Understanding the structure of mechanical devices can significantly ease both maintenance and repairs. Familiarity with the layout of various elements allows for efficient troubleshooting, ensuring that malfunctions are quickly diagnosed and corrected. Knowing how different modules interact within a machine provides a clear path to resolving technical issues.

In this guide, we delve into the key features of mechanical systems commonly found in household equipment. By breaking down their configuration, we aim to offer a comprehensive overview that highlights the role and position of each functional element. This knowledge is essential for anyone looking to perform successful repairs or upgrades.

Moreover, recognizing the placement of these components ensures better operational efficiency. Whether it’s maintaining optimal performance or replacing faulty elements, this understanding is crucial for long-term functionality and reliability.

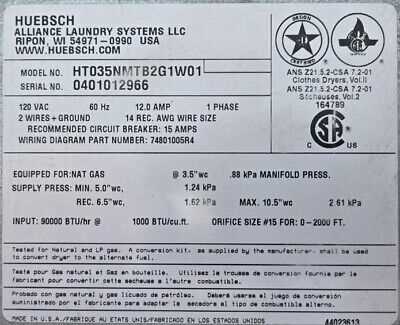

Huebsch Dryer Components Overview

The system for fabric care relies on a combination of intricate mechanisms that work together to ensure efficient performance. These assemblies include both electrical and mechanical elements, each serving a unique role in the overall operation.

| Component | Function |

|---|---|

| Heating Element | Generates the required temperature for the drying process. |

| Motor Assembly | Powers the rotation and airflow mechanisms within the unit. |

| Control Panel | Allows the user to set and adjust various settings for optimal performance. |

| Lint Filter | Traps lint and other debris to maintain air circulation efficiency. |

Understanding Key Dryer Mechanisms

In many modern machines used for drying textiles, the efficient functioning of various internal systems plays a crucial role in ensuring consistent performance. Each component, though serving a different purpose, works in harmony to achieve the desired results. By understanding the primary mechanisms, it becomes easier to diagnose issues and optimize the machine’s operation.

Heating and Airflow Control

One of the most critical systems in these machines is the combination of heating elements and air circulation. The heat generation ensures moisture is removed, while the airflow distributes warmth evenly, preventing overheating and ensuring efficient operation. Proper maintenance of these systems is key to consistent performance.

Rotation and Timing Systems

The drum’s movement is powered by a rotating mechanism, which ensures that textiles are evenly exposed to the generated heat. The timing mechanism regulates the duration of operation, ensuring optimal drying cycles based on load size and material type. Ensuring these systems function without interruption is crucial for maintaining operational efficiency.

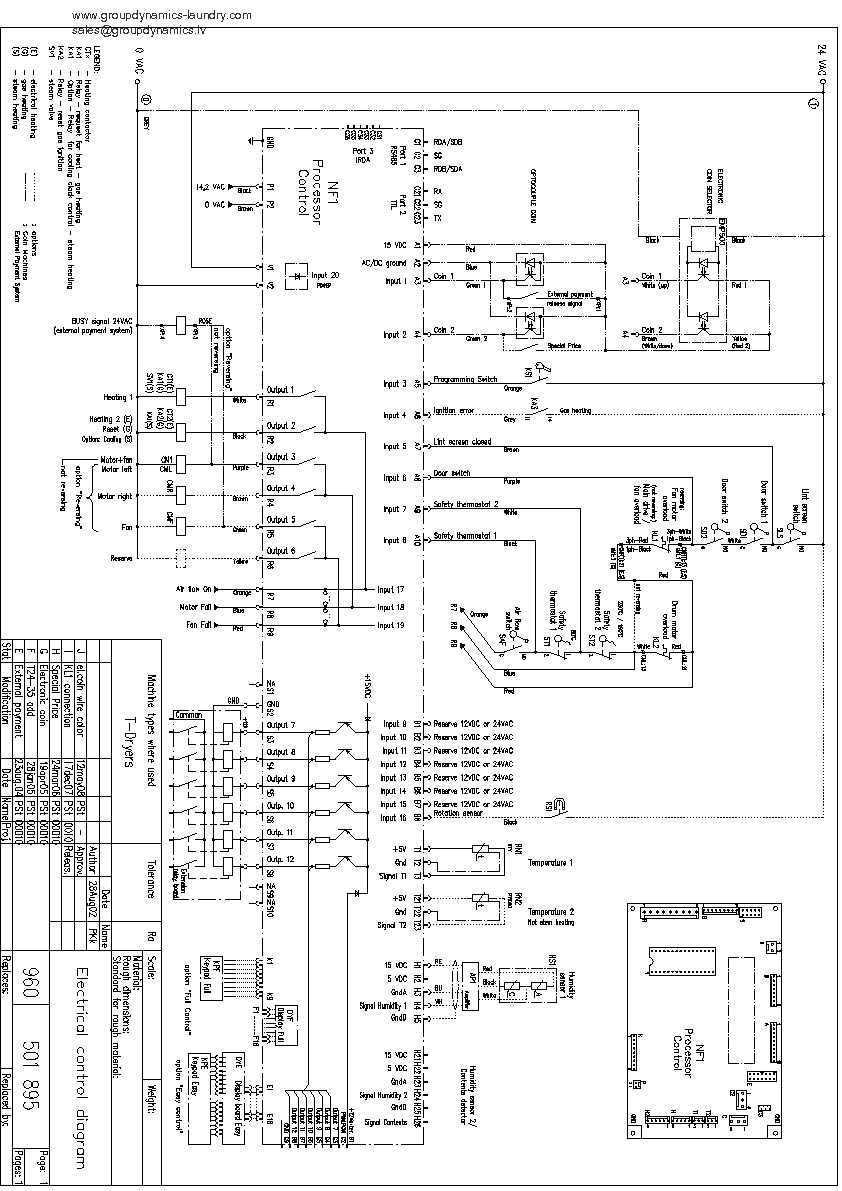

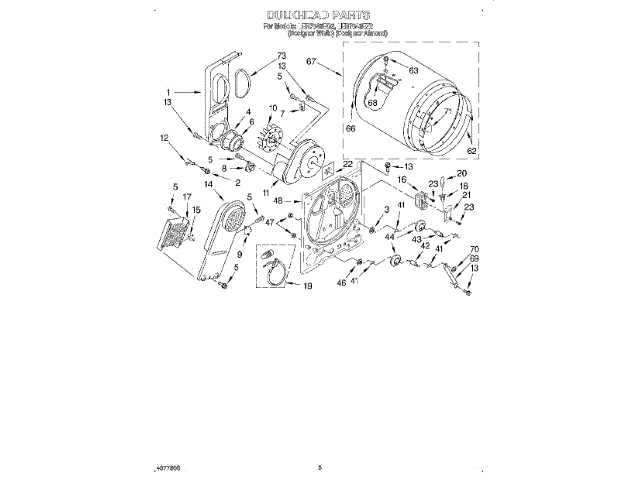

Locating Vital Parts in the Diagram

Understanding the layout of essential components within a schematic is crucial for efficient maintenance and repair. By identifying the key sections, you can quickly navigate through the visual representation and find the necessary elements for troubleshooting or replacement.

Breaking Down the Main Areas

The first step in navigating the illustration is recognizing the central areas where important mechanisms are likely to be located. Focus on larger sections, such as the control panel and heating section, which often house critical elements.

Identifying Small but Critical Elements

Smaller, yet equally important, elements are often positioned near the edges or close to the main sections. These might include connectors, sensors, or wiring that ensures the system’s proper functionality.

Commonly Replaced Dryer Elements

In many appliances designed for drying clothes, certain components tend to wear out more frequently due to regular use. Identifying these elements can help maintain the efficiency and longevity of the machine. Replacing worn parts at the right time ensures smooth operation and reduces the risk of costly repairs.

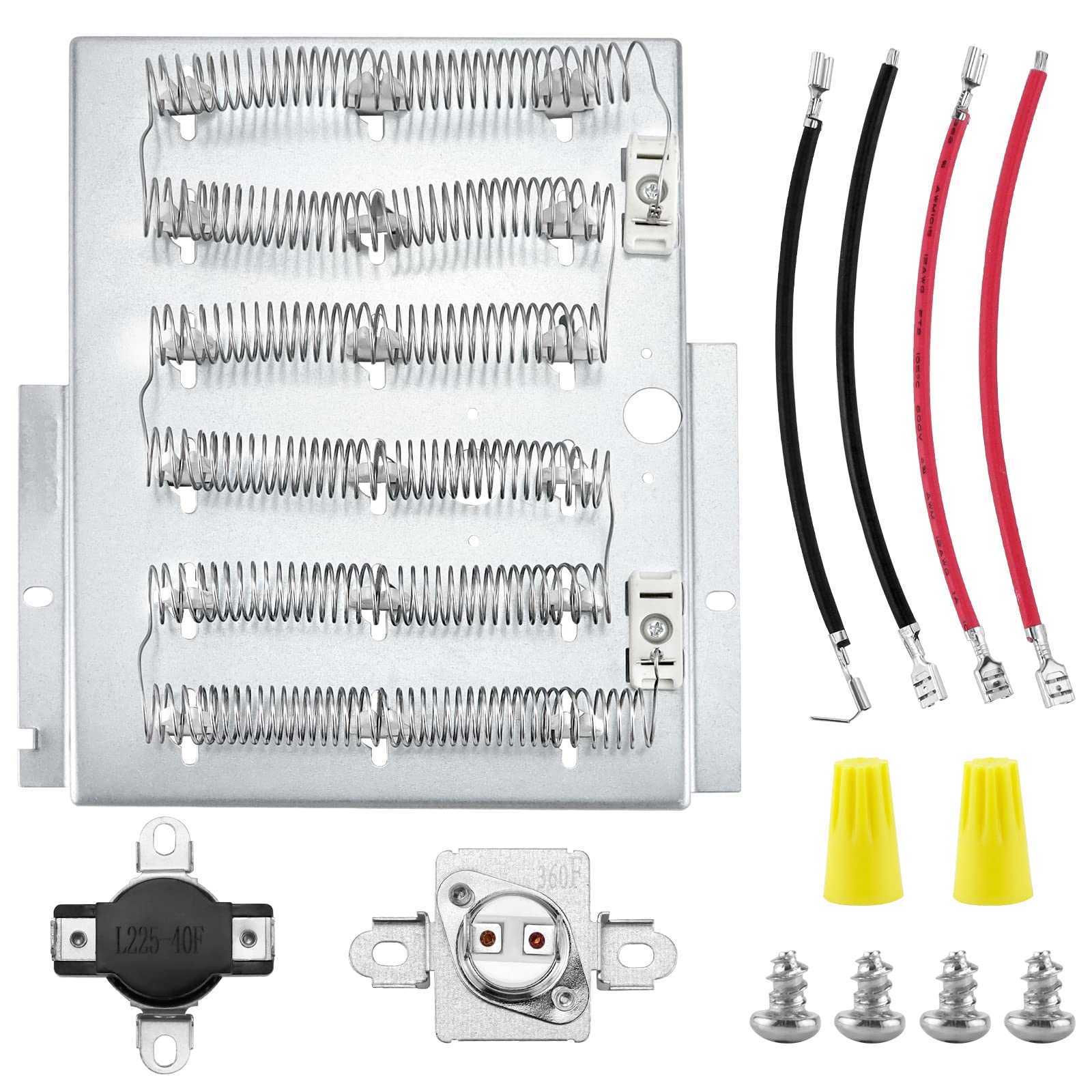

Heating elements are often subject to wear, as they are responsible for generating the necessary heat. When they malfunction, it may result in inadequate or no heat production. Regular checks on this part can help avoid such issues.

Another essential component is the thermal fuse, which acts as a safety mechanism. If it fails, the machine may not operate at all. Monitoring and replacing the fuse as needed is crucial for safety and performance.

Motor Assembly and Related Components

The motor assembly plays a crucial role in ensuring the operation of the overall machine. It is responsible for converting electrical energy into mechanical motion, enabling the various mechanical processes. Understanding how the motor works alongside its associated parts is essential for both maintenance and troubleshooting.

Key Components of the Motor System

The motor assembly consists of several important elements. The core component, the motor itself, generates the necessary force to drive the system. Supporting elements include belts, pulleys, and brackets, all of which contribute to the smooth function of the mechanism. These components ensure that the motor’s power is efficiently transferred to the machine’s moving parts.

Common Issues and Maintenance Tips

Over time, the motor assembly and its related components may experience wear and tear. Regular inspection and timely replacement of worn-out elements, such as belts or bearings, can prevent breakdowns. Proper lubrication and ensuring secure connections also help maintain optimal performance.

Identifying the Heating System Parts

The thermal components play a crucial role in ensuring the efficient operation of the entire setup. Properly recognizing and understanding these elements is essential for effective maintenance and troubleshooting.

- Heating Element: The core component responsible for generating warmth during operation. It’s essential for regulating temperature levels.

- Thermal Fuse: This safety device prevents overheating by cutting off power when temperatures exceed a certain threshold.

- Thermostat: A sensor that monitors heat levels and ensures the system remains within safe operational ranges.

- Temperature Switch: This device controls when the heating element turns on or off, depending on the system’s thermal needs.

Wiring and Electrical Connections

Understanding the electrical layout and connections is essential for ensuring proper operation and safety. By carefully examining the different wire terminals and power routes, users can address performance issues and prevent potential hazards.

Key Electrical Components

The wiring system consists of various critical elements such as relays, switches, and connectors. These components allow current to flow to the appropriate mechanisms, ensuring smooth functionality. Identifying faulty connections in this network can resolve common operational problems.

Connecting Power Sources

Electrical connections are established through a series of terminals that link to the main power supply. Correctly aligning and securing these wires ensures stable power distribution and reduces the risk of electrical faults or damage.

Airflow and Venting System Diagram

The proper functioning of the air circulation and exhaust pathway is crucial for ensuring optimal performance. A well-designed airflow route maintains balanced temperatures and prevents the buildup of moisture or debris within the system, allowing it to operate efficiently.

The system consists of several key components that work together to guide air through the system and expel it outside. Understanding this flow is important for troubleshooting and maintenance.

- Inlet Vent: Draws fresh air into the unit to maintain a steady temperature.

- Blower Fan: Circulates air through the heating element and the main chamber.

- Exhaust Duct: Channels warm air and moisture outside the unit, preventing heat buildup.

- Lint Filter: Captures fibers and debris, ensuring a clean airflow and preventing obstructions.

Maintaining clear airflow and checking these components regularly helps to prevent overheating and improves energy efficiency. Regular cleaning and inspection are key to ensuring long-term functionality.

Control Panel and Operational Parts

The control interface is a vital component in ensuring efficient functionality and user interaction with the appliance. It serves as the command center, allowing users to regulate various settings and monitor the machine’s performance. Understanding this interface is crucial for effective operation and maintenance.

Key Elements of the Control Interface

The main features typically include buttons, dials, and display indicators, each designed for specific functions. Users can select drying cycles, adjust temperatures, and manage time settings through these controls. Additionally, the layout is designed for ease of use, making it accessible to all users.

Operational Components Overview

Beyond the control interface, the appliance contains several operational components that work in harmony to achieve optimal performance. These include sensors that detect moisture levels, timers that regulate drying duration, and safety mechanisms that prevent overheating. Regular inspection and maintenance of these elements are essential for ensuring longevity and reliability.

Maintenance Tips for Dryer Parts

Regular upkeep of your appliance’s components is essential for optimal performance and longevity. By following a few straightforward guidelines, you can ensure that each element functions efficiently and reduces the risk of unexpected breakdowns.

Here are some essential maintenance tips to consider:

- Inspect Regularly: Schedule routine checks to identify wear and tear.

- Clean Filters: Remove lint and debris from filters after each use to maintain airflow.

- Check Belts: Examine belts for cracks or fraying and replace them if necessary.

- Lubricate Moving Parts: Use appropriate lubricants on hinges and rollers to prevent rust.

- Examine Electrical Connections: Ensure that all connections are secure and free from corrosion.

Implementing these practices can significantly enhance the efficiency of your appliance, leading to improved performance and reduced energy consumption.

Diagnosing Issues with Key Components

Identifying problems within essential elements of a laundry appliance is crucial for maintaining efficiency and functionality. By understanding common faults associated with these components, users can effectively troubleshoot and resolve issues, ensuring optimal performance and longevity of the equipment.

Common Symptoms and Their Causes

Many issues can arise from the primary elements of the appliance. Recognizing specific symptoms can aid in pinpointing the underlying causes. For instance, if the machine fails to start, it may indicate a faulty power source or issues with the control board. Similarly, unusual noises during operation often signal wear and tear on moving parts.

Steps for Effective Troubleshooting

To effectively diagnose problems, begin with a thorough inspection of all vital components. Check the wiring connections for any signs of damage or loose connections. Testing individual elements using a multimeter can provide insights into their functionality. By following a systematic approach, users can resolve issues more efficiently and restore the appliance to proper working order.

Improving Efficiency with Proper Parts

Optimizing performance in laundry equipment relies heavily on selecting and maintaining the right components. Ensuring that each element functions harmoniously enhances energy consumption and reduces operational downtime. Understanding the various elements involved is crucial for maximizing overall effectiveness.

Regular inspection and timely replacement of worn or damaged components play a significant role in maintaining efficiency. Using high-quality materials can prevent frequent malfunctions and extend the lifespan of the machinery. Additionally, proper alignment and installation of each element contribute to smooth operations.

| Component | Function | Maintenance Tips |

|---|---|---|

| Belt | Transmits motion from the motor | Check for wear and tension regularly |

| Rollers | Support and guide the load | Clean and lubricate to ensure smooth operation |

| Heating Element | Generates heat for drying | Inspect for damage and replace if necessary |

| Control Panel | Regulates settings and functions | Test buttons and settings for responsiveness |