In the realm of gardening and landscaping, a thorough comprehension of various mechanisms is essential for optimal performance and maintenance. By examining the intricate assembly of tools, users can enhance their proficiency and ensure the longevity of their devices. This exploration offers insights into the structural elements that play a pivotal role in the functionality of these machines.

Understanding how different components interact can significantly improve troubleshooting efforts. Each section of a machine is designed to serve a specific purpose, contributing to the overall effectiveness of the equipment. By familiarizing oneself with these details, operators can better address issues, perform necessary repairs, and engage in preventive measures.

Furthermore, gaining insight into the organization of essential elements fosters confidence in handling outdoor apparatus. Knowledge of the configuration allows users to approach maintenance tasks with assurance, ensuring that their tools remain in peak condition for many seasons to come. This guide aims to clarify the assembly and enhance your experience with outdoor machinery.

This section highlights the essential characteristics of the equipment, emphasizing its versatility and efficiency in various applications. The design focuses on user-friendly operation while maintaining durability and performance.

Versatile Functionality

The equipment offers multiple functionalities, making it suitable for a range of tasks. Key aspects include:

- Interchangeable attachments for various jobs

- Adjustable power settings for different requirements

- Lightweight construction for easy maneuverability

Enhanced Performance

Designed for optimal operation, the equipment incorporates several features that contribute to its effectiveness:

- High-efficiency engine for reduced fuel consumption

- Robust build quality for prolonged usage

- Easy maintenance procedures for user convenience

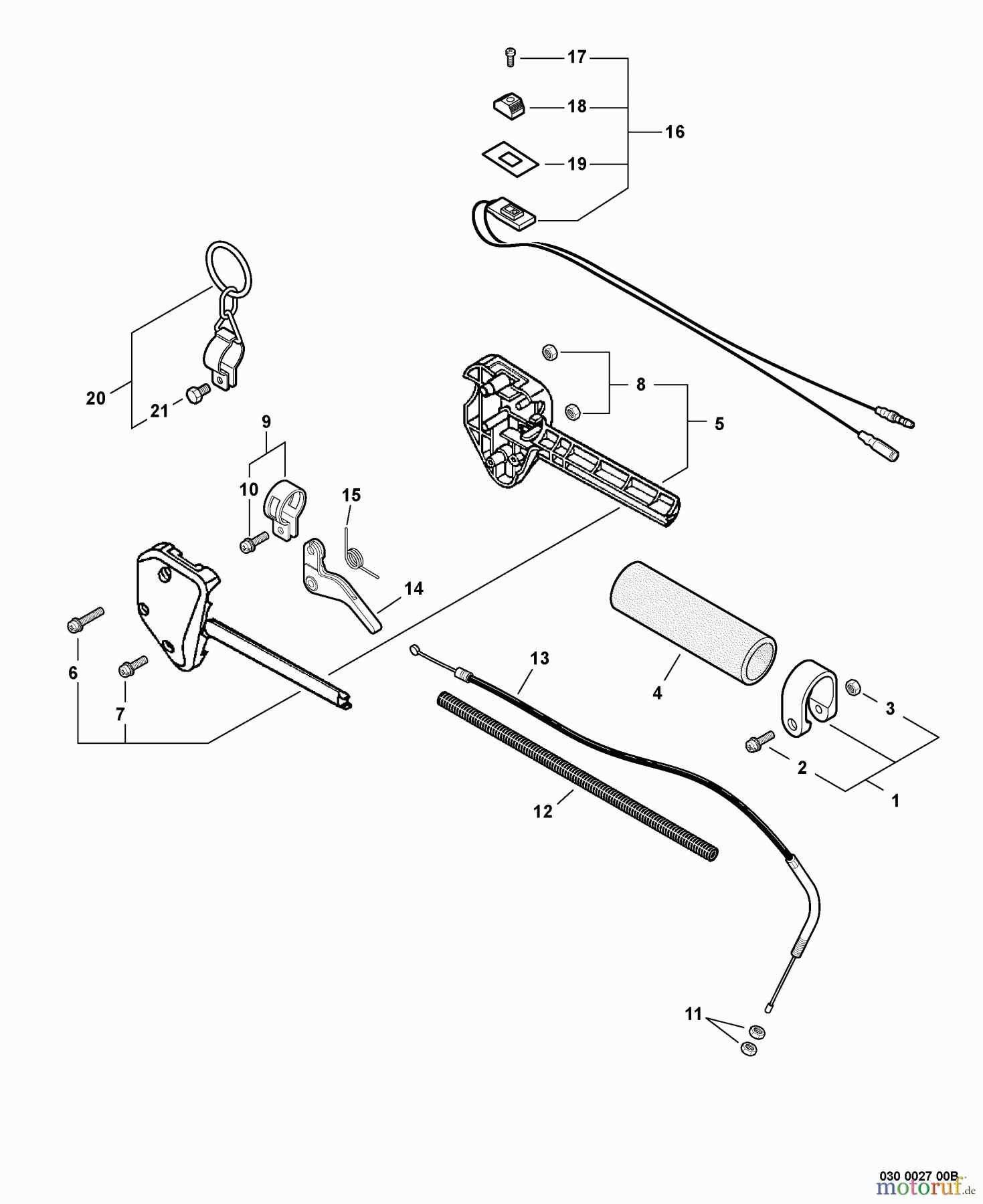

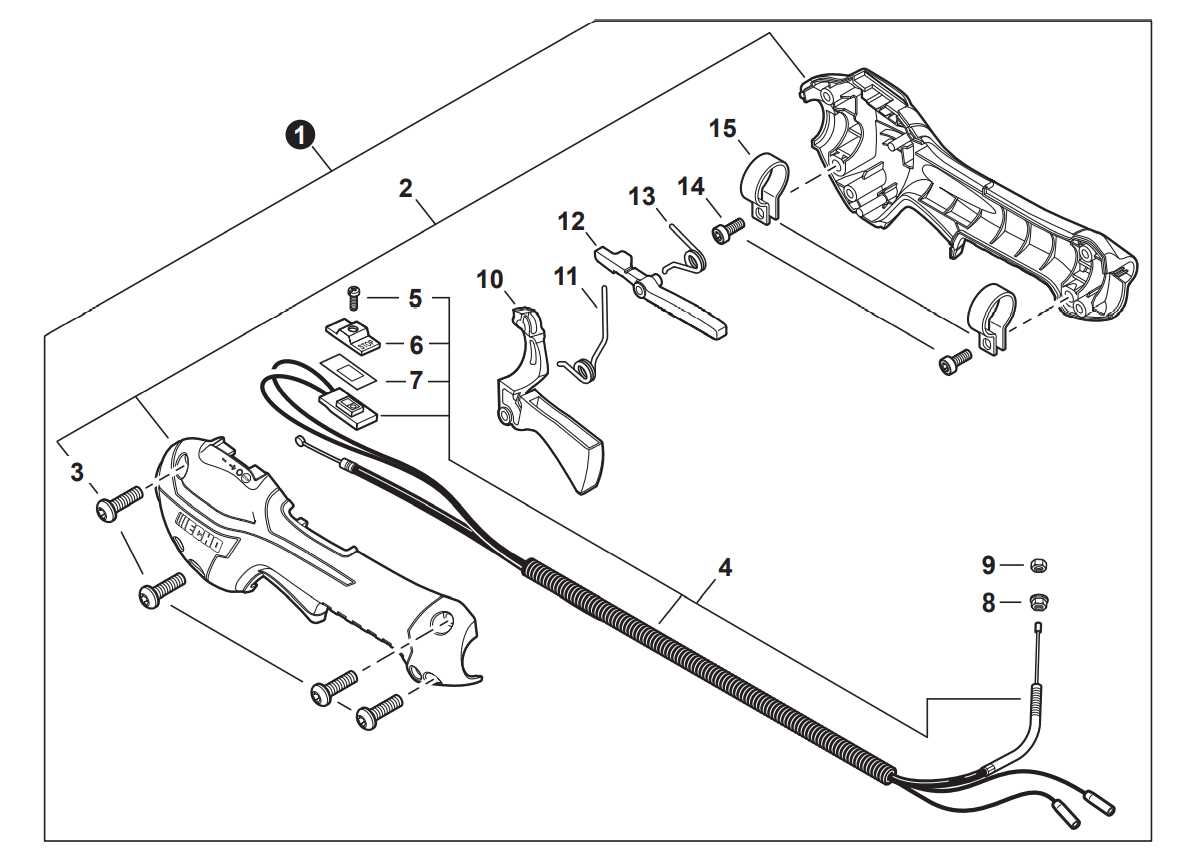

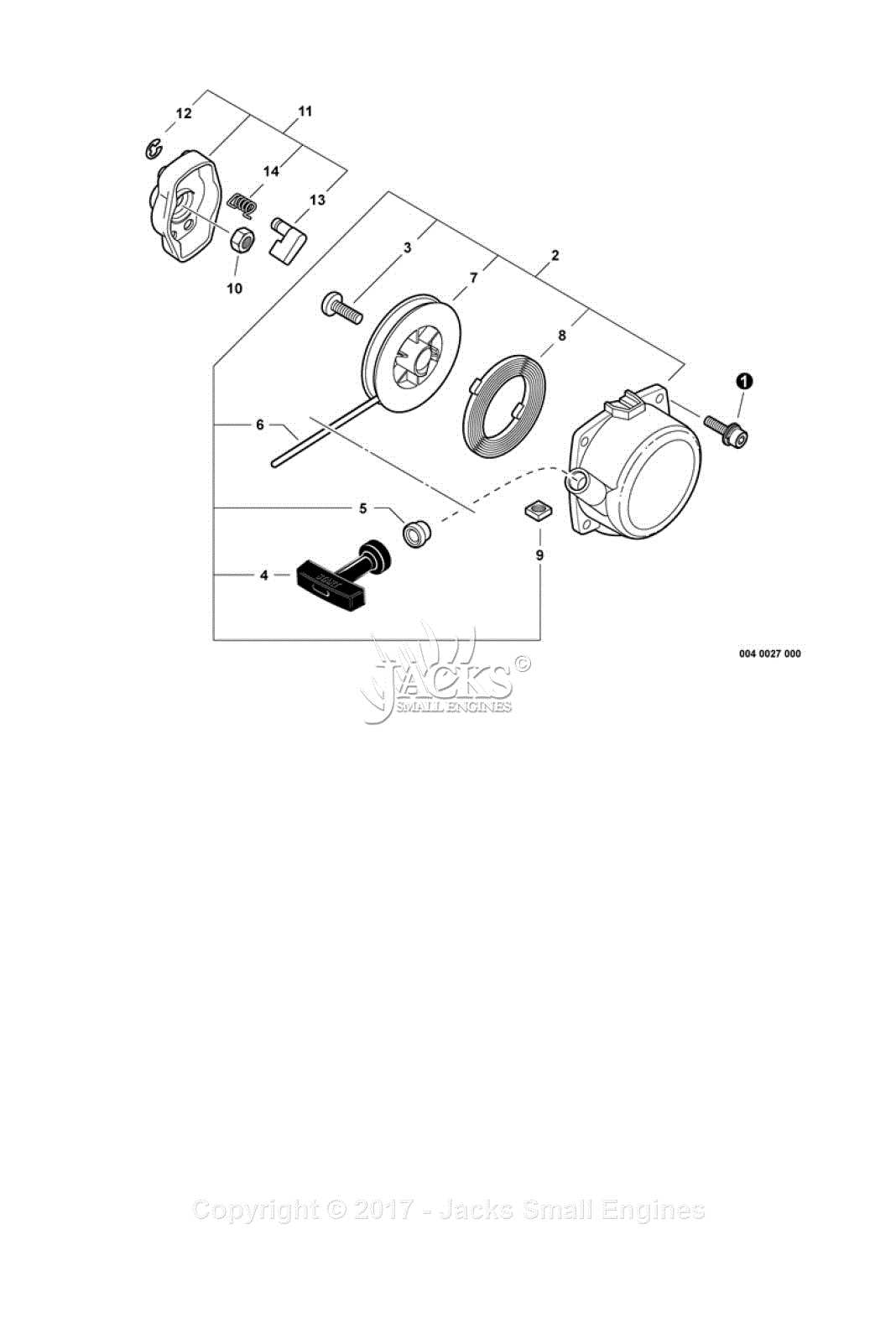

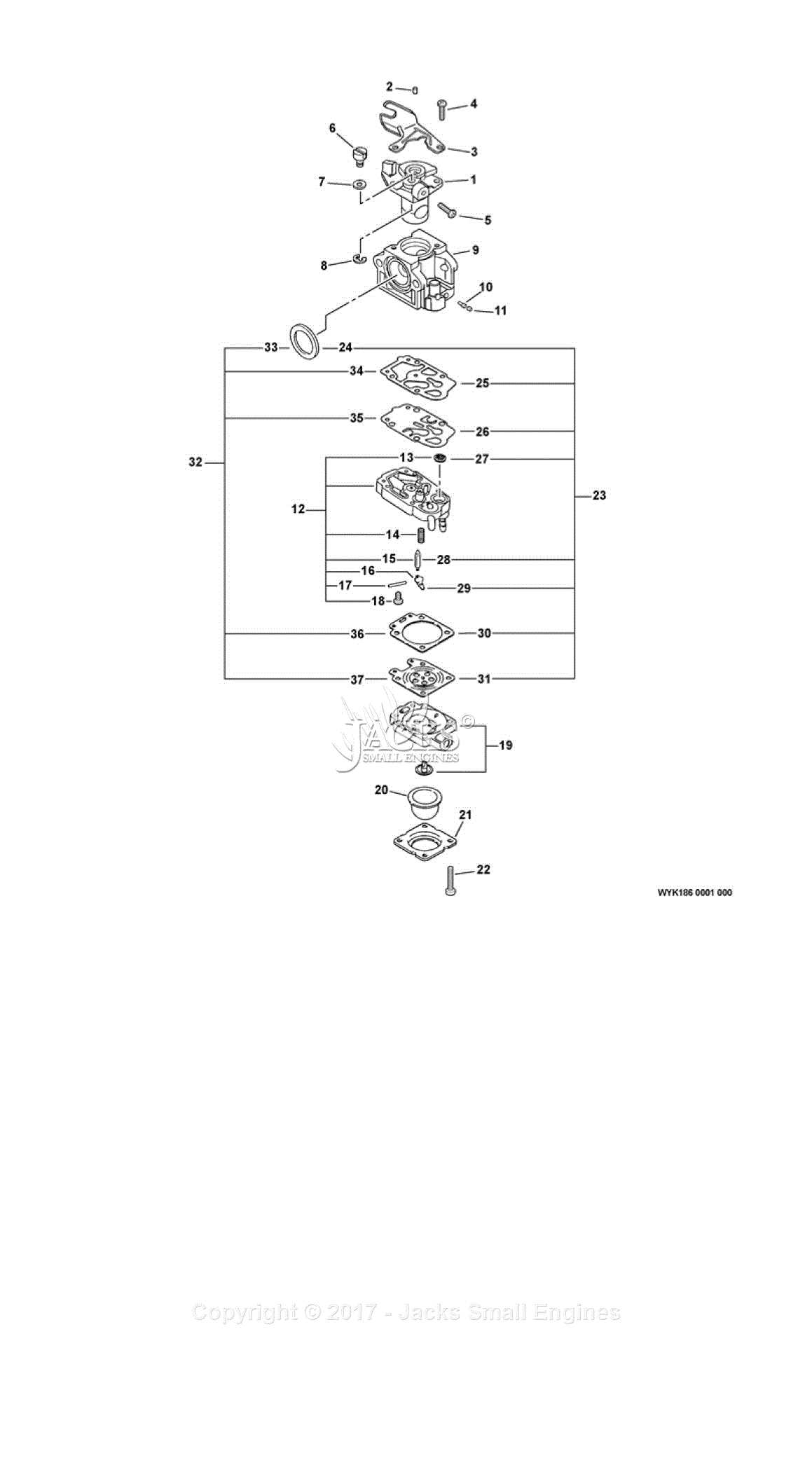

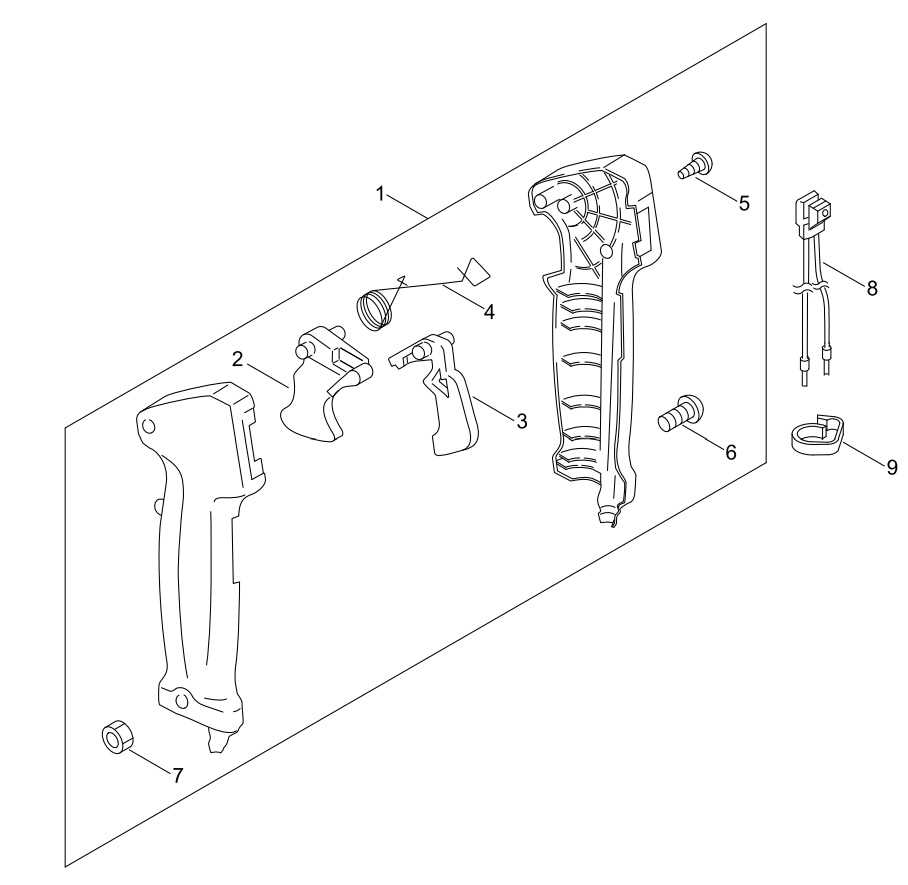

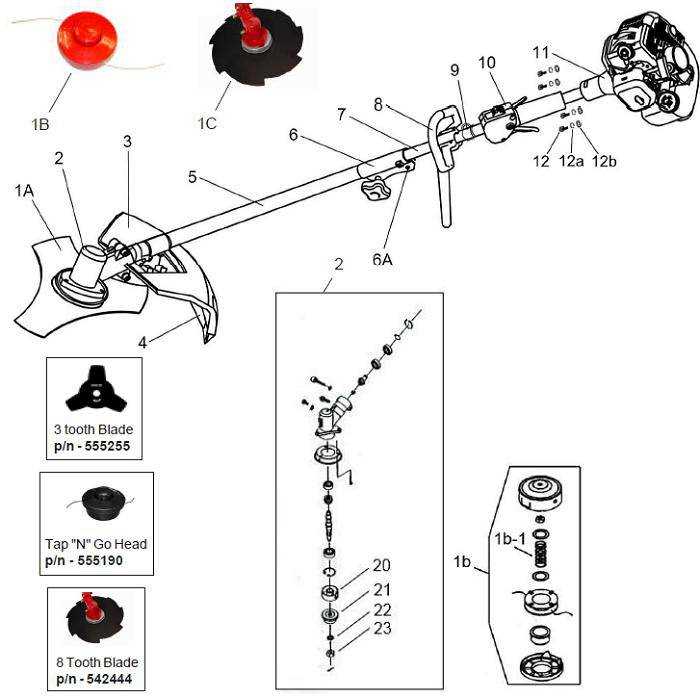

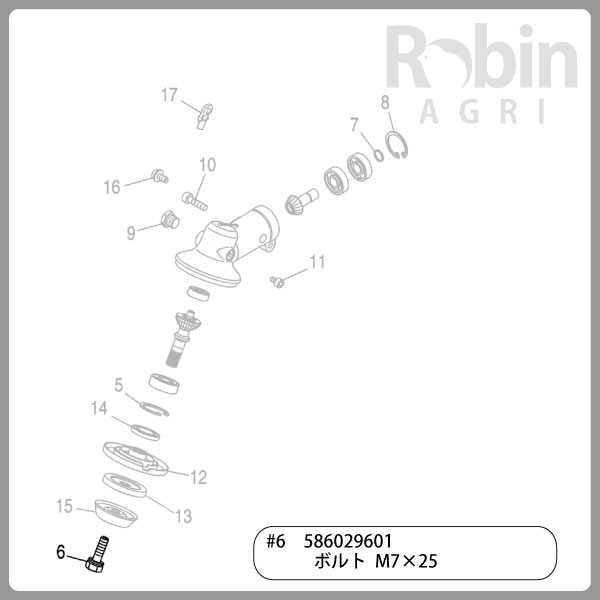

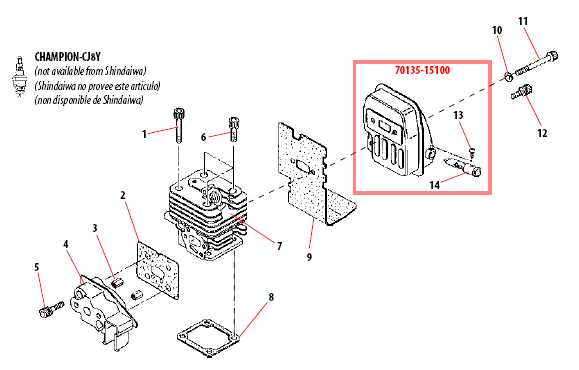

Understanding the Parts Diagram

Comprehending the assembly layout of a device is crucial for effective maintenance and repair. This illustration serves as a valuable resource for identifying components and their arrangement, facilitating a deeper understanding of the machinery’s operation.

By familiarizing yourself with the various elements, you can efficiently troubleshoot issues and perform necessary replacements. The following points highlight the benefits of examining such an illustration:

- Enables easy identification of individual components.

- Assists in understanding the relationship between different parts.

- Facilitates efficient repairs by showing how parts fit together.

- Enhances knowledge about the overall functionality of the equipment.

Furthermore, studying this layout can empower users to make informed decisions when sourcing replacements or upgrades. Overall, a thorough grasp of the structure can significantly improve the user experience and extend the lifespan of the device.

Essential Components Explained

This section delves into the critical elements that make up a specific type of equipment. Understanding these components is vital for effective operation and maintenance. Each part plays a unique role, contributing to the overall functionality and efficiency of the system.

| Component | Description |

|---|---|

| Motor | The driving force behind the mechanism, converting electrical energy into motion. |

| Gear Assembly | A series of gears that facilitate the transfer of power, allowing for speed adjustments and torque multiplication. |

| Handle | The ergonomic grip that provides control and comfort during operation, ensuring ease of use. |

| Fuel Tank | A reservoir that stores the necessary fuel to power the engine, designed for optimal capacity and efficiency. |

| Air Filter | An essential component that prevents dirt and debris from entering the engine, promoting longevity and performance. |

Maintenance and Replacement Parts

Proper upkeep and timely substitutions of components are essential for ensuring the longevity and optimal performance of your equipment. Regular attention to maintenance not only enhances efficiency but also minimizes the risk of unexpected failures, providing peace of mind during usage.

Key Maintenance Practices

- Regularly inspect the equipment for any signs of wear or damage.

- Clean the external surfaces and ensure that ventilation areas are free from debris.

- Check and replace any filters to maintain optimal airflow.

- Lubricate moving parts as per the manufacturer’s recommendations.

Common Components for Replacement

- Filters: Ensure air and fuel filters are replaced periodically to enhance performance.

- Blades: Dull or damaged blades should be sharpened or replaced to maintain cutting efficiency.

- Hoses: Inspect for cracks or leaks and replace as necessary to prevent fluid loss.

- Spark plugs: Regular replacement can improve ignition efficiency and reduce emissions.

Troubleshooting Common Issues

Addressing frequent challenges can significantly enhance the performance and longevity of your equipment. This section offers guidance on identifying and resolving typical problems that users may encounter. By following these steps, you can ensure optimal functionality and prevent future complications.

Below is a table summarizing common issues, their potential causes, and suggested solutions:

| Issue | Possible Causes | Recommended Solutions |

|---|---|---|

| Equipment won’t start | Insufficient fuel, blocked air filter, faulty ignition system | Check fuel levels, clean or replace the air filter, inspect ignition components |

| Poor performance | Dirty spark plug, dull blade, low oil levels | Replace or clean the spark plug, sharpen or replace the blade, check and refill oil |

| Unusual noise | Loose parts, worn bearings, foreign objects | Tighten any loose components, replace worn parts, remove debris |

| Excessive vibration | Imbalanced attachments, damaged components | Ensure attachments are properly balanced, replace damaged parts |

Benefits of Regular Inspections

Conducting routine evaluations of equipment is essential for ensuring optimal performance and longevity. Regular checks help identify potential issues before they escalate into significant problems, promoting safety and efficiency in operations. By investing time in these inspections, users can enjoy peace of mind and enhanced functionality.

Enhancing Performance

Frequent assessments contribute to maintaining peak performance levels. When machinery is examined regularly, any minor discrepancies can be addressed swiftly, ensuring that the equipment operates smoothly. This proactive approach minimizes the risk of unexpected breakdowns and reduces downtime, ultimately leading to improved productivity.

Cost Savings

Regular evaluations can result in significant cost reductions over time. By identifying wear and tear early on, users can prevent costly repairs or replacements. Additionally, maintaining equipment in good condition often leads to increased fuel efficiency and reduced operational expenses.

| Inspection Benefits | Impact |

|---|---|

| Early Issue Detection | Prevents major breakdowns |

| Increased Efficiency | Optimizes performance |

| Lower Repair Costs | Reduces financial strain |

| Enhanced Safety | Minimizes accident risks |

Where to Find Spare Parts

Locating components for maintenance and repairs can significantly enhance the lifespan of your equipment. Various sources provide essential elements for these tasks, ensuring you can keep your device functioning optimally.

Online marketplaces and specialized retailers often stock a wide selection of accessories and replacements. Websites dedicated to outdoor tools frequently offer comprehensive catalogs, allowing users to search by model or specific requirements.

Local authorized dealers also serve as reliable sources, providing genuine items tailored to your machine’s specifications. Visiting these establishments can ensure you receive high-quality replacements and expert advice.

Additionally, community forums and groups focused on equipment enthusiasts can be invaluable. Members often share recommendations for trustworthy suppliers, along with tips for sourcing hard-to-find components.

Assembly and Disassembly Guide

This section provides a comprehensive overview of the processes involved in putting together and taking apart the equipment. Understanding these procedures is essential for effective maintenance and repair, ensuring the device operates at its best. By following the steps outlined here, users can efficiently manage the components, extending the lifespan and functionality of the tool.

Step-by-Step Assembly Instructions

To begin the assembly, gather all necessary components and tools. Start by aligning the main sections according to the provided specifications. Secure each part with the appropriate fasteners, ensuring a snug fit. It’s crucial to follow the order of assembly to prevent complications later on. Regularly check for any misalignments as you proceed to maintain structural integrity.

Disassembly Process Explained

When it comes time for disassembly, carefully reverse the assembly steps. Begin by removing any securing elements and gently detach the components. Take special care to document the arrangement of parts, as this will facilitate reassembly. Handle each element with caution to avoid damage, ensuring that all components remain in good condition for future use.

Safety Precautions During Repairs

Ensuring a safe environment while conducting maintenance on equipment is crucial for both the technician and the device. By following appropriate guidelines, one can prevent accidents and injuries, promoting a more efficient repair process. Prioritizing safety measures not only safeguards the individual performing the task but also prolongs the lifespan of the machinery.

Personal Protective Equipment

Wearing suitable protective gear is essential when undertaking repair work. This equipment serves as a barrier against potential hazards that may arise during the process. Here are some important items to consider:

| Equipment | Purpose |

|---|---|

| Safety goggles | Protects eyes from debris and chemicals |

| Gloves | Prevents cuts and exposure to harmful substances |

| Steel-toed boots | Offers foot protection against heavy objects |

| Dust mask | Filters out harmful particles from the air |

Workspace Organization

Maintaining a tidy and organized workspace is vital for safety. Clutter can lead to slips, trips, and falls, increasing the risk of accidents. Here are some tips for keeping your area secure:

- Ensure that tools are stored properly after use.

- Keep the floor free of unnecessary items to prevent tripping hazards.

- Provide adequate lighting to enhance visibility.

Comparative Analysis with Similar Models

When evaluating various devices within a specific category, it is essential to assess their features and functionality in relation to each other. This comparative analysis aims to highlight the similarities and differences among models that serve comparable purposes, allowing potential users to make informed decisions based on their needs.

Performance Metrics: In terms of operational efficiency, the examined units display varying levels of power output and handling capabilities. While some models excel in heavy-duty tasks, others are optimized for lighter applications, offering a balance between power and ease of use.

Design and Usability: The ergonomics and overall design of these units can significantly impact user experience. Many alternatives prioritize lightweight construction and user-friendly controls, making them more accessible for extended usage. However, others may incorporate robust designs aimed at durability in challenging environments.

Maintenance Requirements: Maintenance needs also vary widely. Some devices require frequent servicing to maintain peak performance, while others boast low-maintenance designs that allow users to focus more on operation rather than upkeep. This aspect is crucial for users seeking hassle-free experiences.

In conclusion, by examining these comparative factors, individuals can better understand which model aligns best with their specific preferences and operational demands, ensuring a suitable choice for their tasks.