In the realm of outdoor machinery, grasping the intricacies of your tools is essential for optimal performance and maintenance. A well-structured overview of the individual elements can significantly enhance your understanding and troubleshooting abilities. This section aims to provide clarity on the assembly of your essential gardening equipment.

By exploring a detailed layout of the various components, users can identify each piece’s function and interrelation. This insight is invaluable for anyone seeking to improve their proficiency in equipment care and repair. Understanding how these parts work together is crucial for achieving the ultimate efficiency in your outdoor tasks.

Moreover, recognizing the specific elements involved allows for informed decisions regarding upgrades or replacements. Engaging with this information empowers users to delve deeper into their machinery’s capabilities, ensuring that every task is performed with precision and reliability.

Understanding Stihl KM HL 135 Components

Gaining insight into the various elements that comprise this versatile tool is essential for effective maintenance and operation. Each component plays a critical role in ensuring optimal performance, contributing to the overall efficiency and longevity of the equipment. Familiarity with these parts enables users to troubleshoot issues more effectively and enhance their understanding of how the device functions as a whole.

The core assembly includes the engine, which powers the entire system, and various attachments designed for specific tasks. Each attachment serves a unique purpose, allowing for a range of applications from trimming to edging. Knowledge of these interchangeable elements can significantly expand the utility of the machine.

Furthermore, understanding the assembly layout aids in identifying potential wear and tear points. Regular inspection of components such as the throttle and ignition systems can preempt mechanical failures, ensuring a smooth operational experience. This proactive approach to equipment care ultimately leads to improved results and reduced downtime.

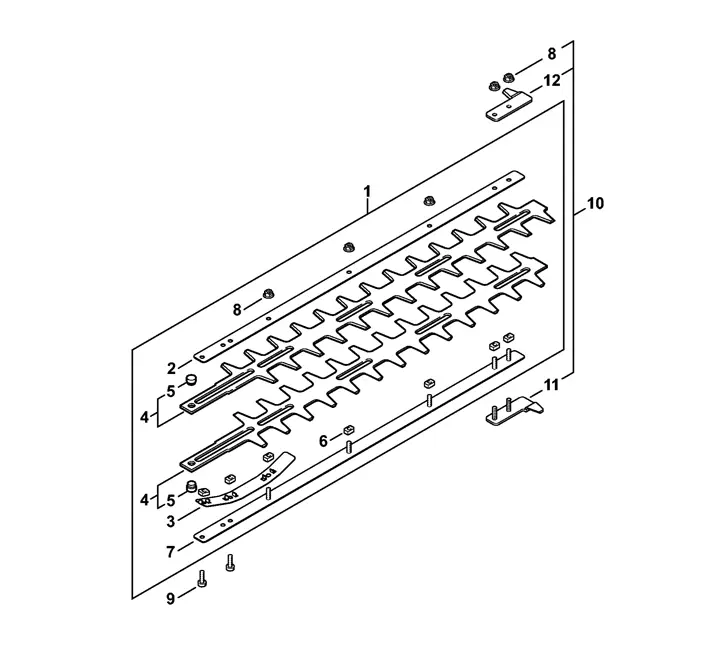

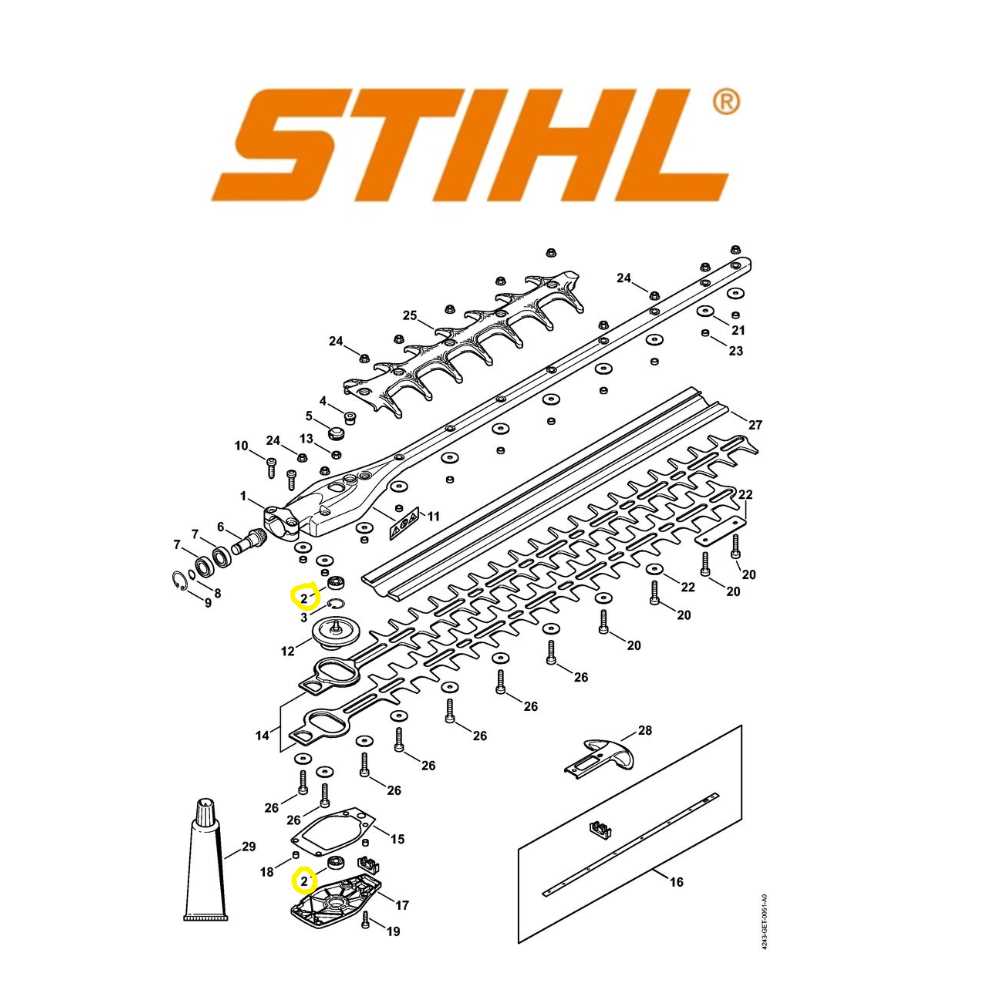

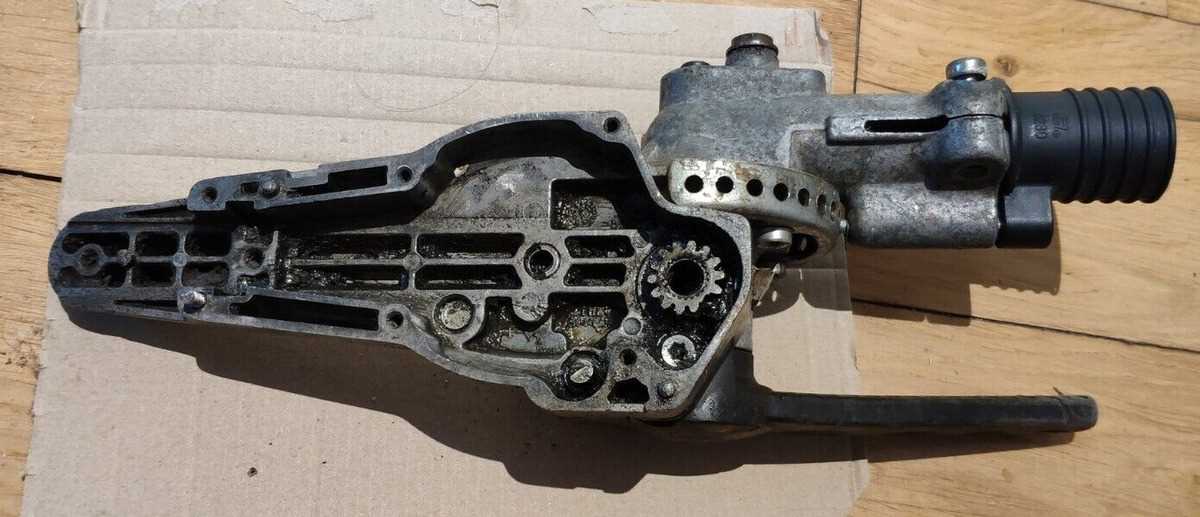

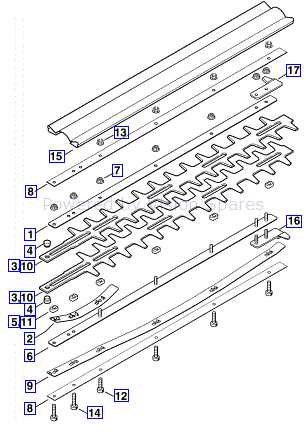

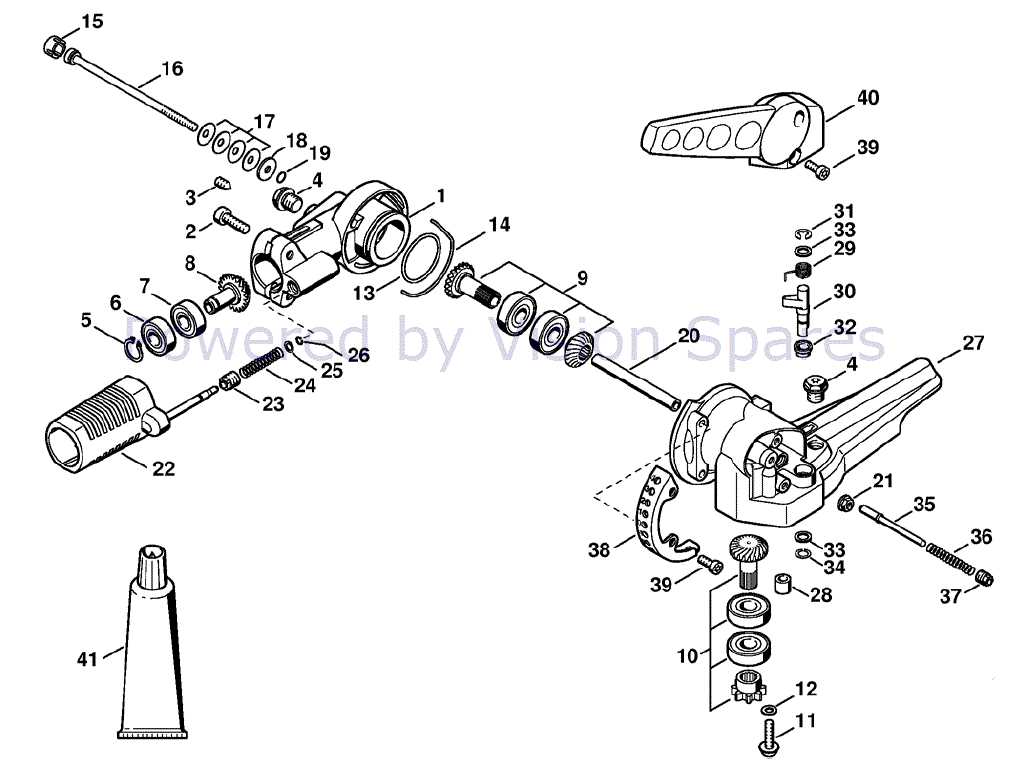

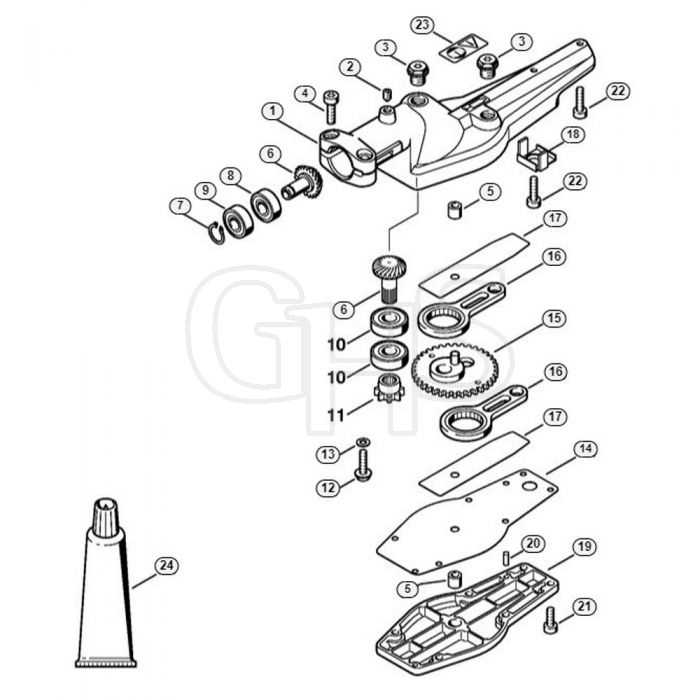

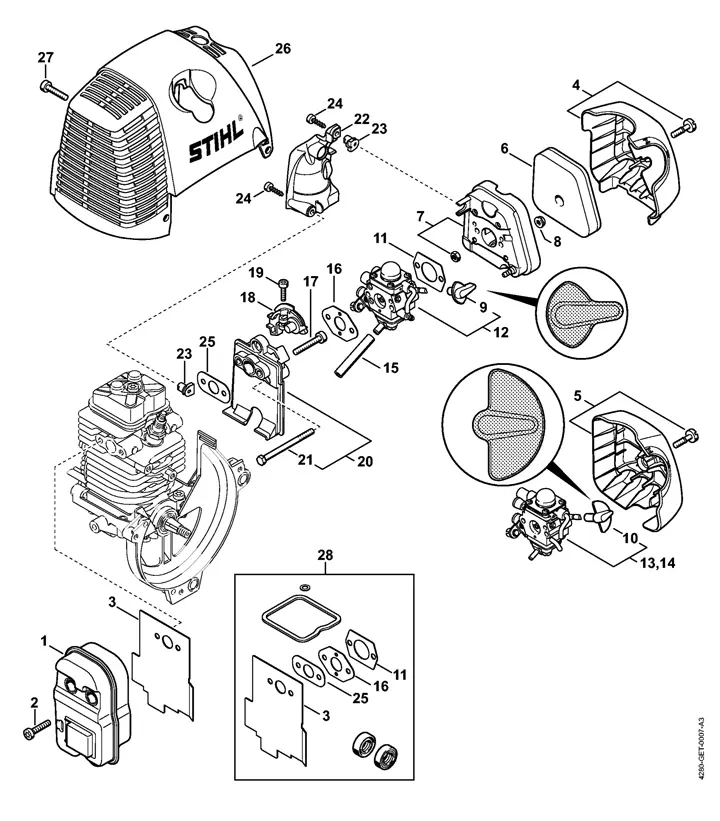

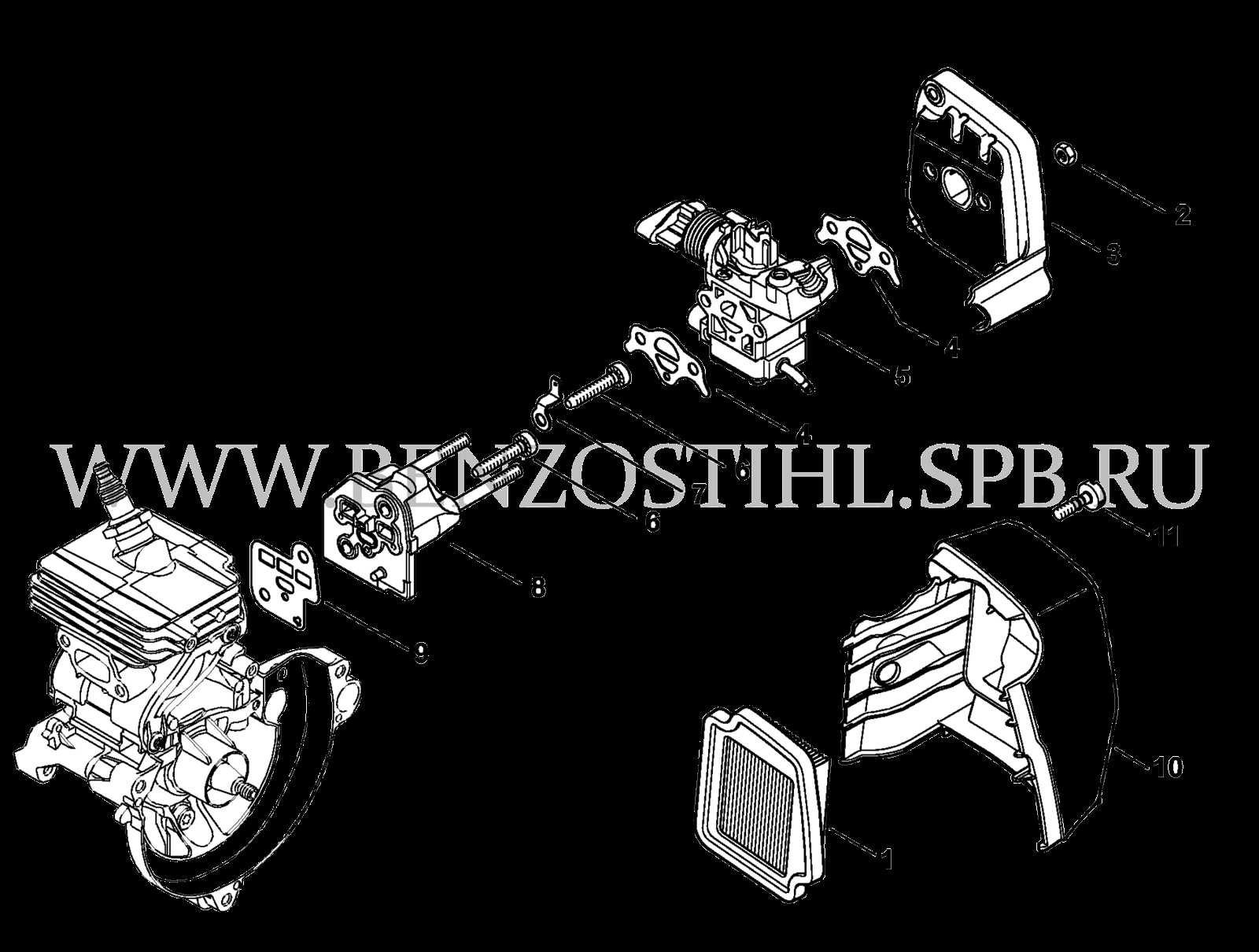

Overview of the Parts Diagram

This section provides a comprehensive examination of the visual representation that illustrates the various components of the equipment. Understanding this layout is crucial for effective maintenance and repair, enabling users to identify each element and its function within the system.

Importance of the Visual Guide

A detailed visual reference enhances the ability to locate specific elements quickly, streamlining the process of troubleshooting or replacing any malfunctioning parts. Familiarity with this guide can ultimately lead to improved performance and longevity of the machine.

Key Components Highlighted

| Component | Description |

|---|---|

| Handle | Provides control and maneuverability. |

| Engine | The power source that drives the entire unit. |

| Attachment | Interchangeable tools for various tasks. |

| Fuel Tank | Holds the necessary fuel for operation. |

Common Issues with Stihl KM HL 135

When operating a versatile outdoor tool, users may encounter various challenges that can affect performance and efficiency. Understanding these common problems can help in maintaining optimal functionality.

- Starting Difficulties: Users often face issues with ignition, which can stem from fuel problems or electrical failures.

- Engine Stalling: This may occur due to a clogged air filter or fuel line obstructions.

- Reduced Power: Lack of power during operation might be linked to worn components or improper fuel mixtures.

- Vibration: Excessive shaking can indicate loose parts or imbalanced attachments.

- Overheating: Insufficient cooling or blocked vents can lead to overheating issues.

Addressing these problems promptly can enhance longevity and performance, ensuring a better experience with your equipment.

Maintenance Tips for Optimal Performance

Regular upkeep is essential to ensure your equipment runs smoothly and efficiently. Implementing effective maintenance practices not only extends the lifespan of your machine but also enhances its overall functionality. By focusing on key areas, you can achieve the best performance possible.

Routine Cleaning

Cleanliness is vital for optimal operation. Make sure to remove dirt, debris, and residues after each use. Regular cleaning helps prevent clogging and wear, which can hinder performance. Use appropriate tools to maintain all surfaces, ensuring everything remains in peak condition.

Periodic Inspections

Conduct regular inspections to identify any potential issues early on. Check essential components such as blades, filters, and fuel lines for wear and tear. Addressing problems promptly can save you from costly repairs and ensure that your equipment continues to function at its best.

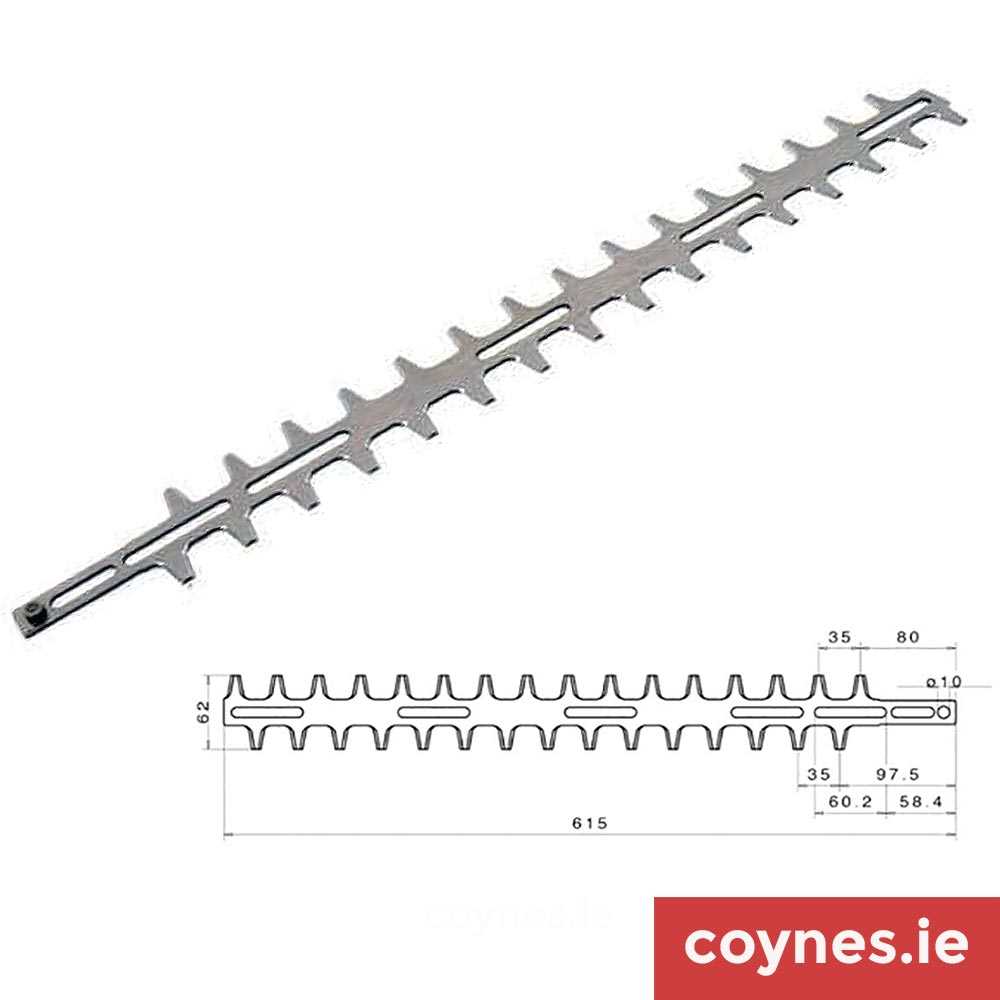

Identifying Parts in the Diagram

Understanding the components within a visual representation is crucial for effective maintenance and repair. By recognizing each element, users can ensure their equipment operates efficiently and safely. This section will guide you through the process of identifying these essential parts.

Key Components Overview

Familiarity with the primary elements will enhance your ability to troubleshoot and make necessary adjustments. Here are some common sections found in such visuals:

| Component Name | Description |

|---|---|

| Engine Housing | Encases the motor, providing protection and stability. |

| Handle Grip | Facilitates user control and comfort during operation. |

| Fuel Tank | Holds the necessary fuel for powering the device. |

| Blade Assembly | Responsible for cutting or trimming, depending on the application. |

Utilizing the Visual Representation

By closely examining the layout, users can pinpoint specific areas needing attention. This knowledge not only aids in repairs but also in optimizing the functionality of the equipment.

Where to Buy Replacement Parts

Finding the right components for your outdoor equipment is essential for maintaining its performance and longevity. There are various sources where enthusiasts can acquire high-quality items to ensure their tools operate efficiently.

| Source | Description |

|---|---|

| Authorized Dealers | Official retailers provide genuine components with warranties and expert advice. |

| Online Retailers | Websites offer a wide selection, often at competitive prices, with convenient delivery options. |

| Local Repair Shops | Neighborhood services can supply parts and assist with installations, ensuring compatibility. |

| Manufacturer’s Website | Direct purchase from the creator guarantees authenticity and access to the latest releases. |

| Aftermarket Suppliers | These providers offer alternatives that can be more affordable, but quality varies. |

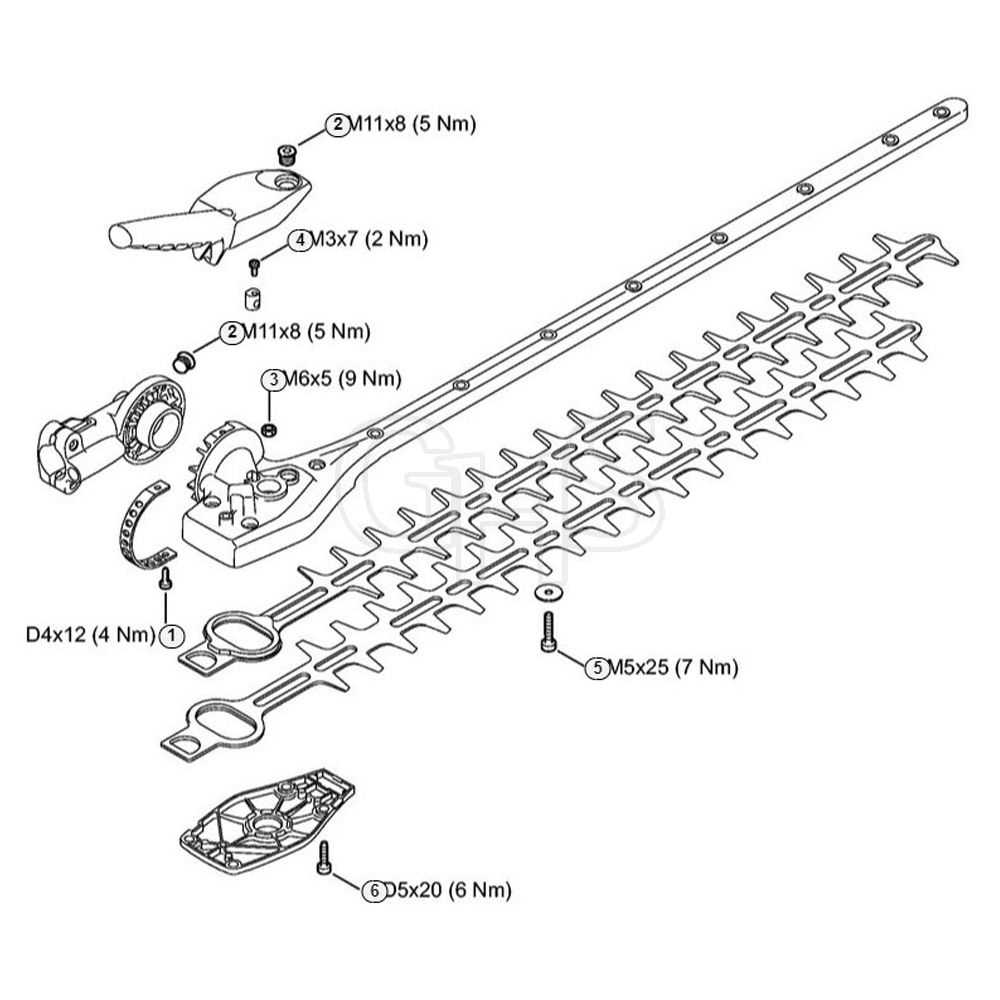

Assembly Process Explained

The assembly process of outdoor power equipment involves a systematic approach to ensure that each component is correctly fitted and functions optimally. Understanding the sequence and methodology can enhance both efficiency and performance.

Here are the key stages involved in the assembly:

- Preparation:

- Gather all necessary tools and components.

- Review the assembly guide for detailed instructions.

- Ensure a clean and organized workspace.

- Initial Assembly:

- Start with the base unit, securing any foundational elements.

- Attach major components, such as the engine or motor, ensuring all connections are snug.

- Component Integration:

- Incorporate secondary parts like handles and safety guards.

- Verify the alignment and fit of each piece.

- Final Adjustments:

- Conduct a thorough inspection of all connections and assemblies.

- Make necessary adjustments to ensure proper operation.

- Testing:

- Perform functionality tests to check performance.

- Address any issues that arise during testing.

Following these stages methodically not only leads to a successful assembly but also contributes to the longevity and reliability of the equipment.

Comparison with Similar Models

When exploring various outdoor power equipment, it is essential to assess how different models stack up against each other. Understanding the nuances in design, functionality, and performance can guide users in selecting the most suitable option for their needs.

Key Features

- Engine Power: Compare horsepower and efficiency levels.

- Weight: Consider portability and ease of handling.

- Attachments: Examine the versatility in available accessories.

Performance Metrics

- Operational Range: Look into the reach and capability in various tasks.

- Fuel Efficiency: Assess how long models run on a tank.

- Maintenance Needs: Evaluate the ease of upkeep for long-term use.

Benefits of Using Genuine Parts

Utilizing authentic components ensures optimal performance and longevity of your equipment. These meticulously crafted pieces are designed to fit seamlessly, minimizing the risk of malfunctions and enhancing overall efficiency.

One significant advantage is the assurance of quality. Genuine items undergo rigorous testing and adhere to strict manufacturing standards, guaranteeing reliability that aftermarket alternatives often lack.

Moreover, employing original components can safeguard your warranty. Many manufacturers stipulate that using non-genuine parts may void warranty claims, leading to potentially costly repairs.

Additionally, authentic items often provide better support and service. Manufacturers typically offer comprehensive customer assistance, ensuring that users can resolve issues effectively.

Tools Needed for Repairs

When undertaking maintenance or fixing equipment, having the right instruments is crucial for efficiency and effectiveness. Proper tools not only streamline the process but also ensure that repairs are carried out safely and accurately.

- Wrenches: Essential for loosening and tightening various components.

- Screwdrivers: Necessary for removing and securing screws in different sizes.

- Socket Set: Useful for dealing with nuts and bolts in tight spaces.

- Pliers: Versatile tools for gripping, twisting, and cutting wires.

- Grease Gun: Important for lubrication to enhance performance and longevity.

Ensuring you have these tools on hand will facilitate smoother repair processes and help achieve the ultimate results you desire.

FAQs about Stihl KM HL 135

This section addresses common inquiries related to a versatile tool designed for various landscaping tasks. Understanding its features and maintenance can enhance your experience and efficiency while using it.

Common Questions

| Question | Answer |

|---|---|

| What is the recommended fuel type? | It is advisable to use a mixture of high-quality gasoline and two-stroke oil. |

| How often should I perform maintenance? | Regular maintenance is recommended every 10 hours of use, including checking the air filter and spark plug. |

| Can I use attachments from other models? | Compatibility varies; always consult the user manual for specific attachment guidance. |

Performance Tips

To achieve optimal results, ensure your tool is well-maintained and that you follow the manufacturer’s guidelines regarding operation and storage. Regularly check the sharpness of cutting components to maintain efficiency.