Marine propulsion systems play a crucial role in ensuring smooth and efficient movement through water. Understanding the various components that make up these systems is essential for maintaining and optimizing performance. These mechanical parts are designed to work together, driving the vessel with precision and reliability. Each section serves a specific function, contributing to the overall effectiveness of the boat’s operation.

The mechanisms involved in marine propulsion are built to withstand harsh environments and high loads. Key elements include structures responsible for transferring power from the engine to the propeller, ensuring a seamless conversion of energy. Proper maintenance and knowledge of these components can significantly enhance longevity and reduce the risk of operational failures.

For boating enthusiasts and professionals alike, familiarity with the various elements of a marine propulsion system is vital for troubleshooting and replacement. By gaining a clear understanding of how these mechanical parts

Overview of the Alpha One Gen 2

This section introduces the essential features of a widely recognized marine propulsion system. Designed for durability and smooth operation, this unit offers a balance between performance and reliability, making it a preferred choice for various watercraft applications. Understanding its structure and mechanisms helps in better maintaining and operating it efficiently.

- High-performance drive system designed for efficiency in various conditions.

- Optimized for long-lasting service with minimal maintenance.

- Well-engineered components ensure smooth transitions and improved control.

The system’s construction is focused on achieving both power and durability, ensuring it can handle high demands without compromising its performance. With regular inspections, users can extend its lifespan and prevent common issues.

Main Components of the Outdrive

The propulsion system of a marine vessel relies on various interconnected elements to ensure efficient movement and control. These essential components work together to transfer power from the engine to the water, enabling smooth navigation and maneuvering.

Propeller: This rotating blade is crucial for converting engine power into thrust, pushing the boat forward or backward.

Drive Shaft: A vital link between the engine and the rotating parts below the waterline, it transmits power directly from the motor to the propeller.

Gimbal Bearing: This component provides support to the drive shaft while allowing it to rotate freely. It also absorbs vibrations and ensures smooth movement.

Trim and Tilt System: The trim system allows for adjusting the angle of the propeller in relation to the water, improving performance, while the tilt mechanism helps lift the lower

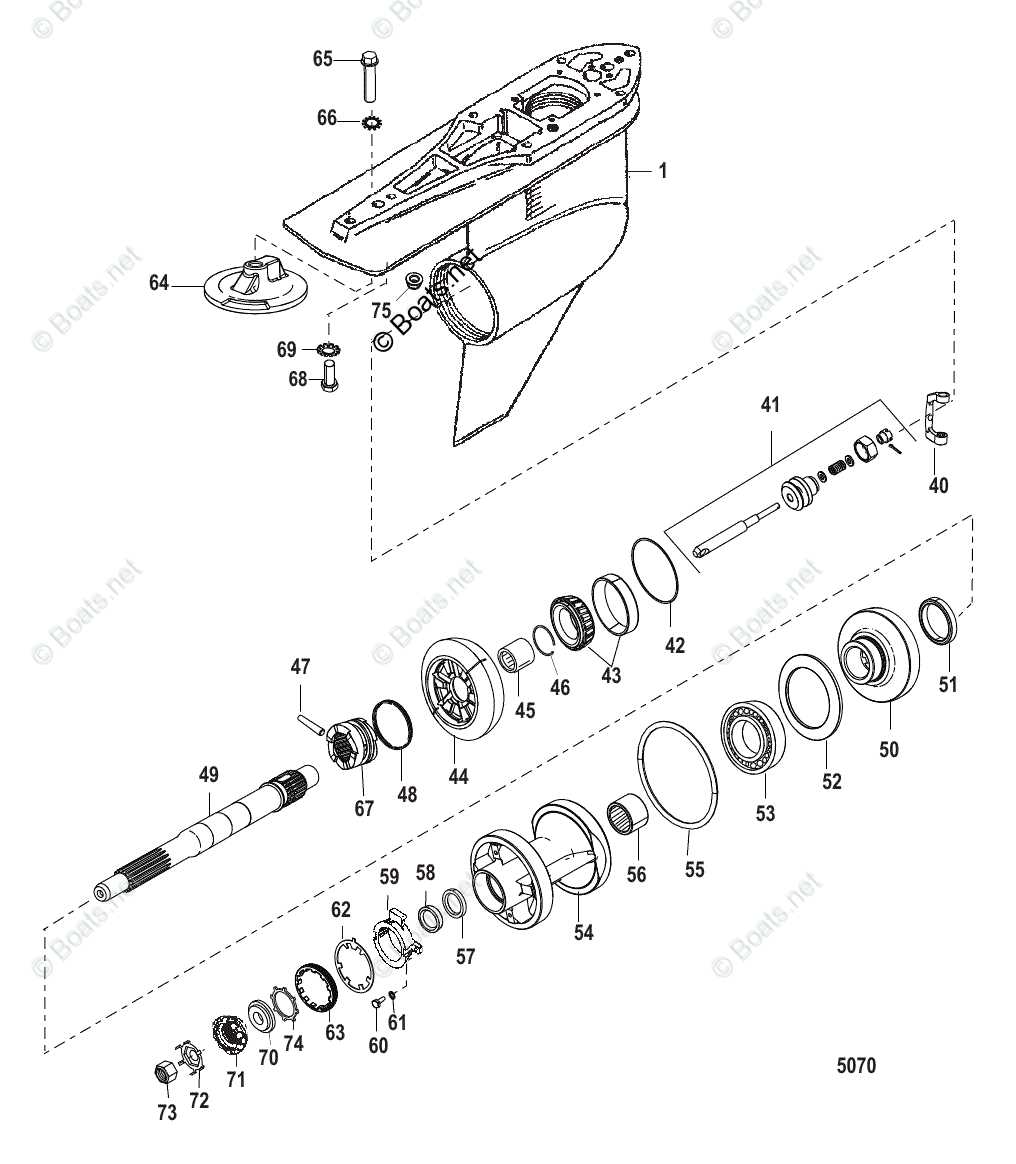

Understanding the Gear Assembly

The gear assembly plays a crucial role in ensuring smooth operation and power transfer within the marine propulsion system. This component allows for efficient handling of torque and speed variations, ensuring the proper functionality of the entire system. It consists of several interlocking parts, all working together to manage rotational movement and adjust performance based on operating conditions.

At the core of this assembly are gears of varying sizes and types, which work in sync to regulate the power flow from the engine. The design is structured to minimize wear while maximizing efficiency, making it a vital part of maintaining optimal performance. Proper understanding of how each element interacts is essential for troubleshooting and maintenance.

Propeller Shaft and Its Role

The propeller shaft plays a critical function in marine propulsion, serving as a conduit between the engine and the propeller. This essential component transfers rotational energy, enabling the vessel to move efficiently through the water. By ensuring a smooth transmission of power, it directly influences the boat’s overall performance and maneuverability.

One of the main tasks of the shaft is to maintain stability while minimizing vibrations, contributing to a quieter and more comfortable ride. Its proper maintenance and alignment are key factors in preserving the longevity of the system and ensuring optimal efficiency during operation.

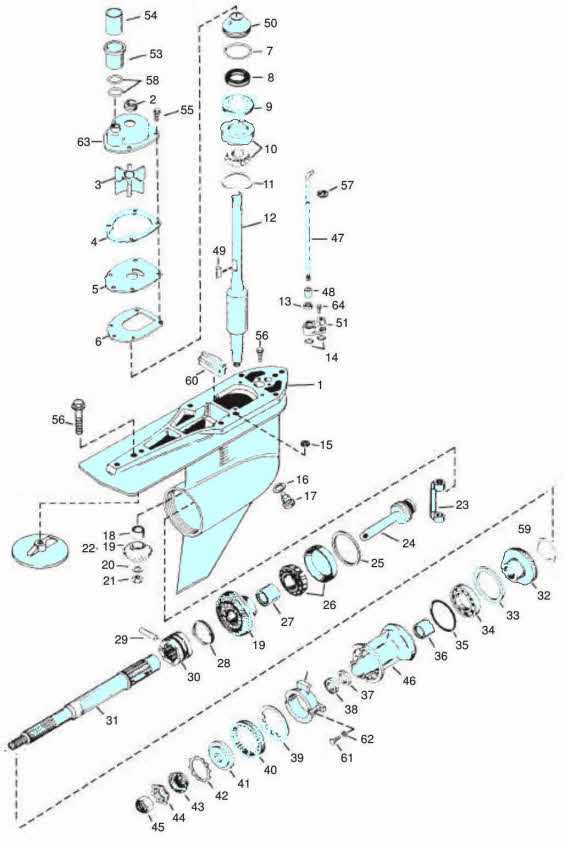

Water Pump Functionality and Parts

Efficient operation of the cooling system relies on the correct functioning of the water pump, which circulates fluid through the engine. This ensures that the temperature remains optimal during various performance levels.

The system is composed of several key components working in unison to maintain flow and prevent overheating. Below are the main elements contributing to its effectiveness:

- Impeller – Responsible for pushing the liquid through the system, ensuring a steady flow.

- Gaskets – These provide a seal between different sections, preventing leaks and maintaining pressure.

- Housing – Protects the internal components and ensures that the coolant is channeled correctly.

- Seals – These

Detailed Breakdown of the Upper Unit

This section provides a comprehensive analysis of the components found in the upper assembly of a marine drive system. Understanding the individual elements is crucial for effective maintenance and troubleshooting.

Key Components

- Housing: Protects internal parts and supports overall structure.

- Gear Mechanism: Enables power transfer from the engine to the propeller.

- Shaft: Connects the gear assembly to the propeller, facilitating motion.

- Seals: Prevents water intrusion and maintains lubrication within the unit.

- Bearing: Reduces friction between moving parts, ensuring smooth operation.

Maintenance Tips

- Regularly inspect seals for wear and replace as needed.

- Check lubricant levels and top off to ensure proper function.

- Inspect gears for signs of damage or excessive wear.

- Clean any debris from the housing to prevent overheating.

- Monitor the shaft for alignment and ensure it is securely fastened.

Lower Unit Components and Maintenance

The lower section of a marine propulsion system is crucial for ensuring optimal performance and durability. Understanding its various elements and their functions can help in maintaining the efficiency of the entire setup. Regular checks and proper care of these components can prevent significant issues and extend the lifespan of the unit.

Key Components Overview

This section highlights the essential elements found in the lower unit and their roles in overall operation:

Component Function Gear Assembly Transfers engine power to the propeller. Propeller Shaft Connects the gear assembly to the propeller. Water Pump Circulates coolant to prevent overheating. Seal and Gasket Prevents leakage of lubricants and water. Housing Encases and protects internal components. Maintenance Tips

To ensure the longevity and effectiveness of the lower unit, follow these maintenance practices:

- Regularly check fluid levels and replace as needed.

- Inspect seals for wear or damage to prevent leaks.

- Clean the water pump to ensure proper cooling function.

- Examine the gear assembly for any signs of wear.

- Store in a dry place during off-seasons to avoid corrosion.

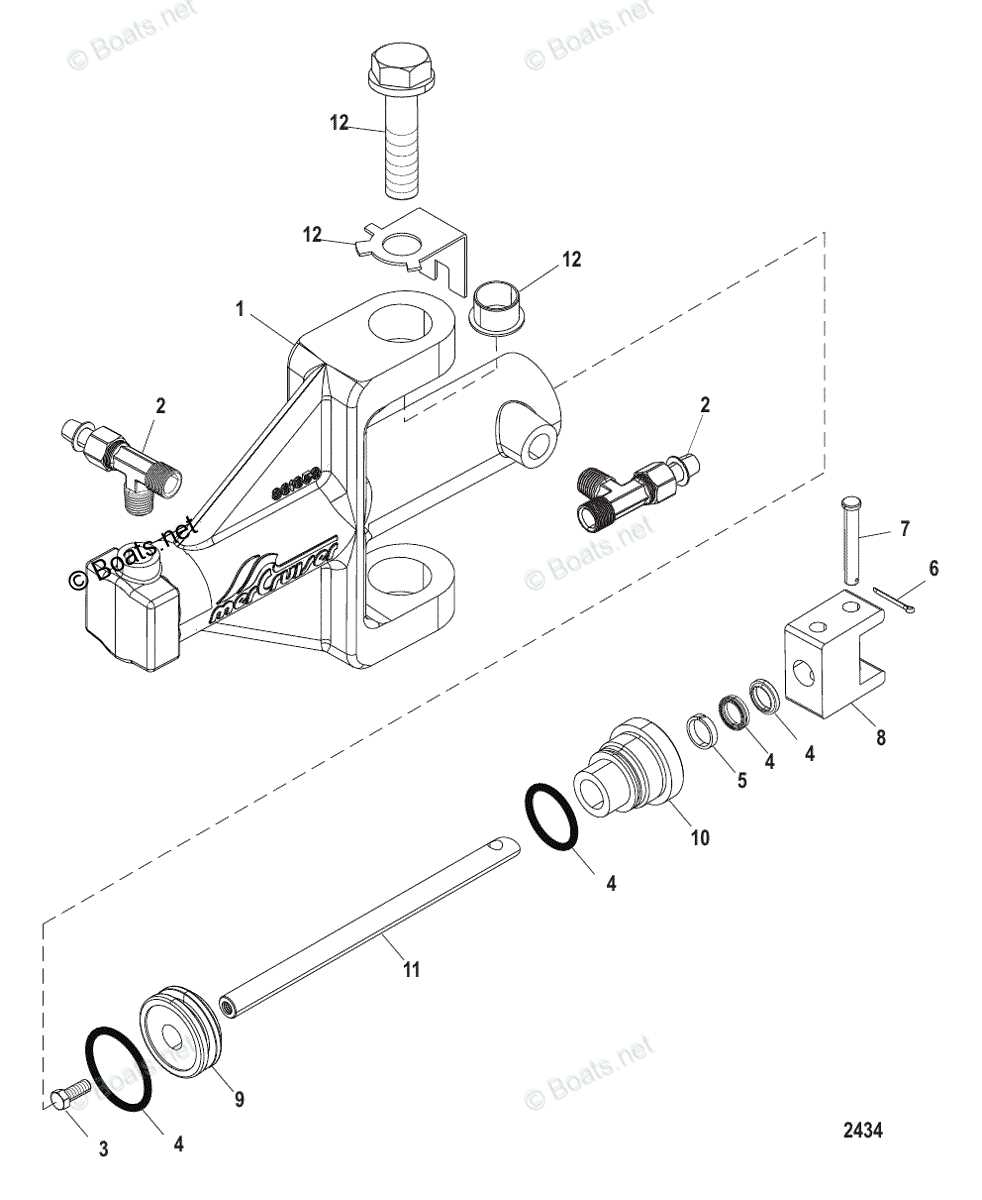

Explaining the Trim Cylinder Operation

The trim cylinder plays a crucial role in adjusting the angle of the propulsion unit, affecting both performance and handling of the vessel. This component enables operators to fine-tune the position of the drive system, enhancing efficiency and control in various water conditions.

When the trim cylinder is activated, hydraulic fluid is directed into the chamber, causing the cylinder rod to extend or retract. This movement alters the tilt of the propulsion mechanism, allowing the boat to rise or lower its bow. The ability to modify this angle directly impacts speed, fuel consumption, and overall maneuverability.

Regular maintenance of the trim cylinder is essential to ensure its proper functioning. Any signs of leaks or reduced responsiveness can indicate issues that may affect the hydraulic system’s efficiency. By understanding how the trim cylinder operates, boat owners can optimize their vessel’s performance and enhance their boating experience.

Identifying Key Seals and Gaskets

Understanding the essential components that prevent fluid leakage is crucial for maintaining optimal performance in marine machinery. These elements play a vital role in ensuring the longevity and efficiency of the system by minimizing wear and tear caused by exposure to various conditions.

Common Types of Seals

Among the most prevalent types of sealing mechanisms are O-rings and lip seals. O-rings are circular in shape and are used to create a barrier between two surfaces, while lip seals feature a flexible edge that adapts to the surfaces they are sealing, providing enhanced protection against leaks.

Importance of Gaskets

Gaskets are critical in maintaining pressure and preventing fluid exchange between different components. Their design often incorporates materials that can withstand high temperatures and pressures, ensuring reliable performance. Regular inspection and replacement of these gaskets can prevent potential damage and costly repairs.

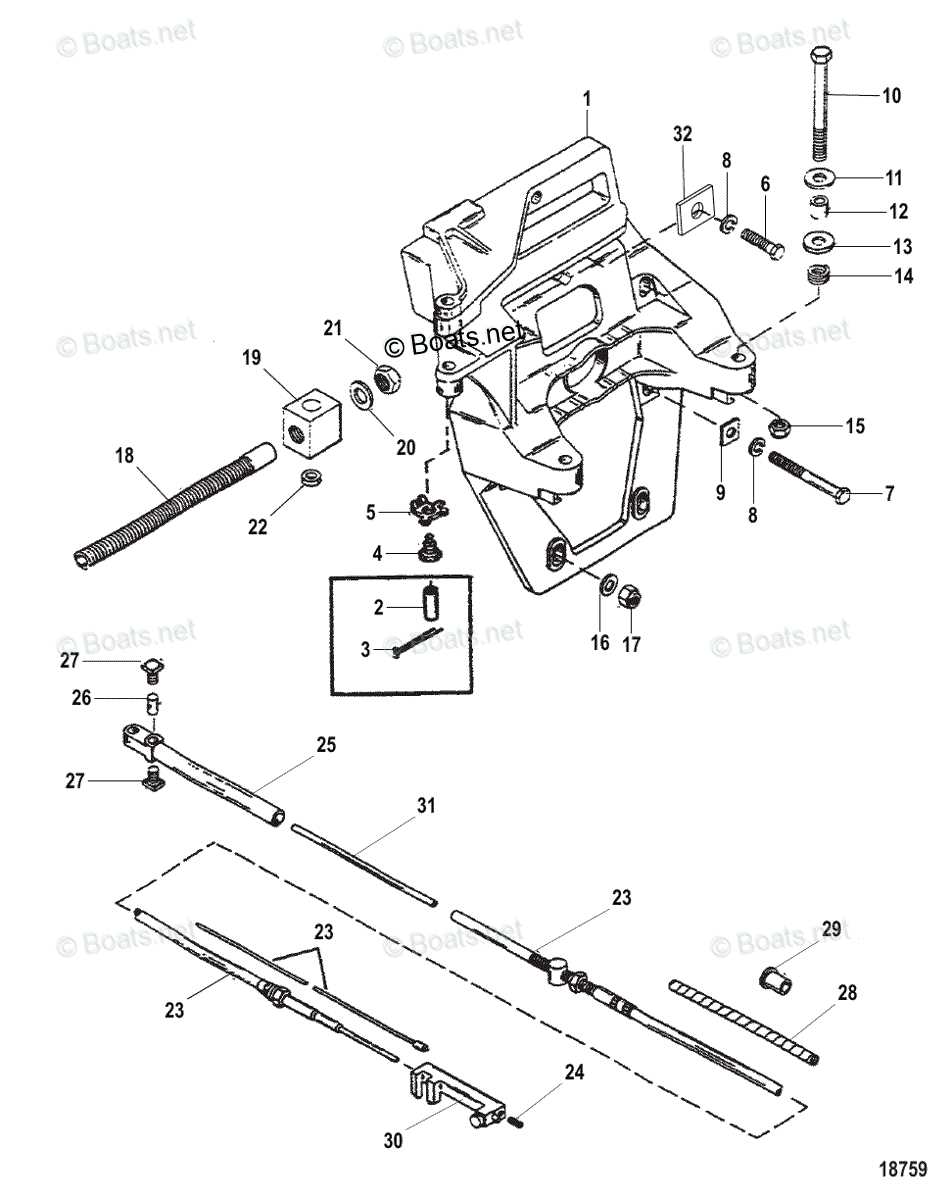

Drive Shaft Components and Their Purpose

The drive shaft is a crucial element in marine propulsion systems, serving as the link between the engine and the propeller. Understanding the individual components that comprise this assembly is essential for maintaining optimal performance and efficiency.

Components Overview: The assembly typically includes several key elements, each designed to perform a specific function. These components work together to transfer power effectively while allowing for necessary movement and adjustments during operation.

Key Elements:

- Universal Joints: These joints facilitate angular movement, allowing the drive shaft to operate smoothly even when the angle of the propeller changes.

- Couplings: Couplings connect the shaft to the engine and other components, providing a secure fit while accommodating minor misalignments.

- Bearings: Bearings support the shaft and reduce friction, enabling smooth rotation and minimizing wear on adjacent parts.

- Seal: Seals prevent water ingress, protecting internal components from corrosion and damage.

Each of these components plays a vital role in the overall functionality of the drive system, ensuring efficient power transmission and durability under varying operating conditions.

Lubrication System and Its Importance

The lubrication mechanism plays a crucial role in the efficiency and longevity of marine propulsion systems. It ensures that moving components operate smoothly by reducing friction, minimizing wear, and preventing overheating. Understanding this system’s function is essential for maintaining optimal performance and reliability.

Effective lubrication not only enhances the lifespan of mechanical parts but also contributes to overall safety while operating in aquatic environments. Regular maintenance of the lubrication system is vital to avoid potential failures that can lead to significant damage and costly repairs.

Key Components Function Oil Pump Circulates lubricant throughout the system Filters Removes contaminants from the oil Coolers Regulates temperature of the lubricant Hoses and Fittings Connect various components for effective oil flow By ensuring that each of these elements is functioning correctly, operators can significantly enhance the efficiency and reliability of their marine systems.

Common Wear and Tear Areas

In marine propulsion systems, certain components are prone to deterioration over time due to regular usage and exposure to harsh environments. Understanding these vulnerable spots is crucial for maintaining optimal performance and ensuring longevity.

Key Components to Monitor

- Seals and Gaskets: These elements often degrade due to exposure to water and temperature changes, leading to leaks.

- Gear Housing: The exterior can suffer from corrosion and pitting, especially if not regularly inspected and maintained.

- Propeller: The blades may exhibit wear from contact with debris, affecting efficiency and handling.

- Drive Shaft: Regular use can cause wear on the shaft, which may lead to vibrations and reduced performance.

Maintenance Tips

- Regularly inspect seals for signs of wear and replace them as needed.

- Clean the gear housing to prevent corrosion buildup.

- Check the propeller for nicks and dents, and ensure it is balanced.

- Monitor the drive shaft for any signs of wear and replace it if necessary.

By being aware of these common areas that experience wear, boat owners can take proactive measures to address issues before they escalate, ensuring a smoother and safer operation on the water.

Troubleshooting Common Outdrive Issues

Dealing with performance problems in marine propulsion systems can be challenging. Identifying the source of these issues often requires a systematic approach. By understanding common symptoms and their potential causes, you can effectively address and resolve many common difficulties.

Identifying Symptoms

Common indicators of malfunction may include unusual noises, vibrations, or reduced speed. Each of these symptoms can signal different underlying issues.

Symptom Possible Cause Recommended Action Unusual noises Worn bearings or misaligned components Inspect and replace damaged parts Excessive vibrations Imbalance or loose fittings Tighten all connections and check for balance Reduced speed Clogged intake or mechanical drag Clear any obstructions and check for drag Preventive Measures

Regular maintenance and inspection are essential to prevent common issues. Following a consistent schedule can help extend the lifespan of your system and ensure smooth operation.