Understanding the intricate framework that supports the agility and stability of the Ram 1500 involves a detailed examination of its foundational elements. This system, crucial for maneuverability and comfort, relies on a sophisticated arrangement of interconnected parts.

Exploring these components unveils their crucial roles in enhancing the vehicle’s handling and ensuring a smooth ride across various terrains. Each element contributes uniquely to the overall functionality, from supporting weight distribution to absorbing road imperfections.

Delving into the anatomy of these components reveals their engineering finesse, designed to withstand rigorous conditions while maintaining optimal performance. From control arms to steering linkages, each part plays a pivotal role in defining the Ram 1500’s responsive driving experience.

Understanding Dodge Ram 1500 Front Suspension

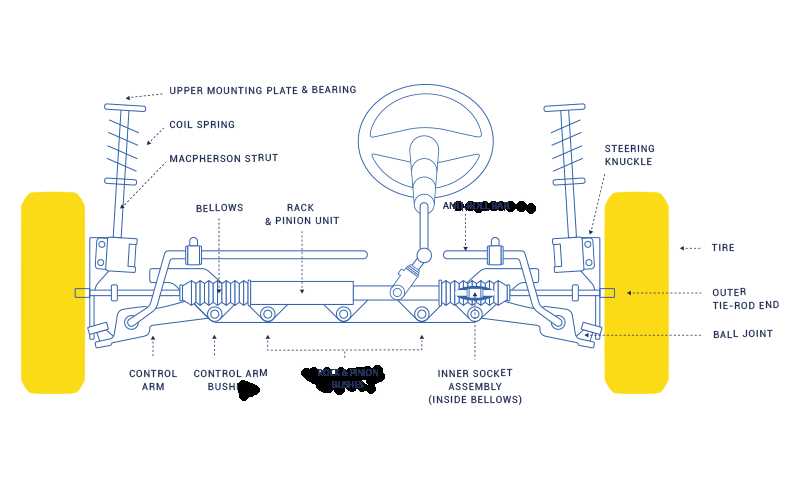

The steering and handling components of a vehicle play a crucial role in ensuring smooth operation and stability. This system is designed to manage the forces from the road, ensuring a comfortable driving experience while maintaining control and balance. Proper functioning of these elements is essential for safe and efficient travel.

Key elements that make up this mechanism include several critical connections between the wheels and the chassis, which work in harmony to absorb shocks and maintain alignment. Regular inspection and maintenance of these parts are important for optimal performance.

- Linking arms that connect the wheels to the main frame

- Shock-absorbing components that help reduce vibrations

- Control units that ensure proper alignment and handling

- Rotational devices that allow for smooth

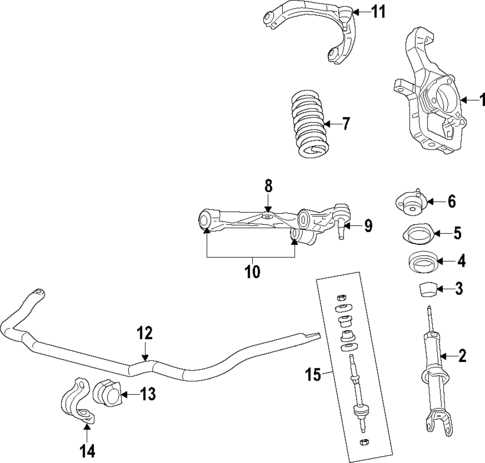

Key Components of Front End Assembly

The assembly under discussion is crucial for ensuring vehicle stability, handling, and overall performance. It is made up of multiple interconnected elements that work together to provide smooth motion, support, and precise control, making driving safe and comfortable. Each part contributes to balancing the load, absorbing impacts, and allowing for smooth directional changes.

Steering Mechanism

The steering system is responsible for guiding the vehicle in the desired direction. Key elements include the steering box and tie rods, which transmit driver input

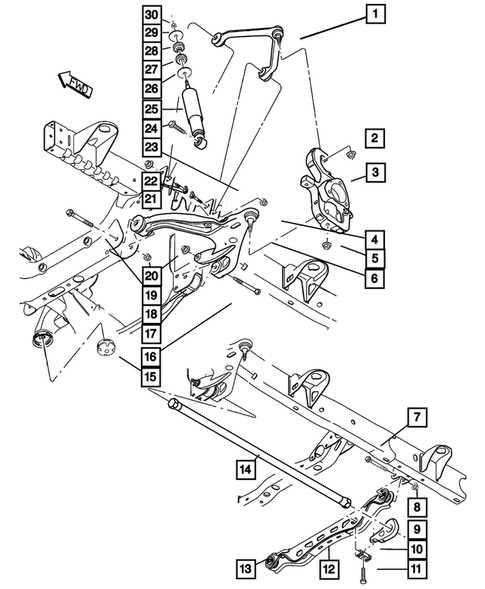

Function of Control Arms in the Suspension

The control arms play a pivotal role in connecting the wheel assembly to the vehicle’s frame, allowing for smooth movement and flexibility. These components are critical for maintaining proper alignment and handling, ensuring that the tires remain in contact with the ground while adapting to various road conditions. By providing a stable linkage, they contribute to overall driving comfort and vehicle performance.

Key Responsibilities of Control Arms

Control arms are responsible for guiding the up and down motion of the wheels while the vehicle moves. They help absorb shocks and vibrations from uneven surfaces, working in tandem with other components to provide stability and control. This minimizes wear and tear on the tires and reduces stress on other mechanical parts, enhancing the longevity of the vehicle.

Upper and Lower Control

Ball Joints and Their Importance

Ball joints play a critical role in the functionality and movement of a vehicle’s steering and mobility systems. These components connect various mechanical parts, allowing for smooth rotation and pivoting, which is essential for controlling the vehicle’s direction and stability during motion.

How Ball Joints Function

The ball joint acts as a flexible connection point that provides controlled movement between the rotating and stationary components of the vehicle. This freedom of motion enables safe and responsive handling, even when the vehicle is navigating uneven surfaces or sharp turns.

Signs of Ball Joint Wear

Over time, ball joints can experience wear due to the stresses and movements they endure. Common signs of wear include unusual noises, uneven tire wear, and reduced steering precision. Identifying

Exploring the Role of Tie Rod Ends

The tie rod ends are crucial components in maintaining the precise movement of a vehicle’s wheels. They ensure that the steering mechanism functions effectively, allowing smooth transitions and turns. These elements serve as connectors between various parts of the system, transmitting the driver’s input directly to the wheels. Without them, the control of the vehicle would be compromised, leading to uneven tire wear and potential safety concerns.

Moreover, tie rod ends play a significant role in stabilizing the alignment of the wheels. They help in maintaining the proper direction and orientation, preventing drifting and ensuring that the vehicle responds accurately to steering commands. Regular inspection and maintenance of these components are vital to ensure optimal performance and safety on the road.

Shock Absorbers in Front Suspension

Shock absorbers are essential components designed to minimize the impact of uneven terrain and ensure a smooth ride. They work by converting kinetic energy from the vehicle’s movement into heat, which is then dissipated. This function helps to reduce excessive bouncing, maintaining control and stability.

Functionality of Shock Absorbers

The primary role of shock absorbers is to manage the energy produced when driving over bumps and dips. They prevent the vehicle from excessive vertical movement by controlling the rebound of the springs. Without them, the ride would feel harsh and uncontrolled, making the driving experience uncomfortable.

Impact on Handling and Safety

Properly functioning shock absorbers improve overall vehicle control, ensuring better grip and responsiveness. They not only enhance comfort but also contribute to the longevity of other components by reducing the strain on the vehicle’s structure.

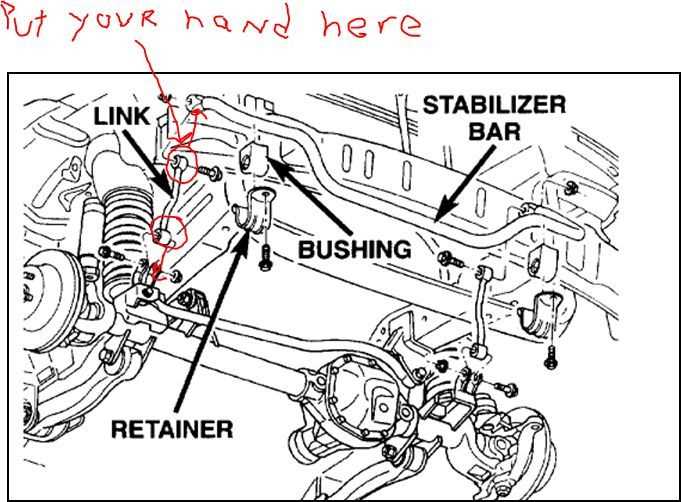

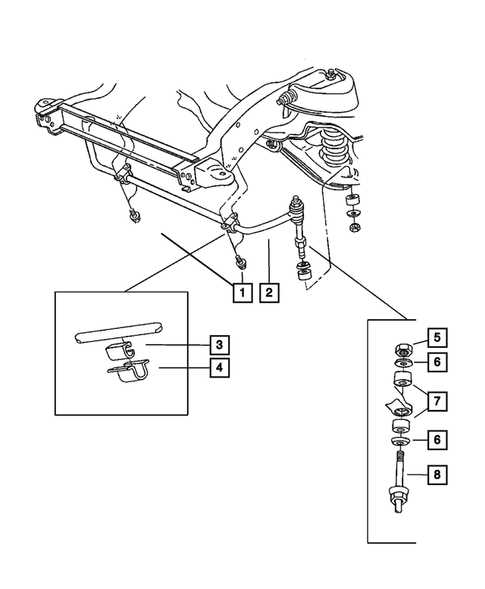

Stabilizer Bar and Its Contribution to Stability

The stabilizer bar, also known as an anti-roll bar, plays a critical role in enhancing vehicle stability. It works by reducing body roll during turns, allowing for improved handling and control. This component is essential for maintaining balance, particularly in larger vehicles.

When a vehicle takes a turn, the centrifugal force causes the body to lean outward. The stabilizer bar helps counteract this force, providing a more level ride and reducing the risk of tipping. The effectiveness of this mechanism is influenced by several factors, including the design and material of the bar.

- Functionality: The stabilizer bar connects the left and right sides of the vehicle’s axle, ensuring that movement on one side is mirrored on the other.

- Material: Typically made from steel or other durable materials, the strength and flexibility of the bar are crucial for its performance.

- Design: The diameter and shape of the bar can vary, with thicker bars generally providing better stability.

Proper maintenance of the stabilizer bar is essential for optimal performance. Worn or damaged components can lead to decreased effectiveness, resulting in poor handling and increased body roll. Regular inspections can help ensure that this crucial part remains in good condition, contributing to overall vehicle safety.

Wheel Bearings and Hub Assembly Breakdown

The assembly that connects the wheel to the vehicle is crucial for maintaining stability and safety. This section delves into the intricate components of the wheel bearings and hub assembly, which play a significant role in ensuring smooth rotation and support for the overall structure. Understanding these elements can help in recognizing potential issues and performing necessary maintenance.

Components of the Wheel Bearing Assembly

The wheel bearing assembly typically consists of several key elements, including the inner and outer races, rolling elements, and seals. The inner and outer races form the tracks for the rolling elements, allowing for smooth motion as the wheel rotates. The rolling elements, usually in the form of balls or rollers, reduce friction and enable efficient operation. Seals protect the assembly from dirt and moisture, extending its lifespan.

Maintenance and Replacement Considerations

Regular inspection and maintenance of the wheel bearings and hub assembly are essential for vehicle longevity. Signs of wear, such as noise or vibration, may indicate the need for replacement. When replacing these components, it is important to use high-quality parts and follow the manufacturer’s specifications to ensure proper fit and function.

Steering Knuckle and Its Purpose

The steering knuckle is a vital component in the vehicle’s wheel assembly, facilitating the connection between the wheel and the suspension system. Its primary role is to enable the rotation of the wheel while providing support for various other parts involved in steering and control. This intricate part is crucial for maintaining stability and handling while driving.

Typically made of durable materials such as cast iron or aluminum, the steering knuckle houses the spindle, which accommodates the wheel hub and brake assembly. The design allows for smooth articulation during steering maneuvers, ensuring that the vehicle responds accurately to driver inputs.

Function Description Wheel Support Holds the wheel hub in place, allowing for smooth rotation. Linkage Connection Connects various components such as the tie rod and control arm. Weight Distribution Helps distribute the weight of the vehicle across the wheel assembly. Steering Precision Facilitates accurate steering input from the driver. Overall, the steering knuckle plays a critical role in ensuring safe and responsive vehicle operation, making it an essential component in automotive design.

Importance of Regular Suspension Maintenance

Maintaining the critical components of a vehicle’s framework is essential for ensuring optimal performance and safety. Regular upkeep not only enhances the driving experience but also prevents costly repairs down the line. It involves routine inspections and timely replacements to keep the system functioning effectively.

Neglecting these essential parts can lead to various issues, such as decreased stability, uneven tire wear, and compromised handling. Additionally, worn components can affect the vehicle’s overall balance, resulting in a bumpy ride and increased stress on other systems. Thus, regular checks are vital to maintain the integrity of the vehicle.

Engaging in consistent maintenance practices allows for early detection of potential problems. Addressing minor issues promptly can save drivers from experiencing more significant, expensive repairs in the future. Ultimately, prioritizing this aspect of vehicle care contributes to safer journeys and enhances the overall lifespan of the automobile.

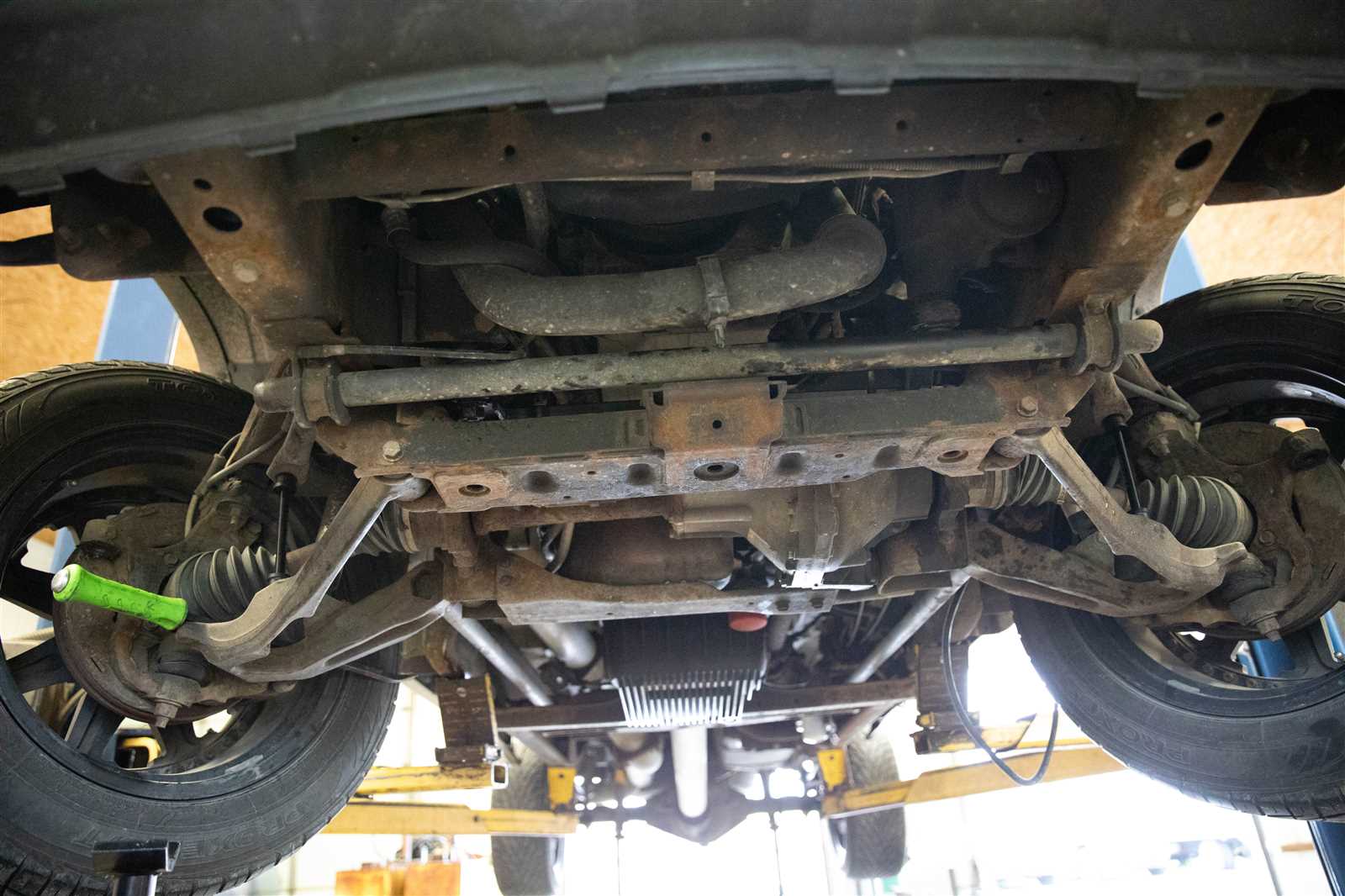

How to Identify Worn Front End Parts

Recognizing signs of deterioration in the components of a vehicle’s undercarriage is essential for maintaining safety and performance. Understanding the symptoms of wear can help prevent further damage and ensure a smooth driving experience. Regular inspections and knowledge of potential indicators can aid in identifying issues before they escalate.

Visual Inspection

Conducting a thorough visual assessment is a crucial first step. Look for any noticeable damage, such as cracks or rust on the metal components. Pay attention to rubber bushings; if they appear cracked or missing, it may indicate deterioration. Also, check for any leaking fluids around joints, as this can signal failing seals.

Performance Testing

In addition to visual cues, performance can reveal underlying problems. Listen for unusual noises while driving, such as clunks or pops, which may indicate loose or damaged elements. Additionally, observe how the vehicle handles during turns; excessive swaying or a feeling of looseness can suggest compromised components. Taking note of these signs will help in addressing issues promptly and effectively.