The intricate design of a heavy-duty vehicle involves various components that work together to ensure optimal performance and safety. Each section plays a crucial role in the overall functionality, requiring careful attention during maintenance and repairs. Analyzing the arrangement of these elements can aid in troubleshooting issues and enhancing the vehicle’s longevity.

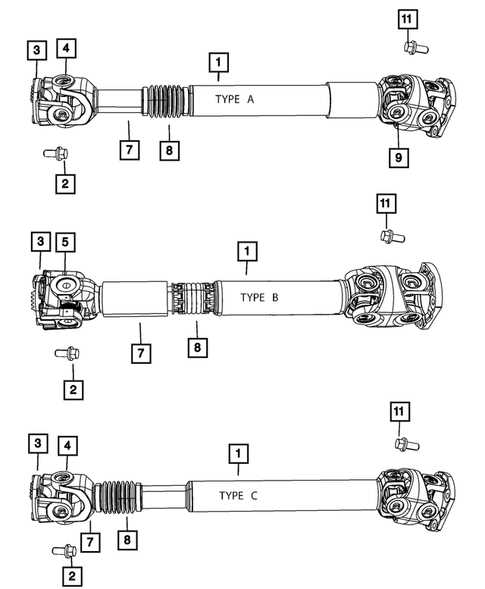

To effectively navigate the complexities of this machinery, it is essential to familiarize oneself with the various segments and their interconnections. A comprehensive visual representation can serve as a valuable resource, providing insights into the arrangement and function of each component. Understanding how these elements interact contributes significantly to efficient upkeep and repair practices.

Moreover, recognizing the specific attributes of each section can empower owners and technicians alike to make informed decisions regarding modifications and upgrades. Knowledge of the layout not only facilitates effective maintenance but also promotes a deeper appreciation of the engineering behind these robust vehicles.

This section provides a comprehensive overview of a heavy-duty vehicle known for its durability and performance. It is widely recognized in the automotive community for its robust construction and reliability, making it a popular choice among enthusiasts and professionals alike. Understanding the essential components of this vehicle can help in maintenance and repair efforts, ensuring optimal functionality.

Key Features and Specifications

The vehicle boasts a range of features designed for strength and efficiency. Its powerful engine options and advanced transmission systems contribute to superior towing and hauling capabilities. Additionally, the chassis design supports enhanced stability, which is crucial for heavy loads and off-road conditions.

Common Components

Several key elements play a vital role in the vehicle’s performance and handling. These components include:

| Component | Description |

|---|---|

| Suspension System | Ensures a smooth ride and aids in load distribution. |

| Steering Mechanism | Facilitates precise control and maneuverability. |

| Braking System | Critical for safety and effective stopping power. |

| Wheel Assembly | Supports the vehicle’s weight and provides traction. |

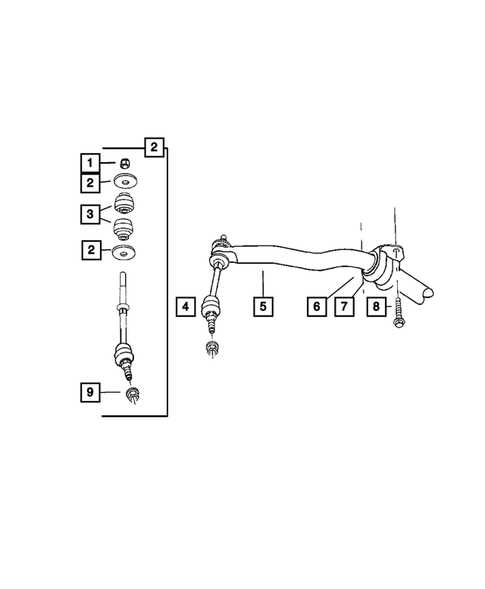

Essential Components of Front End

The framework of a vehicle’s forward section plays a crucial role in ensuring stability, steering precision, and overall safety. Understanding its key elements helps in diagnosing issues and maintaining optimal performance.

| Component | Description |

|---|---|

| Steering Mechanism | This assembly allows the driver to guide the vehicle by translating steering wheel movement into directional changes. |

| Suspension System | This system absorbs shocks from road irregularities, providing a smooth ride and maintaining tire contact with the ground. |

| Control Arms | These components connect the suspension system to the vehicle’s frame, enabling vertical wheel movement while maintaining proper alignment. |

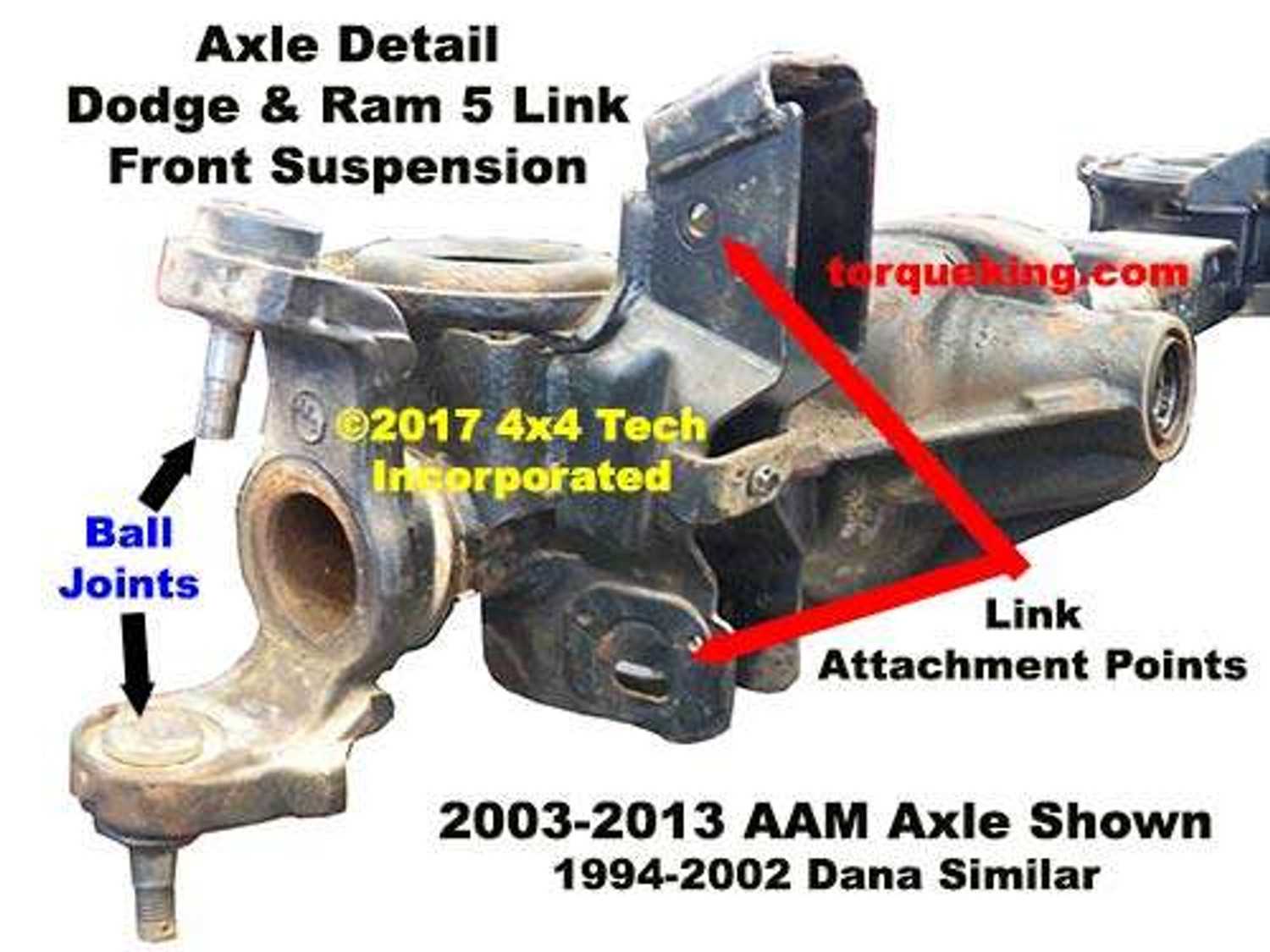

| Ball Joints | These spherical bearings facilitate movement between the control arms and the wheel hub, allowing for steering and suspension articulation. |

| Tie Rods | This linkage connects the steering mechanism to the wheel assembly, transmitting steering force to guide the vehicle. |

Understanding Front Suspension System

The suspension framework of a vehicle plays a critical role in ensuring smooth navigation and stability on various terrains. This complex assembly consists of multiple components that work harmoniously to absorb shocks, maintain tire contact with the road, and enhance overall handling. A solid grasp of this system is essential for any vehicle owner or enthusiast aiming to optimize performance and ride quality.

Key Components of the Suspension Assembly

Each element within the suspension structure contributes to its functionality. Here are the main constituents:

| Component | Function |

|---|---|

| Shock Absorber | Dissipates energy from bumps and uneven surfaces, ensuring a comfortable ride. |

| Control Arm | Links the wheel to the chassis, allowing for vertical movement while keeping the wheel aligned. |

| Sway Bar | Reduces body roll during cornering by stabilizing the vehicle. |

| Spring | Supports the vehicle’s weight and absorbs impacts from the road. |

Importance of Regular Maintenance

To ensure optimal performance and safety, regular inspections and maintenance of the suspension system are paramount. Worn or damaged components can lead to decreased handling, increased tire wear, and a less comfortable ride. By keeping this system in top condition, drivers can enjoy a smoother and more controlled driving experience.

Steering Mechanisms Explained

The steering mechanism is a critical component of any vehicle, responsible for guiding its direction and ensuring a smooth driving experience. Understanding how these systems function can enhance appreciation for automotive engineering and maintenance.

Types of Steering Systems

- Rack and Pinion: This is a popular type due to its simplicity and efficiency. It converts rotational motion into linear motion, allowing for precise control.

- Recirculating Ball: Often found in heavier vehicles, this system uses a series of balls to reduce friction and provide a smoother steering action.

- Power Steering: Utilizing hydraulic or electric assistance, this mechanism reduces the effort required to turn the steering wheel, enhancing maneuverability.

Key Components of Steering Mechanisms

- Steering Wheel: The primary interface between the driver and the steering system.

- Steering Column: Connects the steering wheel to the steering gear and may include additional features like tilt or telescoping functions.

- Linkage: Transfers the motion from the steering wheel to the wheels, ensuring accurate directional control.

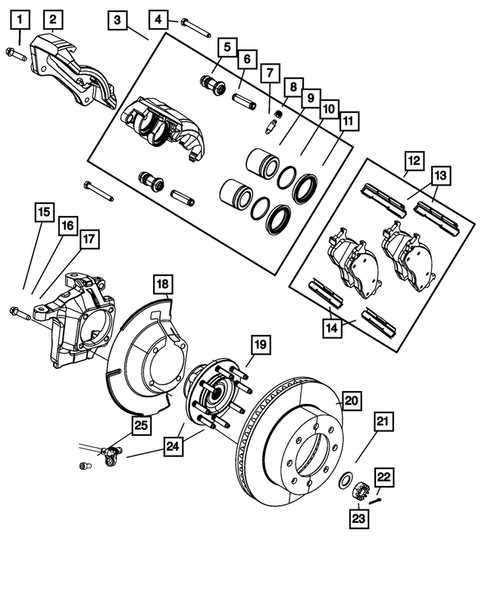

Parts Involved in Front Braking

The braking system of a vehicle plays a crucial role in ensuring safety and control. Various components work together to facilitate effective deceleration and stopping. Understanding these elements is essential for maintenance and repairs, as each component contributes to the overall functionality of the system.

Key Components

Several integral components are responsible for the braking action. These include the brake calipers, rotors, and pads, which function together to create friction and slow down the vehicle. Each part has a specific role in the braking process, and their proper functioning is vital for optimal performance.

Component Specifications

| Component | Description | Function |

|---|---|---|

| Brake Caliper | A hydraulic device that houses the brake pads | Applies pressure to the pads, clamping them against the rotor |

| Brake Rotor | A circular metal disc that the pads press against | Provides a surface for the pads to create friction |

| Brake Pads | Friction material mounted on the caliper | Creates friction against the rotor to slow down the vehicle |

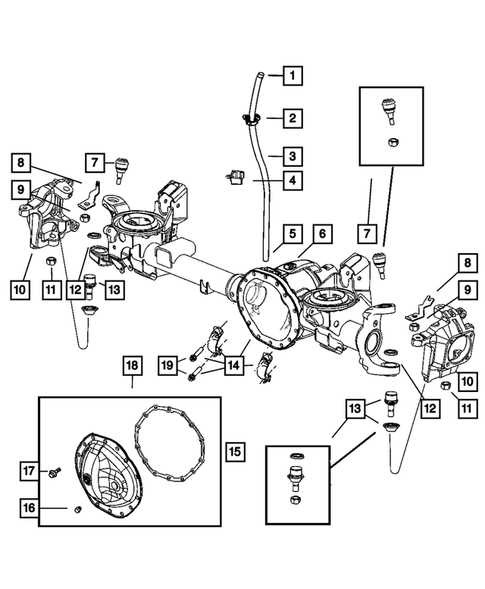

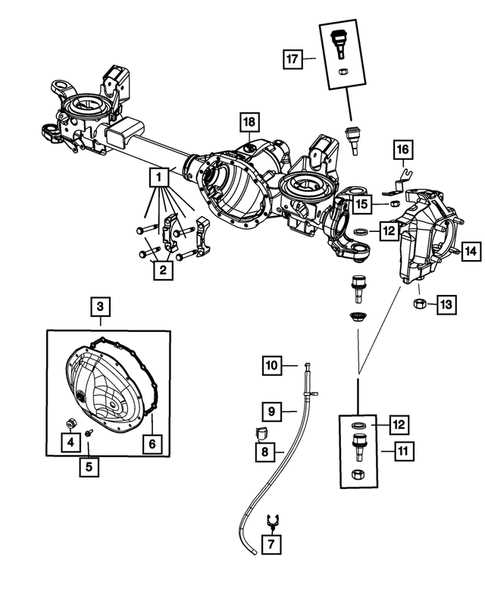

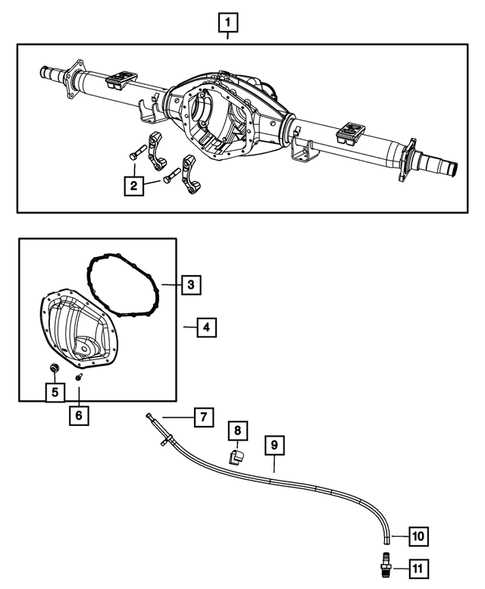

Importance of Front Axle Assembly

The assembly responsible for connecting the wheels to the chassis plays a crucial role in vehicle performance and safety. Its proper functioning ensures stability during motion, enabling efficient handling and maneuverability. Any issues within this assembly can lead to significant consequences, affecting both driving comfort and overall vehicle reliability.

Moreover, the integrity of this assembly directly impacts the vehicle’s ability to navigate various terrains. A well-maintained assembly promotes better traction and enhances the distribution of weight across the wheels. This is essential for maintaining control, especially in challenging driving conditions. Neglecting the maintenance of this vital component can lead to uneven tire wear, decreased fuel efficiency, and potential safety hazards.

Regular inspections and timely replacements of worn components within this assembly are essential to ensure optimal performance. Engaging with experienced professionals for servicing can significantly extend the lifespan of these crucial elements, ensuring a safe and enjoyable driving experience.

Functions of Front Bumper Components

The front bumper assembly serves multiple critical roles in vehicle safety and functionality. It acts as a protective barrier, absorbing impact during collisions and safeguarding internal structures. Additionally, various elements within this assembly contribute to aesthetic appeal and aerodynamic efficiency.

Understanding the specific functions of these components is essential for vehicle maintenance and performance optimization. Below is a table outlining the key components and their respective functions:

| Component | Function |

|---|---|

| Bumper Cover | Provides a sleek exterior appearance and protects underlying structures from minor impacts. |

| Impact Absorber | Dissipates energy during a collision to minimize damage to the vehicle frame. |

| Support Bracket | Secures the bumper to the chassis and maintains structural integrity. |

| Fog Lights | Enhances visibility in adverse weather conditions, improving safety. |

| Grille | Facilitates airflow to the engine while contributing to the vehicle’s aesthetic design. |

Front End Alignment Considerations

Proper alignment of the vehicle’s steering mechanism is crucial for maintaining optimal handling and tire longevity. It involves adjusting the angles of the wheels to ensure they meet the manufacturer’s specifications, which can significantly impact performance and safety.

Importance of Accurate Steering Adjustment

Accurate steering adjustments are essential for ensuring that a vehicle operates smoothly. Misalignment can lead to uneven tire wear, reduced fuel efficiency, and compromised safety. Regular checks and maintenance can help in identifying and rectifying alignment issues before they escalate.

Common Signs of Misalignment

Several indicators can suggest a misalignment issue, including uneven tire wear, the vehicle pulling to one side, and a steering wheel that is off-center. Recognizing these signs early can prevent more severe problems and maintain driving comfort.

| Signs | Possible Causes |

|---|---|

| Uneven tire wear | Improper wheel angles |

| Vehicle pulls to one side | Worn suspension components |

| Steering wheel off-center | Misalignment adjustments needed |

Common Issues with Front Parts

When it comes to vehicle maintenance, various components at the front section can present challenges. Understanding these common issues can help in ensuring optimal performance and longevity. Owners often encounter problems that stem from wear and tear, improper alignment, and environmental factors.

Wear and Tear

Age and mileage can significantly impact the functionality of essential components. Parts such as ball joints and tie rods may deteriorate over time, leading to reduced handling and safety concerns. Regular inspections are crucial to identify these problems early and prevent further damage.

Alignment Issues

Improper alignment can cause uneven tire wear and affect overall vehicle stability. Symptoms may include pulling to one side or excessive vibrations while driving. Addressing alignment problems promptly is vital for maintaining the vehicle’s performance and ensuring a smooth ride.

Maintenance Tips for Front End

Regular upkeep of your vehicle’s leading components is essential for optimal performance and safety. Ensuring that all elements are functioning correctly not only enhances driving comfort but also extends the lifespan of various systems. Below are some effective strategies to maintain these crucial parts.

| Maintenance Task | Frequency | Description |

|---|---|---|

| Inspect Suspension System | Every 6 months | Check for wear and tear on shock absorbers and struts, ensuring a smooth ride and stability. |

| Check Alignment | Every 12,000 miles | Ensure that the wheels are aligned properly to avoid uneven tire wear and improve handling. |

| Inspect Steering Components | Every 6 months | Examine the steering linkage and components for any signs of damage or looseness. |

| Lubricate Joints | As needed | Apply lubricant to all necessary joints and connections to reduce friction and wear. |

| Check Tire Condition | Monthly | Inspect tires for proper inflation, tread depth, and signs of uneven wear to ensure safety. |

Tools Required for Repairs

When undertaking vehicle maintenance or repairs, having the right tools is essential for achieving optimal results. Proper equipment not only facilitates the work process but also ensures safety and precision during the task. Below is a list of necessary tools commonly needed for effective repairs.

- Socket Set: A comprehensive set of sockets in various sizes is crucial for loosening and tightening bolts.

- Wrenches: Both standard and adjustable wrenches are important for gripping and turning nuts and bolts.

- Screwdrivers: A selection of flathead and Phillips screwdrivers is necessary for different types of screws.

- Pliers: Various pliers, including needle-nose and slip-joint pliers, are useful for gripping and manipulating parts.

- Jack and Jack Stands: A hydraulic jack along with sturdy jack stands is essential for lifting the vehicle safely.

- Torque Wrench: This tool ensures that bolts are tightened to the manufacturer’s specifications.

- Hammer: A rubber or dead blow hammer can assist in loosening stuck components without causing damage.

- Measuring Tools: A tape measure or caliper is useful for ensuring accurate measurements during repairs.

By having these essential tools on hand, the repair process can be streamlined, leading to more efficient and effective results.

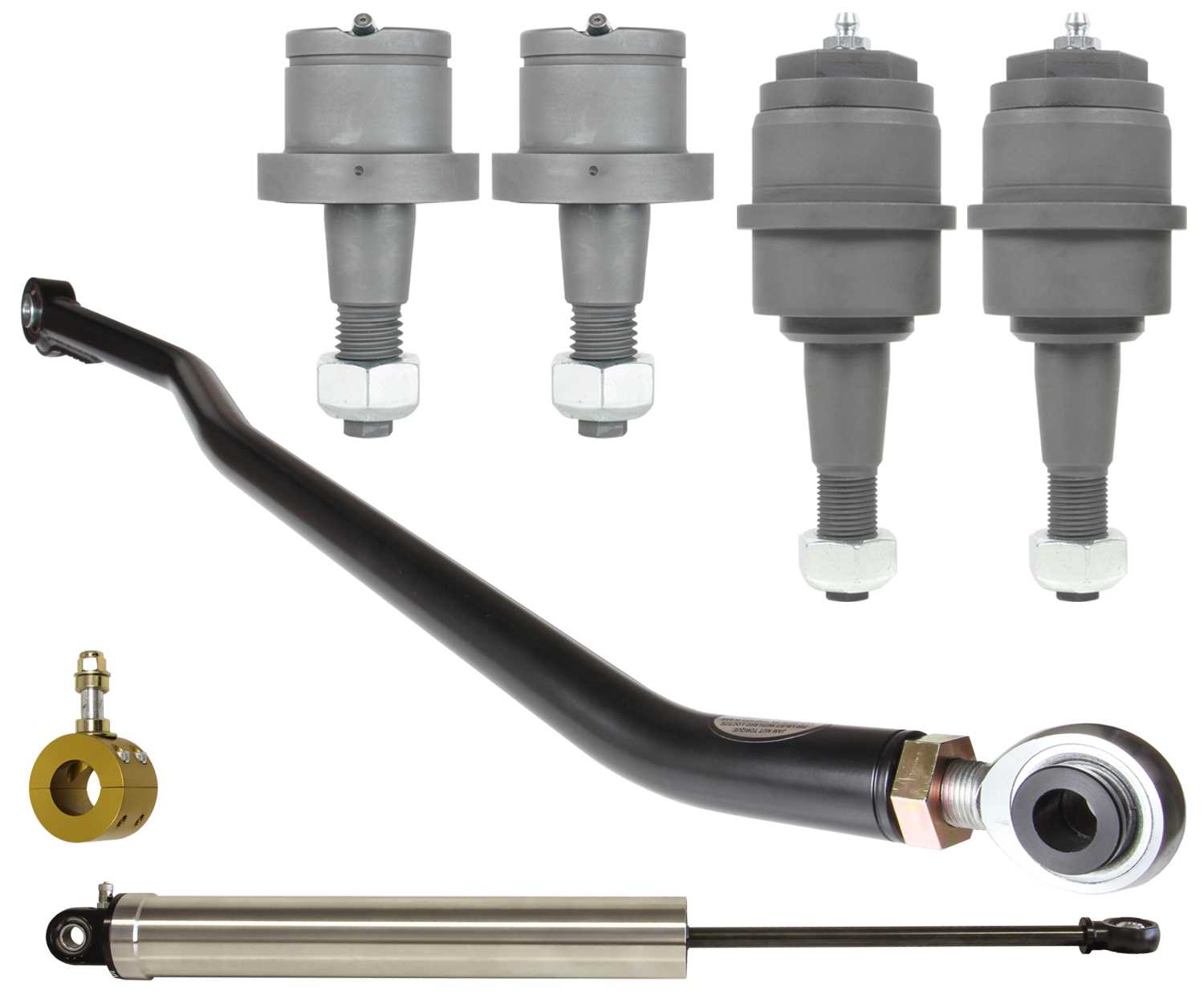

Upgrading Front End Components

Enhancing the essential elements of your vehicle’s suspension and steering system can significantly improve its overall performance and driving experience. Whether you’re looking to boost handling capabilities or increase durability, a variety of options are available to suit your needs.

Benefits of Component Upgrades

- Improved handling and stability

- Increased responsiveness during turns

- Enhanced ride comfort on rough terrains

- Extended lifespan of vehicle components

Key Upgradable Elements

- Shocks and Struts: Upgrading these components can enhance the absorption of bumps and improve overall ride quality.

- Sway Bars: Installing heavier sway bars can reduce body roll and improve cornering stability.

- Ball Joints: High-performance ball joints can increase steering precision and longevity.

- Tie Rod Ends: Upgrading tie rod ends can improve alignment and steering response.

When considering enhancements, it is crucial to select high-quality components designed for your specific vehicle type. This ensures compatibility and optimal performance, providing a safer and more enjoyable driving experience.

Resources for Parts Replacement

Finding reliable resources for replacing vehicle components is crucial for maintaining optimal performance and safety. Whether you are a seasoned mechanic or a DIY enthusiast, having access to the right information and suppliers can make the replacement process smoother and more efficient.

Numerous online platforms offer detailed catalogs and diagrams, allowing users to identify necessary components with ease. Websites dedicated to automotive repair often provide guides, videos, and forums where users can share experiences and advice. Additionally, many manufacturers have official parts retailers that guarantee the authenticity and quality of the items.

Local auto parts stores can also be invaluable resources, providing immediate access to components and knowledgeable staff who can assist in finding the correct replacements. Networking with local mechanics or automotive enthusiasts can lead to recommendations for trustworthy suppliers and potential cost-saving options.