When exploring the intricate systems that allow for entry and exit in heavy-duty vehicles, one can appreciate the complexity involved in the construction and functionality of various assemblies. These structures not only provide security but also contribute to the overall efficiency and user experience of the vehicle. A comprehensive examination reveals the essential elements that work together to ensure smooth operation and durability.

Delving into the individual elements reveals how each component plays a vital role in the larger mechanism. From structural supports to locking mechanisms, every piece is designed with precision to fulfill specific functions. Understanding these elements is crucial for effective maintenance and repairs, ensuring that each system operates optimally.

Moreover, recognizing the interactions between different components enhances one’s ability to troubleshoot issues that may arise over time. Familiarity with the configuration and roles of these elements empowers users to make informed decisions regarding upgrades or replacements, ultimately contributing to the longevity of the vehicle.

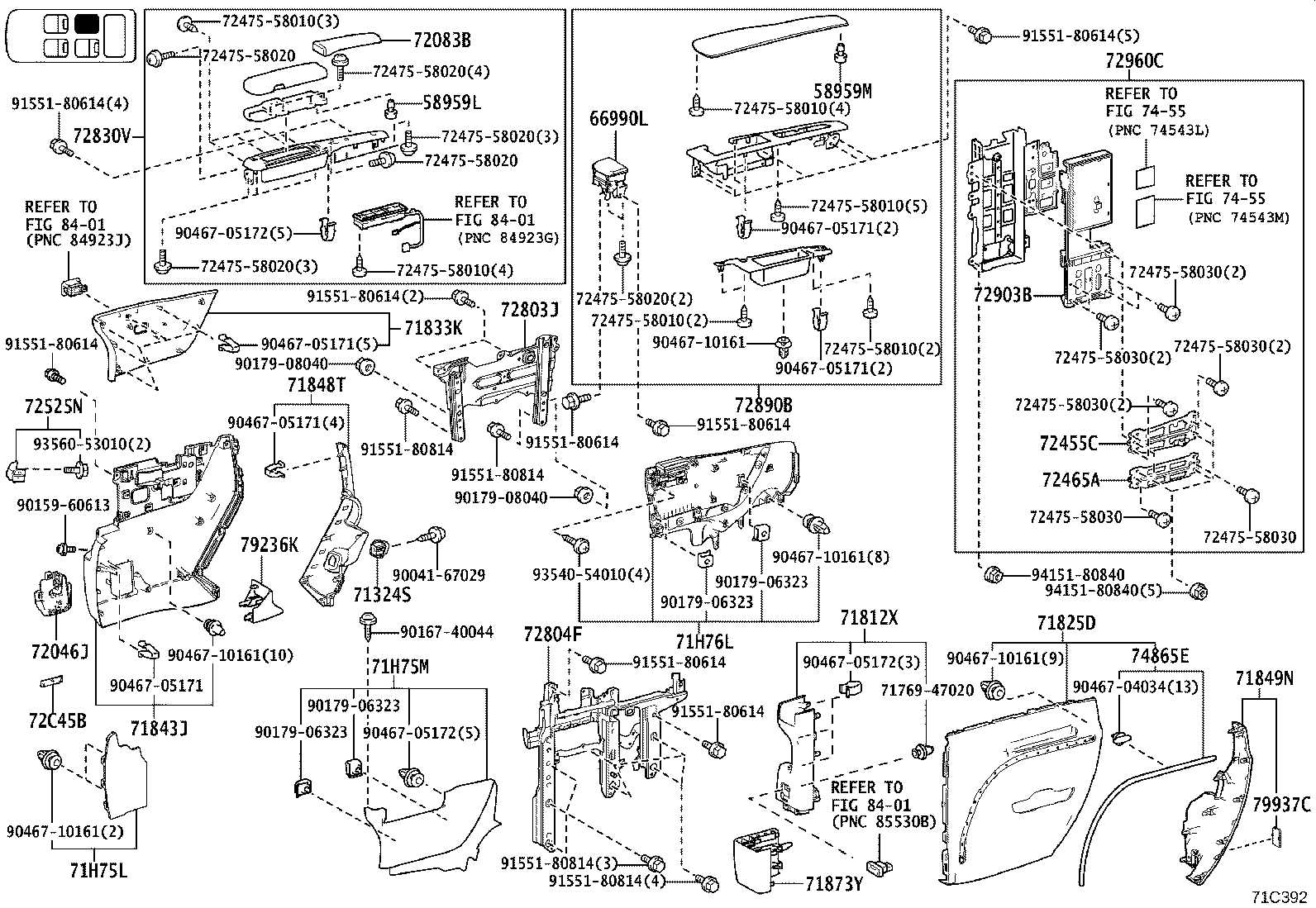

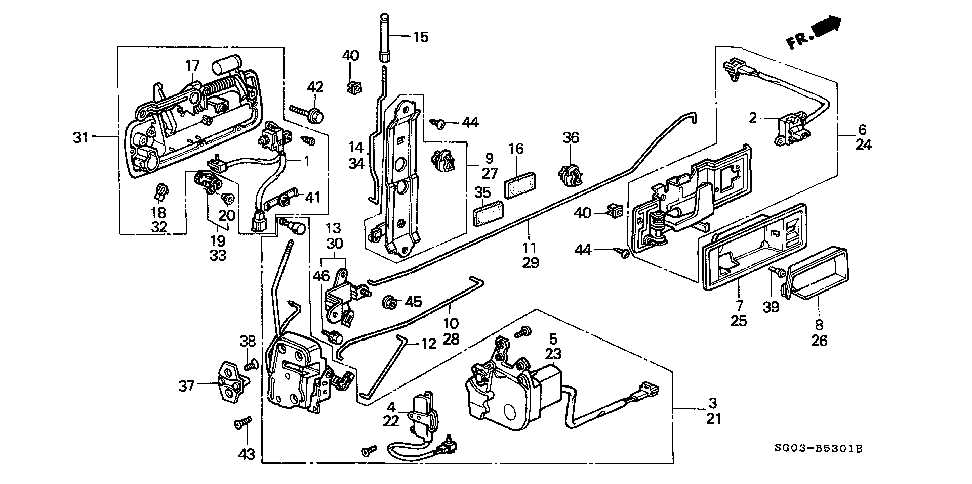

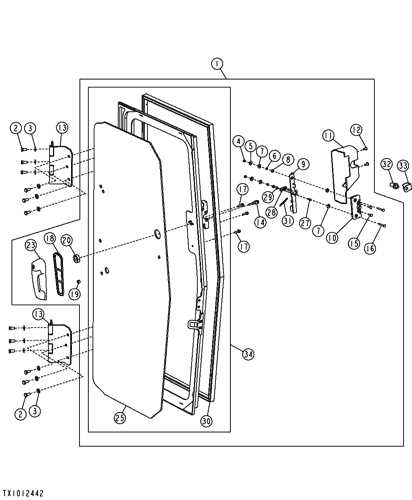

Overview of Kenworth Door Components

This section delves into the various elements that make up the vehicle access system, emphasizing their significance in functionality and user experience. Understanding these components is crucial for maintaining optimal operation and ensuring safety.

The assembly typically consists of several critical elements, each serving a unique purpose in the overall mechanism. These parts work harmoniously to facilitate secure entry and exit, while also providing protection against external elements.

| Component Name | Description |

|---|---|

| Handle | Enables opening and closing, providing a secure grip for users. |

| Latch | Secures the access point when closed, ensuring safety and stability. |

| Hinge | Facilitates smooth movement, allowing the mechanism to swing open and shut effortlessly. |

| Seals | Prevents water and debris from entering, enhancing durability and comfort. |

| Interior Panel | Offers a finished appearance and houses various controls for user convenience. |

By familiarizing oneself with these elements, users can better appreciate the engineering behind access mechanisms and their importance in vehicle functionality.

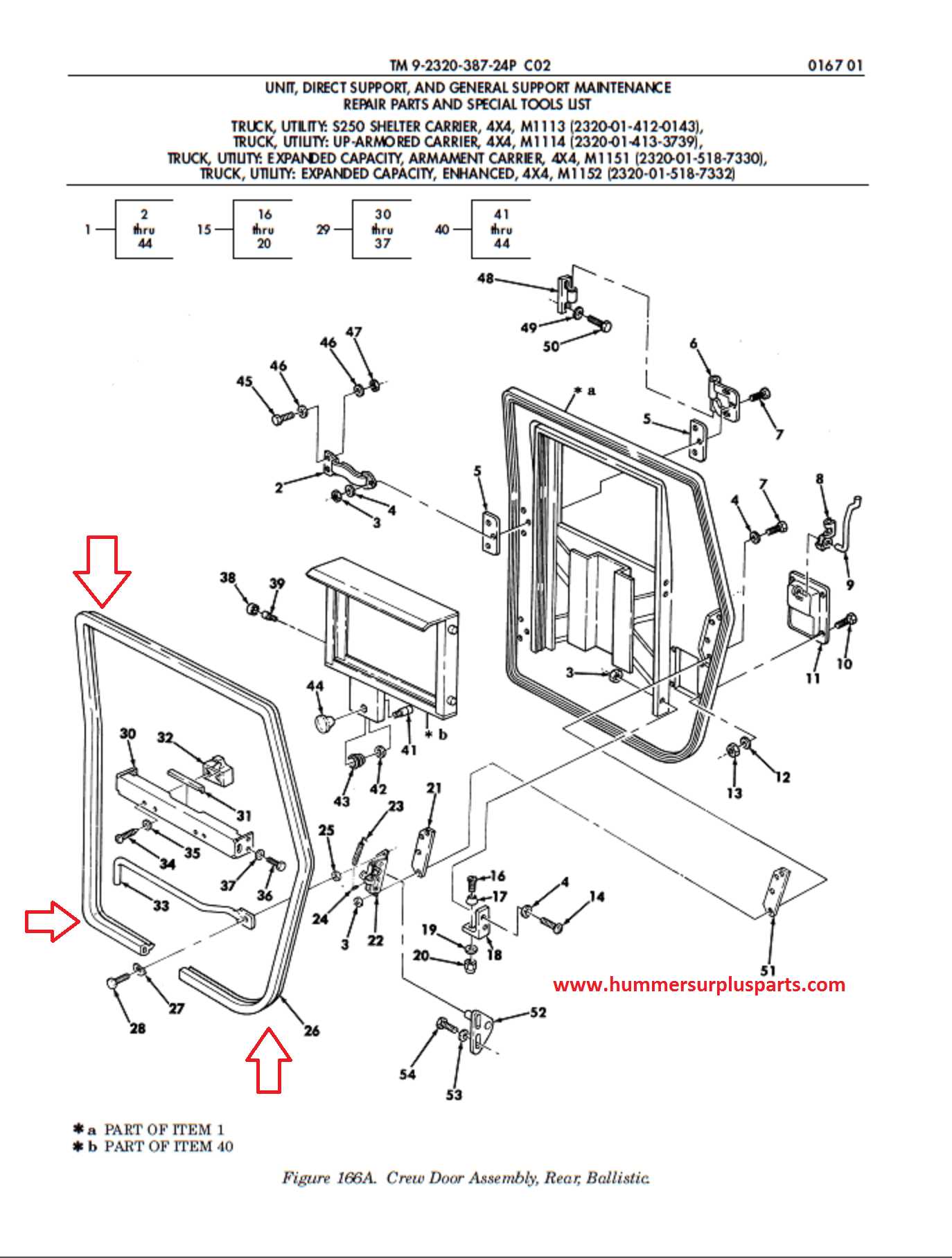

Understanding Door Assembly Structure

The assembly of an entryway comprises various components working in harmony to provide functionality and security. Each section plays a vital role in ensuring optimal operation, enhancing both convenience and safety for users.

At the core of this construction lies the framework, which serves as the backbone. This robust structure supports all other elements, offering stability and alignment. In conjunction with the frame, the mechanism for securing and releasing the entryway is crucial. This system ensures that access can be controlled efficiently, while also safeguarding against unauthorized entry.

Furthermore, the aesthetic aspect cannot be overlooked. The exterior finish contributes to the overall appeal and design integrity of the vehicle, reflecting the manufacturer’s branding and style. Additionally, insulation and weatherproofing materials are essential for maintaining an internal environment that is comfortable and protected from external elements.

Understanding these components and their interactions is key to appreciating the complexity and craftsmanship involved in the assembly. Maintenance and regular inspections are necessary to preserve the integrity and functionality of the structure, ensuring it remains effective throughout its lifespan.

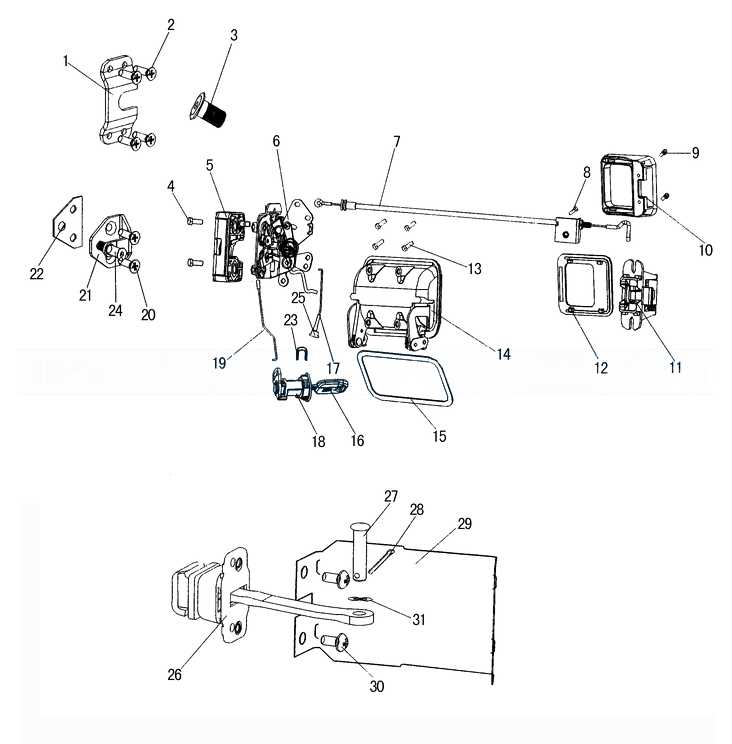

Key Elements of Door Mechanism

The functionality of an access opening is determined by several essential components that work in harmony. Understanding these elements is crucial for maintaining and repairing the system effectively.

- Frame Structure: This component provides the necessary support and alignment for the entire assembly.

- Locking System: A vital feature that ensures security, it typically includes a latch and a bolt mechanism.

- Hinge Assembly: Facilitates smooth movement, allowing the structure to pivot open and closed seamlessly.

- Weather Seals: These elements protect against external elements, ensuring a tight fit that prevents water and air infiltration.

- Handle Mechanism: Designed for user convenience, it allows for easy operation of the access opening.

Each of these components plays a significant role in ensuring reliability, security, and ease of use, highlighting the intricate design and engineering behind an effective entry system.

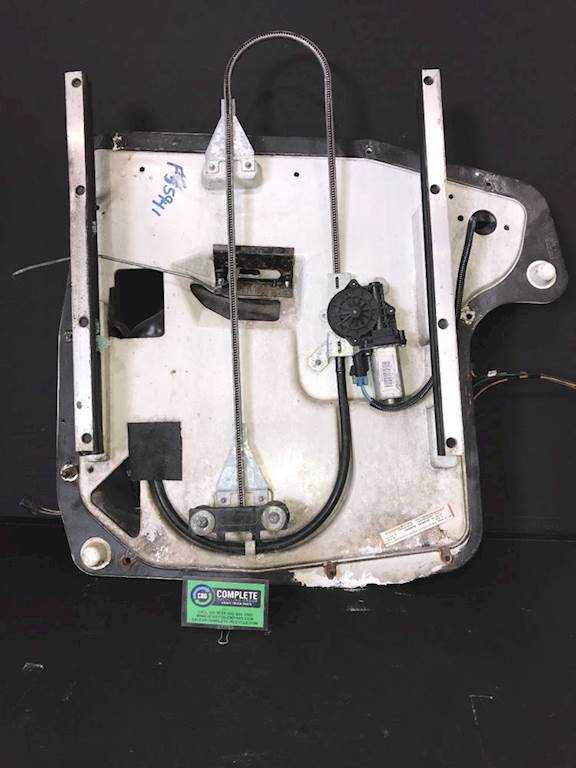

Common Issues with Door Parts

In any vehicle, the elements that allow for access and security can experience various challenges over time. Recognizing these issues early can lead to more efficient maintenance and enhance the longevity of the components involved.

Wear and Tear: Regular usage can cause natural degradation of components, leading to reduced functionality. This can manifest as difficulties in opening or closing mechanisms, often requiring adjustments or replacements.

Misalignment: Components can shift from their intended positions due to impacts or wear. This misalignment may cause friction or prevent proper closure, which can compromise the overall integrity of the system.

Corrosion: Exposure to the elements can lead to rust and other forms of corrosion. This degradation affects metal components, potentially leading to failures that necessitate prompt attention to ensure safety.

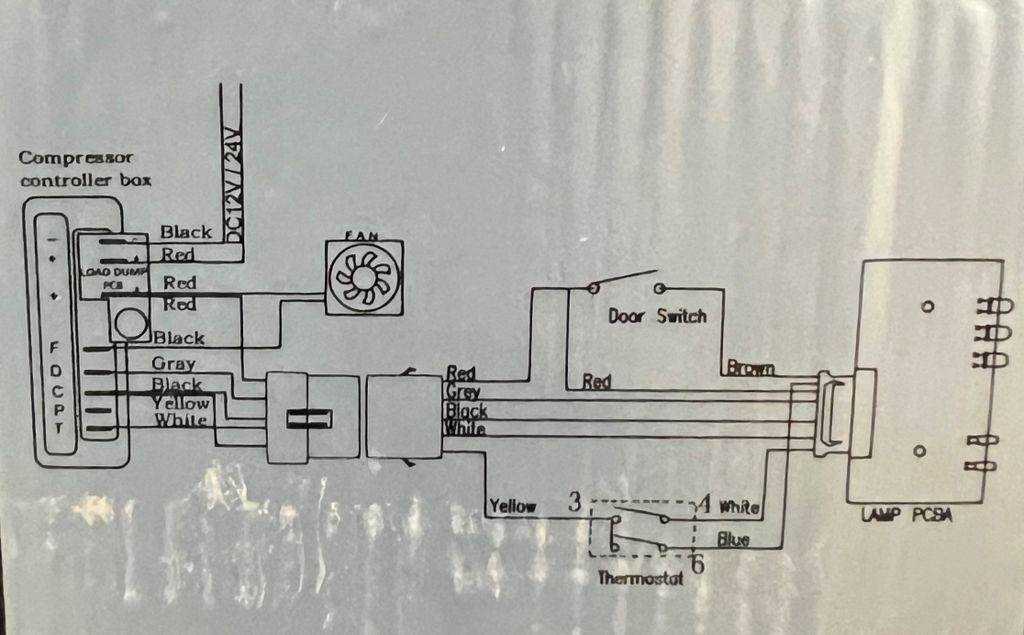

Electrical Failures: In systems that incorporate electronic elements for locking mechanisms or window controls, electrical issues can arise. Faulty wiring or damaged connectors may lead to malfunctions, making it crucial to inspect these areas regularly.

Noise: Unusual sounds during operation can indicate underlying problems. Rattling or grinding noises often suggest that certain elements are not functioning as intended, signaling the need for immediate investigation.

Addressing these common challenges proactively can prevent more significant issues down the road, ensuring smooth operation and security.

Importance of Quality Replacement Parts

Utilizing high-grade components is crucial for maintaining the functionality and longevity of any vehicle. The reliability and safety of an automobile significantly depend on the materials and items employed during repairs or replacements. When subpar alternatives are chosen, it can lead to various issues, impacting overall performance and potentially jeopardizing safety.

Benefits of Using Premium Components

Opting for superior quality elements ensures optimal performance and reduces the risk of premature wear and failure. Quality components often come with enhanced durability and better resistance to environmental factors, ensuring that they can withstand harsh conditions over time.

Long-Term Cost Efficiency

While it might be tempting to choose less expensive options, investing in high-quality replacements often proves to be more economical in the long run. Although the initial costs may be higher, these components generally offer greater reliability, decreasing the likelihood of frequent replacements and repairs.

| Quality Level | Pros | Cons |

|---|---|---|

| High Quality | Increased durability, enhanced performance, long-term savings | Higher initial investment |

| Low Quality | Lower cost | Reduced lifespan, increased maintenance, potential safety risks |

Tools Needed for Door Repairs

When undertaking repairs on a vehicle’s entry system, having the right tools is essential for a successful and efficient process. Various instruments not only facilitate the disassembly and reassembly of components but also ensure that the repair work meets safety and functional standards. Below is an overview of the necessary equipment that will help streamline the repair process.

Basic Hand Tools

A variety of hand tools are indispensable for any repair task. Commonly needed items include screwdrivers, wrenches, pliers, and a hammer. These tools assist in loosening and tightening fasteners, as well as manipulating parts during the installation or removal process. Additionally, a utility knife can be useful for cutting through weather stripping or other materials.

Specialized Equipment

In some cases, specialized tools may be required to handle specific tasks effectively. For instance, a trim removal tool can help detach paneling without causing damage, while a torque wrench ensures that fasteners are tightened to the manufacturer’s specifications. Furthermore, a multimeter may be necessary for checking electrical connections and components related to locking mechanisms or window operations.

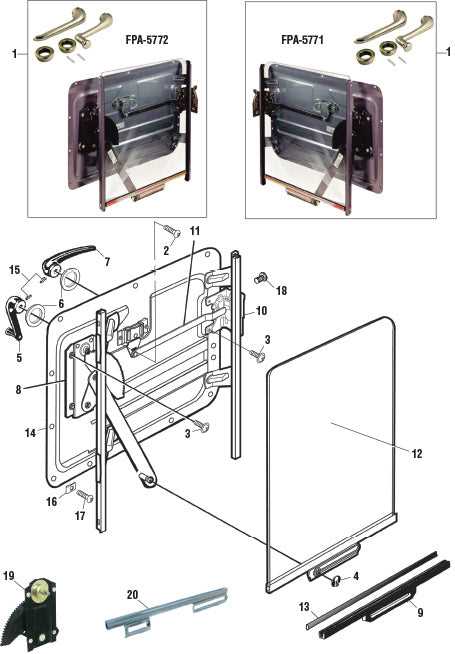

Installation Steps for Door Components

Proper assembly of entry mechanisms is essential for ensuring functionality and security. Following systematic procedures during installation can prevent future issues and enhance the overall performance of the assembly. This section outlines crucial steps to effectively integrate these components into your vehicle’s structure.

Preparation and Tools Required

Before commencing installation, gather all necessary tools and components. Essential tools may include screwdrivers, pliers, and a torque wrench, among others. Ensure that all components are compatible with the existing framework and are in optimal condition to facilitate a smooth installation process.

Step-by-Step Assembly Process

Begin by securing the main framework, ensuring that it is clean and free of debris. Position the components according to the layout plan, aligning them correctly for optimal fit. Gradually fasten each part, checking for stability and alignment as you proceed. Complete the installation by testing the functionality of each component to ensure everything operates smoothly and efficiently.

Maintenance Tips for Door Longevity

Ensuring the durability and functionality of vehicle access mechanisms requires regular attention and care. Implementing effective maintenance strategies can significantly enhance their lifespan and performance. Here are some practical suggestions to keep these components in optimal condition.

Regular Inspection

- Check for any signs of wear or damage, including cracks and rust.

- Examine hinges and latches for proper alignment and functionality.

- Inspect seals for deterioration to prevent water and dust intrusion.

Cleaning and Lubrication

- Clean surfaces with a mild detergent to remove dirt and grime.

- Apply lubricant to hinges and moving parts to ensure smooth operation.

- Use silicone spray on seals to maintain flexibility and prevent cracking.

By adhering to these maintenance practices, you can prolong the life of vehicle entry systems and enhance their efficiency, ultimately contributing to a better driving experience.

Safety Considerations During Repairs

Ensuring safety during repair tasks is paramount to prevent injuries and maintain a secure working environment. Workers should prioritize safety measures to mitigate risks associated with handling tools and components. Adopting proper practices not only protects individuals but also enhances the overall efficiency of the repair process.

Protective Gear

Wearing appropriate protective equipment is crucial. Safety goggles, gloves, and steel-toed boots can significantly reduce the risk of injury. Additionally, using ear protection when operating loud machinery can prevent hearing damage, while respirators may be necessary when working with harmful substances.

Tool Handling and Workspace Organization

Proper tool handling techniques are essential for safety. Ensure that all tools are in good condition and suitable for the task at hand. Keep the workspace tidy and free from hazards, such as spills or debris, which can lead to slips and falls. By maintaining an organized environment, workers can focus on their tasks without unnecessary distractions.

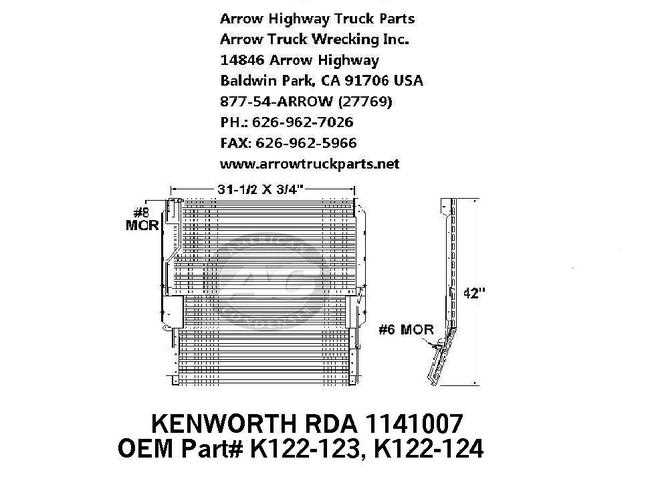

Finding Genuine Kenworth Parts

When it comes to maintaining the integrity of your vehicle, sourcing authentic components is essential. High-quality replacements ensure reliability, longevity, and optimal performance. Whether you’re looking to replace worn-out elements or upgrade existing features, obtaining original materials is crucial for preserving the functionality of your machine.

Identifying Authentic Components requires a careful approach. Start by researching reputable suppliers and manufacturers known for their commitment to quality. Look for certifications or endorsements that guarantee the authenticity of the items offered. Engaging with communities and forums can also provide valuable insights and recommendations.

Investing in genuine materials not only enhances the operational efficiency of your vehicle but also contributes to its resale value. Keep an eye out for warranties or guarantees that come with original items, as these can offer added peace of mind. Always prioritize quality over cost to ensure the longevity of your investment.

Comparing OEM and Aftermarket Options

When it comes to selecting components for vehicle maintenance and repairs, there are two primary categories to consider: original manufacturer products and alternative market solutions. Each option presents distinct advantages and potential drawbacks that can impact both performance and budget.

Original manufacturer products are typically designed to meet the specific standards set by the vehicle’s creator. These offerings often provide reliability and quality assurance, but they can come at a higher price. Here are some key characteristics:

- Precision engineering tailored to fit the vehicle model.

- Higher resale value retention due to quality assurance.

- Access to warranty support and service history.

On the other hand, alternative market solutions often appeal to cost-conscious consumers seeking budget-friendly options. While these alternatives may offer similar functionality, it’s essential to evaluate their quality and compatibility. Consider the following aspects:

- Potential cost savings, making repairs more affordable.

- Availability of a wider variety of choices and styles.

- Varied quality levels, requiring thorough research before purchase.

Ultimately, the decision between original and alternative products will depend on individual needs and preferences. Weighing the benefits and limitations of each option can lead to a more informed choice that aligns with maintenance goals.