The intricate network responsible for transmitting energy from the engine to the wheels is essential for any vehicle’s functionality. This section delves into the various elements that facilitate this crucial process, ensuring optimal performance and efficiency.

By exploring the connections and mechanisms involved, one can appreciate how each component contributes to the seamless operation of the entire system. Grasping the relationships between these elements allows for better maintenance and enhances the longevity of the vehicle.

In addition, recognizing the significance of these parts empowers individuals to make informed decisions regarding upgrades and repairs. A comprehensive understanding of this system is invaluable for both enthusiasts and professionals alike.

Overview of Driveline Components

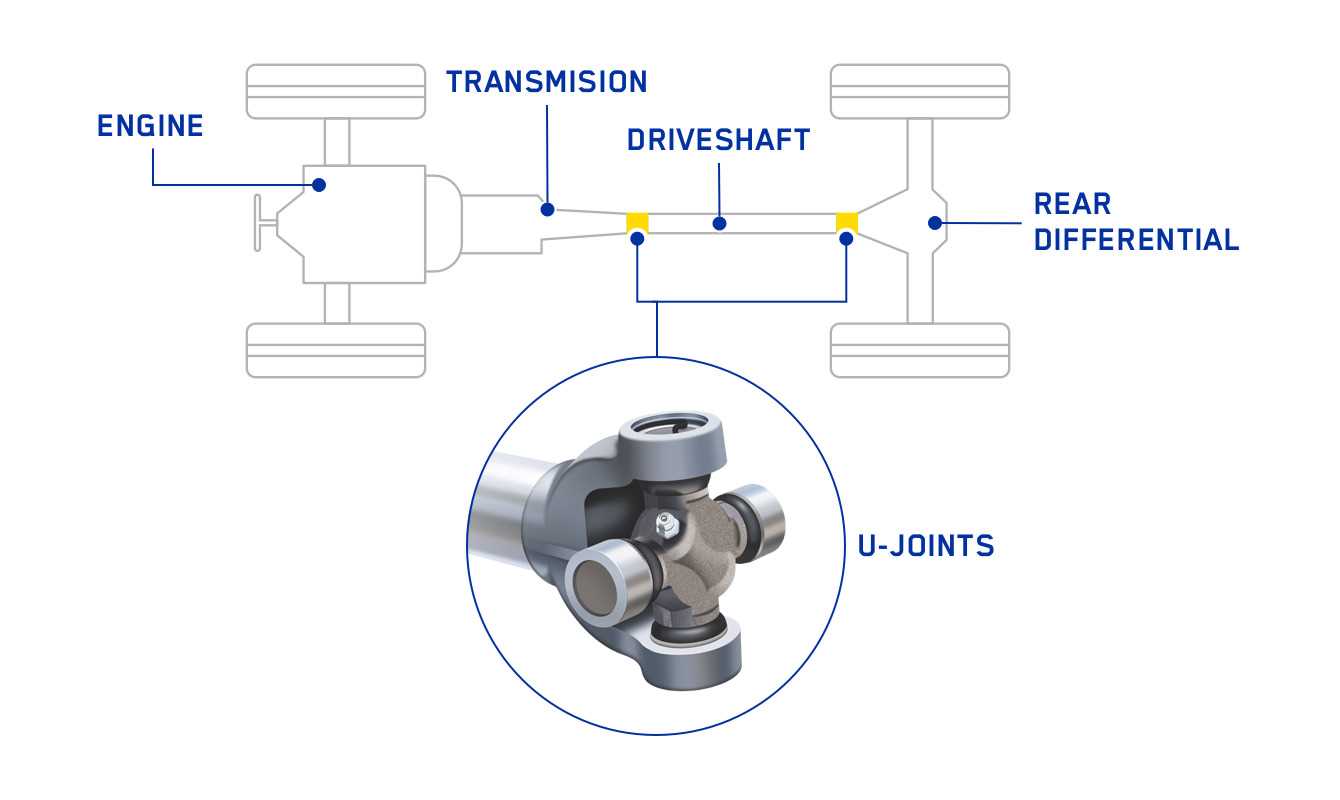

This section delves into the essential elements that contribute to the overall functionality of a vehicle’s transmission system. Each component plays a pivotal role in ensuring efficient power transfer from the engine to the wheels, enhancing performance and drivability.

| Component | Function |

|---|---|

| Transmission | Regulates power and torque to the wheels. |

| Driveshaft | Transmits rotational force from the transmission to the differential. |

| Differential | Distributes torque to the wheels while allowing them to rotate at different speeds. |

| Axles | Support the weight of the vehicle and transfer power to the wheels. |

| CV Joints | Facilitate smooth movement of the wheels while accommodating changes in angle. |

Main Function of the Driveline

The primary role of the system responsible for transmitting power within a vehicle is to ensure efficient movement from the engine to the wheels. This crucial mechanism facilitates a seamless driving experience, optimizing performance and enhancing overall functionality.

Key Responsibilities

- Transmission of torque from the engine

- Adjustment of power delivery according to driving conditions

- Coordination between various components for optimal performance

Importance in Vehicle Dynamics

The effectiveness of this assembly significantly impacts handling and stability. Proper functioning ensures:

- Improved acceleration and deceleration

- Enhanced traction and grip on different surfaces

- Better fuel efficiency through optimized power usage

Common Issues with Driveline Parts

In automotive systems, various components work together to transmit power from the engine to the wheels. However, these components can encounter several challenges that affect performance and efficiency. Understanding these issues is crucial for maintaining a reliable vehicle.

Typical Problems

Among the most frequent challenges are wear and tear, misalignment, and fluid leaks. These problems can lead to reduced efficiency and potential failures if not addressed promptly.

Impact of Issues

Addressing the following issues early can prevent more extensive damage:

| Issue | Description | Consequences |

|---|---|---|

| Wear and Tear | Gradual degradation of components due to friction and stress. | Increased noise, vibration, and eventual failure. |

| Misalignment | Improper positioning of components leading to uneven wear. | Reduced efficiency and potential damage to surrounding parts. |

| Fluid Leaks | Loss of lubricants affecting the smooth operation of components. | Overheating and accelerated wear of crucial systems. |

Types of Driveline Assemblies

This section explores the various configurations of power transmission systems, focusing on their unique characteristics and applications in different vehicles. Understanding these assemblies is essential for optimizing performance and ensuring compatibility with engine outputs.

Common Configurations

Power transmission systems can be categorized based on their arrangement and function. Here are some prevalent types:

| Type | Description |

|---|---|

| Front-Wheel Drive | This configuration channels power to the front wheels, offering better traction in adverse conditions. |

| Rear-Wheel Drive | In this setup, the rear wheels receive power, enhancing handling and balance, especially in performance vehicles. |

| All-Wheel Drive | This assembly distributes power to all four wheels, providing improved stability and control on varying terrains. |

| Four-Wheel Drive | This system allows for manual selection of drive modes, suitable for off-road conditions. |

Specialized Variants

In addition to the common types, specialized configurations exist to meet specific demands:

| Type | Description |

|---|---|

| Independent Suspension | This setup enhances ride quality by allowing wheels to move independently, improving handling on uneven surfaces. |

| Live Axle | Here, the axle connects both wheels, offering strength and durability, commonly found in trucks and off-road vehicles. |

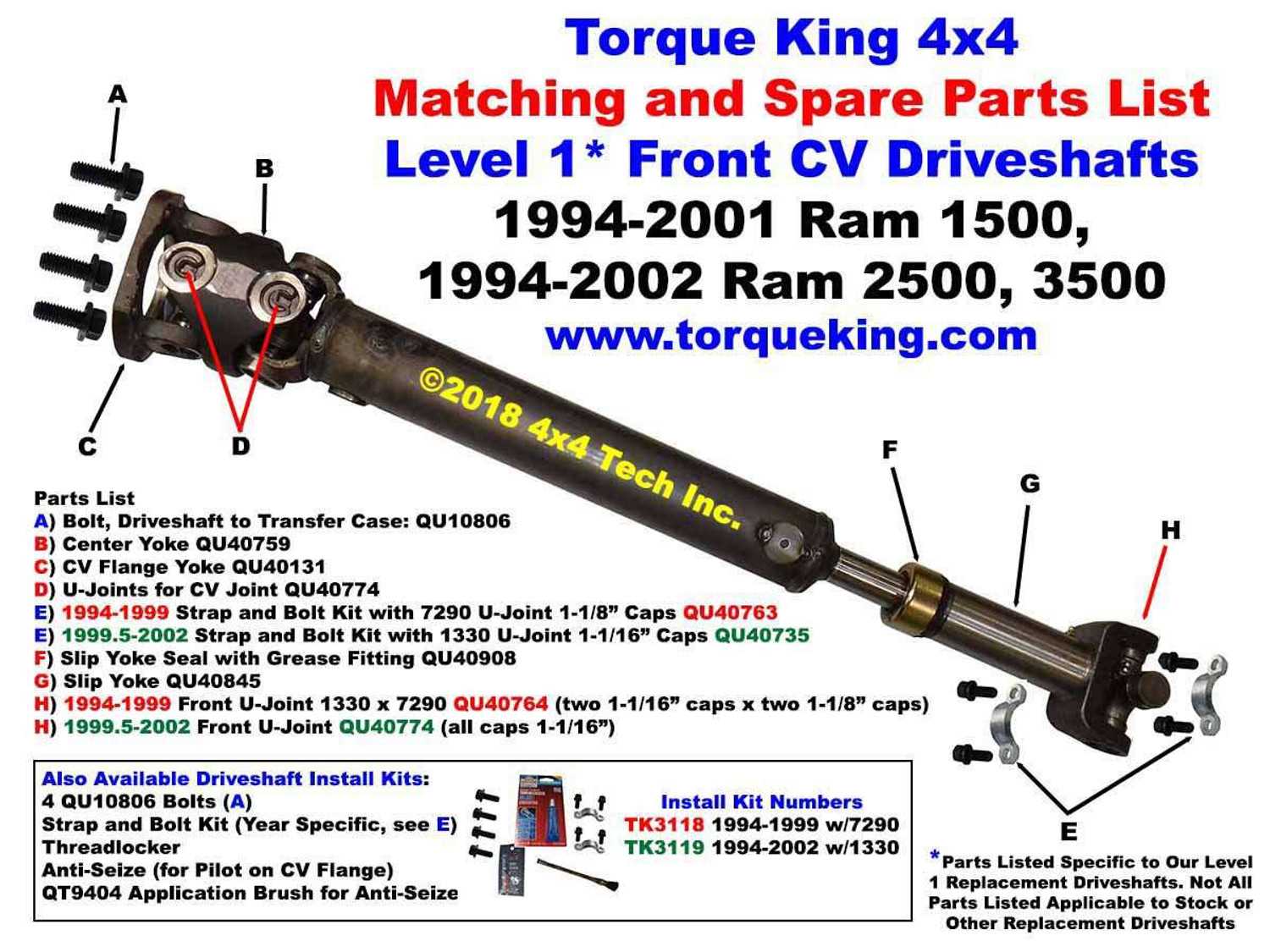

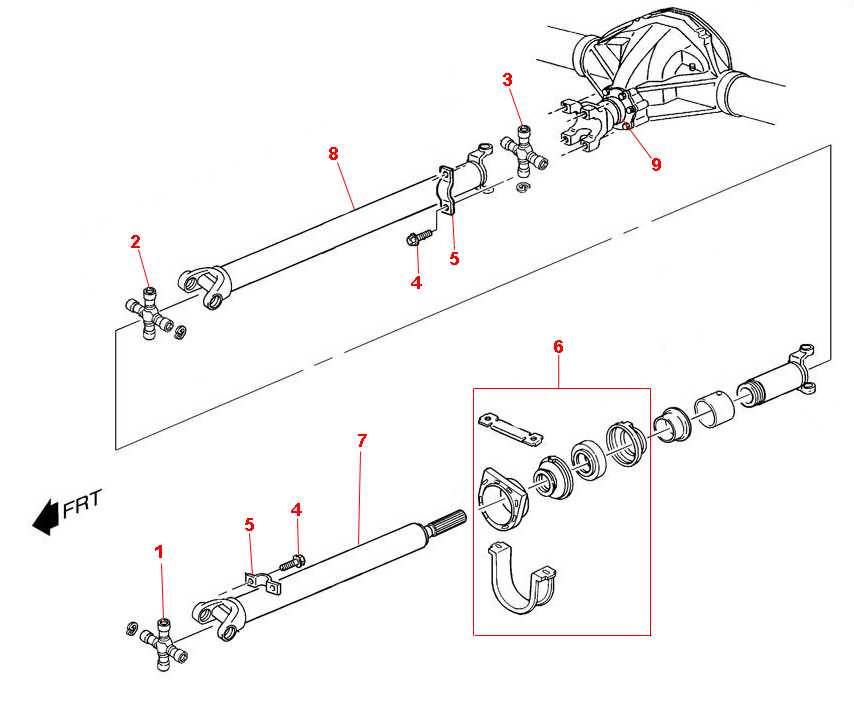

Key Driveline Components Explained

This section delves into essential elements that facilitate the transfer of power within a vehicle’s system. Understanding these crucial components enhances one’s knowledge of how motion is generated and transmitted from the engine to the wheels.

- Transmission: The mechanism responsible for changing gears, enabling the vehicle to adjust its speed and torque effectively.

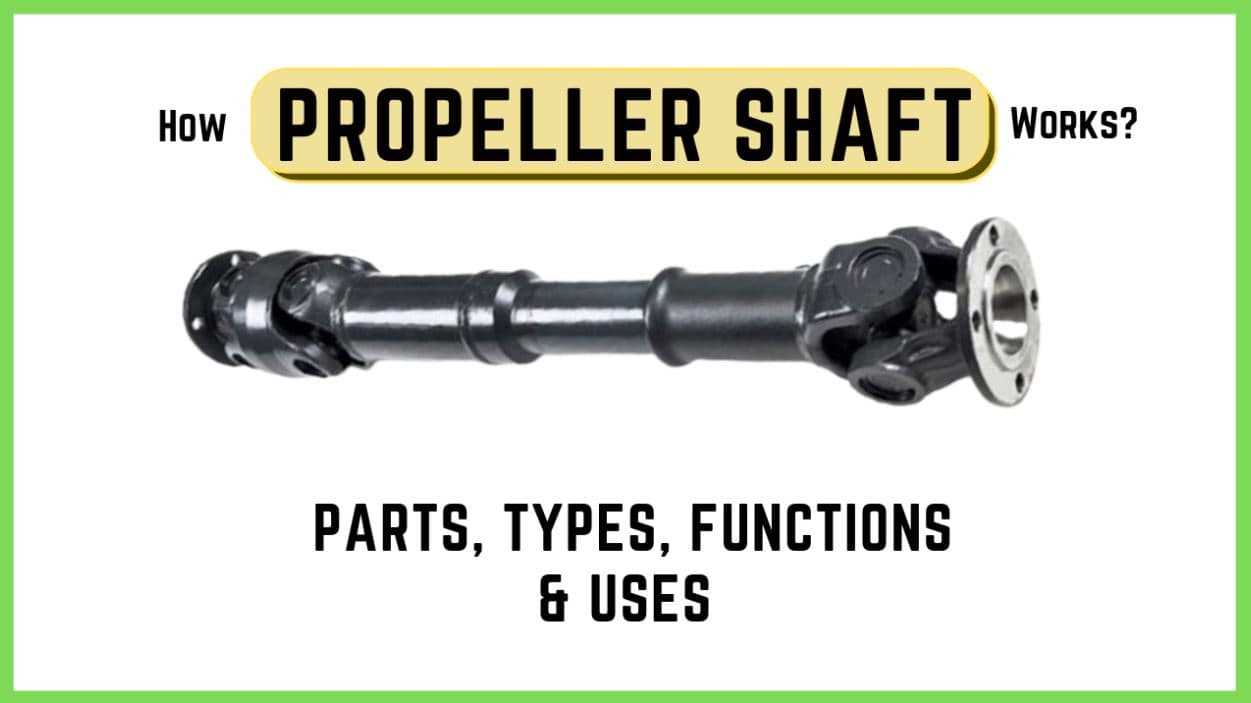

- Driveshaft: A rotating shaft that transmits power from the transmission to the differential, allowing for wheel movement.

- Differential: A device that enables wheels to rotate at different speeds, particularly useful during turns, ensuring smooth handling.

- Axles: Components that support the weight of the vehicle and transfer power from the differential to the wheels.

- CV Joints: Constant velocity joints that allow for smooth power transmission while accommodating the movement of the suspension.

Each of these elements plays a vital role in ensuring that a vehicle operates efficiently, contributing to performance and overall driving experience.

How to Identify Driveline Failures

Recognizing issues within the system that transfers power from the engine to the wheels is crucial for maintaining vehicle performance. Several symptoms can indicate potential malfunctions, and early detection can prevent more severe damage and costly repairs.

Common signs include unusual noises such as clunking or grinding, which may suggest wear or misalignment. Additionally, vibrations felt in the steering wheel or floor can signal an imbalance or damaged components. Monitoring fluid leaks underneath the vehicle is essential, as this may indicate a failing seal or joint.

Regular inspections and maintenance can help identify these problems before they escalate. Paying attention to warning lights on the dashboard can also provide valuable insights into underlying issues that require immediate attention.

Maintenance Tips for Driveline Systems

Regular upkeep of mechanical systems is crucial for ensuring longevity and optimal performance. By implementing effective maintenance strategies, you can prevent issues and extend the lifespan of essential components.

Routine Inspections

Conduct frequent inspections to identify wear and tear. Check for leaks, unusual noises, and any signs of damage that may indicate a need for repair or replacement. Early detection can save time and money.

Lubrication and Fluid Levels

Maintain appropriate lubricant levels and replace fluids as recommended by the manufacturer. Proper lubrication reduces friction and helps components operate smoothly, enhancing overall efficiency.

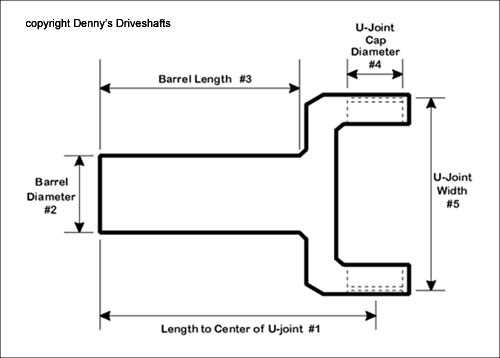

Tools Required for Driveline Repairs

Repairing the components that transmit power requires a selection of essential instruments. Proper tools ensure efficiency and precision during the maintenance process, ultimately enhancing the performance and longevity of the system.

Basic Hand Tools

Having a variety of basic hand tools is crucial. Wrenches, pliers, and screwdrivers allow for easy access to different fasteners, while a torque wrench ensures that connections are tightened to the correct specifications. Quality hand tools contribute significantly to the overall success of any repair task.

Specialized Equipment

In addition to standard tools, some specialized equipment is necessary for more intricate tasks. Gear pullers and alignment tools facilitate the removal and installation of components without causing damage. Furthermore, an impact wrench can expedite the process by loosening stubborn bolts efficiently.

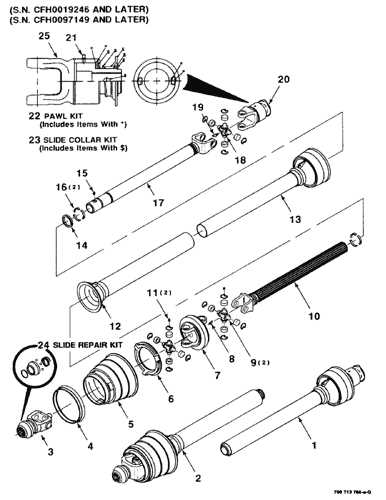

Replacing Worn Driveline Parts

When components of the power transmission system become fatigued or damaged, timely replacement is crucial to maintain vehicle performance and safety. This section outlines the importance of recognizing signs of wear and the steps necessary for effective replacement.

Identifying Signs of Wear

It is essential to monitor specific indicators that suggest components are nearing the end of their lifespan. Common signs include unusual noises, vibrations during operation, and reduced responsiveness when accelerating. Addressing these symptoms promptly can prevent more extensive damage and costly repairs.

Replacement Process Overview

The procedure for replacing worn components typically involves several key steps. Begin by ensuring the vehicle is safely elevated and secured. Then, follow the manufacturer’s guidelines for disassembling the affected area. Once the old components are removed, install the new ones carefully, making sure all connections are secure.

| Step | Description |

|---|---|

| 1 | Lift and secure the vehicle. |

| 2 | Remove the damaged components. |

| 3 | Install new components following guidelines. |

| 4 | Test for proper operation. |

Importance of Regular Driveline Inspections

Regular evaluations of key components in a vehicle are crucial for maintaining optimal performance and safety. By ensuring that all elements function properly, potential issues can be identified early, preventing costly repairs and enhancing overall reliability.

Here are several reasons why frequent assessments are essential:

- Enhanced Safety: Regular checks help prevent failures that could lead to dangerous situations on the road.

- Increased Longevity: Timely maintenance extends the lifespan of essential components, saving money in the long run.

- Improved Performance: Keeping everything in top condition ensures that the vehicle operates smoothly and efficiently.

- Early Issue Detection: Inspections allow for the identification of minor problems before they escalate into major concerns.

In summary, consistent inspections of the vehicle’s crucial systems contribute significantly to safety, performance, and financial savings. Prioritizing these evaluations is a wise choice for any vehicle owner.

Upgrading the Driveline for Better Performance

Enhancing the system that transmits power from the engine to the wheels can significantly improve your vehicle’s efficiency and responsiveness. By selecting high-quality components and making thoughtful modifications, drivers can experience better acceleration, handling, and overall performance.

Consider the following upgrades:

- Lightweight Components: Reducing weight can lead to faster acceleration and improved fuel efficiency.

- High-Performance Differential: An upgraded differential can provide better torque distribution, enhancing traction and stability.

- Aftermarket Driveshaft: A stronger driveshaft can withstand higher power outputs, ensuring reliability under demanding conditions.

- Enhanced Transmission: Upgrading to a more responsive transmission can lead to smoother gear changes and improved power delivery.

Implementing these enhancements can lead to a more thrilling driving experience, ensuring your vehicle performs at its best in various conditions.

Choosing the Right Driveline for Your Vehicle

Selecting the appropriate transmission system is crucial for optimizing your vehicle’s performance and efficiency. Understanding your driving habits and the terrain you’ll be navigating can significantly impact your choice. The right configuration ensures smooth power transfer and enhances overall driving experience.

When considering options, focus on factors such as torque requirements and fuel efficiency. Different setups offer unique advantages tailored to specific conditions, from off-road challenges to highway cruising. It’s essential to assess how these choices align with your vehicle’s intended use.

Additionally, compatibility with existing components plays a vital role in the selection process. Ensuring that your chosen system integrates seamlessly with the engine and suspension can prevent future issues. Always consult with professionals or refer to manufacturer guidelines for the best recommendations.