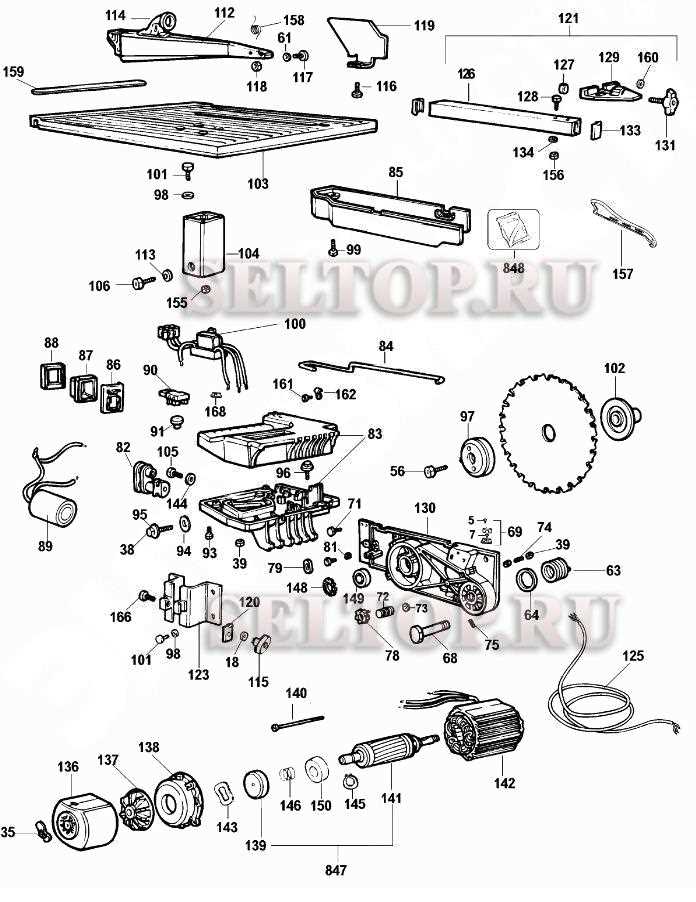

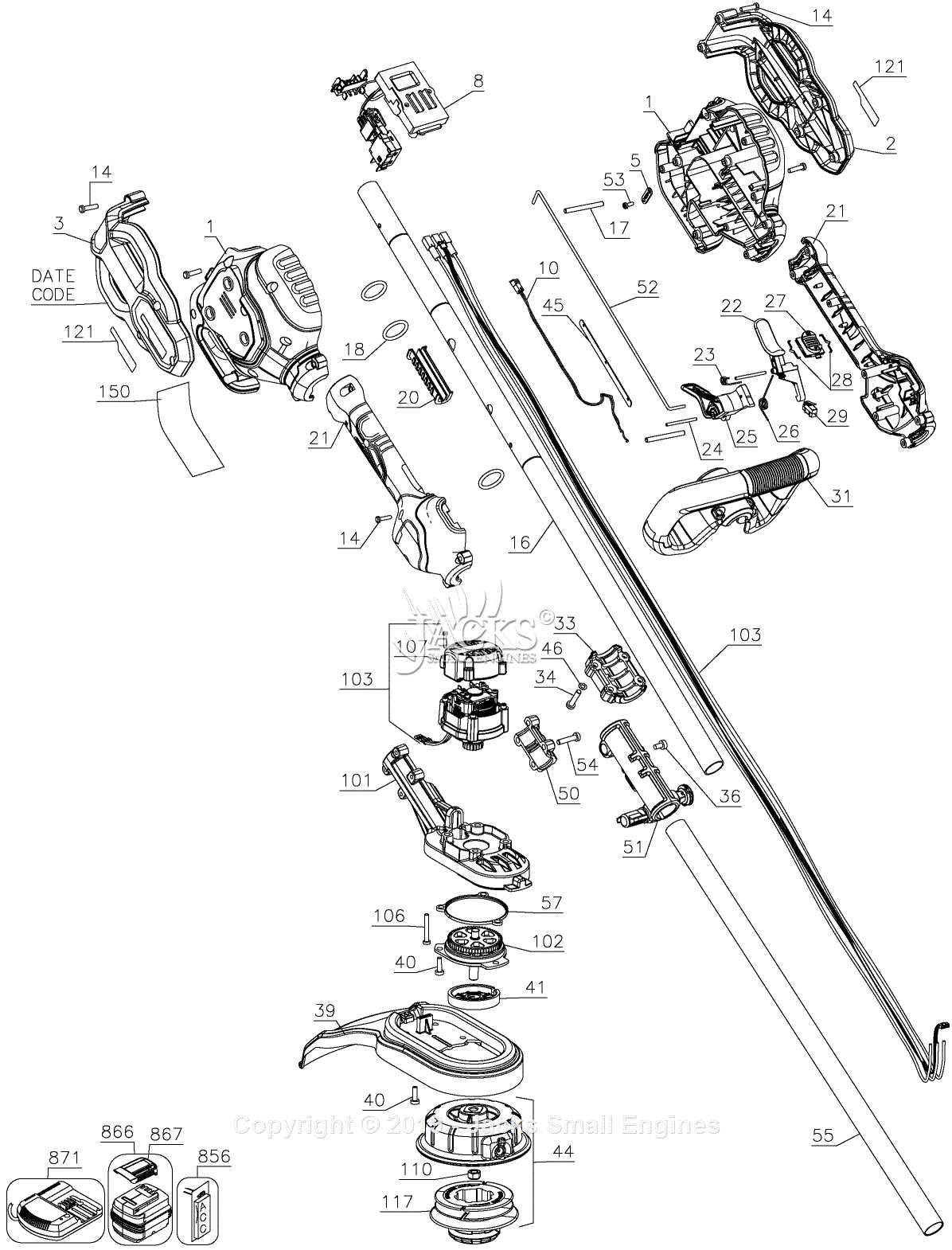

When dealing with outdoor machinery, having a clear view of how each element fits together is essential for both maintenance and repair. These types of machines, designed for cutting and shaping outdoor surfaces, often consist of several interconnected mechanical and electrical parts. Knowing how these components work in unison helps ensure smooth operation and prolongs the lifespan of the equipment.

Whether you’re addressing wear and tear or simply performing routine upkeep, the internal and external structures of this machinery can vary significantly. From the main cutting mechanism to the supporting hardware and power systems, it’s important to familiarize yourself with each section. A thorough understanding can make disassembling, fixing, and reassembling much easier and more efficient.

In this guide, we will explore the different elements that contribute to the functionality of this equipment, highlighting key mechanical and structural aspects that ensure performance.

Key Components Overview for a Grass Cutting Machine

The essential elements of any machine designed for trimming grass are crucial for its smooth and efficient operation. Each component plays a significant role in ensuring that the machine functions optimally, providing a clean and precise cut. Understanding these parts can help in maintaining and repairing the equipment when necessary.

- Power Source: The driving force behind the machine, this unit powers all other mechanisms, ensuring a steady and reliable performance.

- Blades: These sharp, rotating components are responsible for the actual cutting, ensuring a clean and even trim across any surface.

- Chassis: The structure that houses all critical parts, offering protection and stability during use.

- Wheels: Designed to provide mobility, these allow

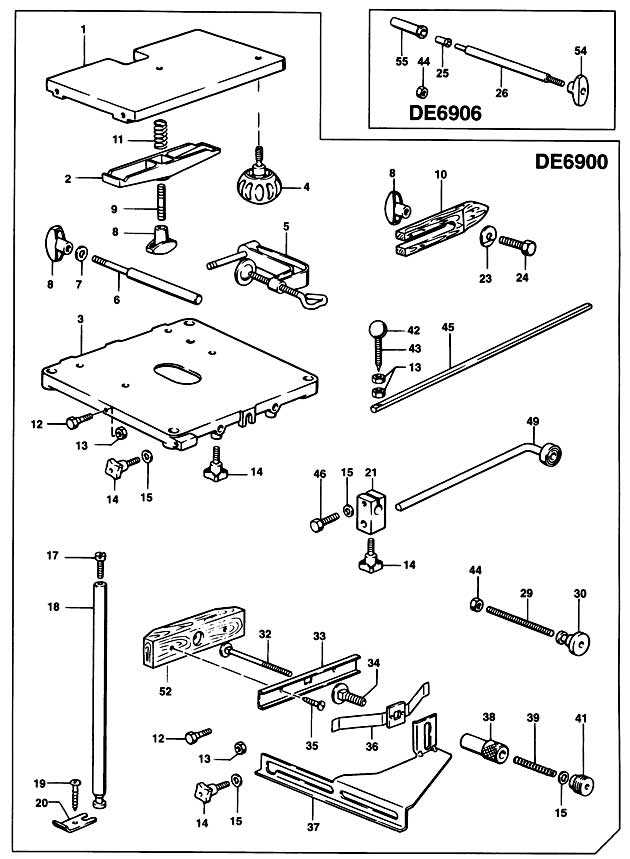

Key Features of the Cutting Deck

The cutting platform plays a crucial role in ensuring efficient trimming of the vegetation. This component is responsible for delivering precise and even results, while also contributing to the overall performance and durability of the machine. Let’s take a closer look at its main attributes.

Durability and Materials

One of the essential characteristics of a high-quality cutting system is the strength and longevity of the materials used. Robust metals and anti-corrosion coatings are typically employed to enhance the life expectancy and resilience of this part under various conditions.

Precision and Adjustability

Adjustable settings allow users to fine-tune the height and angle of the blades. This versatility provides the opportunity to achieve different cutting results, depending on the sp

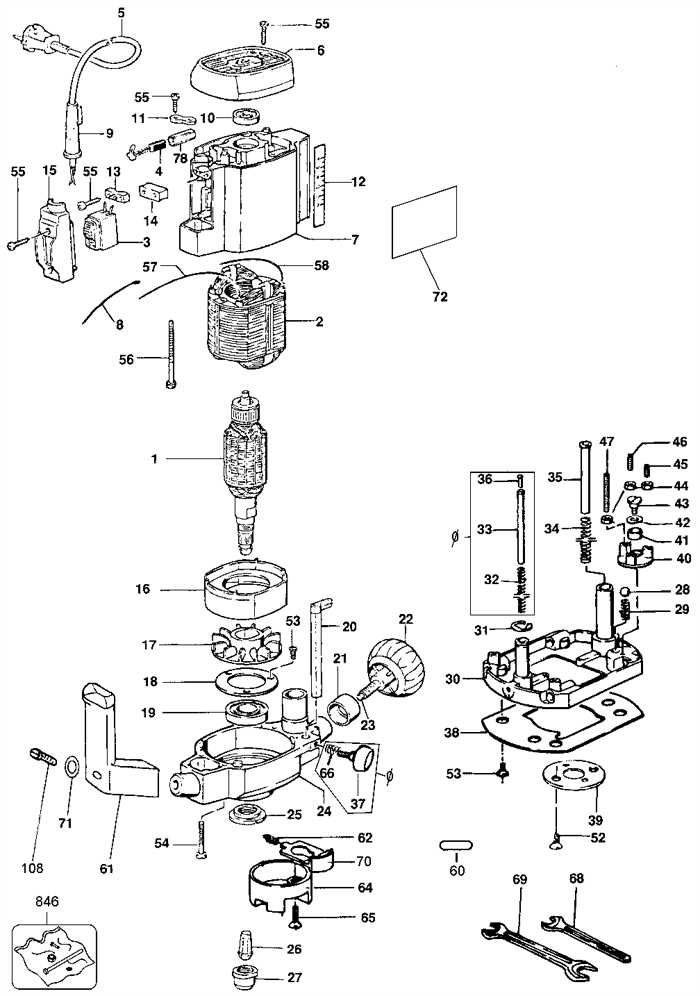

Understanding the Blade Mechanism

The cutting component of any grass-trimming equipment is essential for its overall performance and efficiency. Its functionality is built around a specific system that ensures smooth operation, precise cuts, and optimal results during use. To achieve this, it is crucial to understand how the various parts within this system interact and function in unison.

Key Components Involved

The mechanism consists of multiple elements working together. From the attachment of the blade itself to the driving force that powers its movement, each component has a vital role. Understanding how these parts align and engage during operation helps ensure effective maintenance and longer service life.

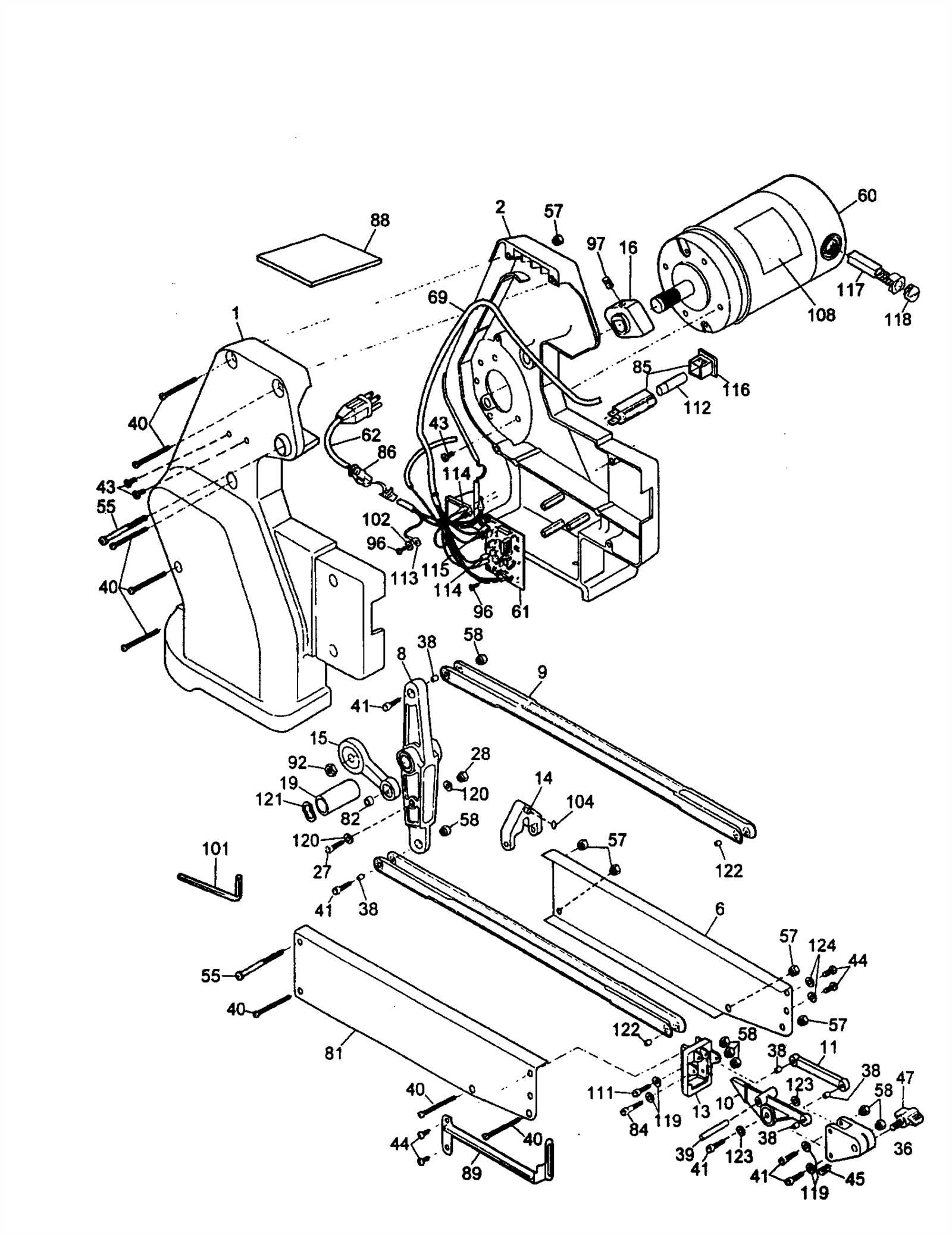

Motor Housing and Its Role

The motor housing serves as a crucial element in the overall structure of any equipment powered by an engine. It not only protects the internal components but also ensures the stability and durability of the entire system. By providing a shield from external elements such as dust and moisture, the housing helps maintain the longevity of the machine.

One of the key functions of the motor housing is to prevent damage from environmental factors and mechanical impacts. This enclosure also supports heat dissipation, allowing the engine to operate at optimal temperatures. Additionally, the motor housing aids in noise reduction, contributing to a more efficient and quieter operation.

Another essential aspect is its role in ensuring the safe use of the equipment. By enclosing the motor securely, it minimizes the risk of accidental contact with moving parts, providing an added layer of safety

Essential Control Panel Elements

The control panel serves as the central hub for managing various operational functions. Each component is designed to provide users with easy access to key features, ensuring smooth and efficient operation. Understanding these elements is crucial for maximizing the functionality and overall performance of the equipment.

Main Controls

Primary controls typically include switches and levers that allow for immediate adjustments. These components are responsible for starting, stopping, and modifying the operational settings to suit different conditions. They are strategically placed for user convenience, allowing for quick actions during operation.

Safety Features

Built-in safety mechanisms are a critical part of the control panel. These may include emergency shut-off buttons or indicators that monitor the system’s status. These features help ensure safe operation and prevent potential hazards by alerting the user to

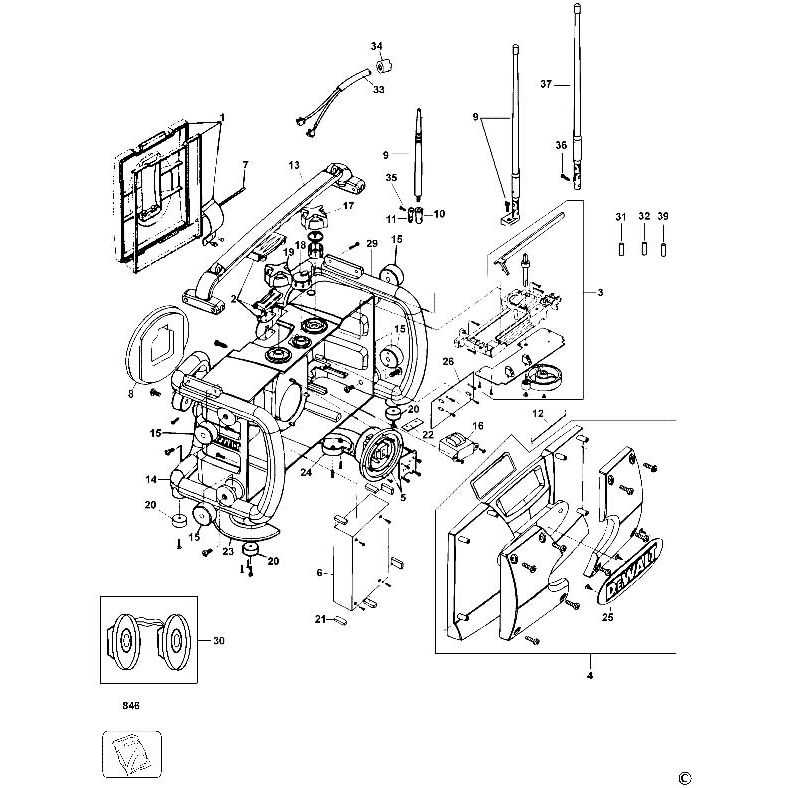

Rear Wheel Drive System Explained

The rear wheel drive system is an essential component that enhances maneuverability and traction in various outdoor machinery. This configuration allows the machine to effectively transfer power to the rear wheels, improving performance on diverse terrains. Understanding how this system operates can lead to better maintenance and optimal usage.

Key Components of the Drive System

At the core of the rear wheel drive system are several critical elements. The drive belt plays a pivotal role in transferring energy from the engine to the wheels. Coupled with the wheel assembly, these components work together to ensure smooth movement and stability, especially when navigating uneven surfaces.

Advantages of Rear Wheel Drive

One of the significant benefits of utilizing a rear wheel drive setup is enhanced traction. By distributing the weight toward the back, these systems provide improved grip, particularly in wet or slippery conditions. Additionally, this configuration allows for tighter turning radii, making it easier to maneuver in confined spaces.

Guide to the Grass Collection Unit

The grass collection unit is an essential component for efficient turf maintenance, designed to gather clippings and debris during the cutting process. This mechanism not only ensures a neat appearance but also promotes healthy growth by preventing thatch buildup. Understanding its structure and functionality can enhance your experience and optimize performance.

Components of the Collection Unit

Several key elements make up the grass collection unit, each playing a vital role in its operation. Familiarity with these components will help in maintenance and troubleshooting.

Component Description Hopper The container that collects the grass clippings. Chassis The framework that supports the hopper and connects to the main body. Airflow System Channels that facilitate the movement of clippings into the hopper. Mounting Brackets Hardware used to secure the unit to the main apparatus. Maintenance Tips

To ensure optimal performance, regular upkeep of the grass collection unit is necessary. Cleaning the hopper and inspecting for blockages can prevent operational issues. Additionally, checking the mounting brackets for stability will enhance the overall efficiency of your equipment.

Handlebar Adjustments and Comfort Settings

Finding the perfect balance of comfort and control is essential for an enjoyable experience when using your equipment. Proper adjustments to the handlebar can significantly enhance maneuverability and reduce fatigue during operation.

Here are key aspects to consider for optimizing handlebar settings:

- Height Adjustment: Ensure the handlebar is at a height that allows for a natural arm position. This minimizes strain on your back and shoulders.

- Angle Setting: Adjust the angle of the handlebar to suit your posture and grip style. A slight tilt can enhance comfort during prolonged use.

- Grip Comfort: Inspect the grips for wear and ensure they provide sufficient cushioning. Consider replacing them if they feel hard or slippery.

- Stability Check: After making adjustments, verify that the handlebar is securely fastened and does not wobble during operation.

By taking the time to fine-tune these settings, users can achieve a more pleasant and effective experience, enabling better control and reducing the likelihood of discomfort.

Battery Placement and Replacement Tips

Proper positioning and timely substitution of power sources are crucial for the optimal functioning of your device. Ensuring that the energy unit is correctly seated can significantly enhance performance and longevity. It’s essential to familiarize yourself with the installation process to avoid any potential issues.

When placing the energy unit, ensure that the contacts are clean and free from debris. Align the unit according to the designated slots, ensuring a secure fit. It’s advisable to check the manufacturer’s guidelines for specific instructions related to your model.

For replacement, always use compatible energy units that meet the required specifications. Before removing the old unit, ensure the device is powered down. Carefully detach the previous energy unit, making sure not to damage the connectors. Insert the new unit with attention to the correct orientation, and confirm that it clicks into place.

Regular maintenance of the power source, including checking for wear and ensuring secure connections, can prevent unexpected failures. By following these guidelines, you can ensure that your equipment operates efficiently and reliably.

Frame Construction and Durability Aspects

The framework of any outdoor machinery plays a crucial role in its overall performance and longevity. A robust construction not only supports the essential components but also contributes to the machine’s ability to withstand various environmental conditions. This section explores the structural integrity and resilience features that enhance the operational lifespan of these devices.

Key elements influencing the durability of the frame include:

- Material Quality: The choice of materials significantly impacts the strength and resistance to wear and tear. High-grade metals and composites are often used for optimal performance.

- Design Engineering: Innovative designs that distribute stress evenly across the frame can prevent premature failures and enhance stability during operation.

- Corrosion Resistance: Protective coatings and treatments are essential for shielding the structure from rust and deterioration caused by exposure to moisture and other elements.

- Shock Absorption: Incorporating features that absorb shocks and vibrations helps maintain the integrity of the frame, reducing the risk of cracks and deformities.

By focusing on these aspects, manufacturers aim to provide equipment that not only meets performance expectations but also assures reliability and durability over time.

Protective Shields and Safety Measures

Ensuring safety during operation is crucial when using outdoor machinery. Protective shields play a significant role in preventing accidents by minimizing exposure to moving parts and debris. These barriers not only enhance the overall safety of the equipment but also protect the user from potential hazards.

In addition to shields, it is essential to follow certain precautions while operating the equipment. Wearing appropriate safety gear, such as goggles and gloves, significantly reduces the risk of injury. Regular maintenance checks and proper handling further contribute to a safer working environment, ensuring that all components function as intended.

Ultimately, combining effective protective measures with user awareness creates a safer experience, allowing individuals to focus on their tasks without undue concern for their well-being.

Maintenance Tips for Optimal Performance

Regular upkeep is essential for ensuring the longevity and efficiency of your equipment. Implementing a consistent maintenance routine not only enhances functionality but also prevents potential issues that could arise from neglect. By following a few key practices, you can significantly improve the performance and reliability of your tools.

Routine Inspection and Cleaning

Conduct frequent inspections to identify any wear or damage. Ensure that components are free from debris and dirt, which can hinder performance. Cleaning all accessible areas is crucial; use a brush or compressed air to remove clippings and dirt build-up. This simple step can extend the lifespan of your equipment.

Regular Lubrication and Adjustments

Proper lubrication is vital for smooth operation. Check moving parts regularly and apply appropriate lubricants to minimize friction. Additionally, making necessary adjustments to tension and alignment can prevent excessive wear and enhance overall performance. Staying proactive with these tasks will keep your tools in top condition.