction, which reduces the risk of accidents. Additionally, following maintenance guidelines can extend the lifespan of tools, making them a worthwhile investment.

| Maintenance Task | Frequency | Benefits |

|---|---|---|

| Cleaning | After each use | Prevents buildup and maintains performance |

| Lubrication | Monthly | Reduces friction and wear |

| Inspection | Quarterly | Identifies wear and potential issues |

| Sharpening | As needed | Ensures efficiency and quality of work |

Common Replacement Parts Explained

Understanding the essential components of a tool can significantly enhance its longevity and performance. Many users often encounter situations where specific elements require substitution due to wear and tear or damage. This section outlines the most frequently replaced components, providing insights into their functions and importance.

- Batteries: These are crucial for the operation of cordless tools, providing the necessary power. Regularly replacing old or depleted batteries ensures optimal performance.

- Cutting Blades: Over time, blades can become dull or chipped. Swapping out old blades for new ones is essential for maintaining cutting efficiency and precision.

- Motor Brushes: These components help transfer electricity to the motor. If a tool experiences reduced power, checking and replacing motor brushes might be necessary.

- Housing Units: The outer casing can sustain damage from drops or impacts. Replacing a broken housing not only improves aesthetics but also protects internal components.

- Filters: Dust and debris can clog filters, impacting performance. Regular replacement ensures that the tool operates smoothly and efficiently.

By staying informed about these key elements, users can ensure their tools remain in peak condition, minimizing downtime and maximizing productivity.

Tools Needed for Repairs

When it comes to performing maintenance or fixing equipment, having the right instruments at your disposal is essential for ensuring efficiency and effectiveness. Utilizing appropriate tools not only simplifies the repair process but also minimizes the risk of damage to the device.

Key implements may include wrenches, screwdrivers, and pliers, which are fundamental for loosening or tightening various components. Additionally, specialized tools designed for specific functions can greatly enhance the repair experience. Ensuring that you have a comprehensive toolkit ready will facilitate smoother repairs and help maintain the longevity of the machinery.

Identifying Wear and Tear Signs

Recognizing indicators of deterioration is crucial for maintaining the longevity and efficiency of your tools. Regular inspections can help in detecting issues before they escalate, ensuring optimal performance during use.

Common signs of wear include frayed cables, which may expose wiring and pose safety hazards, and worn-out components that can affect functionality. Additionally, look for unusual noises during operation, which often signal internal damage. A thorough check of all moving parts can reveal any abnormal wear patterns that might require attention.

Taking the time to assess your equipment regularly not only enhances safety but also extends the lifespan of your tools. By addressing these signs promptly, you can avoid costly repairs and maintain the effectiveness of your equipment.

Tips for Efficient Troubleshooting

When encountering issues with your equipment, a systematic approach can significantly enhance the problem-solving process. By following a few practical strategies, you can quickly identify and resolve malfunctions, ensuring optimal performance.

Start by gathering essential tools and documentation related to your device. Familiarize yourself with its features and functionalities, as this knowledge will aid in diagnosing problems more effectively. When a malfunction occurs, begin by examining the most common issues that could be causing the problem.

| Common Issues | Possible Solutions |

|---|---|

| Device not starting | Check the power source and connections |

| Inconsistent performance | Inspect for debris and ensure proper maintenance |

| Unusual noises | Look for loose parts and lubricate moving components |

| Battery not charging | Test the battery and verify charger functionality |

By following these suggestions and maintaining a methodical approach, you can efficiently troubleshoot issues and keep your tools in peak condition.

Where to Purchase Replacement Parts

Finding components for your equipment is essential for maintaining its performance and longevity. There are several reliable sources to consider when looking for new items that can help restore your tool to its optimal state. Whether you are seeking to replace a worn-out element or upgrade your device, understanding where to look can make the process smoother.

Authorized Retailers

One of the best places to find quality replacements is through authorized sellers. These retailers often carry a comprehensive selection of genuine components, ensuring compatibility and reliability. Additionally, purchasing from recognized dealers provides the assurance of authentic products, often backed by warranties.

Online Marketplaces

For convenience, online platforms can be an excellent option. Many e-commerce websites specialize in offering a vast range of components for various tools. When shopping online, ensure that the seller has good reviews and offers return policies in case the item does not meet your expectations. This method allows you to compare prices easily and find the best deals available.

Step-by-Step Repair Process

Repairing a tool can be a straightforward process if you follow a systematic approach. By understanding the components and their functions, you can effectively troubleshoot and resolve issues that may arise during operation. Here’s a structured guide to help you navigate the repair process efficiently.

- Gather Necessary Tools and Materials:

- Replacement components

- Basic hand tools (screwdrivers, wrenches)

- Safety gear (gloves, goggles)

- Identify the Problem:

Start by observing the tool during use to pinpoint any malfunction. Common issues include unusual noises, loss of power, or failure to start.

- Disassemble the Tool:

Carefully remove the outer casing to access the internal mechanisms. Keep track of all screws and small parts to ensure a smooth reassembly.

- Inspect Internal Components:

Look for any signs of wear or damage, such as broken parts or debris that may hinder operation. Take notes of any components that need replacement.

- Replace Faulty Parts:

Install new components where necessary, ensuring they are compatible and properly fitted. Refer to manuals or online resources for guidance on assembly.

- Reassemble the Tool:

Carefully put the tool back together, following the reverse order of disassembly. Double-check that all parts are securely fastened.

- Test the Tool:

Before full operation, conduct a preliminary test to ensure everything functions as expected. Look for any irregularities during the test run.

- Final Inspection:

Once testing is complete, perform a thorough check to confirm that all components are working correctly and there are no leftover parts.

Following these steps will help you successfully restore functionality to your equipment, ensuring it operates efficiently for future tasks.

Resources for Further Assistance

When seeking support for maintenance or troubleshooting, a variety of resources are available to ensure users can effectively resolve issues. These materials can offer valuable insights and guidance tailored to specific equipment models.

Online Forums and Communities

Participating in online discussions can provide access to a wealth of shared experiences and advice from fellow users. Many enthusiasts and professionals frequent forums dedicated to tool maintenance and repair, offering solutions and recommendations based on personal encounters.

Manufacturer’s Website and Support

For official information, visiting the manufacturer’s website is a reliable option. Here, users can find comprehensive manuals, FAQs, and troubleshooting tips. Additionally, reaching out to customer support can help clarify any specific questions or concerns regarding equipment usage.