The realm of electric propulsion systems is intricate and multifaceted, offering various components that work in harmony to ensure optimal performance. Each element plays a crucial role in enhancing efficiency and reliability, making it essential for users to familiarize themselves with the layout and functions of these mechanisms.

In exploring the assembly of these systems, one can uncover the various integral components that contribute to seamless operation. A detailed overview of these elements not only aids in maintenance but also enhances one’s ability to troubleshoot potential issues.

Furthermore, understanding the relationships between different components can ultimately lead to improved decision-making when it comes to upgrades or replacements. By delving into the specifics of these systems, enthusiasts and operators alike can gain valuable insights into maximizing their equipment’s potential.

Understanding Minn Kota E Drive

This section aims to explore the intricacies of a popular propulsion system used in various aquatic vessels. Its design incorporates innovative technologies that enhance efficiency and usability for enthusiasts and professionals alike.

- Key Features:

- Enhanced performance in diverse water conditions.

- Quiet operation for a more enjoyable experience.

- Robust construction for longevity and reliability.

- Components Overview:

- Power unit that provides energy for movement.

- Control systems allowing for precise handling.

- Cooling mechanisms to maintain optimal functioning.

Understanding the mechanisms behind this system is crucial for proper maintenance and optimal use, ultimately leading to improved performance on the water.

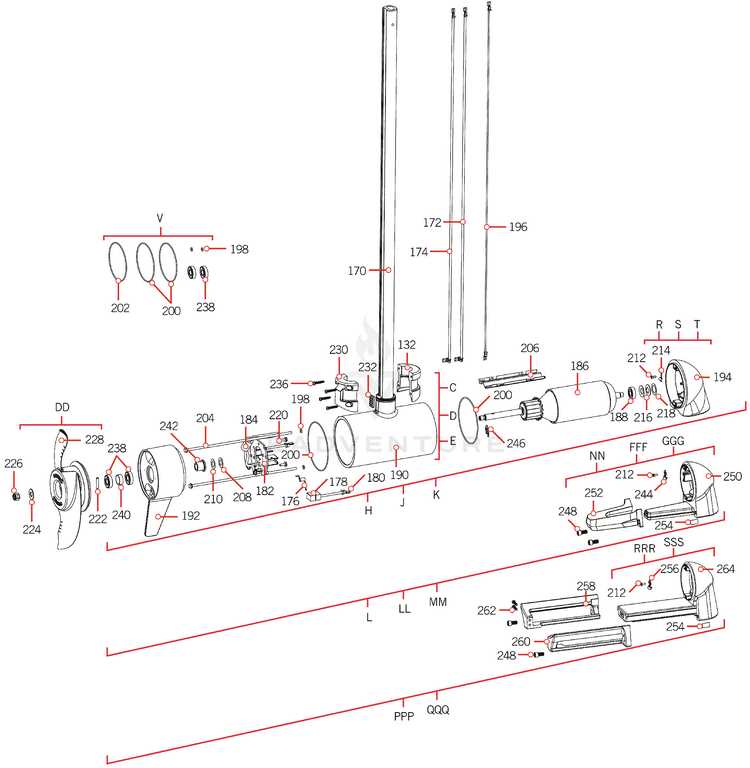

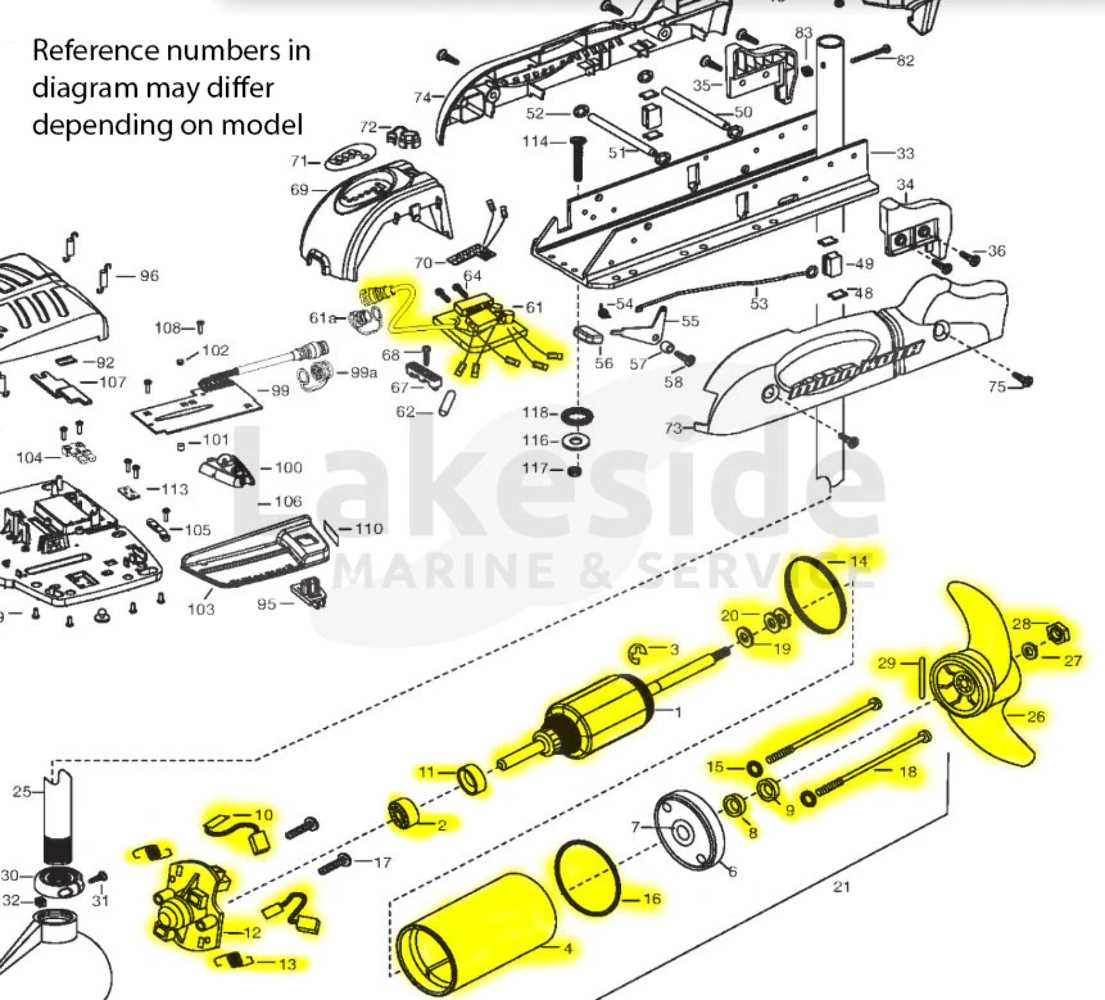

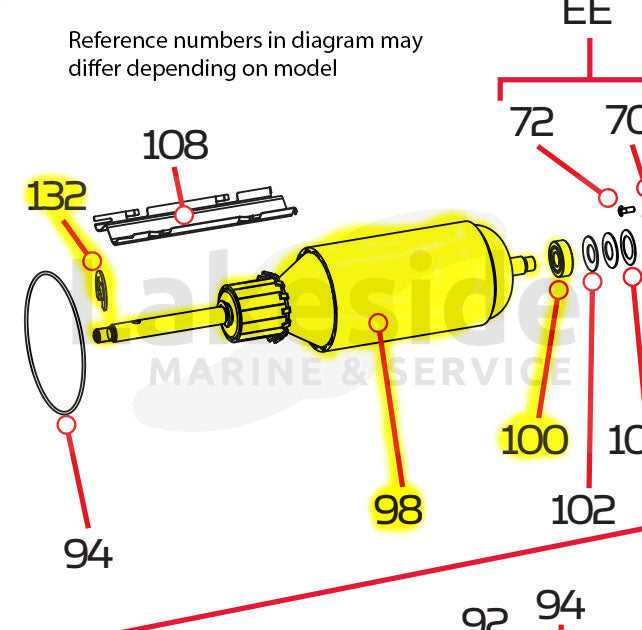

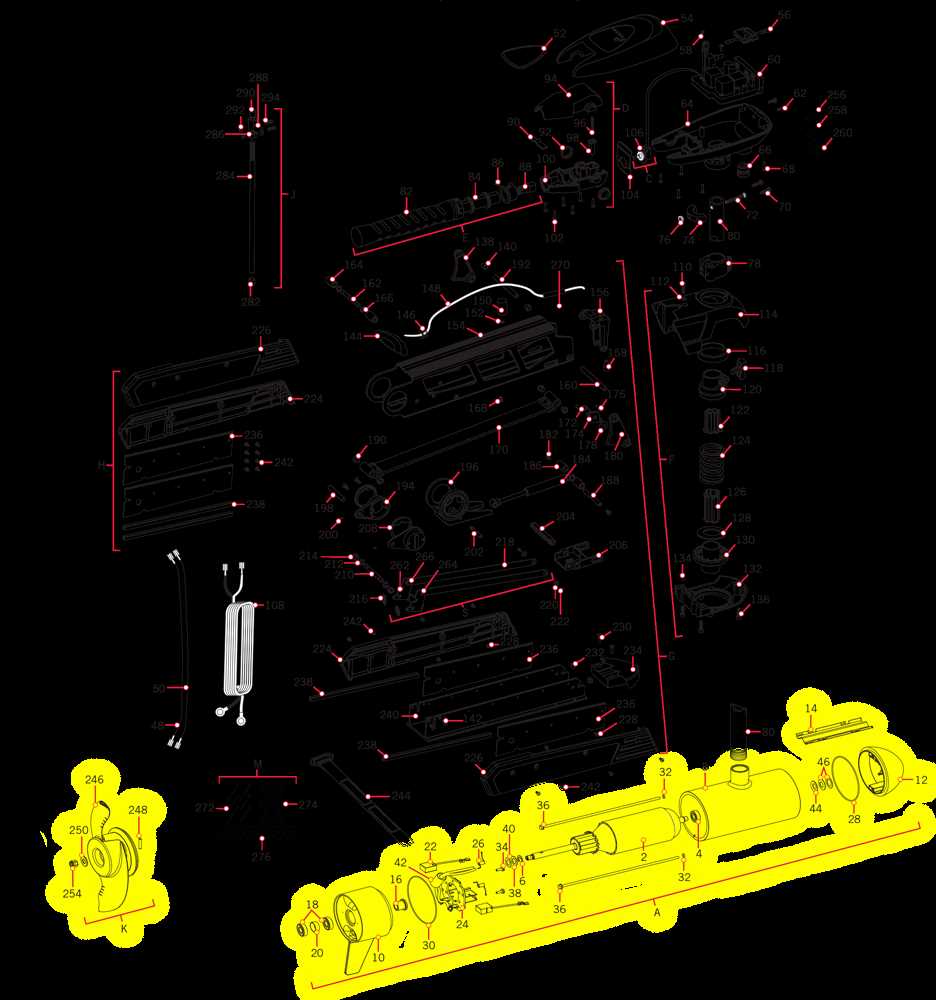

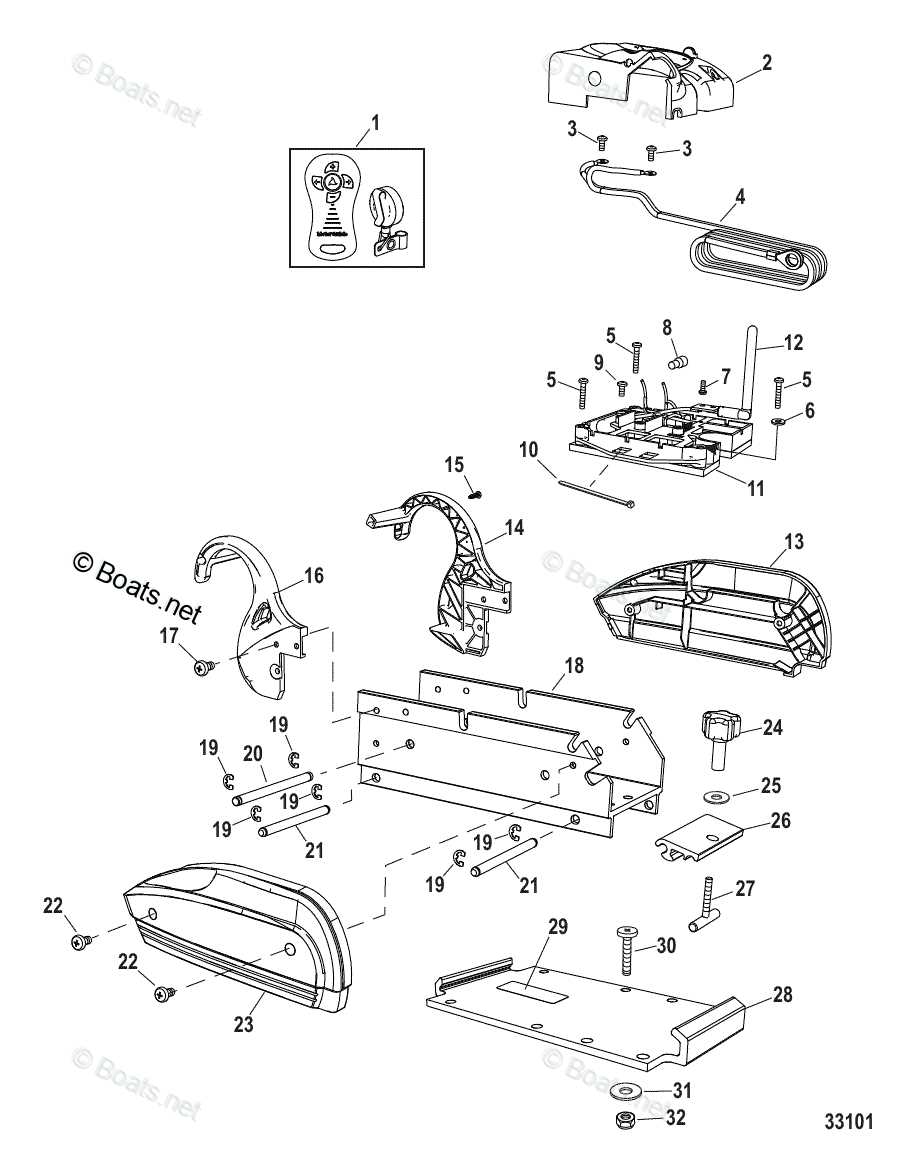

Key Components of E Drive System

The electric propulsion system comprises several essential elements that work together to ensure efficient operation and performance. Understanding these components is crucial for maintenance and enhancement of functionality.

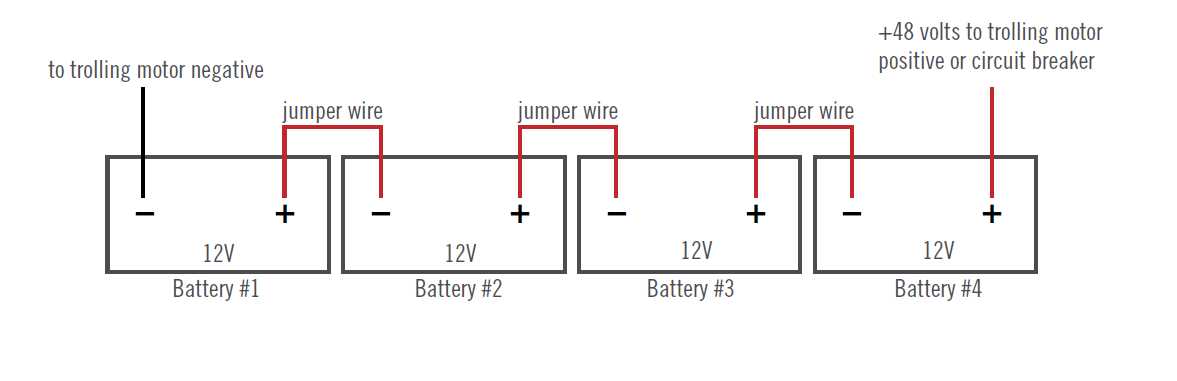

Power Source

The primary energy source provides the necessary voltage and current for operation. Typically, this includes batteries designed to deliver reliable energy output while ensuring longevity and safety.

Control Unit

The control unit manages the system’s overall functionality, regulating speed and direction. It acts as the brain, allowing for precise adjustments based on user input and environmental conditions.

Benefits of E Drive Technology

E drive technology offers a range of advantages that enhance the overall experience for users. This innovative approach to propulsion systems significantly improves efficiency, reduces environmental impact, and provides smoother operation, making it a preferred choice for many enthusiasts.

Enhanced Efficiency

One of the primary benefits of this technology is its ability to optimize energy usage. By utilizing advanced components, users can enjoy longer operational times while consuming less power, translating to cost savings and extended battery life.

Environmental Impact

This propulsion method minimizes emissions, contributing to cleaner waterways. As a result, users can enjoy their activities without compromising the health of the environment.

| Benefit | Description |

|---|---|

| Energy Efficiency | Reduces power consumption for longer usage. |

| Lower Emissions | Minimizes harmful pollutants in the environment. |

| Smooth Operation | Provides a quieter and more stable experience. |

Common Issues and Troubleshooting Tips

When operating an electric propulsion system, users may encounter several frequent challenges that can hinder performance. Understanding these issues and having effective troubleshooting strategies can significantly enhance the overall experience and ensure smooth functionality.

Common Problems

- Insufficient Power Output

- Intermittent Functionality

- Unusual Noises During Operation

- Battery Life Shortage

- Unresponsive Controls

Troubleshooting Strategies

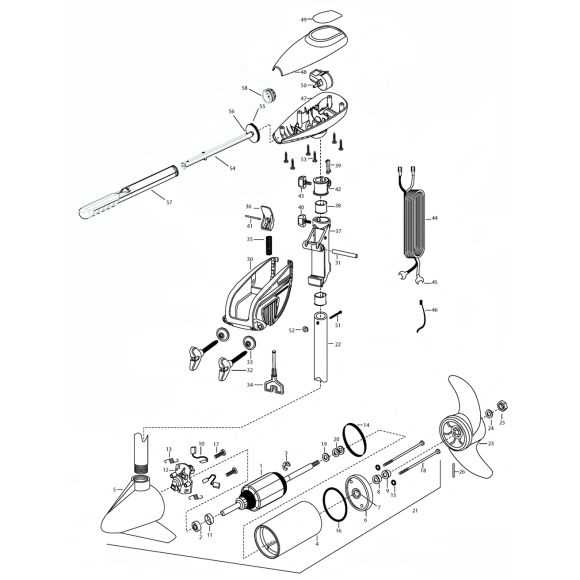

- Check Battery Connections: Ensure all terminals are clean and securely attached. Loose or corroded connections can lead to power issues.

- Inspect the Propulsion Unit: Look for any signs of wear or damage. Regular maintenance can prevent many common failures.

- Test Control System: If controls are unresponsive, examine the wiring and switches for faults. Replacing faulty components may be necessary.

- Monitor Battery Health: Keep track of battery voltage and capacity. Using a multimeter can help assess if the battery is holding a charge effectively.

- Seek Professional Help: If issues persist after troubleshooting, consult a qualified technician for a thorough diagnosis.

Maintenance Tips for E Drive Parts

Proper upkeep of your propulsion components ensures longevity and optimal performance. Regular attention to these elements can prevent costly repairs and enhance efficiency.

- Inspect all connections for corrosion or wear.

- Clean the exterior regularly to remove dirt and debris.

- Check for any loose or damaged wires that may affect functionality.

Additionally, consider the following maintenance practices:

- Lubricate moving components according to the manufacturer’s recommendations.

- Replace any worn seals or gaskets to maintain water resistance.

- Test the system regularly to ensure everything operates smoothly.

By following these guidelines, you can significantly extend the life of your propulsion system and enjoy a more reliable experience on the water.

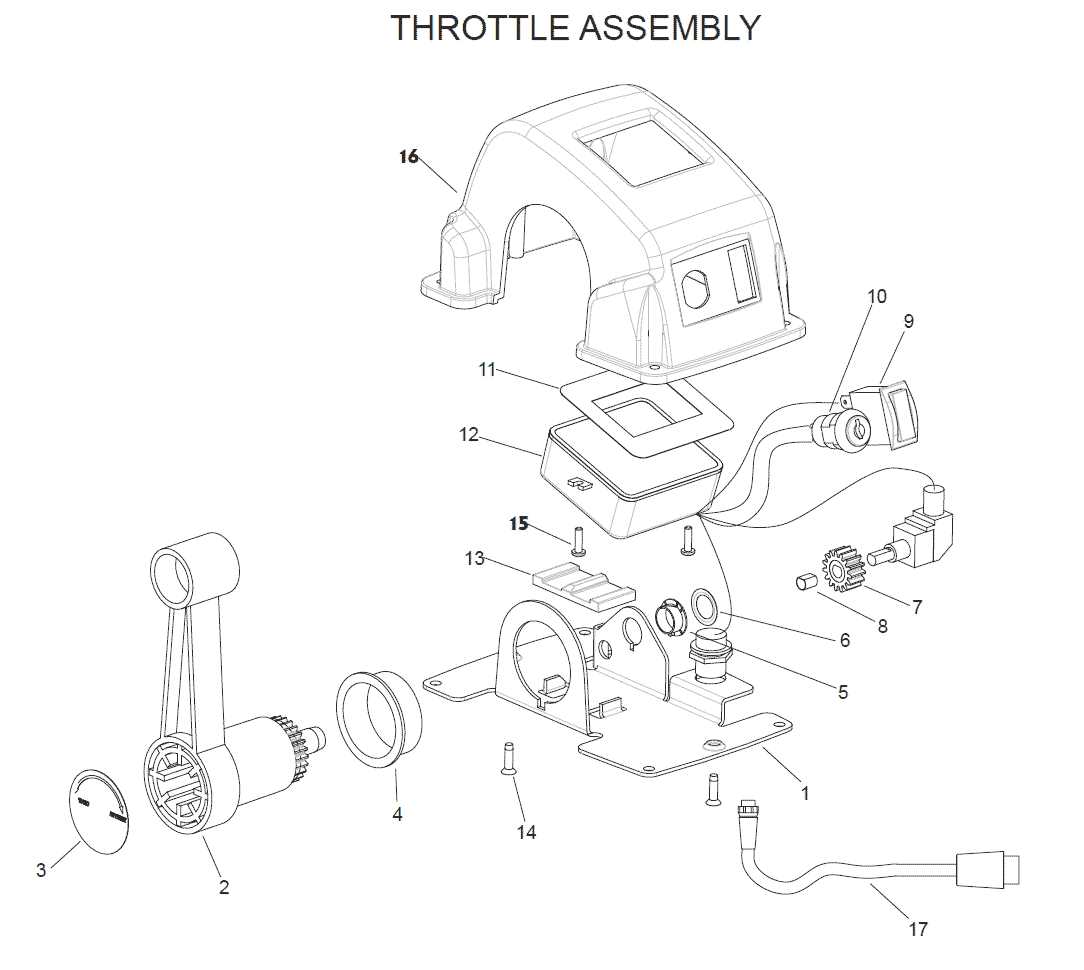

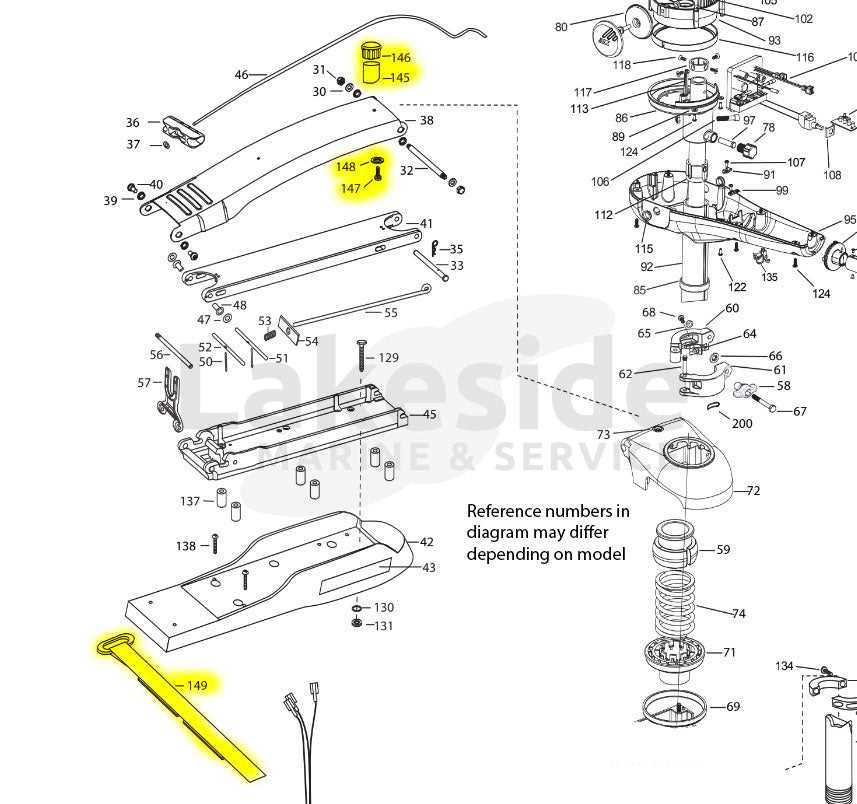

How to Replace E Drive Components

Maintaining and upgrading the essential elements of your electric propulsion system can significantly enhance performance and longevity. This guide provides a step-by-step approach to efficiently substitute various components, ensuring optimal functionality.

-

Gather Necessary Tools:

- Wrench set

- Screwdrivers

- Replacement components

- Multimeter for electrical checks

-

Disconnect Power Source:

Before beginning, ensure that the power supply is completely turned off to avoid any accidents.

-

Remove Old Components:

Carefully detach the existing elements by unscrewing and disconnecting any wiring. Take note of the configuration for easy reinstallation.

-

Install New Components:

Position the new parts in place, securing them with screws and reconnecting the wiring as per your earlier notes.

-

Test the System:

Once everything is in place, restore power and perform a test run to ensure all components are functioning correctly.

Comparing E Drive to Traditional Motors

When evaluating modern propulsion systems versus conventional engines, several key factors come into play. These differences can influence performance, efficiency, and user experience, making it essential to understand how each option stacks up against the other.

| Aspect | Modern Propulsion Systems | Conventional Engines |

|---|---|---|

| Efficiency | Typically more energy-efficient, reducing operational costs. | Often less efficient, leading to higher fuel consumption. |

| Maintenance | Generally requires less maintenance due to fewer moving parts. | More maintenance-intensive with regular servicing needed. |

| Noise Level | Quieter operation, enhancing the overall experience on the water. | Produces more noise, which can be disruptive in serene environments. |

| Environmental Impact | Often designed to be more eco-friendly, reducing emissions. | Typically has a larger carbon footprint due to fuel usage. |

| Power Delivery | Provides instant torque for responsive handling. | Power delivery can be less immediate, affecting acceleration. |

In summary, modern propulsion options present various advantages over traditional engines, particularly in terms of efficiency and environmental impact. Understanding these differences helps in making informed choices for optimal performance and sustainability.

Electric Propulsion in Boating Industry

In recent years, the marine sector has witnessed a significant shift towards eco-friendly technologies, particularly in the realm of propulsion systems. This transformation aims to enhance sustainability while maintaining performance, leading to innovative solutions that reduce environmental impact and improve energy efficiency.

Advantages of Electric Systems

Electric propulsion offers numerous benefits, including lower operational costs and reduced noise pollution. By utilizing advanced battery technologies, vessels can achieve remarkable efficiency, allowing for longer voyages without the need for frequent refueling.

Future Trends

The ongoing development in electric propulsion technology suggests a promising future for the industry. As manufacturers continue to invest in research and innovation, we can expect to see an increase in the adoption of these systems across various types of watercraft, ultimately leading to a cleaner and more sustainable marine environment.

Innovations in Minn Kota Technology

The evolution of electric propulsion systems has transformed how enthusiasts experience the water. Cutting-edge advancements enhance efficiency, control, and user satisfaction, ensuring every outing is memorable.

Key Advancements

- Enhanced Battery Management: New algorithms optimize energy usage, extending battery life.

- Smart Connectivity: Integration with mobile apps allows for real-time monitoring and adjustments.

- Quiet Operation: Improved motor designs reduce noise, ensuring a peaceful environment.

Future Prospects

- Autonomous Navigation: Development of systems that can navigate pre-set routes.

- Eco-Friendly Solutions: Focus on sustainable materials and energy sources.

- Advanced User Interfaces: Intuitive controls for a seamless experience.

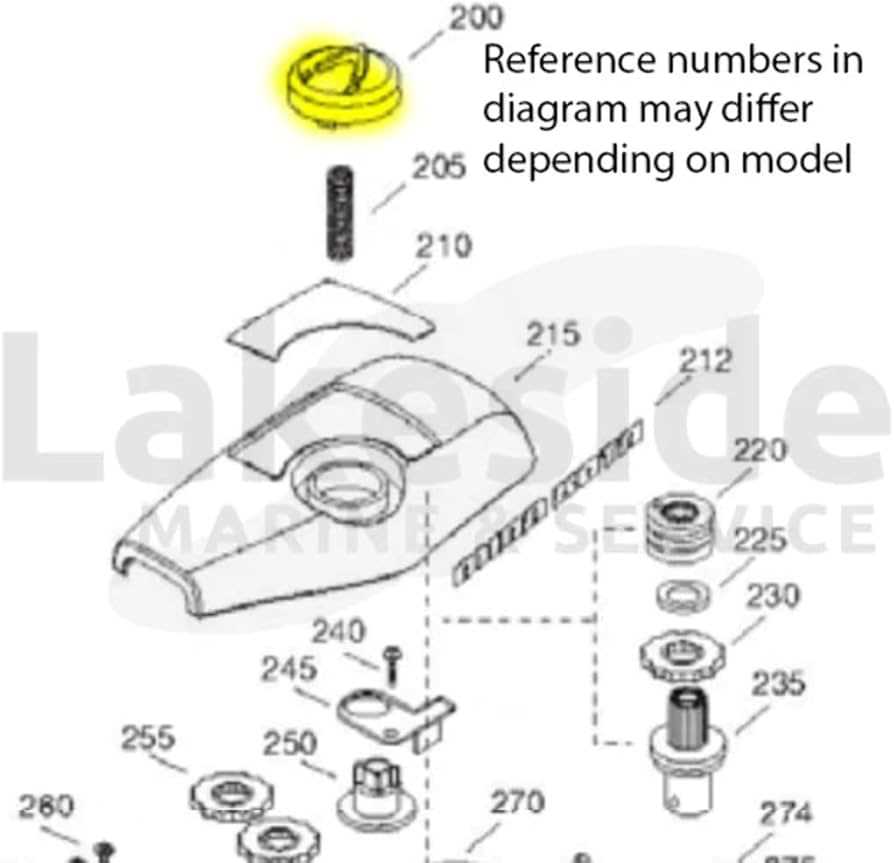

Choosing the Right Parts for Replacement

When it comes to ensuring optimal functionality of your equipment, selecting the appropriate components for substitution is crucial. Understanding the intricacies of each element can significantly enhance performance and longevity.

Assessing Compatibility

Before making any purchase, evaluate the compatibility of the new component with your existing system. Referencing the manufacturer’s specifications can aid in identifying suitable options. Incompatibility may lead to subpar performance or even damage.

Quality and Durability

Opt for high-quality replacements that promise durability. Investing in reputable brands often results in a longer lifespan and better performance. Research customer reviews and ratings to inform your decision-making process.

Understanding E Drive Performance Metrics

Evaluating the effectiveness of electric propulsion systems involves analyzing various performance indicators. These metrics provide insights into the operational efficiency, reliability, and overall capability of the technology in use. By understanding these key aspects, users can make informed decisions to enhance their experience and optimize performance.

Key Performance Indicators

- Power Consumption: Measurement of energy usage during operation, crucial for assessing efficiency.

- Torque Output: Indicates the rotational force produced, essential for understanding the system’s capability to handle loads.

- Speed Regulation: The ability to maintain consistent speed under varying conditions.

- Response Time: The time taken to react to changes in input, affecting overall handling and maneuverability.

Evaluating Efficiency

Efficiency can be analyzed through several means:

- Energy Transfer Ratio: Compares input energy to output performance, indicating how effectively power is utilized.

- Operational Range: The distance achievable on a single charge, important for long excursions.

- Load Capacity: Assessment of maximum weight that can be efficiently managed while maintaining performance standards.

By focusing on these metrics, users can gain a comprehensive understanding of their electric propulsion systems and enhance their performance accordingly.