In the world of machinery and tools, a thorough understanding of individual components is essential for efficient operation and maintenance. This section delves into the intricacies of various elements that comprise a specific model, shedding light on their functions and interrelations. By grasping the configuration of these essential units, users can enhance their proficiency and ensure optimal performance.

The exploration of these assemblies provides insights into the engineering behind their design, highlighting how each part contributes to the overall functionality. Recognizing the role of each component not only aids in troubleshooting but also empowers users to undertake repairs and modifications with confidence. As we dissect the relationships among these critical elements, a clearer picture of their significance in the broader context will emerge.

Whether you are a novice looking to familiarize yourself with essential components or an experienced operator seeking advanced knowledge, this section serves as a valuable resource. By immersing yourself in the details of these configurations, you will gain a deeper appreciation for the precision and innovation involved in their creation.

This section will provide a comprehensive overview of the various elements that comprise a specific model. Understanding these components is crucial for both maintenance and enhancement of functionality. A thorough exploration of each element will aid users in navigating the intricacies of assembly and disassembly, ultimately leading to better performance.

Key Features of Each Component

- Detailed descriptions of the primary components

- Functions and importance of each part

- How components interact within the overall system

Common Issues and Solutions

- Identifying frequent problems associated with specific elements

- Step-by-step troubleshooting guidelines

- Tips for preventive maintenance and care

This structured approach not only enhances understanding but also promotes informed decision-making when it comes to repairs and upgrades. By dissecting each section, users will gain valuable insights into the intricacies of the overall design, empowering them to make better choices and extend the lifespan of their equipment.

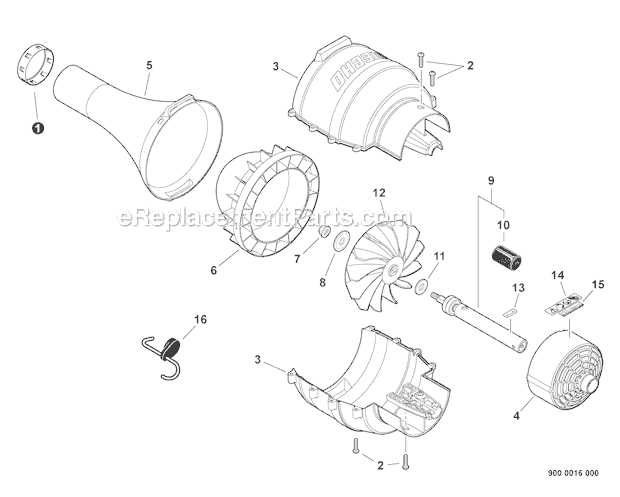

Understanding Echo Assembly Layout

The configuration of a device is crucial for its optimal functionality. A well-organized assembly not only enhances performance but also simplifies maintenance and troubleshooting. This section delves into the structure and components involved, highlighting their relationships and roles within the system.

Component arrangement plays a vital role in achieving efficiency. Each element is strategically placed to ensure seamless operation and accessibility. By analyzing the layout, one can gain insights into how individual parts interact, contributing to the overall performance.

Furthermore, understanding the assembly framework allows for easier identification of issues. When components are laid out logically, technicians can quickly locate and address potential problems, minimizing downtime and enhancing reliability. Familiarity with the setup fosters a deeper comprehension of the device’s capabilities and limitations.

In summary, exploring the structure of this assembly provides valuable knowledge for users and technicians alike. A well-designed layout is essential for maximizing functionality and ensuring longevity, making it a key aspect of effective device management.

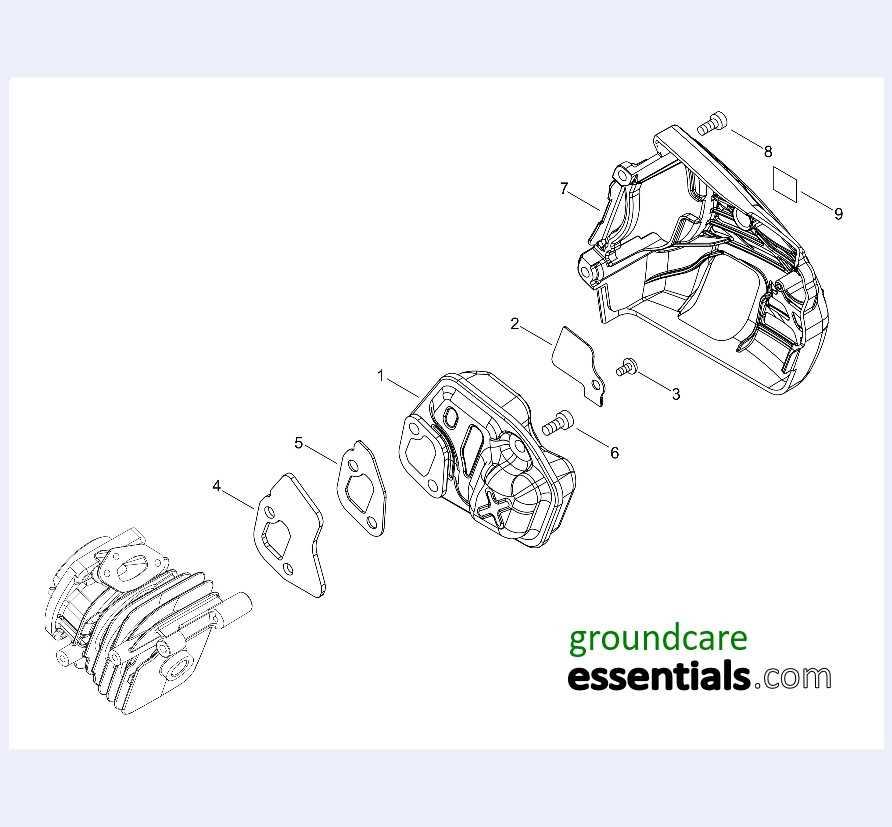

Key Functional Parts Explained

This section delves into the essential components that contribute to the overall performance and functionality of the system. Each element plays a pivotal role in ensuring smooth operation and efficiency, working in harmony to achieve desired outcomes.

At the heart of the mechanism lies the primary assembly, which serves as the core structure, providing stability and support. This foundational unit is crucial for integrating various functionalities and ensuring that all components operate cohesively.

Complementing this core assembly are the energy conversion elements, responsible for transforming energy from one form to another. These units are vital for powering the system, enabling it to perform tasks effectively and reliably.

Another significant feature includes the control interfaces, which facilitate user interaction. These interfaces are designed to offer intuitive access to the system’s capabilities, allowing users to make adjustments and modifications with ease.

Furthermore, the safety mechanisms integrated within the design are essential for preventing potential hazards. These protective features ensure that the system operates within safe parameters, safeguarding both the equipment and its users.

Finally, the overall configuration is enhanced by auxiliary components that support specific functions. These supplementary elements are tailored to improve efficiency and optimize performance, adding significant value to the entire assembly.

Importance of Accurate Diagrams

Precise representations of mechanical systems play a crucial role in ensuring optimal performance and functionality. They serve as a reference point for understanding complex configurations, assisting technicians and engineers in troubleshooting and maintenance tasks. When these visuals are accurate, they enable seamless communication and reduce the likelihood of errors during assembly or repairs.

Benefits of Precision in Visual Representations

- Enhanced Clarity: Detailed illustrations eliminate ambiguity, allowing users to interpret information with ease.

- Streamlined Maintenance: Accurate visuals facilitate quicker diagnostics, reducing downtime and enhancing efficiency.

- Improved Safety: Clear instructions contribute to safer operations, minimizing the risk of accidents and injuries.

- Cost Efficiency: Correctly formatted visuals prevent costly mistakes and reduce the need for rework.

Impact on User Experience

Users greatly benefit from well-crafted visual aids. Clear representations not only enhance comprehension but also build confidence among those engaged in assembly or repair activities. When individuals can easily navigate through instructions, their overall experience improves, fostering a greater sense of satisfaction and success in their tasks.

Tools Needed for Assembly

Successfully assembling equipment requires a selection of essential instruments to ensure a smooth process. These tools facilitate precise adjustments and effective handling, contributing to an efficient workflow.

Basic Hand Tools

- Wrenches: A variety of sizes to fit different fasteners.

- Screwdrivers: Both flathead and Phillips types for various screws.

- Pliers: Needle-nose and standard pliers for gripping and bending.

- Utility Knife: For cutting materials as needed.

Specialized Instruments

- Torque Wrench: Ensures fasteners are tightened to the correct specifications.

- Measuring Tape: For accurate measurements during assembly.

- Level: To verify alignment and ensure stability.

- Wire Strippers: If wiring connections are part of the assembly process.

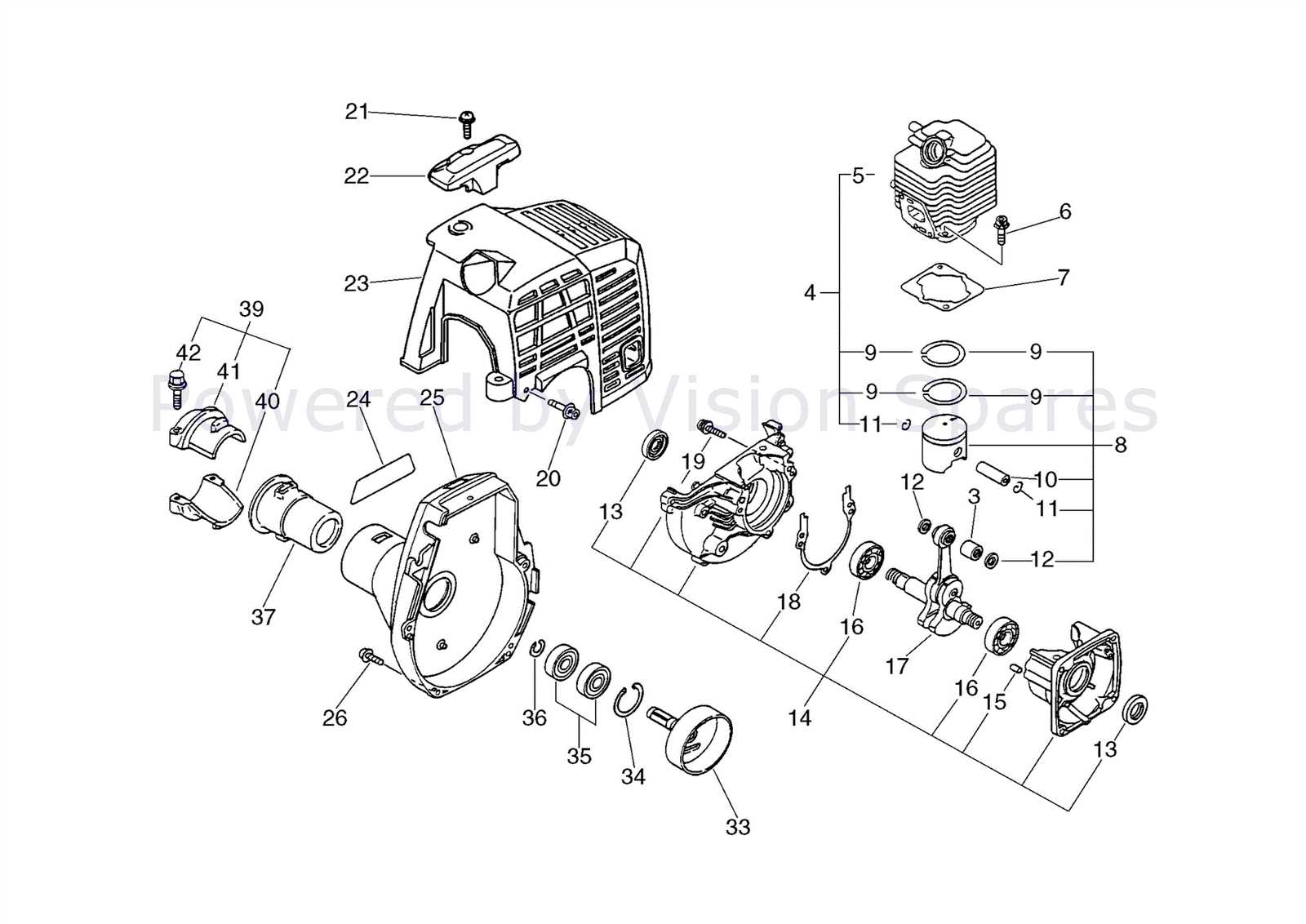

Common Issues in Echo Parts

When it comes to maintaining and troubleshooting various components of outdoor equipment, several challenges can arise. These issues may range from minor malfunctions to significant failures, impacting the overall performance and efficiency of the machinery. Understanding these common challenges can aid users in identifying problems early and taking appropriate action.

One frequent problem encountered is wear and tear on essential components due to regular usage. This deterioration can lead to reduced efficiency, affecting the device’s operation. Users should regularly inspect these crucial elements and replace them as necessary to maintain optimal functionality.

Another issue that often arises is improper assembly or loose fittings. Over time, vibrations during operation can cause connections to loosen, leading to performance issues. Ensuring that all components are securely attached and correctly aligned is vital to prevent such complications.

Fuel system malfunctions are also a common concern. Clogs or leaks in the fuel lines can hinder performance and lead to engine stalling. Regular maintenance, including cleaning filters and checking for leaks, is essential to keep the system functioning smoothly.

Lastly, ignition troubles can prevent machinery from starting. This can be due to worn-out spark plugs or issues within the ignition system itself. Regular inspection and replacement of these components can help avoid frustrating startup problems.

Maintenance Tips for Echo Devices

Proper upkeep of your voice-activated assistant can significantly enhance its performance and longevity. By following a few essential guidelines, you can ensure that your device continues to operate smoothly and efficiently.

- Regular Software Updates: Always check for the latest software updates. Keeping the firmware current helps improve functionality and security.

- Cleaning: Dust and dirt can affect performance. Wipe the surface regularly with a soft, dry cloth, avoiding any liquids.

- Optimal Placement: Position the device in a central location, away from walls and obstructions, to ensure better sound recognition and connectivity.

- Power Supply: Use the original power adapter to avoid issues with charging and ensure consistent performance.

- Voice Calibration: Take time to adjust voice recognition settings. This can improve responsiveness and accuracy in understanding commands.

Following these tips will not only keep your device running smoothly but also enhance your overall experience. Regular maintenance contributes to a reliable and efficient assistant that meets your needs.

Parts Identification Techniques

Effective identification of components is crucial for maintaining and repairing machinery. Various methods can enhance the accuracy of this process, ensuring that technicians can quickly locate the necessary items for efficient workflow. Understanding these techniques can significantly reduce downtime and improve overall productivity.

One popular method involves visual inspection, which allows for immediate recognition based on distinct characteristics. Another technique utilizes reference materials, such as manuals or online databases, to cross-verify information. The combination of these approaches can lead to a comprehensive understanding of the required elements.

| Technique | Description |

|---|---|

| Visual Inspection | Examining components closely for identifying marks, shapes, and colors. |

| Reference Materials | Utilizing manuals, catalogs, or online resources to confirm specifications. |

| Measurement | Taking precise measurements to ensure compatibility and proper fit. |

| Comparison | Matching suspected items with known examples to verify identity. |

| Consultation | Seeking advice from experts or forums for difficult-to-identify elements. |

Replacement Parts and Upgrades

Maintaining and enhancing the functionality of your equipment is essential for optimal performance. Upgrades and replacements can significantly improve efficiency, extend lifespan, and ensure reliability. Identifying the right components for your specific model can make a substantial difference in overall operation.

Key Considerations: When seeking to upgrade or replace components, it’s crucial to evaluate compatibility, quality, and purpose. High-quality alternatives can often provide better performance compared to original components, while also offering advanced features.

Popular Upgrades: Common enhancements include improved filters, upgraded engines, and advanced electronic systems that offer better control and efficiency. These modifications can lead to increased productivity and reduced maintenance requirements.

Consulting a professional or accessing reliable resources can guide you in making informed decisions about the best components for your needs. Proper installation and maintenance of these elements are equally important to ensure that your equipment functions smoothly and efficiently.

Safety Precautions During Repairs

When undertaking any maintenance or troubleshooting tasks, it is essential to prioritize safety. Proper precautions can help prevent accidents, injuries, and damage to equipment. Following established guidelines ensures a safer environment and promotes efficient repairs.

- Wear appropriate personal protective equipment (PPE) such as gloves, goggles, and masks to shield against potential hazards.

- Ensure the workspace is well-ventilated to avoid the accumulation of harmful fumes or dust.

- Disconnect power sources before starting any repair work to minimize the risk of electric shock.

- Use insulated tools to reduce the chance of electrical accidents.

Additionally, organizing your workspace can greatly enhance safety. A clutter-free environment reduces the risk of tripping hazards and ensures that tools and materials are readily accessible.

- Identify and label all components involved in the repair to prevent confusion.

- Keep emergency contact numbers handy for quick access in case of accidents.

- Document the repair process for future reference and to track any issues that may arise.

Lastly, be aware of the specific characteristics of the equipment you are working on. Understanding its design and function can help you make informed decisions and avoid potential pitfalls during repairs.