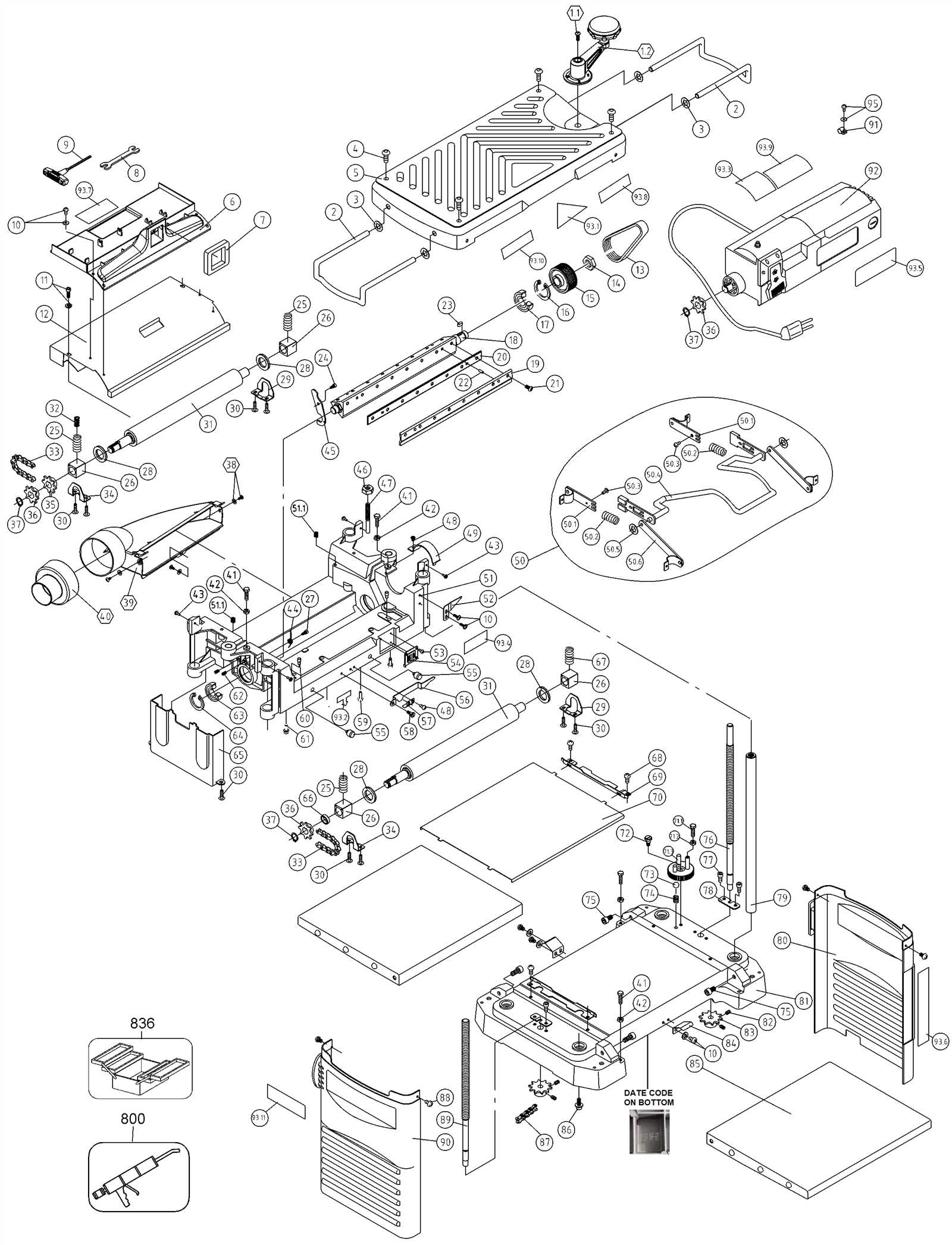

Understanding the assembly and organization of essential tools is crucial for both maintenance and effective usage. This section delves into the intricate arrangement of various elements that contribute to the functionality of a specific woodworking machine. By familiarizing oneself with these components, users can enhance their operational efficiency and troubleshoot potential issues more effectively.

Accurate knowledge of the individual segments not only aids in efficient repairs but also fosters a deeper appreciation for the craftsmanship involved in tool design. Recognizing the significance of each element encourages users to engage in proper upkeep, ultimately extending the lifespan of their equipment. Moreover, grasping the layout can facilitate smoother operations, empowering users to achieve their woodworking objectives with greater ease.

As we navigate through the various segments, emphasis will be placed on the role each part plays in the overall functionality. This exploration aims to equip users with valuable insights, enabling them to tackle any challenges that may arise during the use of their machinery. Engaging with the details presented here will serve as a foundational step towards mastering the intricacies of this vital equipment.

This section provides a comprehensive insight into a specific tool that enhances woodworking projects. Understanding its components is essential for effective maintenance and optimal performance. Each part plays a vital role in the functionality, ensuring precision and reliability in various tasks.

The subsequent table outlines the main elements of this tool, detailing their functions and importance:

| Component | Function |

|---|---|

| Motor | Drives the machine, providing necessary power for operation. |

| Cutter Head | Houses the blades, enabling the cutting of materials to desired thickness. |

| Feed Roller | Assists in smoothly guiding the material through the machine. |

| Depth Adjustment Mechanism | Allows users to set the cutting depth according to project requirements. |

| Table | Provides a stable surface for supporting materials during processing. |

Key Features of DW734

This high-performance woodworking tool offers a range of innovative characteristics that enhance its functionality and user experience. Designed for efficiency, it integrates advanced technology to ensure precision and reliability in various applications.

Powerful Motor: The device is equipped with a robust motor that delivers exceptional performance, allowing users to tackle even the toughest materials with ease.

Compact Design: Its sleek and lightweight construction makes it highly portable, enabling users to transport it effortlessly to different job sites without compromising on stability.

Easy Blade Replacement: The tool features a user-friendly blade change mechanism that simplifies maintenance, ensuring minimal downtime and maximum productivity.

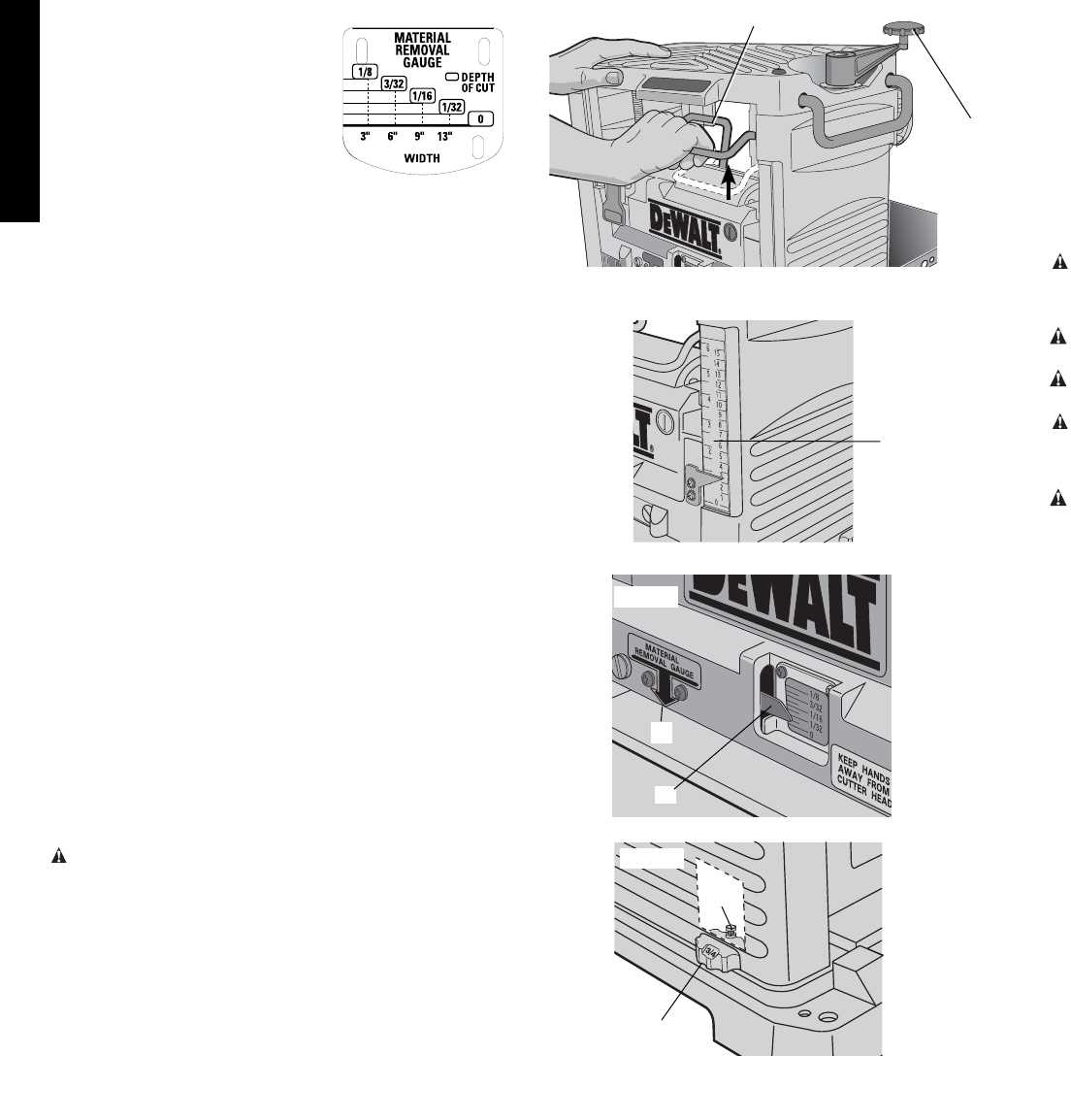

Adjustable Depth Settings: With adjustable depth controls, users can customize their cuts to achieve the desired thickness, providing versatility for various projects.

Durable Build: Constructed with high-quality materials, this tool is designed to withstand rigorous use, ensuring longevity and reliability in demanding work environments.

Importance of Parts Diagrams

Understanding the structure and components of a machine is crucial for effective maintenance and repair. Visual representations that illustrate the arrangement of elements facilitate the identification of specific units, ensuring smoother troubleshooting processes. By having access to these detailed visuals, users can quickly pinpoint areas that require attention or replacement.

Clarity and Efficiency are two significant benefits offered by these visual aids. They provide clear guidance, allowing individuals to follow the assembly or disassembly procedures with confidence. This clarity reduces the risk of errors during repairs, which can lead to improved machine performance and longevity.

Furthermore, these resources enhance the learning experience for both novice and experienced users. They serve as educational tools, helping individuals grasp the operational aspects of their equipment. With a solid understanding of each component’s function, users can make informed decisions regarding maintenance and upgrades.

Common Replacement Parts

Maintaining power tools often requires the replacement of certain components to ensure optimal performance and longevity. Identifying the most frequently worn-out parts can help users keep their equipment running smoothly.

One of the essential components often needing replacement is the blade. Over time, blades can become dull or damaged, impacting cutting efficiency. Additionally, belts play a crucial role in the operation of these tools; worn or frayed belts can cause performance issues and should be inspected regularly.

Another important item is the motor brush. These brushes wear down with use and can lead to reduced power if not changed periodically. Furthermore, bearings are vital for smooth operation, and if they become noisy or stiff, it’s advisable to replace them to prevent further damage.

Finally, checking seals and gaskets is essential, as these can deteriorate over time, leading to leaks or operational inefficiencies. Regular maintenance and timely replacement of these components can significantly enhance the tool’s performance and extend its lifespan.

Understanding Part Numbers

In the realm of tools and machinery, each component is assigned a unique identifier, facilitating easy reference and ordering. These identifiers play a crucial role in ensuring that users can efficiently locate and procure the necessary elements for maintenance or replacement. Recognizing the structure and significance of these identifiers can enhance the overall user experience and streamline repair processes.

The Importance of Unique Identifiers

Unique identifiers simplify the process of finding the correct component, minimizing errors during ordering and repair. When seeking a specific item, users can quickly cross-reference the identifier with manufacturer catalogs or online resources to ensure compatibility with their equipment.

Decoding the Structure

The structure of these identifiers typically consists of a combination of letters and numbers, each segment conveying specific information about the component. Understanding how to interpret these segments can aid users in recognizing the relationships between different parts, further enhancing their ability to maintain their machinery effectively.

Maintaining Your DW734

Proper upkeep of your tool is essential for ensuring its longevity and optimal performance. Regular maintenance helps prevent common issues and allows you to achieve the best results during your projects. By following a few straightforward guidelines, you can keep your equipment running smoothly and efficiently.

Regular Cleaning is one of the most important aspects of maintenance. After each use, it is advisable to remove any sawdust or debris that may accumulate on the surface and in the motor area. This practice not only improves the tool’s efficiency but also reduces the risk of overheating.

Inspection of Components should be carried out periodically. Examine the blades, bearings, and belts for signs of wear or damage. Replacing worn parts promptly can prevent more serious issues down the line. Ensure that all components are properly aligned and secured to maintain accuracy and safety during operation.

Lubrication of moving parts is crucial. Applying the appropriate lubricant helps minimize friction and prolongs the life of your tool. Consult the manufacturer’s guidelines for recommended lubricants and intervals for application.

By incorporating these simple practices into your routine, you can enhance the performance and durability of your equipment, ensuring it remains a reliable partner for all your tasks.

Troubleshooting Common Issues

When working with power tools, encountering challenges is not uncommon. Understanding how to address frequent problems can enhance the efficiency of your equipment and extend its lifespan. This section will provide guidance on identifying and resolving typical issues that may arise during operation.

Identifying Problems

Before attempting repairs, it is essential to pinpoint the exact nature of the issue. Common signs of malfunction include:

- Unusual noises during operation

- Inconsistent power delivery

- Overheating of components

- Inability to start

Resolution Steps

Once you have identified the problem, follow these steps to troubleshoot:

- Ensure the device is disconnected from the power source.

- Inspect the tool for any visible damage or loose connections.

- Check the power supply to confirm it is functioning properly.

- Refer to the user manual for specific guidance related to the identified issue.

- Replace any damaged components as needed.

By systematically addressing these challenges, you can maintain optimal performance and ensure safety during use.

Where to Find Parts

Locating components for your equipment can often seem challenging, but with the right resources, the process can be straightforward and efficient. Whether you need replacements for maintenance or upgrades, understanding where to search is essential.

Online Retailers

Many online platforms specialize in offering a variety of components for different models. These websites typically provide detailed listings, including specifications and pricing, allowing you to compare options easily. Here are some popular sites to consider:

- Major e-commerce platforms

- Specialty tool supply stores

- Manufacturer-approved vendors

Local Supply Stores

Your nearby hardware or tool supply stores can also be valuable resources. They often carry common components and can assist you in identifying the right items for your equipment. When visiting these locations, consider the following:

- Check if they have a dedicated section for equipment components.

- Ask staff for assistance; they may have access to catalogs or ordering systems.

- Inquire about special orders for hard-to-find items.

Exploring Accessories for DW734

When working with power tools, the right accessories can enhance performance and improve the overall user experience. This section delves into various supplementary components designed for a specific model, showcasing how they can optimize functionality and efficiency during use.

Types of Essential Accessories

Various types of attachments and enhancements are available, catering to different tasks and preferences. Some of the most sought-after options include:

| Accessory Type | Description |

|---|---|

| Cutter Blades | Specialized blades for achieving precise cuts in various materials. |

| Dust Collection Systems | Attachments that help maintain a clean workspace by minimizing debris. |

| Replacement Belts | Durable belts that ensure consistent power transmission for optimal performance. |

| Safety Guards | Essential components that enhance user safety while operating machinery. |

Benefits of Using Accessories

Incorporating the right accessories can significantly boost the versatility and capability of your tools. From improving precision to enhancing safety, these additions ensure that each task is performed efficiently and effectively.

Assembly Instructions for Parts

This section provides essential guidance on the assembly of components within your tool. Understanding the correct sequence and method for putting together various elements is crucial for ensuring optimal performance and longevity of your equipment.

Tools Required

Before starting the assembly process, gather the following tools:

- Screwdriver

- Wrench

- Pliers

- Allen key

Assembly Steps

Follow these steps to successfully assemble the components:

| Step | Description |

|---|---|

| 1 | Begin by organizing all elements on a clean, flat surface. |

| 2 | Attach the main body by securing the screws in place with the screwdriver. |

| 3 | Install any additional accessories or attachments as per the instructions. |

| 4 | Ensure all connections are tight and secure to prevent any issues during operation. |

By following these detailed instructions, you will achieve a proper assembly, ensuring that your device operates effectively and safely.

Customer Reviews and Feedback

This section provides insights into user experiences and evaluations regarding a specific tool. Feedback from customers plays a crucial role in understanding the product’s performance, reliability, and overall satisfaction. By sharing their opinions, users contribute to a broader conversation about the effectiveness and usability of the equipment.

Many individuals have praised the durability and efficiency of the model, highlighting its ability to perform under various conditions. Users often express appreciation for its user-friendly features, making it accessible for both professionals and hobbyists. However, some reviews also point out areas for improvement, such as the need for clearer instructions or enhanced support from the manufacturer.

Overall, the feedback reveals a diverse range of experiences that can guide potential buyers in making informed decisions. By considering the opinions of existing users, new customers can better understand what to expect and how to optimize their use of the tool.