Understanding the intricate layout of essential vehicle elements plays a pivotal role in ensuring smooth operation and longevity. A well-documented structural blueprint aids in diagnosing potential issues and streamlining repair efforts, making it easier to maintain high-performance levels over time.

This guide delves into various mechanical systems, offering insights into optimal placement, connectivity, and troubleshooting. From engine assemblies to electrical networks, recognizing how each element interacts within the larger framework is crucial for consistent upkeep and avoiding unexpected malfunctions.

In addition to technical diagrams, this resource provides practical advice on regular inspections and preventive care. Proper familiarity with structural details helps minimize breakdown risks and enhances the effectiveness of routine servicing, ensuring your vehicle remains reliable on every journey.

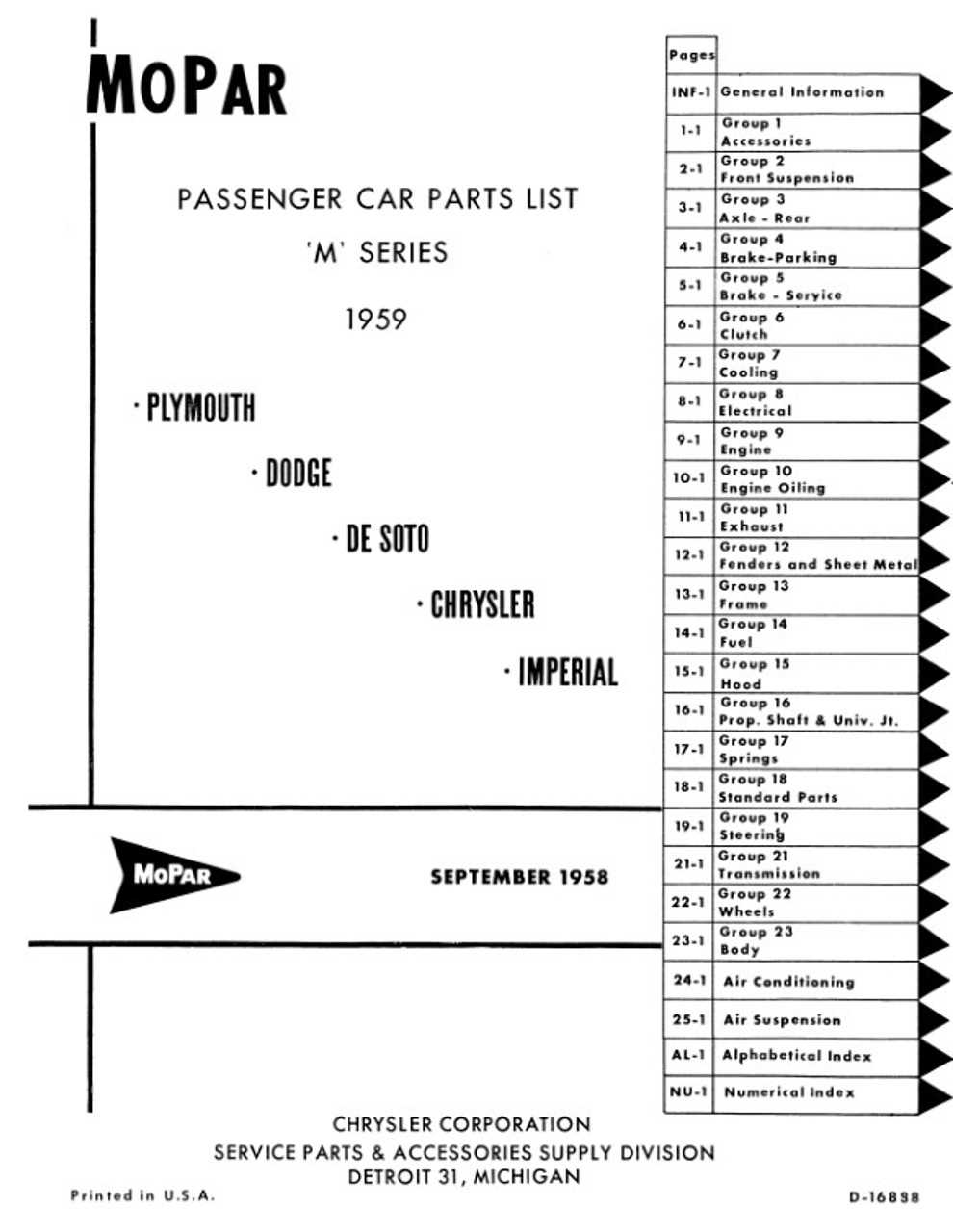

Exploring Key Components in Dodge Trucks

Understanding the essential elements of any vehicle is crucial for effective maintenance and troubleshooting. In these trucks, multiple mechanical and electronic systems work in harmony to ensure reliable performance, each contributing to driving dynamics, safety, and durability.

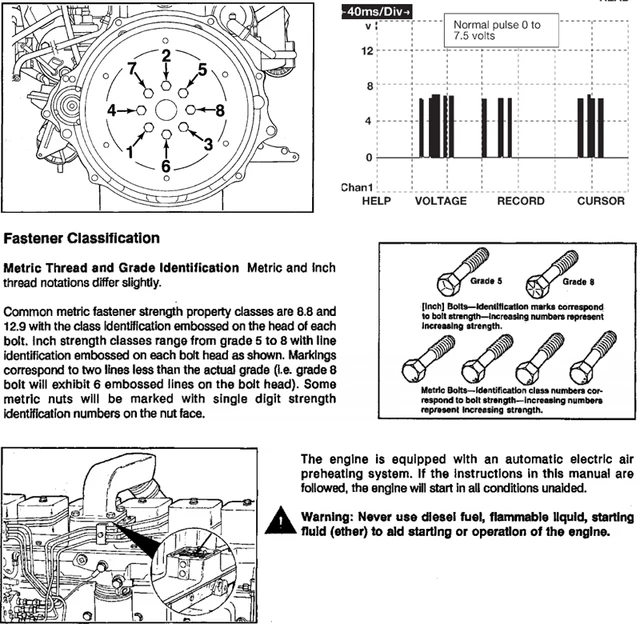

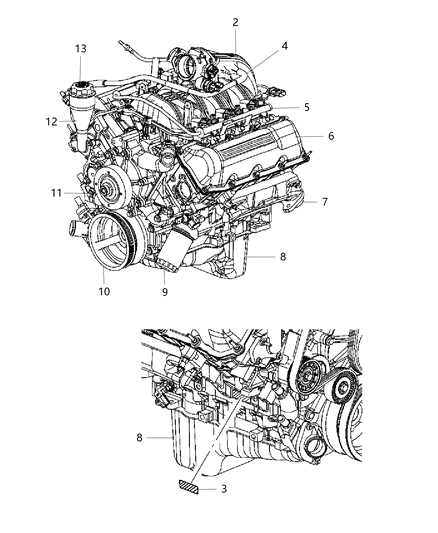

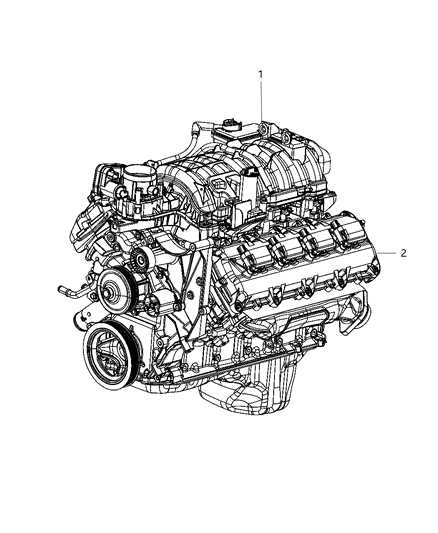

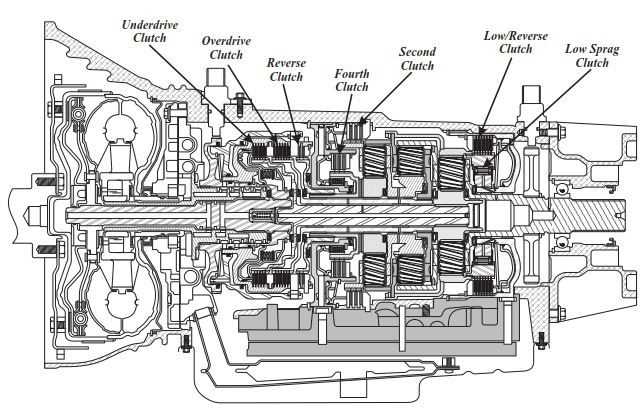

Engine and Transmission

The motor serves as the heart of the vehicle, generating the necessary power to propel it forward. Paired with a transmission, it ensures smooth power delivery across varying speeds. A well-maintained combination of these systems ensures efficiency and longevity on the road.

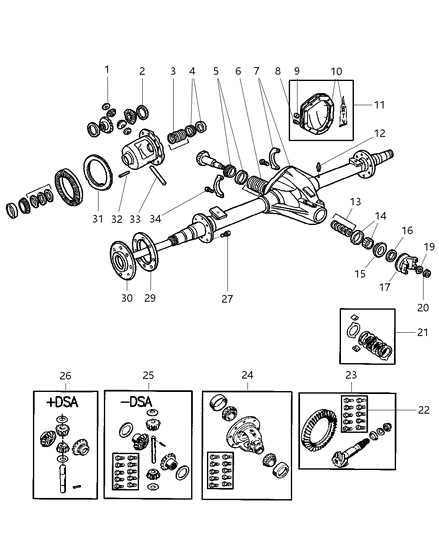

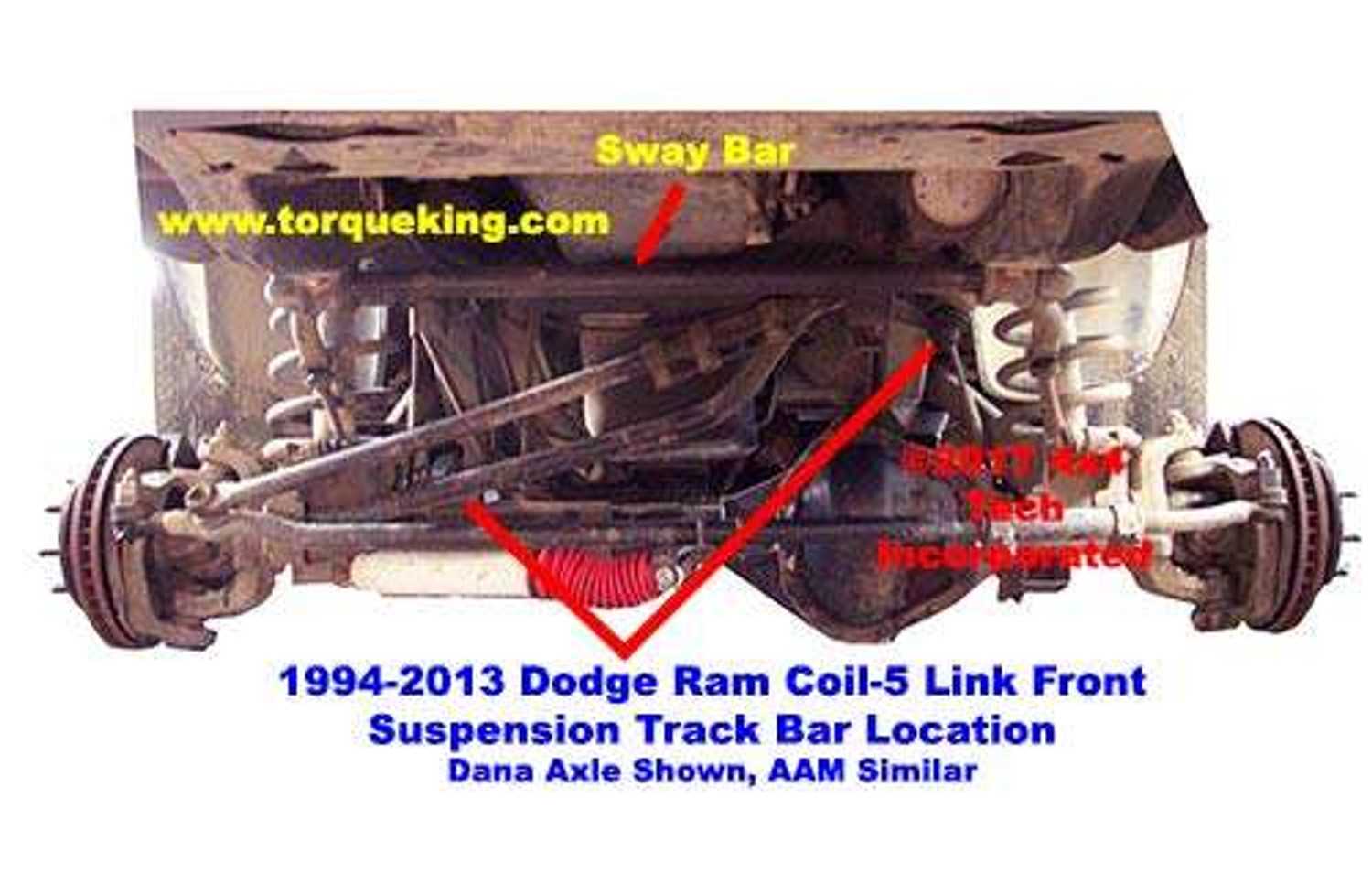

Chassis and Suspension Systems

The structural frame provides the backbone, supporting critical components such as wheels, axles, and suspension units. Suspension elements, including shocks and springs, absorb impacts, offering stability and comfort during drives, even on challenging terrains. Regular inspection of these areas guarantees a safer and smoother driving experience.

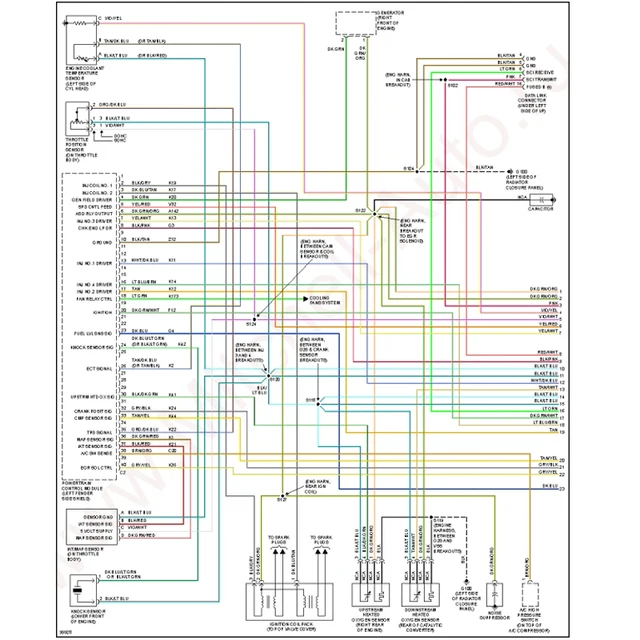

How to Identify Engine Layouts

Recognizing the configuration of an engine is crucial for understanding its performance characteristics and maintenance needs. Engine layouts can vary significantly, impacting factors such as fuel efficiency, power delivery, and ease of repair. Being able to spot key differences between layouts helps owners and technicians alike to make informed decisions when diagnosing or upgrading a vehicle.

Examining Cylinder Arrangement

The positioning of cylinders provides insight into the overall structure. Common arrangements include inline, V-shaped, and flat designs. Inline setups align cylinders in a straight line, typically improving fuel economy. In contrast, V-shaped configurations angle the cylinders in two opposing banks, optimizing power output in a compact space. Flat layouts, often seen in specialized vehicles, offer a low center of gravity, enhancing stability.

Understanding Engine Orientation

In addition to the internal arrangement, engines can be mounted in various ways within a vehicle. Transverse mounting positions the engine sideways, frequently used in front-wheel-drive systems to save space. Longitudinal mounting aligns the engine front-to-back, favoring vehicles that require better weight distribution for rear- or all-wheel drive systems. Recognizing the mounting orientation is key when planning component replacements or upgrades.

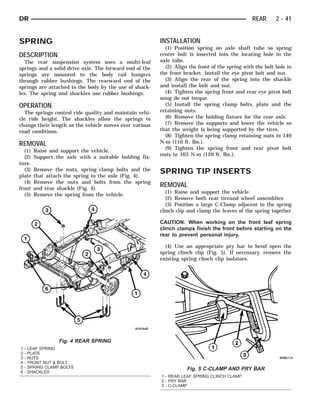

Suspension Systems and Their Variants

The structural design of a vehicle’s suspension plays a critical role in ensuring stability, comfort, and control under various driving conditions. Different types of configurations provide unique benefits, balancing load distribution, shock absorption, and road handling. Understanding the available designs allows for better maintenance and customization to suit specific needs.

- Independent Suspension: Each wheel operates separately, enhancing ride comfort by reducing the transfer of motion from one wheel to another.

- Solid Axle Suspension: Both wheels on the same axle remain connected, offering greater strength, typically used for heavier applications.

- Air Suspension: Uses compressed air instead of traditional springs, providing adjustable height and smoother handling on uneven surfaces.

- Multi-Link Suspension: Consists of multiple arms controlling wheel movement, ensuring superior cornering capabilities and ride quality.

- Leaf Spring Suspension: Commonly used for vehicles carrying heavy loads, this design relies on stacked metal leaves to absorb shocks.

Choosing the right setup depends on factors like load requirements, terrain conditions, and performance expectations. Some systems focus on ride comfort, while others are optimized for durability and heavy-duty tasks, providing flexibility to meet different driving demands.

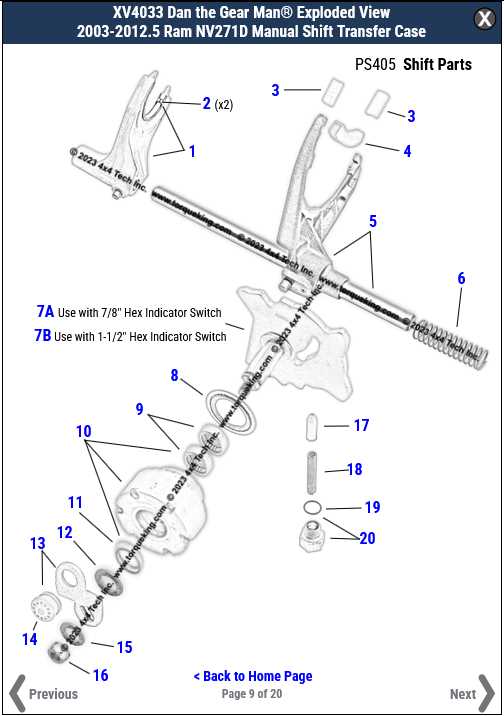

Understanding Transmission Configurations

Modern vehicles rely on various transmission setups to optimize performance, fuel efficiency, and driver comfort. Each configuration offers a unique balance of control and automation, designed to suit different driving conditions and needs. The correct transmission ensures smooth operation by efficiently managing power delivery between the engine and wheels.

- Manual Systems: These setups give drivers full control over gear shifting, often preferred by enthusiasts for their precision and engagement.

- Automatic Systems: Designed for convenience, they shift gears independently, relying on sensors to adjust according to speed and load.

- Continuously Variable Types (CVT): These units offer seamless acceleration by avoiding fixed gears, providing better efficiency and a smooth driving experience.

- Dual-Clutch Variants: Combining the advantages of both manual and automatic types, these systems use two clutches to facilitate quicker shifts.

Choosing the appropriate configuration depends on driving preferences, environmental factors, and performance requirements. Each system has its strengths and limitations, making it essential to understand how they align with personal or professional needs.

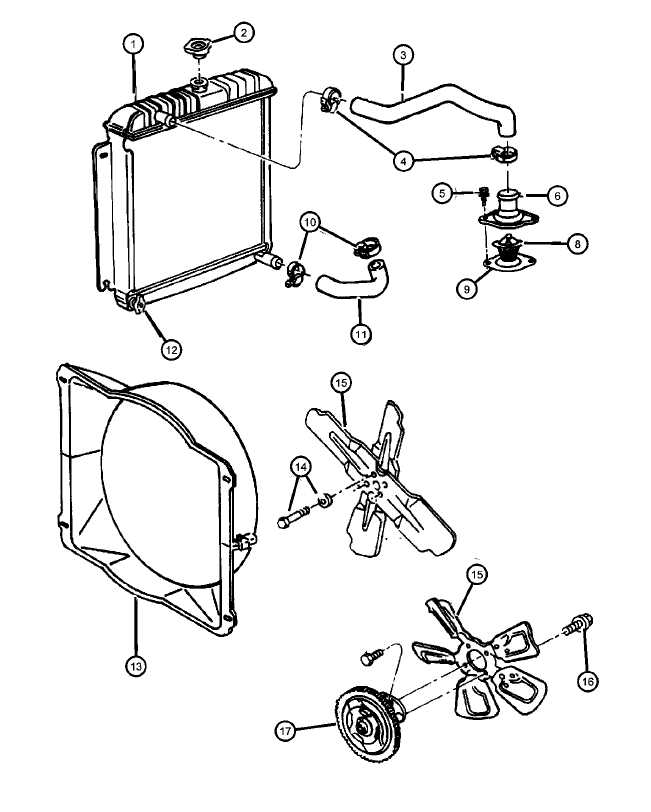

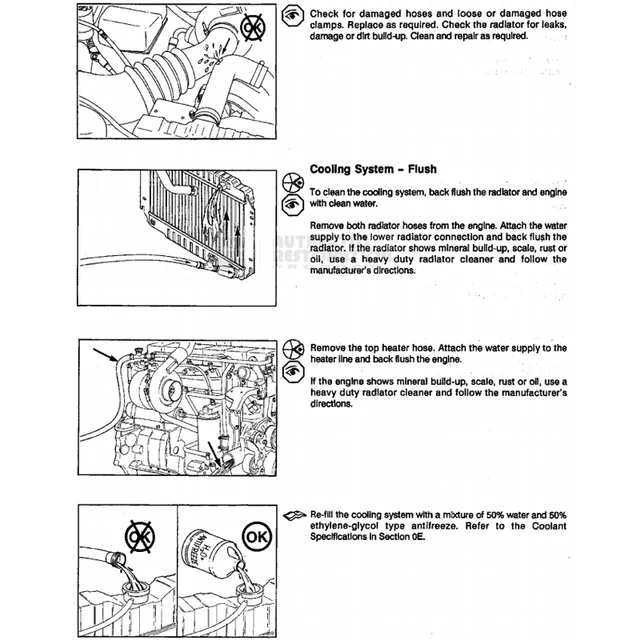

Cooling Systems Maintenance Overview

The longevity and efficiency of any engine depend heavily on proper temperature regulation. Ensuring that thermal management components are functioning correctly is critical to preventing overheating, reducing wear, and optimizing performance under various conditions.

Regular inspections help identify potential issues such as blockages, leaks, or corrosion. Over time, coolant levels may decrease, and fluid quality can degrade, affecting the system’s ability to transfer heat effectively. Timely replacement of fluids and damaged elements helps maintain the overall stability of the system.

Key practices include monitoring temperature indicators, performing pressure tests, and cleaning radiators to improve airflow. Preventive care minimizes risks associated with extreme operating environments and ensures reliable performance during extended use.

Brake System Inspection and Repairs

Regular evaluation and maintenance of the braking mechanism are essential for ensuring safety and performance. This section emphasizes the importance of identifying potential issues and addressing them promptly to avoid more significant problems. A well-functioning braking system contributes to the overall driving experience and vehicle longevity.

The inspection process involves several key steps:

- Visual Examination: Check for any visible signs of wear or damage, such as cracked hoses, leaking fluids, or worn-out pads.

- Fluid Level Check: Ensure that the brake fluid is at the appropriate level. Low fluid can indicate a leak or worn components.

- Brake Pad Condition: Assess the thickness of the pads. Replacing them before they become too thin is crucial for effective stopping power.

- Disc and Drum Inspection: Look for grooves, warping, or other irregularities on rotors and drums. These issues can affect braking performance.

- Brake Line Integrity: Inspect lines and hoses for cracks or corrosion that could lead to fluid leaks.

If any issues are detected during the inspection, timely repairs are necessary. Common repair tasks include:

- Replacing brake pads and shoes to maintain effective stopping power.

- Machining or replacing rotors and drums to ensure smooth operation.

- Flushing and replenishing brake fluid to maintain hydraulic pressure.

- Repairing or replacing damaged brake lines and hoses.

- Adjusting the braking system to factory specifications to enhance performance.

Following these inspection and repair guidelines will help ensure that the braking system operates optimally, enhancing safety and reliability on the road.

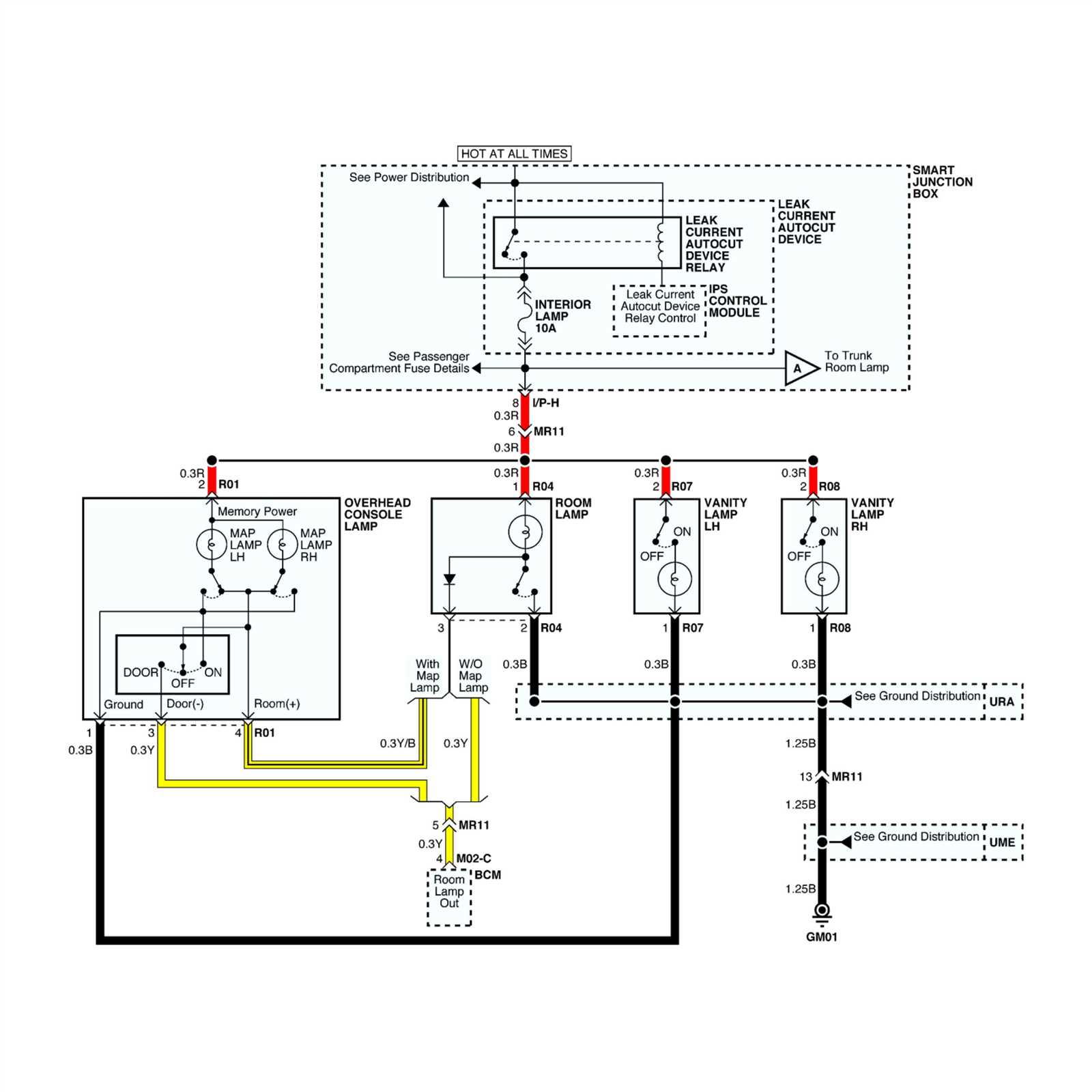

Lighting and Electrical Wiring Guide

This section aims to provide a comprehensive overview of the illumination and electrical connectivity systems in your vehicle. Understanding the intricacies of these systems is essential for ensuring optimal performance and safety. Properly maintained lighting and wiring contribute to a reliable driving experience and enhance visibility on the road.

Key components of the lighting and electrical systems include:

- Headlights: Essential for visibility during nighttime and adverse weather conditions.

- Taillights: Indicate the vehicle’s presence and actions to other drivers.

- Turn Signals: Communicate intentions for lane changes and turns to enhance safety.

- Interior Lighting: Provides illumination inside the vehicle for comfort and convenience.

- Fuses and Relays: Protect the electrical circuits from overloads and control the flow of electricity.

When inspecting or working on the electrical system, consider the following guidelines:

- Always disconnect the battery before beginning any electrical work to prevent shocks and short circuits.

- Use appropriate tools and connectors to ensure secure and reliable connections.

- Regularly check for signs of wear, such as frayed wires or corroded connectors, to maintain system integrity.

- Consult the specifications for correct bulb types and wattage to prevent damage to the electrical system.

By adhering to these practices, you can effectively maintain and troubleshoot the illumination and electrical systems, ensuring they function optimally throughout the lifespan of the vehicle.

Steering Mechanisms and Common Issues

The steering system is a vital component of any vehicle, responsible for directing the front wheels and ensuring precise control while driving. Understanding how these systems operate can help identify potential problems and enhance overall vehicle safety.

Types of Steering Systems can vary widely, with many vehicles utilizing either rack-and-pinion or recirculating ball mechanisms. Each system has its own advantages, affecting handling and responsiveness differently. For instance, rack-and-pinion systems are often praised for their direct feel and compact design, making them popular in modern automobiles.

Common Issues associated with steering mechanisms can include difficulty in turning the wheel, unusual noises while steering, and excessive play in the steering wheel. These symptoms may indicate issues such as low power steering fluid, worn-out components, or misaligned parts. Regular inspection and maintenance are essential to prevent these problems from escalating.

In conclusion, being aware of the steering system’s function and potential issues can significantly contribute to maintaining a safe and enjoyable driving experience. Addressing problems promptly not only enhances vehicle performance but also prolongs the lifespan of the steering components.

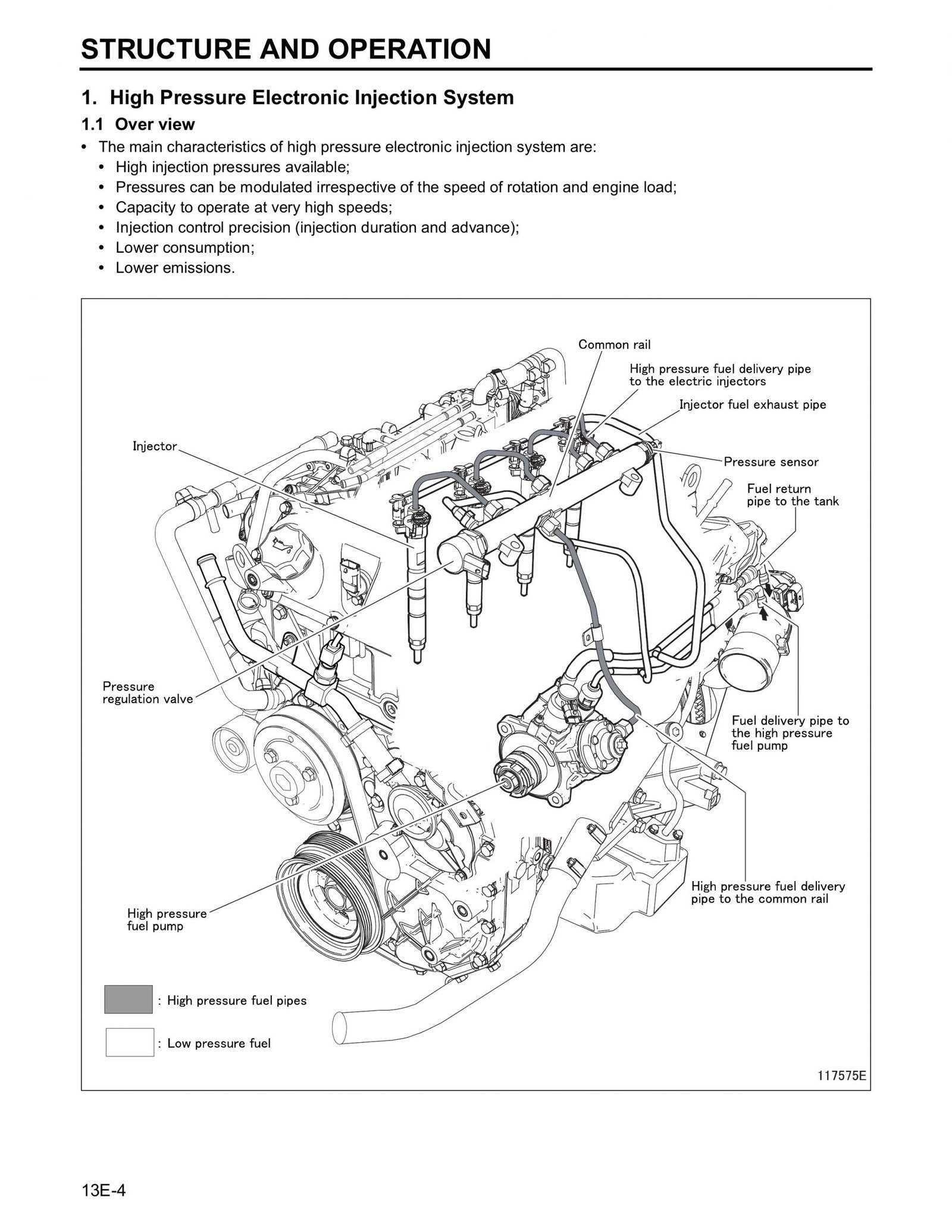

Fuel Delivery and Injection Systems

This section focuses on the mechanisms responsible for transporting fuel to the engine and ensuring optimal combustion. Understanding these systems is crucial for maintaining performance and efficiency in any vehicle.

Overview of Fuel Delivery

The fuel delivery system plays a vital role in supplying the correct amount of fuel to the engine. It consists of several components that work together to ensure a seamless flow of fuel from the tank to the engine’s combustion chamber.

Injection Mechanisms

Injection mechanisms are essential for accurately dispersing fuel into the engine. These systems utilize various technologies to enhance performance and reduce emissions, ensuring that the engine operates efficiently under different conditions.

| Component | Function |

|---|---|

| Fuel Pump | Transfers fuel from the tank to the engine |

| Fuel Filter | Removes impurities from the fuel |

| Fuel Injectors | Disperses fuel into the combustion chamber |

| Pressure Regulator | Maintains the appropriate fuel pressure |

| Intake Manifold | Directs fuel-air mixture to the engine cylinders |

Exhaust Components and Upgrades

When it comes to enhancing vehicle performance, the exhaust system plays a crucial role. Understanding the various elements that comprise this system and the potential improvements can lead to better efficiency and a more powerful engine output. Upgrading components not only boosts performance but can also improve the sound and appearance of your vehicle.

Key components of an exhaust system include the manifold, catalytic converter, muffler, and piping. Each of these parts serves a specific function, contributing to the overall effectiveness of the exhaust flow. By upgrading to high-performance alternatives, vehicle owners can achieve better gas flow, reduced back pressure, and enhanced throttle response.

| Component | Description | Upgrade Benefits |

|---|---|---|

| Manifold | Collects exhaust gases from the engine cylinders. | Improved flow and heat resistance. |

| Catalytic Converter | Reduces harmful emissions from exhaust gases. | High-flow versions can enhance performance while maintaining emissions compliance. |

| Muffler | Reduces noise produced by the exhaust gases. | Performance mufflers can improve sound and increase horsepower. |

| Piping | Connects various components of the exhaust system. | Larger diameter pipes reduce back pressure for better performance. |

In summary, upgrading exhaust components can lead to significant improvements in vehicle performance, sound, and aesthetics. Whether considering a complete overhaul or selective enhancements, understanding the impact of each component is essential for optimal results.

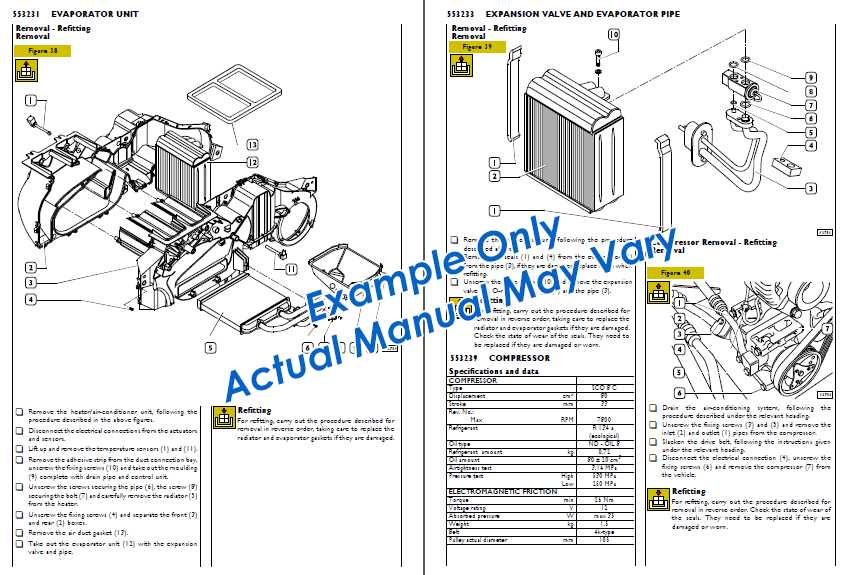

Air Conditioning and Heating Controls

The regulation of temperature and airflow within a vehicle is essential for ensuring passenger comfort and safety. This section delves into the mechanisms and components responsible for managing climate control systems, highlighting their roles and functionalities. Understanding these systems can enhance maintenance and troubleshooting efforts, contributing to a more pleasant driving experience.

Components of Climate Control Systems

Climate control systems consist of various elements that work in tandem to provide optimal temperature regulation. Key components include the control unit, sensors, and the air distribution system. Each part has a distinct function, contributing to the overall efficiency and performance of the climate management system.

| Component | Description | Function |

|---|---|---|

| Control Unit | The interface for the user to set desired temperatures and modes. | Regulates temperature settings and airflow direction. |

| Sensors | Devices that monitor cabin and outside temperatures. | Provide data to the control unit for automatic adjustments. |

| Air Distribution System | A network of ducts and vents that deliver conditioned air. | Distributes heated or cooled air throughout the cabin. |

Maintenance Tips for Climate Control Systems

Regular upkeep of climate control components is crucial for optimal performance. Ensure that filters are cleaned or replaced periodically to maintain airflow efficiency. Additionally, inspecting the system for leaks and ensuring the control unit functions correctly will prolong the lifespan of the climate management system.

Tire Selection and Wheel Alignment Tips

Choosing the right tires and ensuring proper wheel alignment are essential for optimal vehicle performance and safety. Selecting tires that match your driving style and the conditions you frequently encounter can enhance traction, handling, and fuel efficiency. Additionally, proper alignment contributes to tire longevity and improves ride quality, making it a critical aspect of vehicle maintenance.

Tips for Tire Selection

When selecting tires, consider the following factors to ensure you make an informed choice:

| Factor | Considerations |

|---|---|

| Tread Type | Choose between all-season, winter, or performance tires based on climate and driving conditions. |

| Size | Refer to the vehicle’s specifications for the correct tire dimensions to maintain safety and handling. |

| Load Index | Select tires that can support the weight of the vehicle, especially if carrying heavy loads. |

| Tread Life | Look for tires with a longer tread life rating to reduce the frequency of replacements. |

Wheel Alignment Best Practices

Maintaining proper alignment can significantly affect driving dynamics. Follow these best practices:

- Regularly check alignment settings, particularly after hitting potholes or curbs.

- Perform alignment checks at least once a year or when installing new tires.

- Observe any uneven tire wear, as it can indicate misalignment issues.

Interior Components and Dashboard Layout

The arrangement of interior elements plays a crucial role in the overall functionality and aesthetic of any vehicle. A well-designed dashboard and interior layout not only enhance the driving experience but also provide easy access to essential controls and features. Understanding the configuration of these components is vital for both maintenance and customization.

Dashboard Configuration

The dashboard serves as the central hub for the driver, housing various instruments and controls. Key features typically include the speedometer, fuel gauge, and warning lights, all strategically placed for optimal visibility. Ergonomic design is essential, ensuring that all controls are easily reachable and intuitively arranged to minimize distractions while driving.

Interior Features

Additional interior elements contribute significantly to passenger comfort and convenience. Seats are designed with support in mind, while storage compartments provide practical solutions for keeping personal items organized. Technological advancements have also introduced multimedia systems and connectivity options, enhancing the overall driving experience and making it more enjoyable.