The efficient operation of any cutting implement relies on its internal structure and individual elements. Grasping the layout and functionality of these components can significantly enhance maintenance and repair processes. This knowledge allows users to troubleshoot issues effectively, ensuring longevity and peak performance of their equipment.

In this section, we will delve into the various elements that constitute a specific model of a cutting device. By exploring the arrangement and relationships among these parts, users will gain insights into how each section contributes to the overall functionality. Understanding this intricate system not only facilitates better handling but also empowers operators to make informed decisions during servicing.

Equipped with this information, users can navigate potential complications with confidence, ensuring their tool remains in optimal working condition. A comprehensive understanding of the mechanical makeup serves as a foundation for effective troubleshooting and enhances the overall user experience.

Overview of Echo CS-370 Components

This section provides an insight into the various elements that make up a specific model of a power tool. Understanding these components is essential for effective maintenance, repair, and overall performance enhancement. Each part plays a critical role in ensuring the tool operates smoothly and efficiently, contributing to its functionality and longevity.

Key Components and Their Functions

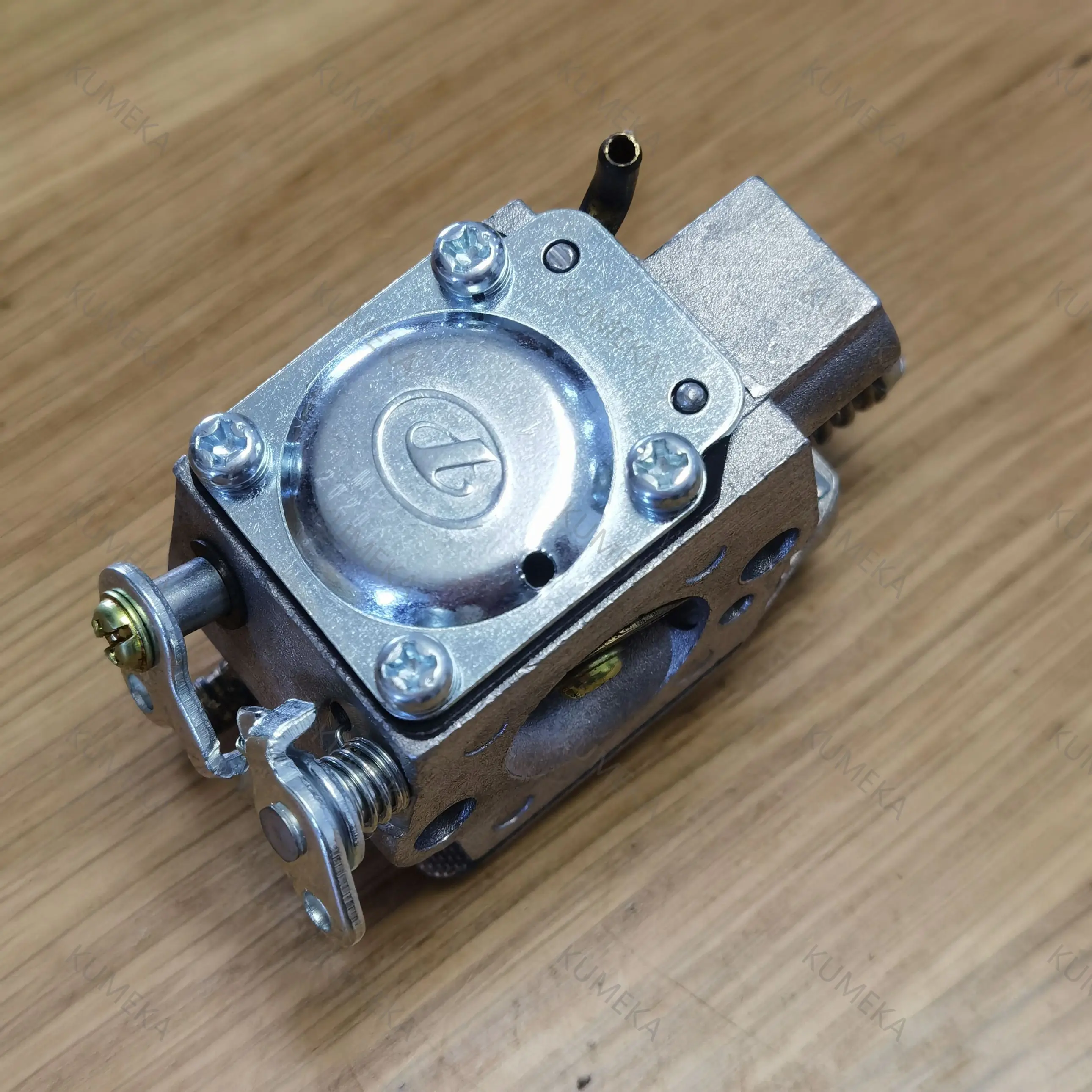

The main elements of this power equipment include the engine, cutting system, and housing. The engine serves as the powerhouse, converting fuel into mechanical energy. The cutting system is responsible for executing the primary task of the tool, utilizing sharp blades to ensure precision and effectiveness. The housing encapsulates these components, providing structural integrity and protecting internal parts from external damage.

Maintenance and Care

Regular upkeep of these components is crucial for optimal operation. Ensuring that the engine is well-lubricated, the cutting system is sharp and intact, and the housing is free from debris can significantly enhance the tool’s performance and lifespan. Proper maintenance practices can prevent common issues and reduce the likelihood of costly repairs.

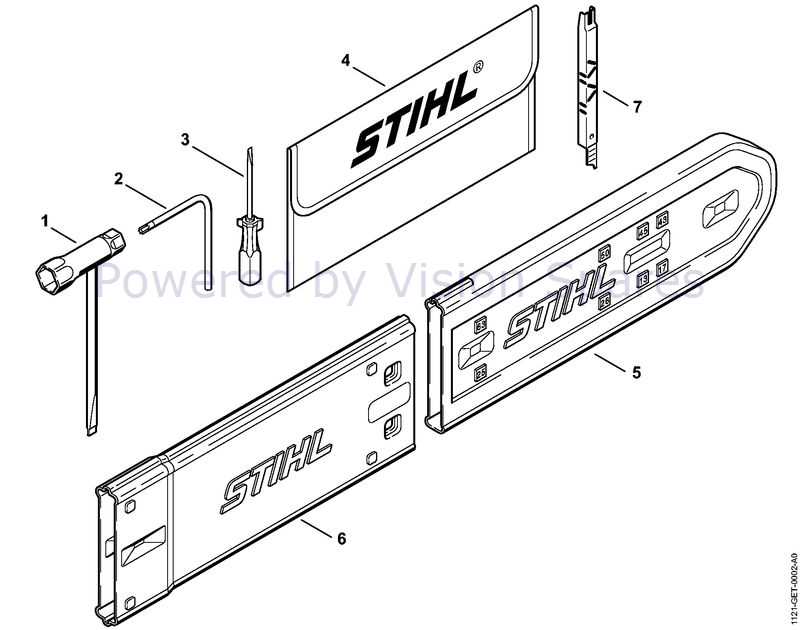

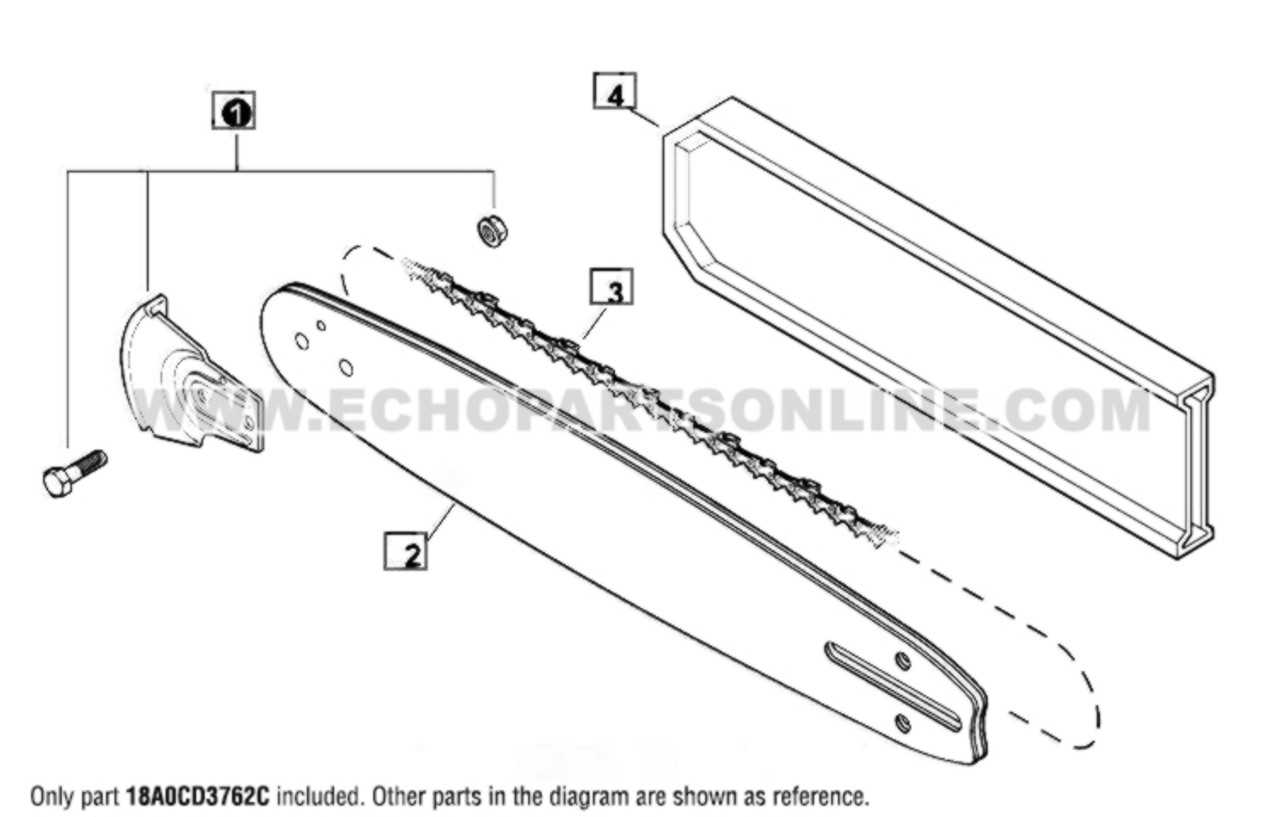

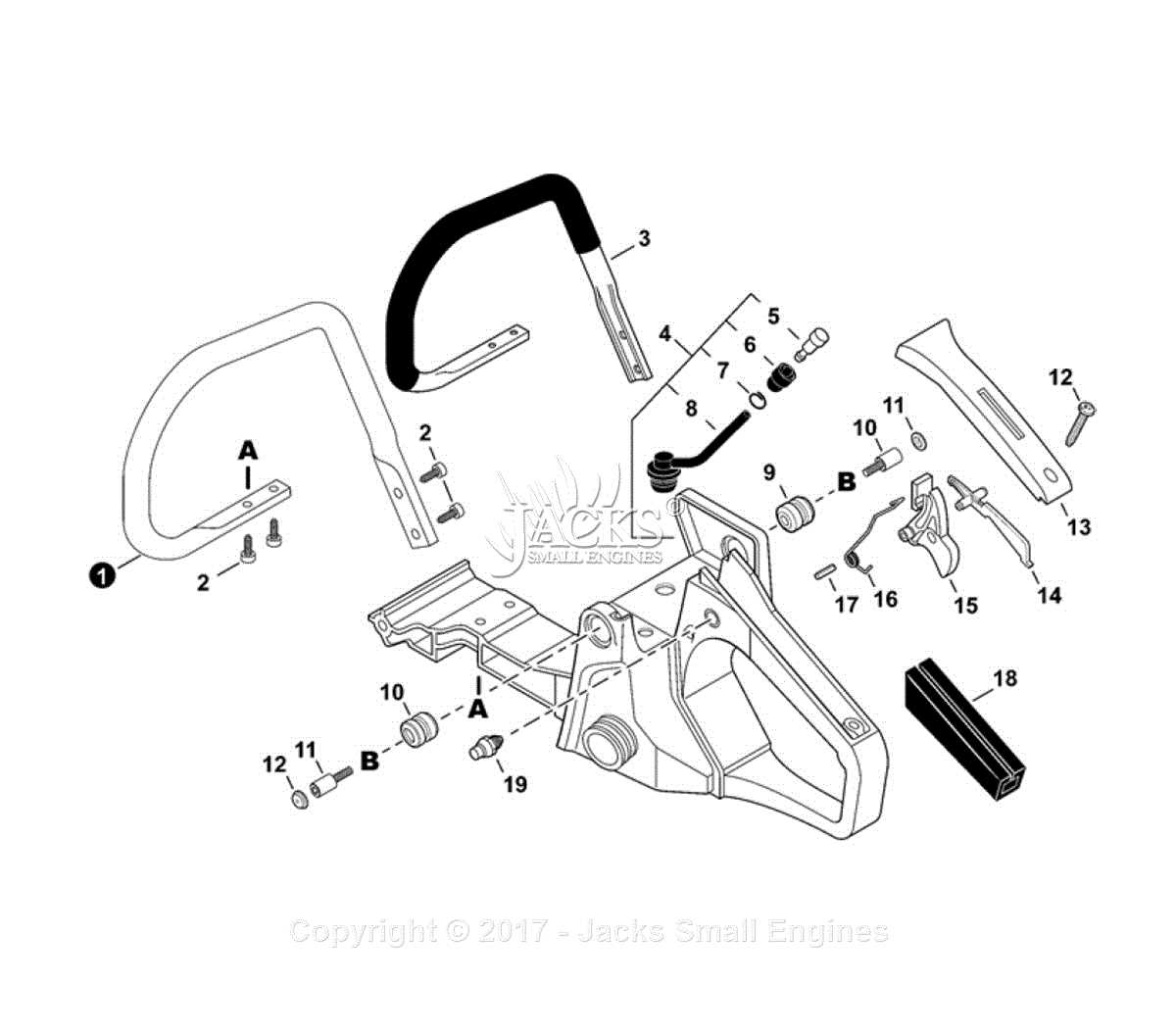

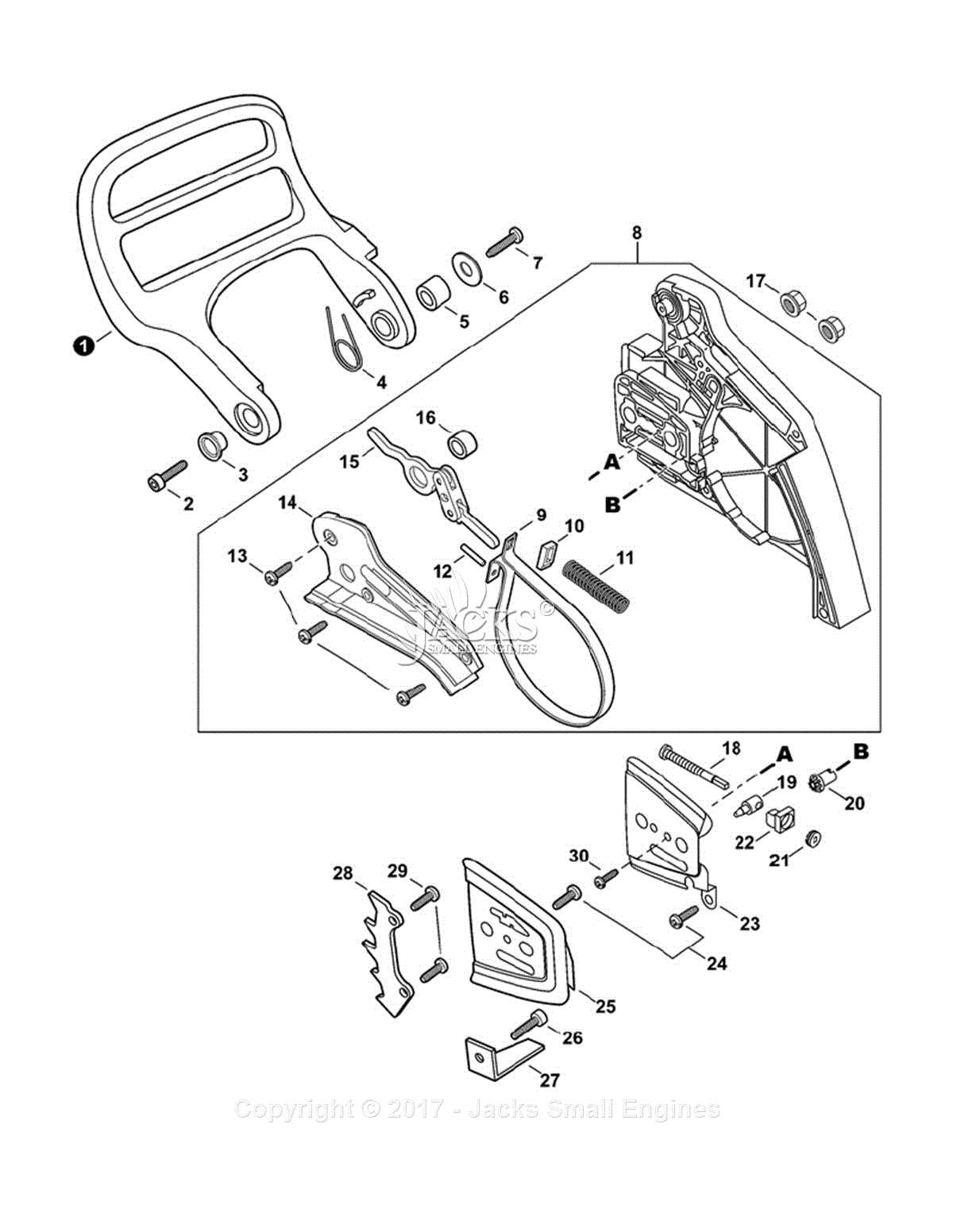

Understanding the Parts Diagram

Analyzing the components layout of a specific machine is essential for effective maintenance and repair. This visual representation offers insights into the various elements that make up the equipment, illustrating their arrangement and interconnections. Grasping this information helps users identify parts easily, facilitating troubleshooting and ensuring proper assembly and disassembly.

Importance of Component Identification

Recognizing individual elements within the visual guide is crucial for anyone involved in upkeep or repairs. Each section indicates the purpose of the components, allowing users to understand how they interact within the entire assembly. This knowledge is beneficial not only for repairs but also for enhancing operational efficiency.

How to Use the Visual Guide

To effectively utilize the visual representation, follow these guidelines:

| Step | Description |

|---|---|

| 1 | Familiarize yourself with the layout to understand the arrangement of the components. |

| 2 | Locate the parts that require attention or replacement. |

| 3 | Refer to the corresponding section in the manual for specific details on each component. |

| 4 | Use the information for efficient disassembly and reassembly during maintenance tasks. |

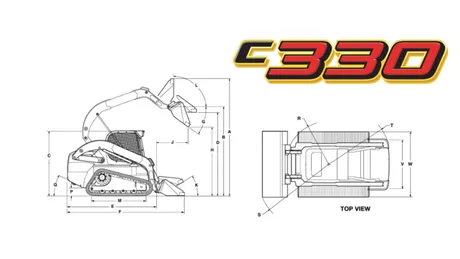

Key Features of the CS-370

This model is designed to provide users with a combination of power and efficiency, making it suitable for various outdoor tasks. Its robust construction ensures longevity, while user-friendly features enhance the overall experience during operation. Understanding its primary attributes allows potential users to appreciate its capabilities and advantages in practical applications.

Performance and Efficiency

The machine boasts a powerful engine that delivers excellent cutting performance, allowing users to tackle thick vegetation with ease. Additionally, its fuel-efficient design helps minimize operational costs while maximizing productivity. The ergonomic handle and lightweight structure further contribute to comfortable handling, reducing fatigue during extended use.

Durability and Maintenance

Built with high-quality materials, this tool is resistant to wear and tear, ensuring it can withstand demanding environments. Regular maintenance is simplified by easily accessible components, enabling users to keep the equipment in optimal condition. These features not only enhance durability but also prolong the lifespan of the device, making it a worthwhile investment for outdoor enthusiasts.

Identifying Replacement Parts

Understanding the components of your equipment is essential for maintaining optimal performance. Knowing how to identify specific elements can significantly enhance the longevity of your device and ensure that it operates efficiently. This section aims to provide insights into recognizing various components that may need replacement over time.

Common Component Types

Devices typically consist of several key elements, including engines, blades, and handles. Each of these plays a crucial role in the overall functionality. Familiarizing yourself with these categories will aid in pinpointing which parts might require attention. Regular inspection of these areas can help prevent unexpected failures and maintain consistent operation.

Finding the Right Components

When looking for replacements, it is important to refer to the user manual or manufacturer’s specifications. These resources often include detailed information about compatible components. Additionally, utilizing online forums and community discussions can provide valuable insights from other users who have faced similar issues, helping you to make informed decisions.

Common Issues with CS-370 Parts

Many users experience various challenges with components of their outdoor power equipment. Understanding these common problems can aid in effective maintenance and prolong the lifespan of the machine. Issues may arise due to wear and tear, improper handling, or environmental factors, impacting overall performance and reliability.

Wear and Tear

Over time, components may suffer from wear due to frequent use. This can lead to diminished efficiency and may require replacements. Regular inspection is essential to identify signs of degradation early, allowing for timely interventions.

Improper Installation

Installation mistakes can cause significant operational issues. If parts are not correctly fitted, it may result in malfunction or damage. Ensuring that each component is installed according to specifications can prevent these complications and enhance performance.

Maintenance Tips for Echo Chainsaw

Proper upkeep of a chainsaw is essential for ensuring its longevity and optimal performance. Regular maintenance not only enhances the tool’s efficiency but also increases safety during operation. Here are some practical suggestions to keep your equipment in prime condition.

Regular Cleaning

- Clean the air filter frequently to prevent debris buildup, which can hinder engine performance.

- Remove sawdust and dirt from the exterior to maintain visibility of the controls and components.

- Inspect and clean the chain and bar after each use to avoid premature wear.

Routine Inspections

- Check the tension of the cutting chain regularly to ensure it is neither too loose nor too tight.

- Examine the spark plug for signs of wear and replace it as necessary to ensure reliable starting.

- Inspect the fuel system for leaks or cracks, replacing any damaged components promptly.

By following these maintenance practices, you can significantly extend the life of your chainsaw and ensure it operates safely and efficiently.

How to Access Internal Components

Gaining entry to the internal structures of a machine can be essential for maintenance and repair tasks. Understanding the steps involved in accessing these parts is crucial for effective troubleshooting and ensuring optimal performance. This guide provides a clear approach to reaching the internal components safely and efficiently.

Preparation Steps

Before starting the process, ensure you have the necessary tools on hand, such as screwdrivers, wrenches, and safety gloves. It’s advisable to work in a well-lit area to clearly see the components and avoid potential hazards. Disconnect any power sources to prevent accidents while disassembling the unit.

Disassembly Process

Begin by removing the outer casing, which usually involves unscrewing various fasteners. Carefully set aside screws and components to avoid misplacing them. Once the casing is removed, you will have direct access to the internal elements. Take your time to inspect each part and refer to any available manuals for guidance on specific locations and assembly methods. Always handle internal components with care to prevent damage.

Ordering Genuine Echo Parts

When it comes to maintaining your outdoor equipment, acquiring authentic components is essential for optimal performance and longevity. Genuine items ensure that your machinery operates as intended and meets safety standards, ultimately enhancing its efficiency. This section provides guidance on how to procure these reliable elements effectively.

Benefits of Using Authentic Components

Utilizing genuine elements offers numerous advantages. Firstly, they are designed specifically for your model, ensuring a perfect fit and seamless functionality. Secondly, authentic components often come with warranties, providing peace of mind regarding their quality and durability. Lastly, using original items helps preserve the integrity of your equipment, reducing the risk of damage or malfunction caused by substandard alternatives.

Where to Purchase

To ensure you are getting legitimate products, consider purchasing directly from authorized dealers or the manufacturer’s website. These sources typically offer a comprehensive selection of components tailored to your specific model. Additionally, many online retailers provide customer support to assist you in selecting the correct items, ensuring you have a smooth purchasing experience.

Tools Required for Disassembly

Proper disassembly of a device requires a specific set of instruments to ensure efficiency and safety. Having the right tools at hand not only facilitates the process but also minimizes the risk of damaging components during the procedure. Whether for maintenance or repair, the following tools are essential for a successful disassembly.

1. Screwdrivers: A variety of screwdrivers, including flathead and Phillips, is crucial for loosening and removing screws from different parts. It’s recommended to have both standard and precision sizes to accommodate various fastenings.

2. Pliers: Needle-nose and standard pliers are useful for gripping, twisting, and pulling components apart. These tools can also assist in bending or shaping wires when necessary.

3. Wrenches: Adjustable and socket wrenches are beneficial for loosening nuts and bolts that may be too tight for manual removal. Their ability to provide leverage makes them invaluable during disassembly.

4. Safety Gear: Always prioritize safety by using protective goggles and gloves. These items safeguard against any potential injuries while handling sharp or moving parts.

5. Container for Small Parts: A small container or magnetic tray helps in organizing screws and components, preventing loss during the disassembly process. Keeping everything sorted can save time and frustration later on.

By ensuring you have these tools ready, you can streamline the disassembly process and enhance your overall experience while working on the device.

Safety Precautions During Repairs

When undertaking maintenance or repair work on machinery, it is crucial to prioritize safety to prevent accidents and injuries. Adhering to specific safety measures ensures a secure working environment and minimizes the risk of damage to the equipment and harm to the individual performing the task.

General Safety Guidelines

- Always wear appropriate personal protective equipment (PPE), including gloves, goggles, and sturdy footwear.

- Ensure that the workspace is well-lit and free from clutter to avoid tripping hazards.

- Keep all tools organized and within reach to prevent unnecessary movements and distractions.

Electrical Safety Considerations

- Disconnect the power source before starting any repair work to prevent electrical shocks.

- Use insulated tools when working on electrical components to minimize the risk of short circuits.

- Check for exposed wires or damaged insulation, and address any issues before proceeding with repairs.

Upgrades and Modifications Available

Improving the performance and functionality of your outdoor equipment can significantly enhance its efficiency and longevity. Various enhancements are available that cater to different needs, from increasing power output to optimizing fuel consumption. These modifications can transform standard models into more powerful and versatile tools, making them better suited for a range of tasks.

Power Enhancements: One of the most popular upgrades is increasing engine output. This can be achieved through modifications such as installing a high-performance muffler or adjusting the carburetor settings. These changes can lead to improved acceleration and overall performance.

Weight Reduction: Another way to enhance usability is by reducing the weight of the unit. Replacing certain components with lightweight alternatives can make handling easier, particularly during extended use. This is particularly beneficial for users who need to maneuver their tools for long periods.

Ergonomic Improvements: Modifying the handle and grip can also provide added comfort during operation. Ergonomically designed components can reduce fatigue and improve control, which is essential for safety and efficiency.

Fuel Efficiency: Upgrading the fuel system can lead to better fuel economy. By installing high-quality filters and optimizing fuel lines, users can ensure that their equipment runs more efficiently, saving both time and money in the long run.

These upgrades not only enhance the performance of your equipment but also extend its lifespan, allowing for more productive use over time. Always consider consulting with professionals or experienced users to ensure the modifications are suitable for your specific model.

Where to Find Repair Manuals

When seeking guidance for maintenance and troubleshooting of your equipment, having access to the right instructional resources is essential. Various platforms offer comprehensive manuals that can aid in the repair process, ensuring you have the necessary information to proceed confidently.

Online Resources

- Manufacturer’s Website: Check the official site for downloadable manuals and product documentation.

- Forums and Community Groups: Engage with online communities dedicated to similar machinery where members often share manuals and tips.

- Specialty Websites: Numerous sites specialize in providing repair guides and manuals for various types of equipment.

Local Resources

- Authorized Dealers: Visit local dealers who may offer printed manuals or digital versions upon request.

- Library: Public libraries often have a collection of technical manuals that can be accessed for free.

- Repair Shops: Local repair professionals may have copies of manuals or can assist in locating them.