When maintaining or repairing your outdoor machinery, it’s crucial to have a clear understanding of its various elements. Familiarity with the individual components not only facilitates effective troubleshooting but also enhances overall performance. This section will guide you through the essential aspects of these vital parts.

By exploring the relationships and functions of each element, you will gain insights into how they work together to optimize the equipment’s efficiency. A comprehensive overview will help you identify which components may need attention, ensuring your machinery operates smoothly.

Additionally, having knowledge of the different sections of your equipment empowers you to make informed decisions regarding repairs and replacements. Whether you’re a novice or an experienced user, understanding these fundamental aspects can significantly enhance your experience and satisfaction.

This section explores the essential characteristics of a popular gardening tool, highlighting its design and functionality. This device is designed for efficiency and ease of use, making it an excellent choice for both amateur gardeners and professionals alike.

Design and Build Quality

The construction of this tool emphasizes durability and user comfort. Lightweight materials combined with an ergonomic design ensure that the device can be handled for extended periods without causing fatigue. The balance and design allow for easy maneuverability, making it ideal for a variety of gardening tasks.

Performance Specifications

Performance is a crucial aspect that influences the effectiveness of any gardening tool. This device is equipped with a powerful engine that delivers exceptional cutting power while maintaining fuel efficiency. Users can expect smooth operation and reliable performance, whether tackling dense grass or overgrown weeds.

| Feature | Description |

|---|---|

| Engine Power | Provides strong cutting capability for various applications. |

| Weight | Lightweight construction for enhanced maneuverability. |

| Ergonomics | Designed for user comfort during extended use. |

| Fuel Efficiency | Optimized for longer operation with less fuel consumption. |

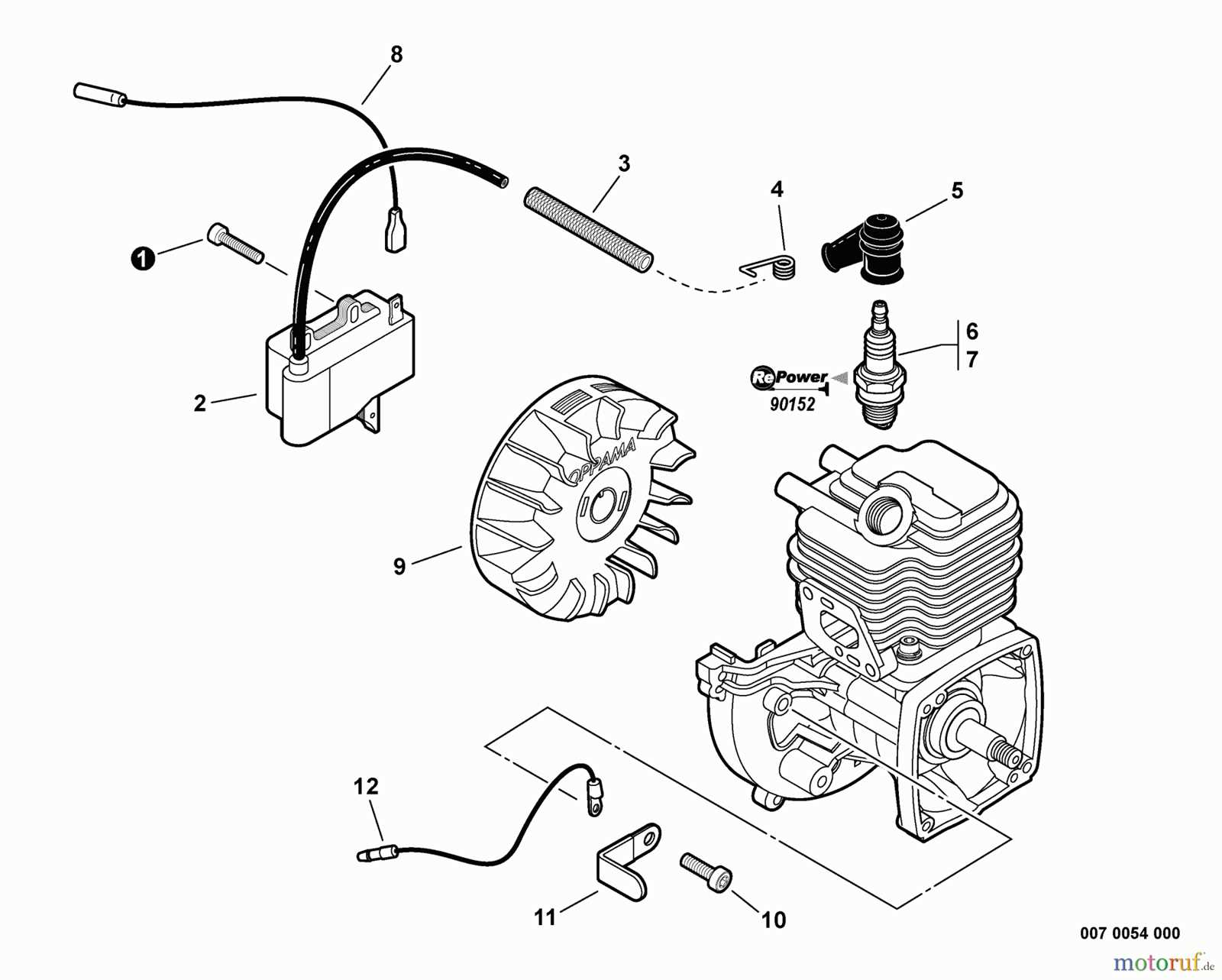

Exploring the Engine Assembly

The engine assembly serves as the heart of any outdoor power equipment, playing a crucial role in its overall performance. This section delves into the various components that make up this essential unit, highlighting their functions and interrelationships. Understanding the engine’s structure can significantly enhance maintenance and repair efforts.

Key Components of the Engine

At the core of the assembly lies the cylinder, which houses the combustion process that powers the machine. Connected to the cylinder are critical parts such as the piston, crankshaft, and connecting rod. Together, these components work in unison to convert fuel into mechanical energy, driving the equipment efficiently.

Maintenance Considerations

Regular maintenance of the engine assembly is vital for optimal performance. Key practices include checking for wear and tear on components, ensuring proper lubrication, and replacing filters as needed. By paying attention to these aspects, users can extend the lifespan of their equipment and ensure it operates at peak efficiency.

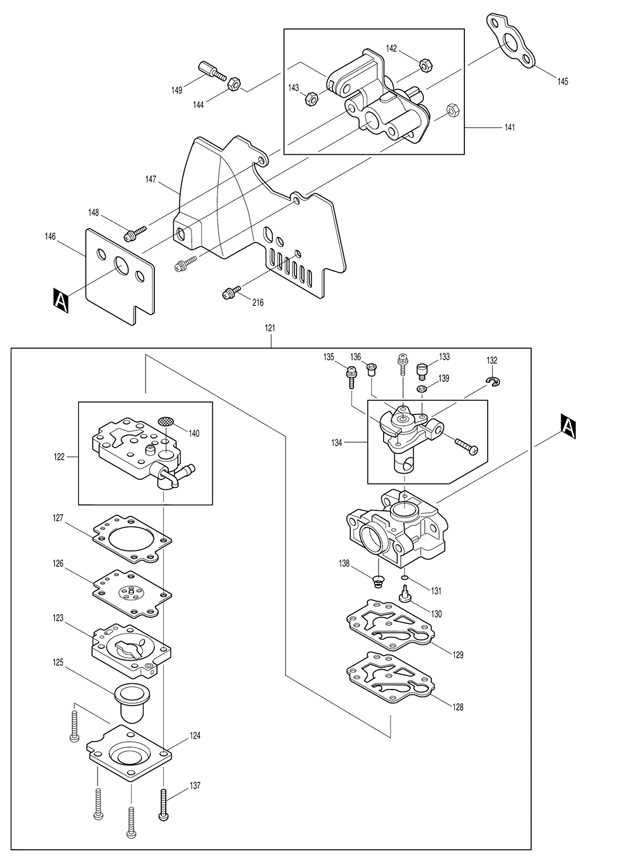

Fuel System Components Overview

The fuel system is essential for the proper functioning of any engine, as it ensures that the necessary mixture of fuel and air is delivered efficiently. Understanding the various elements of this system helps in maintaining performance and longevity. This section provides insights into the key components that contribute to the effective operation of the fuel system.

Key Elements of the Fuel System

At the heart of the fuel delivery process are several vital components. These include the fuel tank, where the fuel is stored, and the fuel lines, which transport the fuel to the engine. Additionally, filters play a crucial role in removing impurities, ensuring that only clean fuel reaches the engine.

Fuel Delivery Mechanisms

Various mechanisms are employed to deliver fuel efficiently. The pump is responsible for drawing fuel from the tank and pushing it through the lines. Meanwhile, the carburetor or fuel injection system mixes the fuel with air before it enters the combustion chamber. This precise mixing is vital for optimal engine performance.

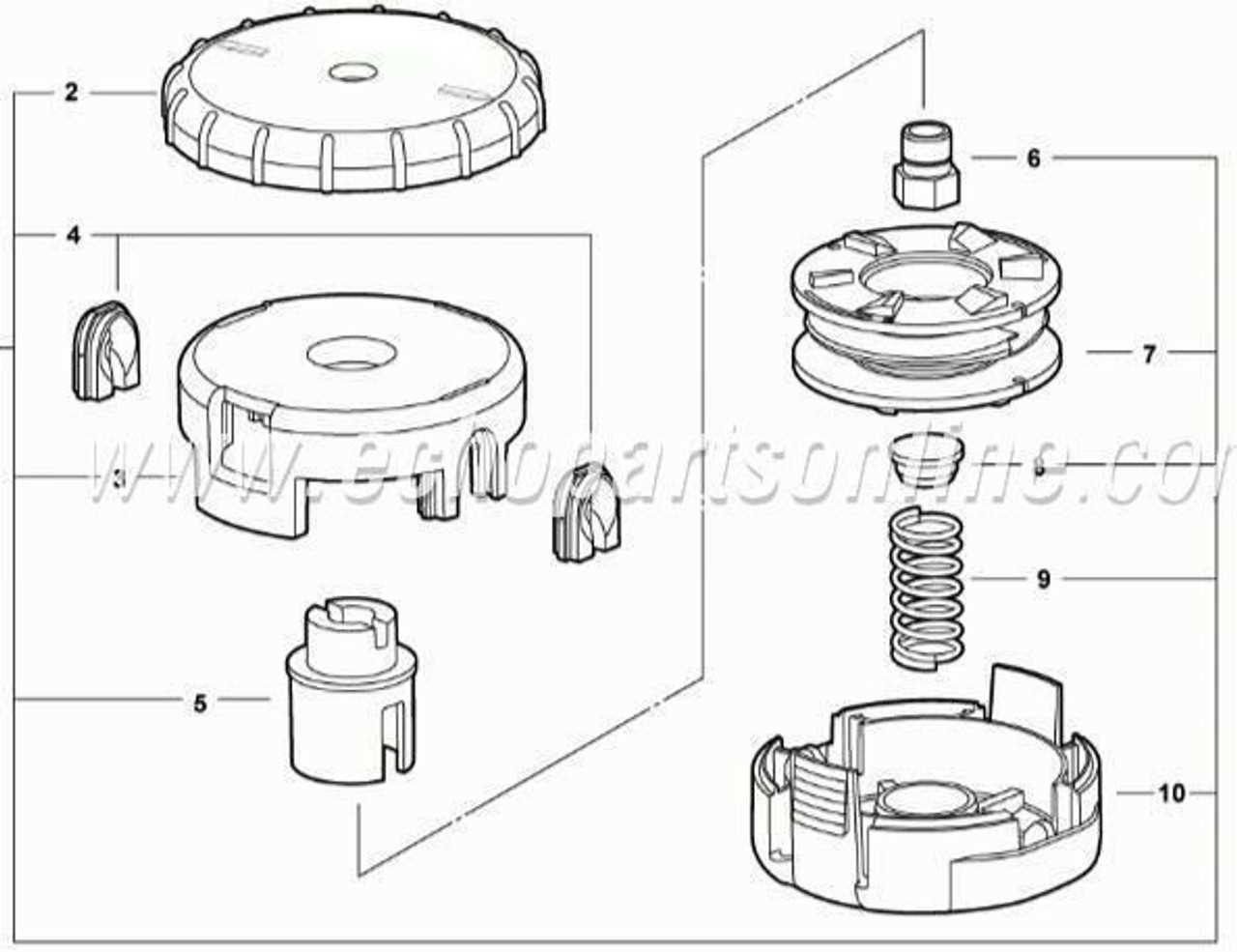

Trimming Head and Line Details

The trimming head is a crucial component in a grass cutting device, playing a significant role in ensuring effective performance. It is designed to accommodate various types of cutting lines, providing versatility and efficiency in maintaining different types of vegetation.

Typically, the head consists of a spool that holds the cutting line securely, allowing for easy replacement when needed. Choosing the right line is essential for optimal cutting, as different lines vary in thickness, durability, and material composition. Understanding the specific requirements for your trimming tasks can greatly enhance the overall effectiveness and longevity of the equipment.

Moreover, proper maintenance of the trimming head is vital. Regularly checking for wear and tear, as well as ensuring the line is wound correctly, will prevent operational issues and improve the lifespan of the tool. Investing time in maintenance pays off by ensuring consistent performance and reliable results.

Cutting Blade Specifications

The cutting blade is a crucial component that influences the performance and efficiency of any trimming device. Understanding its characteristics helps in selecting the right tool for various applications, ensuring optimal cutting results.

Key Features

- Material: The blade is often made from high-quality steel, which ensures durability and resistance to wear.

- Dimensions: Blade length and width play a significant role in determining cutting capabilities and maneuverability.

- Tooth Configuration: The arrangement of teeth can vary, affecting the type of vegetation the blade can efficiently cut through.

Maintenance Guidelines

- Regularly inspect the blade for any signs of damage or dullness.

- Sharpen the blade as needed to maintain cutting efficiency.

- Clean the blade after use to prevent buildup of debris.

Maintenance Parts for Longevity

Ensuring the durability of your equipment involves understanding the key components that contribute to its optimal performance. Regular attention to these elements can significantly enhance the lifespan and efficiency of the device. Proper maintenance practices not only prevent unexpected breakdowns but also keep your machinery running smoothly over time.

Essential Components for Care

Focusing on vital elements such as filters, spark plugs, and fuel systems is crucial. These components play a significant role in the overall functionality of your equipment. Regular inspection and replacement when necessary can help avoid larger issues and ensure continuous operation.

Importance of Regular Inspections

Conducting routine checks on the critical aspects of your machinery allows for early detection of potential problems. This proactive approach minimizes downtime and enhances performance, providing peace of mind for users. Staying ahead of maintenance needs fosters a reliable and efficient operational experience.

Safety Equipment and Accessories

When operating outdoor machinery, ensuring personal safety should be a top priority. Utilizing appropriate protective gear not only safeguards the user but also enhances the overall efficiency of the task at hand. This section highlights essential equipment and accessories that contribute to a safer working environment.

Essential Protective Gear

Wearing suitable protective clothing is crucial. Items such as gloves, goggles, and ear protection help prevent injuries and discomfort during operation. Each piece of equipment plays a vital role in shielding the user from potential hazards associated with the machinery.

Maintenance Tools and Accessories

In addition to personal protective gear, having the right tools for maintenance and care is essential. Accessories like lubricants, cleaning agents, and replacement items ensure that the equipment functions correctly and safely. Regular maintenance minimizes risks and prolongs the lifespan of the machinery.

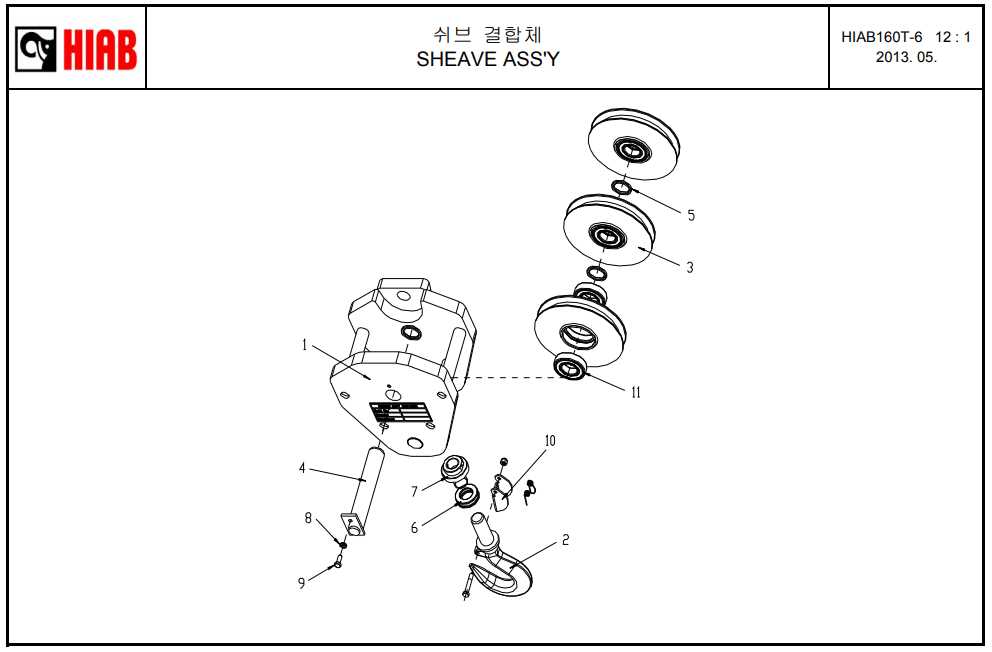

Assembly and Disassembly Process

This section outlines the steps involved in the assembly and disassembly of the equipment, focusing on essential techniques to ensure safety and efficiency. Understanding these processes is crucial for proper maintenance and troubleshooting, allowing users to operate their devices effectively while preserving their longevity.

Disassembly Steps

Begin by ensuring that the machine is powered off and disconnected from any power source. Carefully remove any outer casing to access internal components. Take care to note the arrangement of parts as they are removed; this will facilitate a smoother reassembly later. Utilize appropriate tools for each component, and keep them organized to avoid misplacement.

Reassembly Guidelines

During reassembly, refer to your notes or photographs taken during disassembly to ensure that every piece is correctly positioned. Follow a systematic approach, starting from the interior and working outward. Ensure all fasteners are securely tightened, and double-check connections before finalizing the process to avoid operational issues.

Common Replacement Parts List

When it comes to maintaining your outdoor power equipment, understanding the essential components that may require periodic replacement is crucial. Below is a list of frequently needed items that can help ensure the optimal performance of your device.

- Air Filter

- Fuel Filter

- Spark Plug

- Throttle Cable

- Starter Assembly

- Trimmer Line

- Drive Shaft

Regular checks and timely replacements of these components can significantly enhance the longevity and efficiency of your equipment. Be sure to consult your user manual for specific details on compatibility and installation procedures.

Troubleshooting Parts Issues

When facing challenges with equipment components, identifying the root cause of the problem is essential for effective resolution. Understanding common malfunctions and their symptoms can significantly expedite the repair process and enhance overall performance.

Common Symptoms of Component Failures

Several indicators suggest that a particular element may not function as intended. Unusual noises, reduced efficiency, or intermittent operation are often the first signs. These symptoms can help pinpoint the specific area requiring attention.

Steps for Effective Diagnosis

To address component-related issues, begin by conducting a thorough inspection of the equipment. Check for loose connections, visible wear, or any signs of damage. After initial evaluation, refer to the manufacturer’s guidelines for detailed diagnostic procedures. This systematic approach not only aids in identifying the malfunctioning part but also ensures a comprehensive solution.

Where to Find Replacement Diagrams

Locating detailed illustrations for spare components can significantly ease the process of repairing and maintaining your equipment. Whether you are seeking schematics for assembly or individual pieces, various resources are available to assist you in your search.

Online Resources

- Manufacturer’s Official Website: Many companies provide downloadable resources, including detailed schematics and user manuals.

- Forums and Community Groups: Online forums and social media groups dedicated to your equipment often have members sharing useful diagrams and repair advice.

- Parts Retailers: Websites specializing in replacement components frequently offer technical documents related to the products they sell.

Local Options

- Authorized Service Centers: Visiting a certified service location can provide you with access to professional diagrams and expert guidance.

- Local Repair Shops: Independent repair technicians may have resources or references that can help in finding the necessary illustrations.