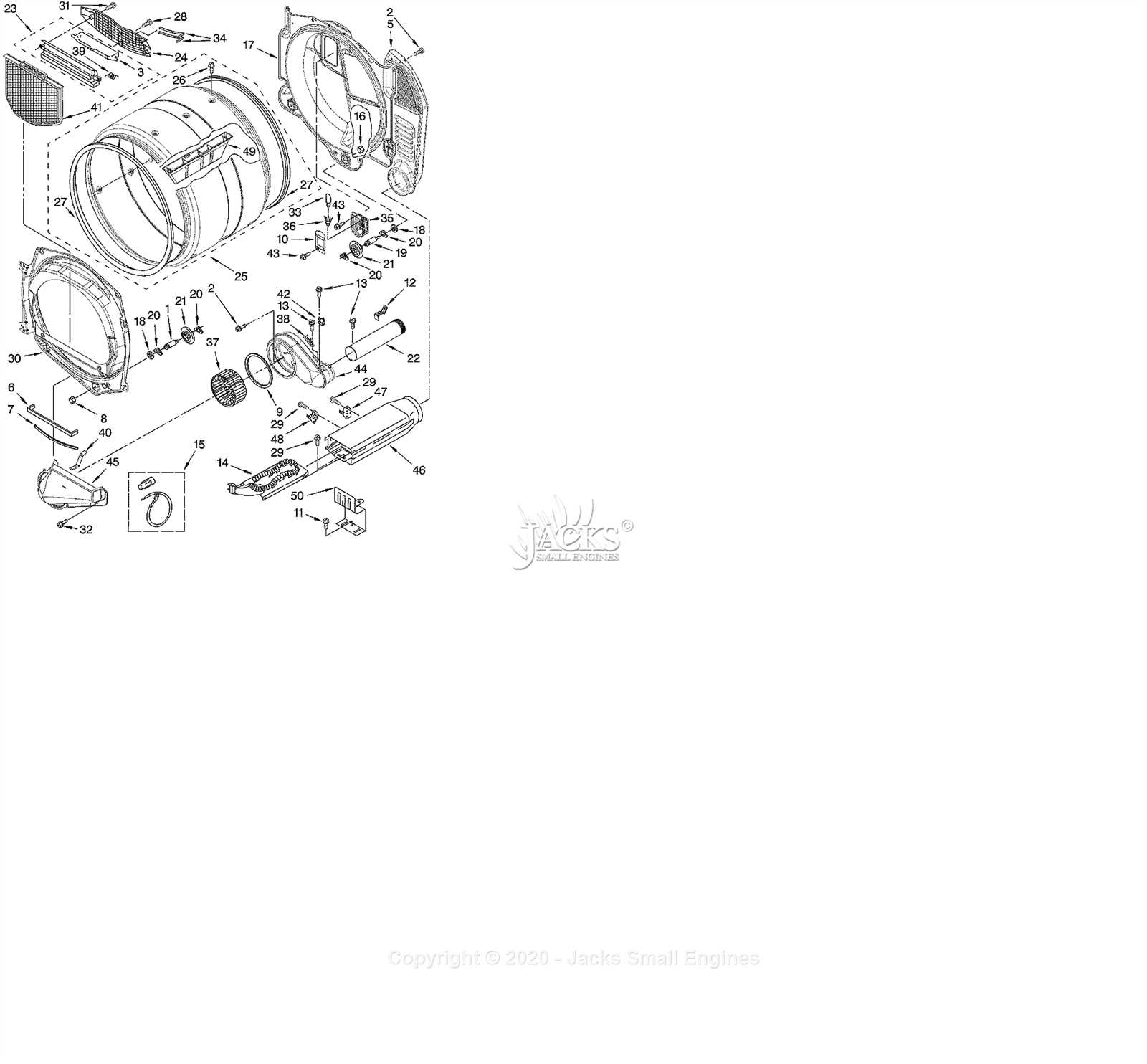

When it comes to home appliances, having a clear understanding of the internal structure can greatly assist in maintenance and troubleshooting. Identifying the main elements and their functions helps to ensure that the machine operates efficiently over the long term. Learning how each section interacts with others can also make it easier to recognize potential issues early on.

Regular upkeep is essential for extending the lifespan of the device. Knowing what to look for and understanding the functions of various sections will enable more efficient problem-solving and repairs. Addressing issues promptly can prevent more serious malfunctions in the future.

Furthermore, gaining insight into the most commonly found elements within this type of equipment will provide users with the confidence needed to manage upkeep tasks themselves. Whether replacing a worn-out component or merely performing routine checks, familiarization with these elements is the first step towards effective maintenance.

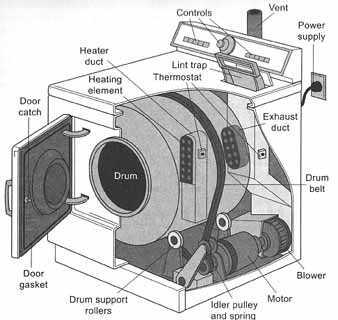

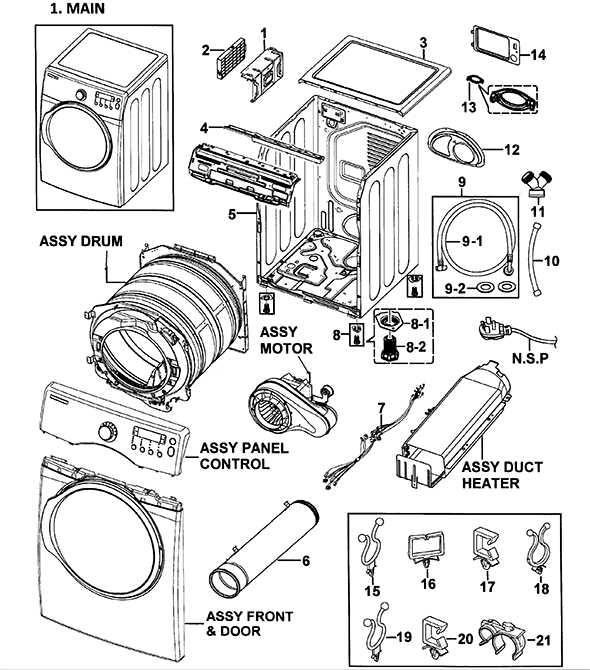

Key Components Inside a Dryer

Understanding the essential elements that make up this appliance can help diagnose issues and maintain it effectively. Each component plays a specific role in the operation, working together to ensure efficient performance and heat distribution.

- Heating Element: Responsible for generating the warmth required to dry items. This element converts electrical energy into heat, which circulates through the appliance’s interior.

- Thermostat: Monitors and regulates the temperature. It ensures that the internal temperature remains within a safe range, preventing overheating.

- Blower Fan: Moves air through the system, allowing for even heat distribution. It ensures that warm air reaches every corner to speed up the drying process.

- Drum: The central rotating compartment where items are placed. Its movement ensures that items are tumbled for uniform drying.

- Motor:

How the Heating Element Works

The heating element plays a crucial role in generating warmth for the appliance, ensuring that the interior reaches the required temperature. It operates by converting electrical energy into thermal energy, creating the heat needed to perform its function effectively. Understanding its operation can help identify issues when the system isn’t reaching optimal temperatures.

Electrical Energy Conversion

At the core of the process, the component utilizes electricity flowing through its metal coils. These coils are made of high-resistance material, causing them to heat up as the current passes through. The generated warmth is then dispersed throughout the system, increasing the internal temperature to the desired level. This controlled heat flow allows for the precise regulation of thermal levels.

Thermostat and Safety Features

The thermostat works alongside the heating element, maintaining a steady temperature. It monitors the warmth generated and switches the electrical supply on and off to prevent overheating. Additionally, safety mechanisms, such as thermal fuses, ensure the component automatically disconnects if the temperature exceeds

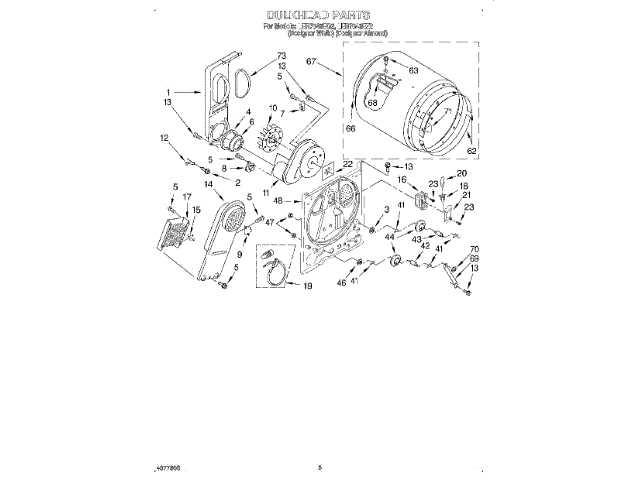

Role of the Drum and Drive Belt

The drum and drive belt are integral components that work together to rotate and maintain the flow within the machine. These elements ensure that the rotation is steady and continuous, promoting uniform motion during operation. Understanding how they interact helps in grasping the overall mechanism and its efficiency.

How the Drum Functions

The drum serves as the central chamber where items are placed for processing. It rotates on a set axis, allowing items inside to tumble freely, which contributes to even exposure to air and heat. This motion is key to preventing items from clumping together and ensures thorough processing.

Purpose of the Drive Belt

The drive belt connects the motor to the drum, transferring the power needed for rotation. Made from durable materials, it ensures a smooth and consistent spin. If the belt wears out, it can affect the rotational speed, leading to reduced effectiveness and uneven results.

Component Description Drum Identifying Common Dryer Sensors

Sensors play a crucial role in regulating the appliance’s operation, ensuring safe and efficient performance. Understanding different types of sensors and their functions can help with troubleshooting and maintenance tasks.

- Temperature Sensor: Monitors the heat levels and adjusts the operation to maintain a stable environment. This helps prevent overheating or insufficient heating during use.

- Moisture Sensor: Detects the level of humidity within the appliance. It enables the system to determine when the load has reached the desired level of dryness.

- Thermal Fuse: Acts as a safety feature that cuts off power if excessive heat is detected, protecting the unit from potential damage.

- Door Switch Sensor: Ensures the device is only operational when the access door is securely closed, preventing accidental activation.

- Humidity Sensor: Measures the amount of moisture left in the air and adjusts the timing or settings to achieve optimal results.

Recognizing the purpose of these components allows for more effective problem-solving and prolongs the appliance’s lifespan by addressing issues promptly.

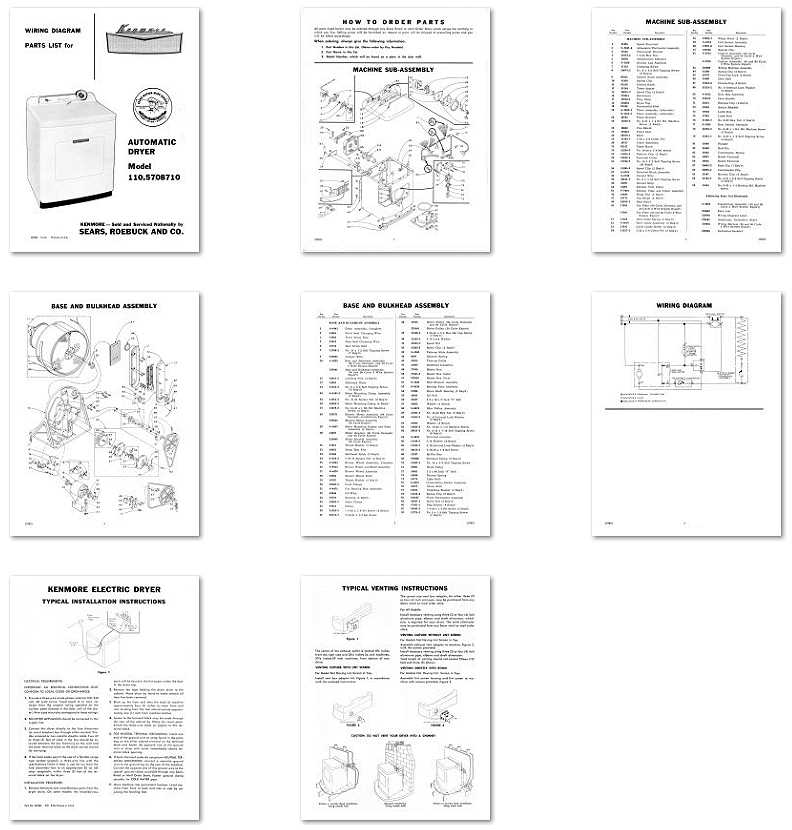

The Function of Dryer Vent Systems

Proper ventilation plays a crucial role in ensuring efficient operation and safety during the process of removing moisture from fabrics. An effective ventilation setup helps to channel warm, humid air away, preventing buildup and improving overall performance. This section explains how these systems contribute to the drying process and the potential issues that can arise without adequate ventilation.

Below is an overview of the key components that contribute to the function and safety of ventilation systems:

Component Role in Ventilation Exhaust Duct Transports the moist air from inside to an external location, helping to maintain optimal air circulation. Vent Cap Prevents external elements like debris, insects, or small animals from entering the duct, while allowing air to escape freely. Filter Screen Captures fibers and particles, reducing the risk of blockages within the venting pathway and ensuring smoother airflow. Exploring Different Dryer Control Panels

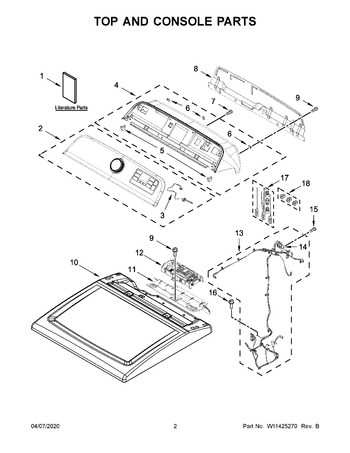

Understanding the various control panels found on laundry machines can enhance the user experience by providing insights into the different settings and functionalities available. These panels are designed with a range of options to accommodate various garment types and drying preferences, making it easier to achieve optimal results.

Mechanical Control Panels are commonly equipped with simple knobs or dials that allow users to manually select time cycles and heat levels. This traditional style offers straightforward operation but may lack some precision found in more advanced models.

Electronic Control Panels incorporate digital displays and touch-sensitive buttons, providing a more intuitive interface. They often include preset programs for specific fabrics, sensors for monitoring moisture levels, and additional features like delayed start. These panels aim to simplify the drying process while improving energy efficiency.

Some models combine manual and digital elements, offering the familiarity of mechanical controls with the enhanced functionality of electronic settings. This hybrid approach provides

Understanding Dryer Timer Mechanisms

The timer mechanism plays a crucial role in controlling the operation cycle of the appliance. It helps regulate the duration of various stages, ensuring that each phase runs for the appropriate amount of time. This function is essential for maintaining efficiency and preventing overuse of energy or overheating.

The mechanism typically relies on a set of internal contacts and gears to manage different intervals. Each position of the timer corresponds to a specific phase, such as heating or cooling. As the timer advances, it sends signals to the other components, activating or deactivating them according to the preset sequence.

Common issues with these mechanisms may arise due to worn contacts, gear malfunctions, or electrical faults. Regular inspection and maintenance can help identify potential problems early, ensuring the smooth functioning of the entire system. When issues occur, addressing them promptly can prevent more extensive damage.

Understanding the principles behind this mechanism allows for better troubleshooting and repair

Overview of the Lint Trap Assembly

The lint trap assembly plays a crucial role in maintaining efficient operation by capturing loose fibers and other debris from clothing during the drying process. This component helps to prevent buildup within the system and ensures that airflow remains unobstructed, contributing to both safety and performance.

Key Features and Components of the lint trap assembly include a removable screen or filter that captures lint, as well as a housing that securely holds the filter in place. Regular cleaning of this section is essential to prevent blockages that could impact overall functionality.

To properly maintain the lint trap, it is important to routinely check for any trapped fibers and ensure the screen is free of damage. This practice not only enhances operational efficiency but also extends the life of the entire unit.

Importance of the Blower Wheel

The blower wheel is a critical component in many appliances, playing a vital role in the circulation of air. Its design and functionality significantly influence the efficiency and performance of the entire system. When this element operates optimally, it ensures that heated air is effectively distributed, facilitating proper drying and enhancing overall effectiveness.

One of the primary functions of the blower wheel is to generate airflow. By rotating at high speeds, it creates a strong current that helps move air through various chambers. This process not only assists in drying but also aids in maintaining consistent temperatures throughout the appliance, preventing overheating and ensuring a balanced environment.

Furthermore, the blower wheel contributes to energy efficiency. A well-designed wheel minimizes energy consumption by optimizing airflow, allowing appliances to operate with less strain on the motor. This can lead to lower utility costs and a reduced carbon footprint, making it an essential factor in modern, eco-friendly designs.

In summary, the blower wheel is more than just a functional piece; it is essential for performance, energy efficiency, and maintaining optimal conditions within the appliance. Its significance cannot be understated, as it directly impacts both the effectiveness of operations and user satisfaction.

Recognizing the Dryer Motor Assembly

Understanding the function and structure of the motor assembly is crucial for efficient operation and maintenance of your appliance. This essential component plays a significant role in facilitating the movement of various elements within the system, ensuring optimal performance.

Key aspects to identify when examining the motor assembly include:

- Location: Typically situated at the rear or bottom of the unit, it is crucial for driving the drum.

- Appearance: The motor usually has a cylindrical shape, with various attached wiring and connectors.

- Connections: Look for belts and pulleys that link the motor to the drum, enabling it to rotate smoothly.

Recognizing the components associated with the motor assembly can simplify troubleshooting and repair processes. Familiarity with these elements not only aids in identifying potential issues but also enhances overall understanding of the appliance’s operation.