Understanding the inner workings and the various elements of a powerful cleaning machine can greatly aid in maintaining its efficiency and extending its lifespan. Each component plays a crucial role in delivering the performance expected from such equipment, making it essential to familiarize oneself with its detailed layout and key sections.

For those who rely on consistent and efficient operation, knowing how each element is arranged provides valuable insights into its functionality. From the core assembly that drives pressure to the intricate mechanisms responsible for stability and control, each aspect requires careful attention.

Identifying the specific elements that ensure optimal performance allows users to address issues more swiftly and make informed choices when replacements are necessary. This overview serves as a guide to better understand the arrangement and purpose of every integral section within this machine.

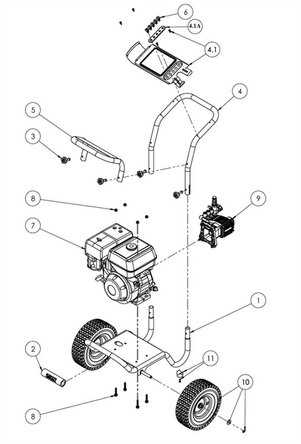

Overview of the Dewalt DXPW3835

The unit is a powerful solution for demanding outdoor cleaning tasks. Its robust build is designed to deliver high pressure, making it suitable for a wide range of heavy-duty applications. It combines efficiency and durability, providing a consistent and reliable performance for users seeking thorough and fast cleaning results.

Equipped with a sturdy frame and high-performance components, this machine ensures long-term usability even in challenging environments. The design emphasizes ease of use, featuring a user-friendly control panel and ergonomic handles for better maneuverability. Its capability to handle tough grime and dirt makes it an excellent choice for both residential and commercial needs.

For those looking for a model that balances power and user convenience, this device stands out due to its advanced features. It is engineered to meet the needs of professionals and hobbyists alike, offering a blend of power, precision, and durability. Whether tackling stubborn stains or preparing surfaces, the machine consistently delivers top-tier results.

Key Components and Functions

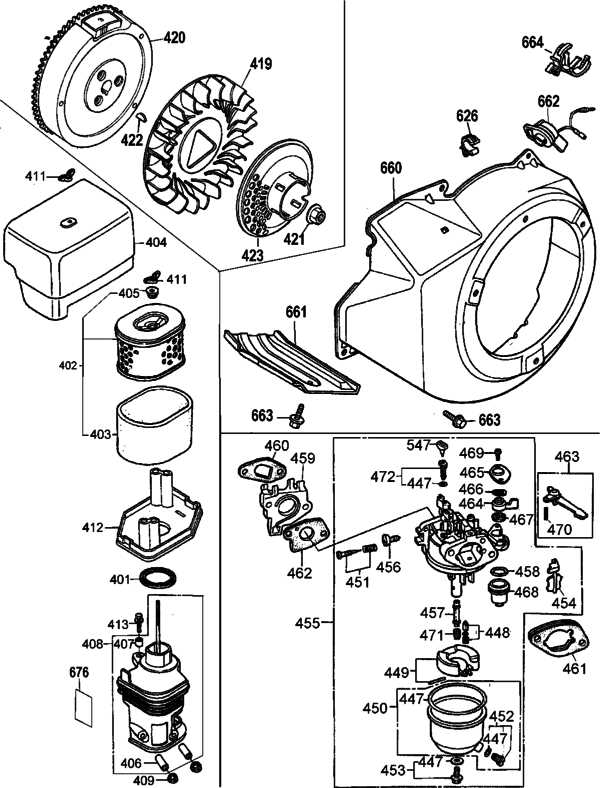

The structure of this equipment relies on several crucial elements working together to ensure optimal operation. Each component plays a specific role, contributing to the overall performance and reliability of the unit. Understanding these elements can help in maintaining the system’s functionality and troubleshooting any issues.

- Pump System: The heart of the setup, responsible for generating the required pressure to tackle tough cleaning tasks. It ensures a consistent flow, allowing for efficient removal of dirt and grime.

- Engine Mechanism: This part powers the entire system, converting fuel into the energy needed to drive other components. It plays a critical role in ensuring that the machine maintains the necessary force during operation.

- Nozzle Assembly: Allows for various output settings, adjusting the pressure and spray pattern according to the task at hand. It provides versatility, making it suitable for different surfaces and applications.

- Frame and Wheels: Supports the overall structure, making transportation easy across different terrains. The robust frame offers durability while the wheels facilitate mobility.

- Hose Connection: Channels the water from the pump to the nozzle, ensuring a smooth and controlled delivery. A quality hose is vital for maintaining pressure without leaks or interruptions.

- Control Panel: Enables the user to adjust settings and monitor the operation. It simplifies the process, allowing for a more tailored and efficient performance.

Each of these elements is integral to the system’s operation, providing the necessary bala

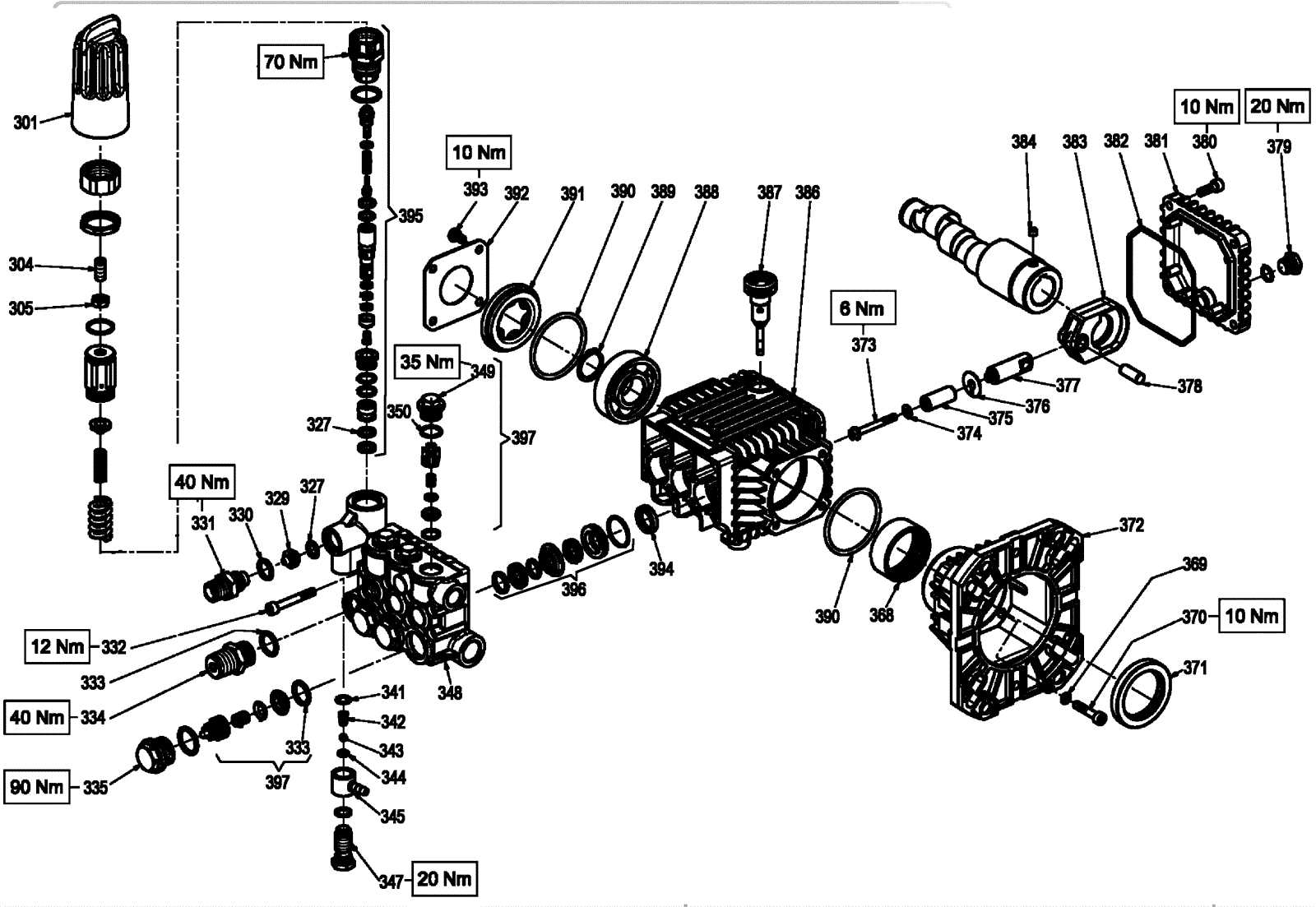

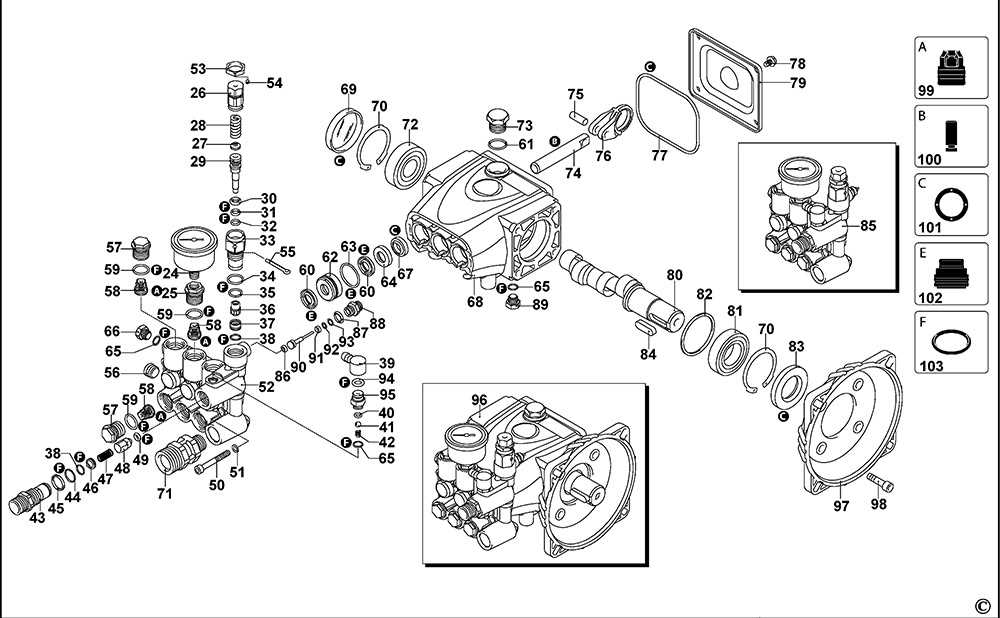

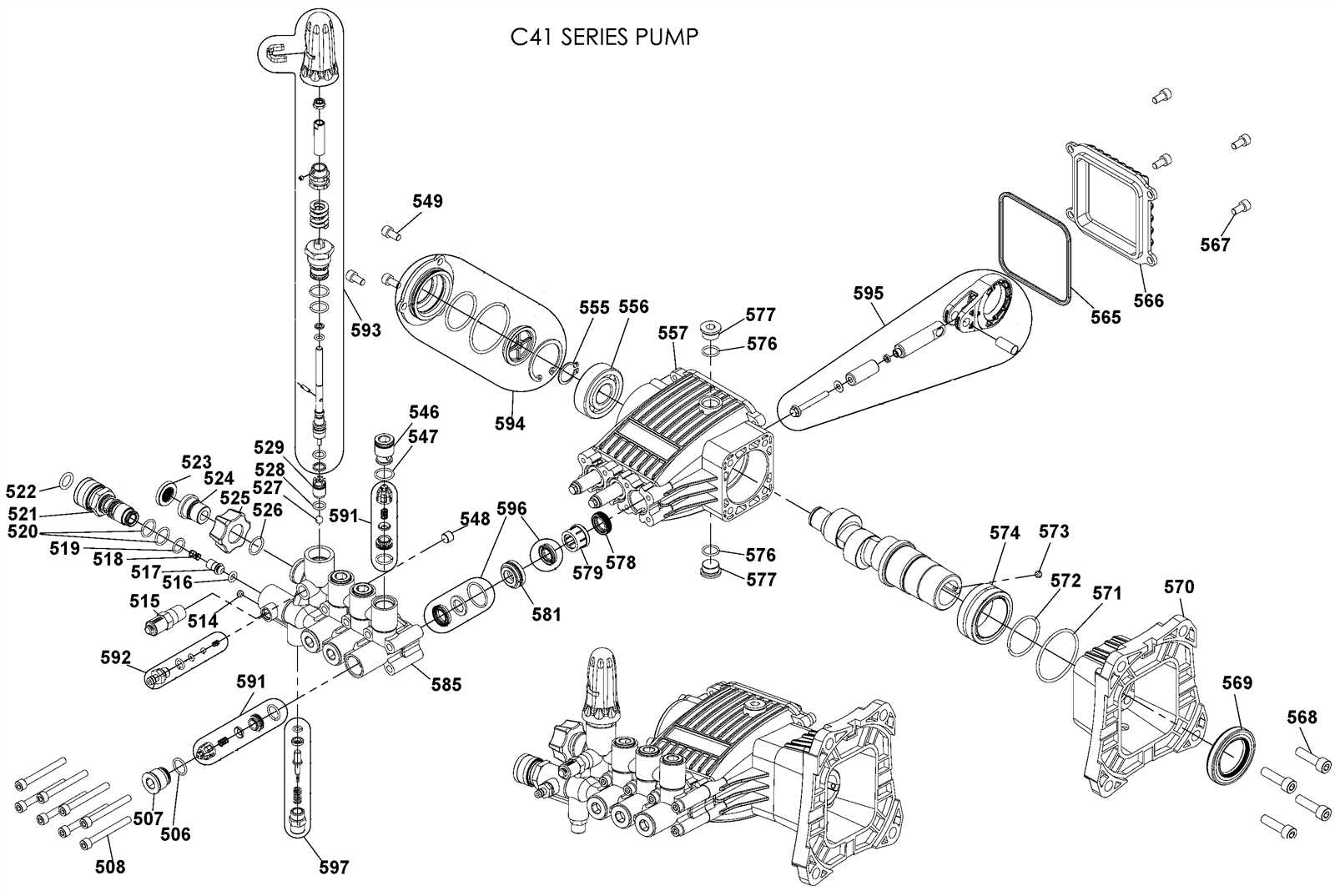

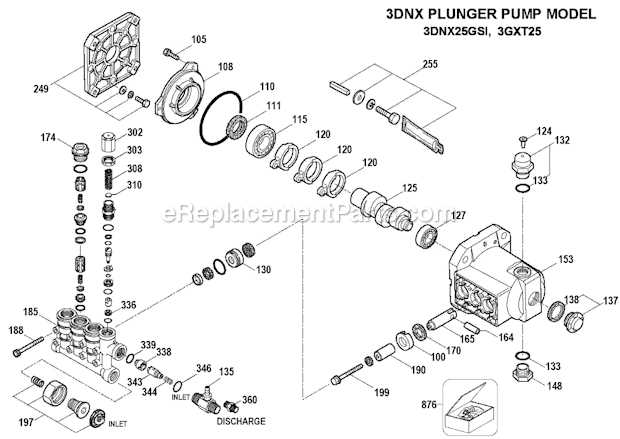

Exploring the Pump Assembly

The core of the water pressure system relies on a meticulously designed mechanism that ensures efficient operation and longevity. This segment delves into the intricate workings of this essential component, offering a closer look at how the various elements work together to maintain consistent flow and power.

Pump Structure and Materials: The assembly is crafted from robust materials to withstand high pressure and frequent use. Its main body often features reinforced alloys, providing both durability and resistance to wear. Internal seals and gaskets play a critical role in preventing leaks, ensuring that pressure remains stable during operation.

Key Components and Their Roles: Within the mechanism, several vital parts function harmoniously to produce the desired water force. The inlet and outlet valves regulate the movement of water, while the pistons and plungers generate the necessary pressure. These elements work together to convert mechanical energy into the powerful output required for various applications.

The precision and alignment of these internal elements are crucial for smooth performance. Regular maintenance, such as inspecting seals and lubricating moving parts, can significantly extend the lifespan of this essential machinery. Understanding the arrangement of these elements allows users to identify potential issues and ensure optimal functioning of the system.

Understanding the Frame Structure

The structural foundation plays a crucial role in ensuring stability and durability. It is designed to support various components while maintaining balance during operation. This framework not only provides strength but also ensures that the equipment remains resilient under heavy use.

Crafted from robust materials, the construction is built to endure harsh conditions, offering long-term reliability. Its design prioritizes both user safety and operational efficiency, ensuring that all essential elements are securely housed and protected. Each segment of the structure is meticulously aligned, promoting an even weight distribution, which reduces strain on specific points.

Moreover, the layout is engineered for easy access during maintenance, making it simpler to perform inspections or adjustments. This approach minimizes downtime and extends the overall lifespan, keeping the machine in optimal working condition. Such a design ensures that each component is supported effectively, allowing for smooth and consistent performance.

How the Motor Operates

The functioning of the motor relies on a sequence of coordinated actions that convert electrical energy into mechanical force. This transformation allows for the generation of motion, enabling various mechanical tasks to be performed efficiently. The process is controlled by specific components that work together to ensure smooth operation.

Energy Conversion Process

The motor’s core mechanism revolves around converting electricity into rotational movement. When current flows through the winding, it creates a magnetic field. This field interacts with permanent magnets or other electromagnets within the system, causing the rotor to spin. The speed and torque are influenced by the input power and the design of the internal elements.

Cooling and Maintenance

As the motor generates power, heat is also produced due to resistance within the windings and friction in the bearings. Effective cooling systems, such as air vents or liquid cooling, help maintain optimal temperature levels, preventing overheating. Regular checks of the internal components and lubricating the moving parts ensure long-term reliability and efficiency.

High-Pressure Hose and Its Role

A high-pressure hose is an essential component in various cleaning and industrial applications, designed to withstand significant force while delivering fluid effectively. Its functionality is critical for ensuring that pressure washing and similar tasks are performed efficiently and safely. Understanding the characteristics and maintenance of this vital accessory can enhance performance and longevity.

Key features and advantages of high-pressure hoses include:

- Durability: Constructed from robust materials, these hoses are engineered to resist wear and tear, providing extended service life.

- Pressure Resistance: Capable of handling high pressures, they facilitate effective cleaning and operational tasks without the risk of bursting or leakage.

- Flexibility: The design allows for easy maneuverability, enabling users to reach various angles and surfaces.

To maximize the efficiency of a high-pressure hose, regular inspection and proper handling are crucial. Consider the following maintenance tips:

- Inspect for any signs of wear, such as cracks or kinks.

- Ensure proper connections to prevent leaks.

- Store the hose in a cool, dry place to avoid damage from extreme temperatures.

In summary, the high-pressure hose plays a pivotal role in optimizing performance across multiple applications, ensuring that tasks are executed effectively while maintaining safety and reliability.

Breakdown of the Spray Gun Assembly

The spray gun assembly is a crucial component of any high-pressure cleaning system, playing a vital role in delivering a controlled flow of cleaning solution. Understanding its structure and function can significantly enhance the maintenance and troubleshooting process.

At the core of this assembly lies the trigger mechanism, which allows for precise control over the release of fluid. When the trigger is engaged, it opens a pathway for the cleaning solution, enabling it to exit the nozzle at high speed. This action is complemented by a nozzle designed to create various spray patterns, catering to different cleaning tasks, from wide dispersal for larger surfaces to a focused jet for stubborn stains.

Another integral element is the handle, which provides both comfort and control during operation. It is often ergonomically designed to reduce fatigue, especially during prolonged use. Additionally, the hose connection facilitates the seamless transfer of fluid from the pump to the spray gun, ensuring efficient operation without leaks.

Regular inspection of these components is essential to maintain optimal performance. Ensuring that the trigger moves freely, the nozzle is unobstructed, and the handle is securely attached can prevent potential issues that may arise from wear and tear. Understanding the breakdown of this assembly empowers users to perform necessary maintenance and repairs, prolonging the lifespan of their cleaning equipment.

Maintenance Tips for Longevity

Proper upkeep of your equipment is essential for ensuring its extended lifespan and optimal performance. Regular attention to maintenance tasks not only prevents costly repairs but also enhances efficiency and reliability during use.

- Regular Cleaning: Keep the unit free from dirt and debris. Use a soft cloth to wipe surfaces and ensure that air vents are unobstructed.

- Inspect Components: Frequently check various elements for signs of wear or damage. Look for loose screws, frayed wires, or any irregularities that may indicate a problem.

- Lubrication: Apply appropriate lubricants to moving parts as specified in the manufacturer’s guidelines. This reduces friction and prevents premature wear.

- Storage Conditions: Store the equipment in a dry, temperature-controlled environment. Avoid exposure to extreme temperatures and humidity, which can degrade materials.

- Scheduled Servicing: Follow a regular servicing schedule. Consult with a qualified technician for comprehensive checks and repairs to maintain peak performance.

By following these guidelines, you can significantly extend the life of your equipment and ensure it operates effectively for years to come.

Exploring the Nozzle Options

When it comes to maximizing performance in pressure cleaning, the choice of nozzle can significantly impact efficiency and effectiveness. Various attachments are designed to accommodate different tasks, providing versatility for a range of cleaning applications.

Understanding the Types of nozzles available can help users select the most suitable one for their needs. For instance, some nozzles offer a wide spray pattern ideal for gentle cleaning, while others concentrate the flow for tackling tough stains. Knowing the purpose of each type ensures optimal results during usage.

Adjustable nozzles present an excellent option for users seeking flexibility. These attachments allow for quick modifications to the spray angle and intensity, adapting to various surfaces and debris levels. Whether it’s a delicate area or a heavily soiled surface, having the ability to switch settings on the go is invaluable.

Specialized nozzles cater to specific tasks, such as rotating or turbo nozzles, which enhance cleaning power by combining high pressure with a swirling action. This unique design effectively removes grime and dirt while reducing the time spent on challenging jobs. Selecting the right specialized nozzle can elevate the cleaning experience significantly.

Ultimately, choosing the right nozzle contributes to both performance and satisfaction. By exploring the available options and understanding their functions, users can ensure they are equipped to tackle any cleaning challenge with confidence.

Replacement Parts and Compatibility

When maintaining a high-performance machine, ensuring the availability of suitable components is crucial. Understanding which items can be substituted and how they fit together can enhance efficiency and longevity. This section explores options for replacements and compatibility, ensuring a seamless experience for users.

Identifying Compatible Components

To maximize the functionality of your equipment, it’s important to know which components can be interchanged. Compatibility often depends on specific features such as size, power ratings, and connection types. This understanding allows for effective repairs and upgrades without compromising performance.

Commonly Needed Components

Here is a list of frequently required items along with their compatibility notes:

| Component | Description | Compatibility Notes |

|---|---|---|

| Pump Assembly | Essential for pressure generation | Check model specifications for fit |

| Hose | Transmits water from the source | Verify diameter and length |

| Filter | Prevents debris from entering the system | Must match original dimensions |

| Trigger Gun | Controls the flow of water | Ensure connector type is the same |

| Nozzle | Affects spray pattern and pressure | Look for interchangeable options |

Troubleshooting Common Issues

When operating a pressure washer, users may encounter a variety of challenges that can impact performance and efficiency. Identifying and resolving these common problems can help ensure a smooth and effective cleaning experience.

- Engine Won’t Start:

- Check fuel levels and ensure there is enough gasoline in the tank.

- Inspect the spark plug for wear or damage; replacing it may be necessary.

- Ensure that the on/off switch is in the correct position.

- Low Pressure:

- Verify that the nozzle is clean and free of debris; a clogged nozzle can reduce pressure.

- Inspect the water supply to ensure adequate flow and pressure from the source.

- Check for any kinks in the hose that could restrict water flow.

- Leaks:

- Examine all hoses and connections for signs of wear or damage; replace as needed.

- Ensure all fittings are securely tightened to prevent water from escaping.

- Inspect the pump seals for deterioration and replace if necessary.

- Excessive Vibration:

- Ensure the pressure washer is placed on a level surface to minimize instability.

- Check for any loose components or fasteners that may need tightening.

- Inspect the wheels and frame for any signs of damage or misalignment.

By systematically addressing these common challenges, users can maintain optimal performance and prolong the lifespan of their equipment. Regular maintenance and timely repairs are key to ensuring reliable operation.

Proper Storage and Care Techniques

Ensuring the longevity and optimal performance of your equipment relies heavily on effective maintenance and appropriate storage methods. Proper techniques can prevent damage, reduce wear, and enhance the reliability of your tools. This section will discuss essential practices that promote the preservation of your machinery over time.

Maintenance Practices

Regular upkeep is crucial in maintaining functionality. Start by cleaning your equipment after each use to remove dust, debris, and moisture. Use a soft cloth or brush for delicate areas to avoid scratches. Additionally, lubrication of moving parts should be performed according to the manufacturer’s recommendations to minimize friction and prevent corrosion.

Storage Guidelines

Storing your machinery in a dry, cool environment is vital to prevent rust and deterioration. Use protective cases or covers to shield against dust and accidental impacts. Organize your tools in a designated area, ensuring they are secure and not overcrowded, which can lead to unnecessary damage. If possible, keep them off the ground to avoid exposure to moisture.

Choosing the Right Accessories

Selecting the appropriate tools and attachments is crucial for optimizing performance and achieving the best results in any project. Understanding the available options can significantly enhance the efficiency and effectiveness of your equipment.

When considering which attachments to incorporate, keep the following factors in mind:

- Compatibility: Ensure that the accessories are designed to fit your equipment model. This guarantees optimal functionality and prevents potential damage.

- Purpose: Identify the specific tasks you intend to perform. Different attachments serve unique functions, such as cleaning, pressure washing, or surface preparation.

- Quality: Opt for high-quality accessories from reputable manufacturers to ensure durability and performance. Investing in reliable products can save you time and money in the long run.

- Ease of Use: Look for attachments that are user-friendly and easy to install. This can make your experience smoother and more enjoyable.

In conclusion, making informed choices when selecting accessories can greatly impact your productivity and the quality of your work. By prioritizing compatibility, purpose, quality, and ease of use, you can enhance your overall experience and achieve superior results.