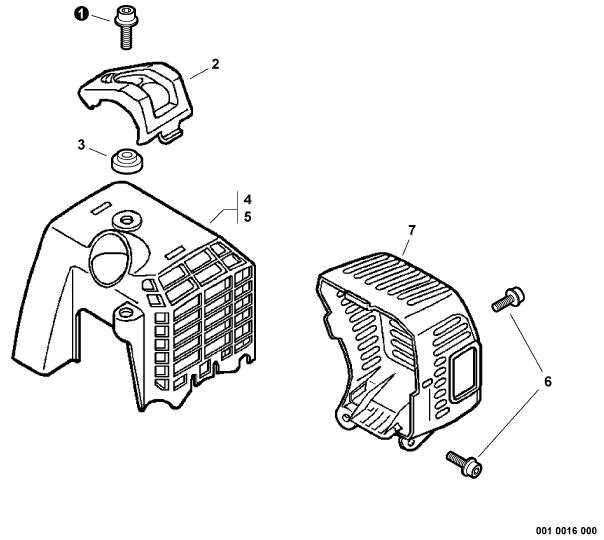

Understanding how the various elements of machinery fit together is crucial for proper maintenance and repairs. In this section, we will explore the structure and arrangement of key mechanical pieces that ensure the efficient operation of your equipment. Each component plays a unique role, contributing to the overall functionality.

Identifying individual elements and their specific purposes helps streamline troubleshooting and maintenance efforts. Whether you are a seasoned technician or a novice, this guide will assist you in recognizing the essential parts and their roles in maintaining peak performance.

Regular inspections and replacements of critical mechanisms can prevent unexpected breakdowns and ensure smooth operation over time. The following guide offers insights into the arrangement and functionality of these components, providing a clear reference for future repairs and adjustments.

Understanding the Main Components of SRM 230

The proper functioning of a high-performance trimmer depends on several key mechanical parts working together. Each element has a specific role, contributing to the overall efficiency and durability of the machine. It’s essential to be familiar with these components to ensure optimal operation and maintenance.

Engine System

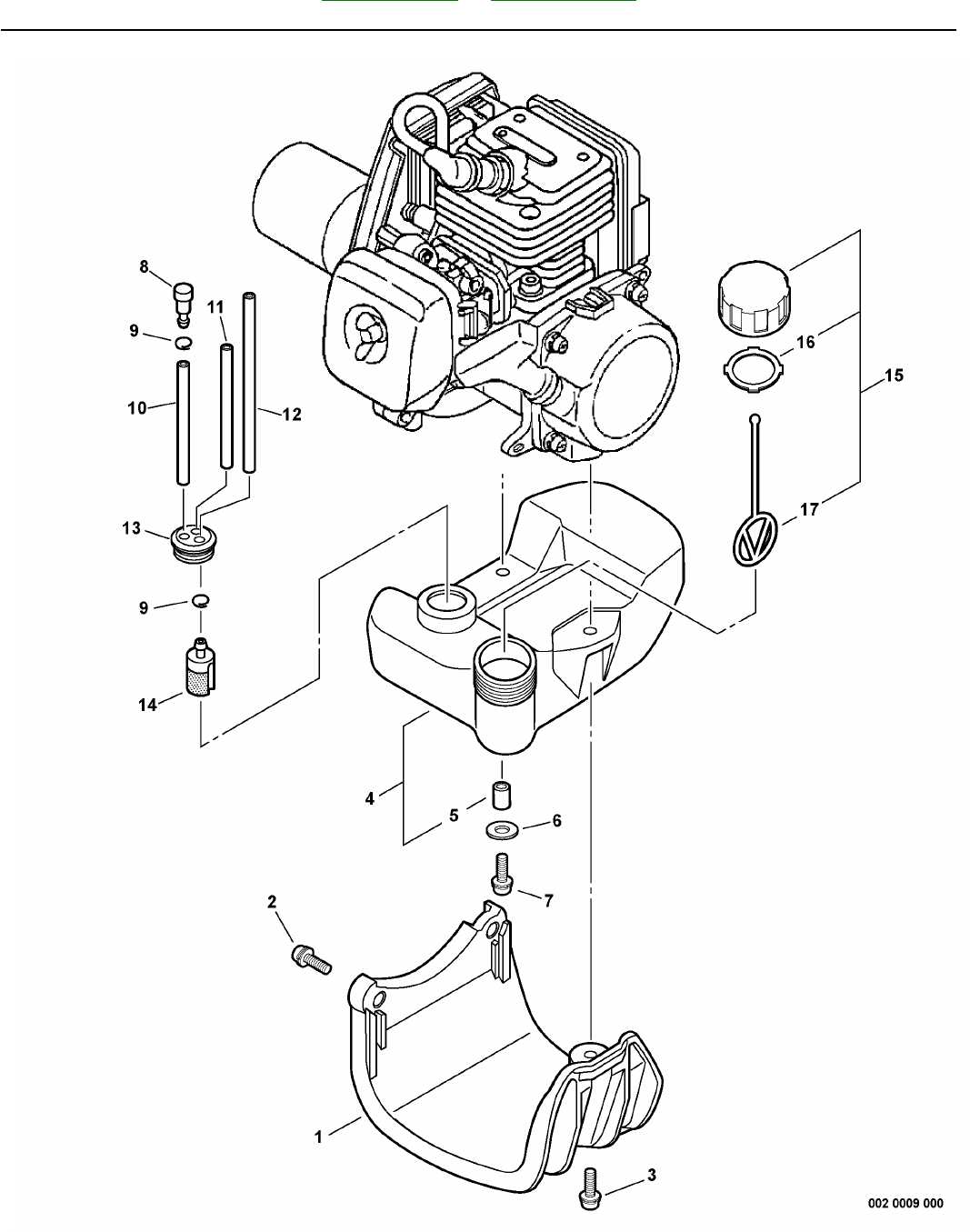

The power unit drives the entire tool, delivering the necessary force to perform trimming tasks efficiently. This system typically includes the combustion engine, fuel tank, and associated mechanisms like the starter and throttle, all of which contribute to the tool’s power and precision.

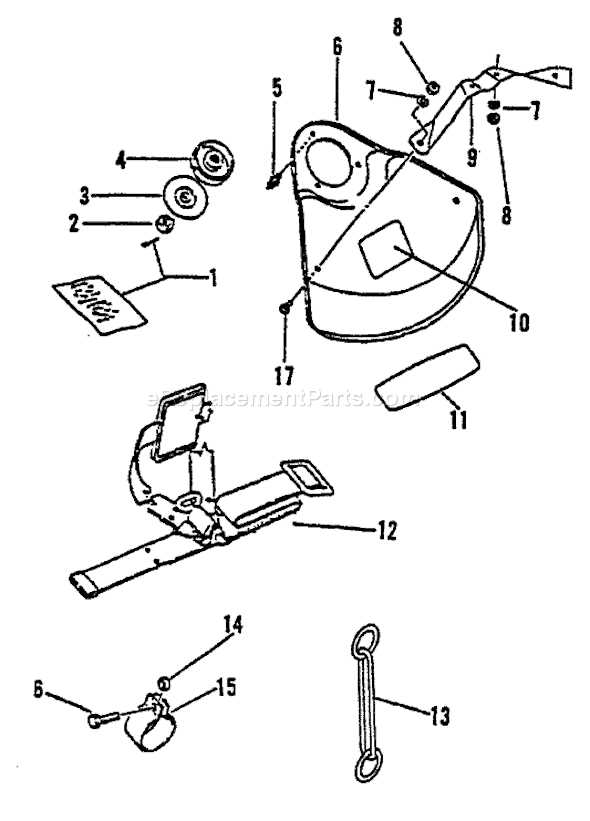

Cutting Mechanism

The cutting unit is crucial for delivering clean and precise cuts. It consists of a rotating head, cutting line, or blades, depending on the design. Proper maintenance of this part ensures consistent results and prolongs the lifespan of the equipment.

Key Parts for Efficient Operation

To ensure the smooth and effective functioning of your equipment, it’s crucial to understand the role of its essential components. Proper maintenance and timely replacement of critical elements significantly enhance performance and extend the lifespan of the machine.

Engine Components: The core of the system, responsible for generating the power needed to drive the entire operation. Regular inspection and care of this area are fundamental to avoid breakdowns.

Cutting Mechanism: This is the section that directly interacts with the materials being handled. Sharpening or replacing the cutting tool ensures precision and efficiency in every task.

Drive Assembly: Responsible for transmitting power from the motor to the cutting section, this part requires attention to prevent power loss or mechanical issues.

Air Filters and Fuel Systems also play

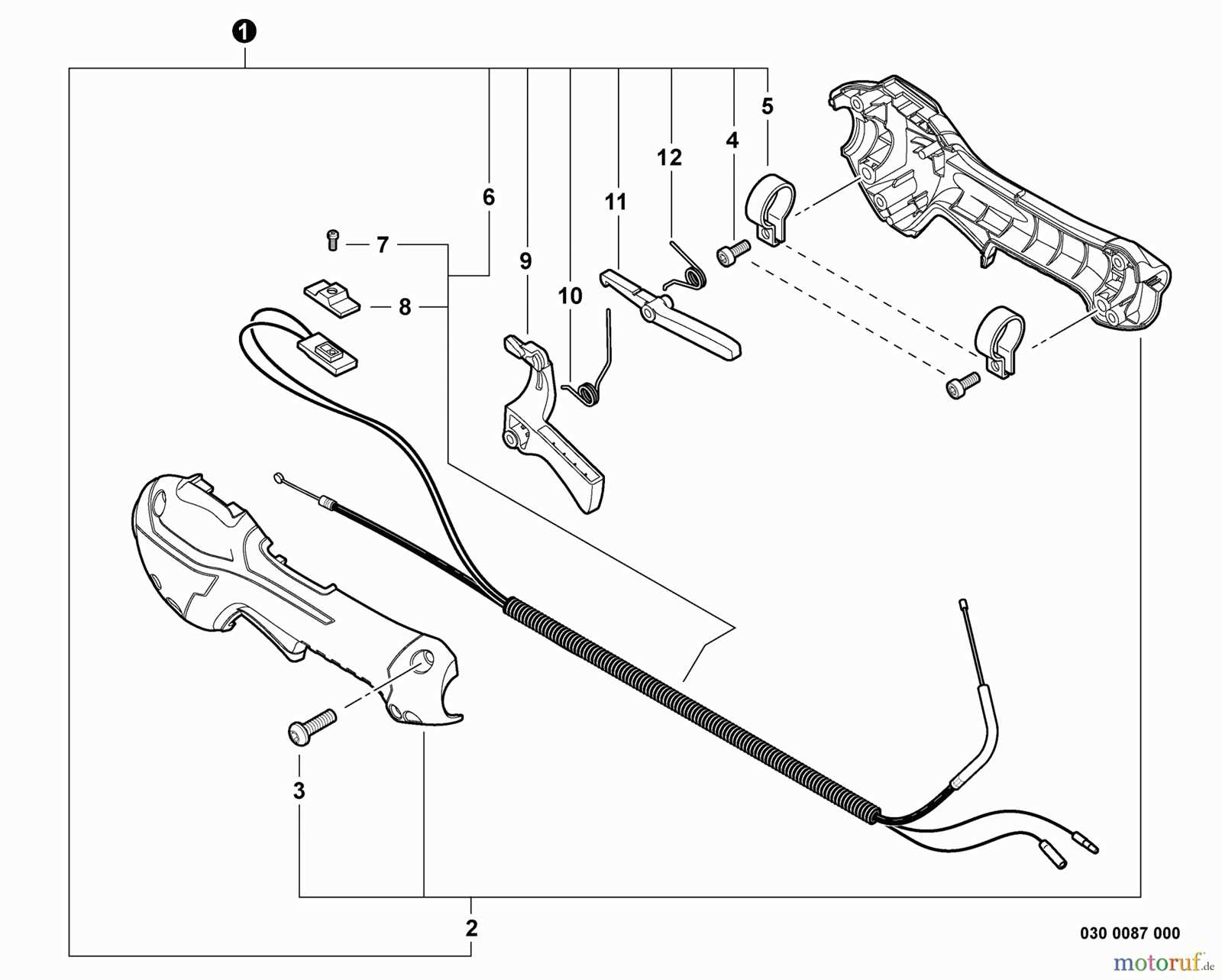

How to Identify Important Parts

Recognizing key components of your equipment is essential for ensuring its proper function and longevity. Understanding the structure and role of each element helps maintain efficiency and prevents potential issues. Regular inspection of these elements can also lead to timely replacements or repairs, which are crucial for preventing breakdowns.

Start by focusing on the most visible and frequently used sections of the tool. These include areas involved in cutting, controlling movement, and ensuring stability during operation. Each part plays a specific role, and it’s important to distinguish between them for optimal performance.

Additionally, familiarizing yourself with the location and function of these elements will make maintenance much easier, especially when handling adjustments or cleaning. Proper identification leads to smoother operations and reduces the need for extensive repairs.

Replacing Worn-Out Components

Over time, various parts of your equipment may experience wear and tear, affecting its overall performance. Recognizing when a component needs replacement can prevent further damage and ensure smooth operation. It is essential to regularly inspect critical elements for signs of deterioration to maintain efficiency and prolong the lifespan of the machine.

When replacing outdated elements, it’s important to select suitable alternatives that match the specifications of the original component. Proper installation is key to avoiding potential issues and ensuring that the machinery continues to function optimally. Make sure to follow the correct steps and consult relevant resources if necessary.

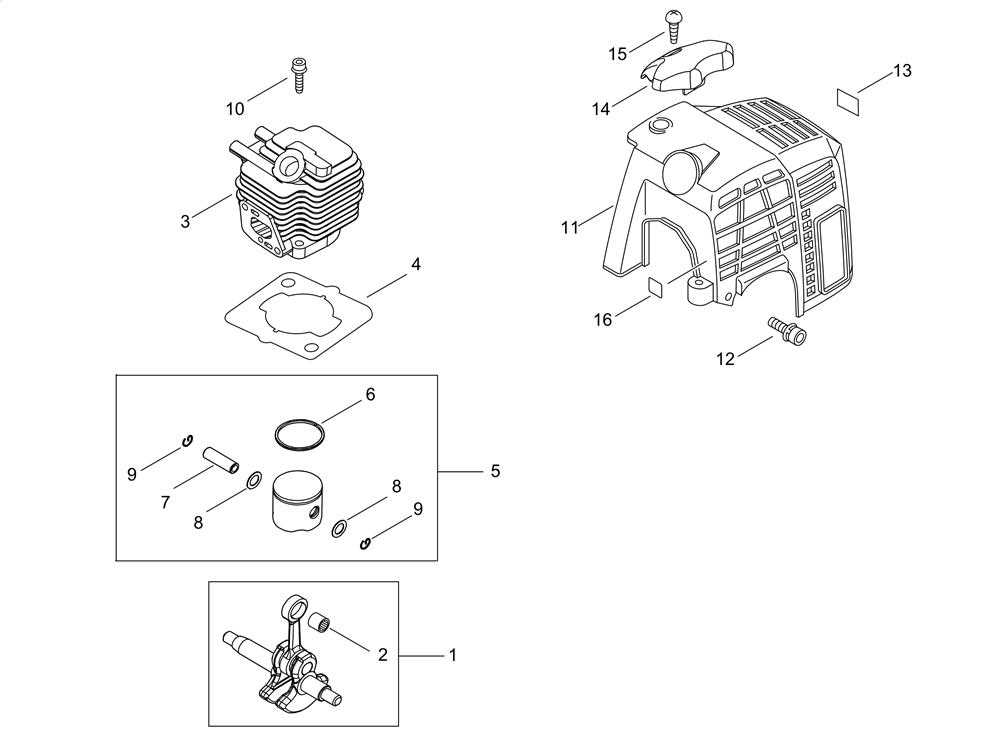

Detailed Breakdown of Engine Assembly

The engine is a complex mechanism, made up of various components that work together to deliver reliable power. Understanding the structure and function of each part is essential for proper maintenance and repair. In this section, we will look closely at the essential elements that form the heart of the machine, focusing on the internal components and their roles in ensuring smooth operation.

Piston and Cylinder: The piston moves within the cylinder, compressing the fuel and air mixture to generate power. The cylinder acts as the housing for the piston, providing a smooth surface for its movement.

Crankshaft and Connecting Rod: The connecting rod links the piston to the crankshaft, which converts the up-and-down motion of the piston into rotational energy. This energy is

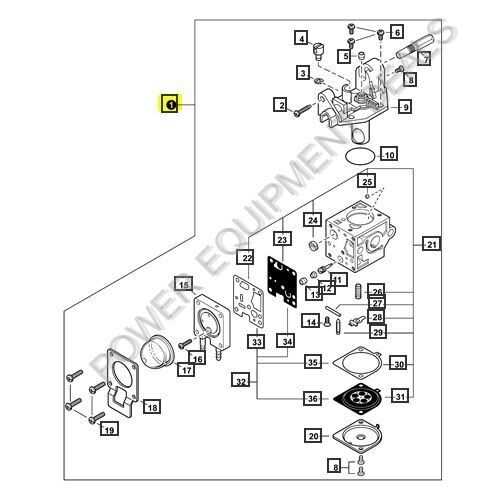

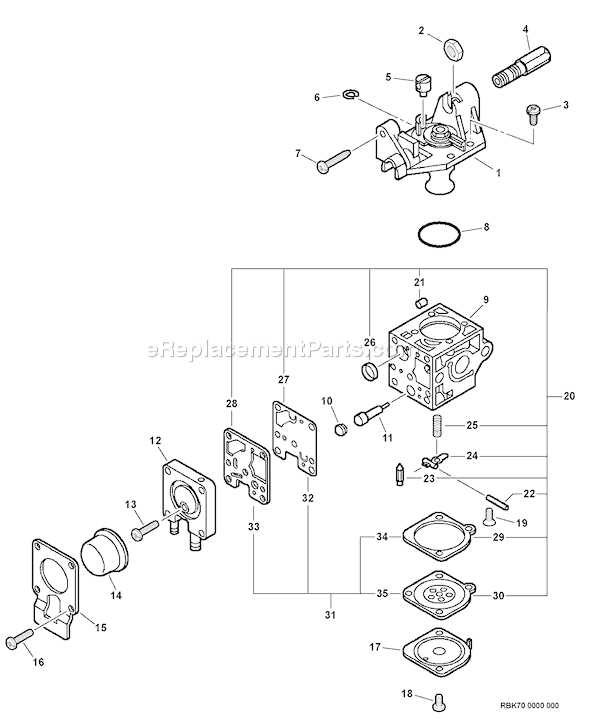

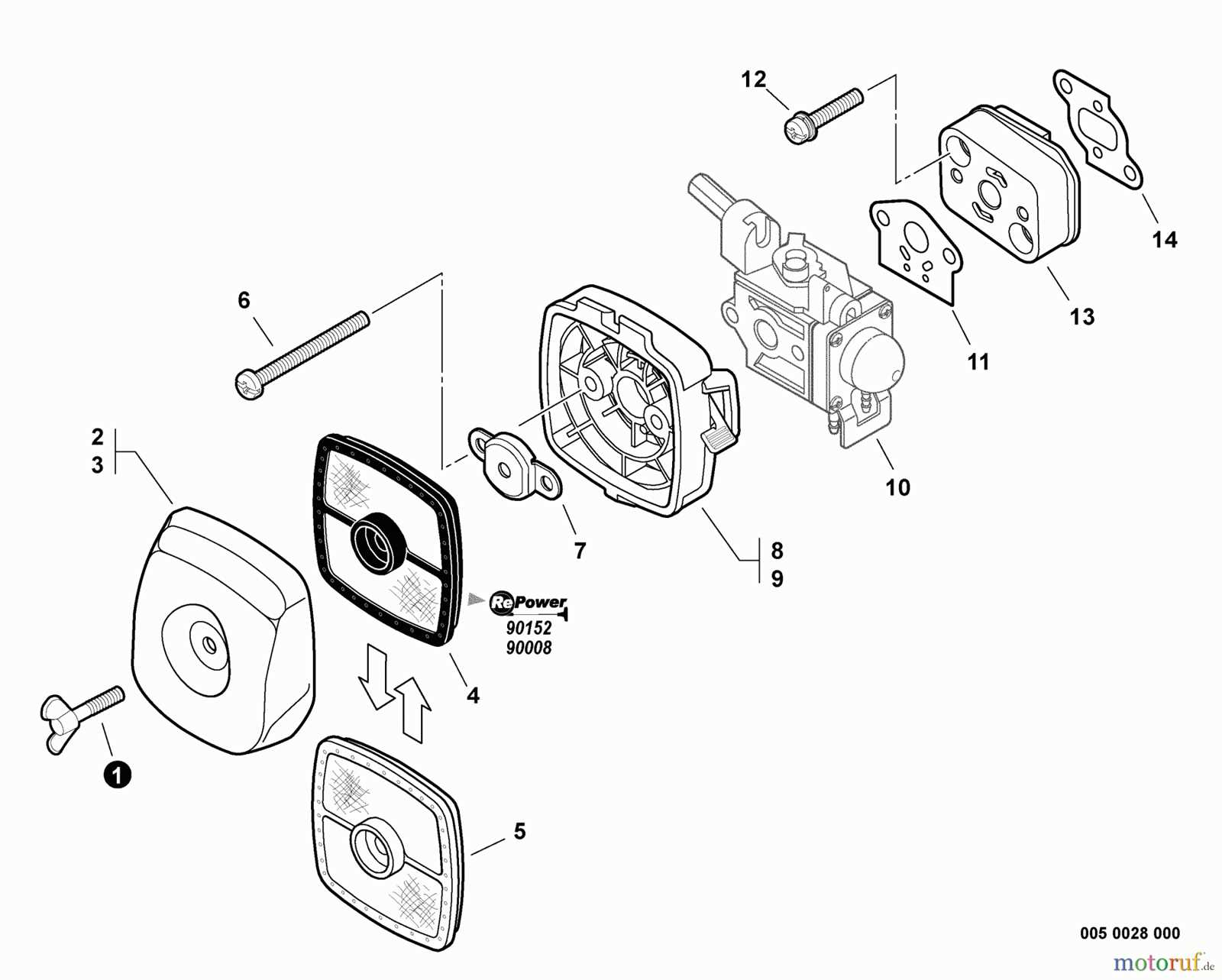

Fuel System Parts and Their Roles

The fuel system in a power tool is vital for its performance and efficiency. It comprises several components that work together to ensure a steady supply of fuel to the engine, facilitating optimal operation. Understanding the functions of each component can aid in proper maintenance and troubleshooting, ultimately enhancing the tool’s lifespan.

Key Components

Several key components constitute the fuel system, each serving a specific function. Below is a brief overview of these essential elements.

| Component | Function |

|---|---|

| Fuel Tank | Holds the fuel supply for the engine. |

| Fuel Filter | Removes impurities from the fuel before it enters the engine. |

| Fuel Pump | Delivers fuel from the tank to the carburetor. |

| Carburetor | Mixes air and fuel in the correct ratio for combustion. |

| Fuel Lines | Transport fuel between the tank, pump, and carburetor. |

Importance of Maintenance

Regular maintenance of the fuel system is crucial for preventing issues such as clogs and leaks. Keeping components clean and in good condition ensures that the engine receives the right amount of fuel, which is essential for reliable performance.

Air Filter and Maintenance Tips

The air filtration system plays a crucial role in the performance and longevity of outdoor power equipment. Proper upkeep of the air intake mechanism ensures optimal functionality, preventing potential damage caused by dirt and debris. Understanding the significance of regular maintenance can enhance the efficiency of your equipment.

Importance of Air Filter Maintenance

- Prevents engine damage by keeping contaminants out.

- Improves fuel efficiency, leading to cost savings.

- Extends the lifespan of the equipment.

Maintenance Steps

- Regularly inspect the air filter for dirt and blockages.

- Remove the filter carefully, ensuring no debris falls into the intake.

- Clean the filter according to the manufacturer’s instructions, using compressed air or a soft brush.

- If the filter is damaged, replace it with a new one to ensure optimal performance.

- Reinstall the filter securely, checking for proper fit.

By following these maintenance steps, you can ensure that your equipment operates smoothly and efficiently, ultimately enhancing its overall performance.

Throttle System Overview and Functions

The throttle mechanism is a crucial component in various engine-driven devices, playing a significant role in regulating power output and ensuring optimal performance. This system controls the airflow entering the engine, which directly influences the speed and efficiency of operation.

Functionality of the throttle assembly involves adjusting the engine’s air intake, thereby managing fuel combustion and, ultimately, the device’s power level. By manipulating this system, users can achieve desired speeds and performance levels, adapting to different working conditions.

In addition to power control, the throttle system also enhances user experience by allowing for precise adjustments during operation. This responsiveness is essential for tasks requiring fine control, making the mechanism an integral part of ensuring effective performance in various applications.

Understanding the mechanical design and operational principles of the throttle assembly aids users in maintaining their equipment and troubleshooting any issues that may arise. Regular inspections and proper adjustments contribute to the longevity and reliability of the device.

Exploring the Ignition Mechanism

The ignition mechanism serves as a vital component in the operation of various small engine devices. Understanding how this system works can greatly enhance maintenance and troubleshooting efforts. This section delves into the critical elements involved in the ignition process, ensuring reliable performance and efficient fuel combustion.

Key Components of the Ignition System

At the heart of the ignition mechanism are several essential parts that work together to initiate the combustion process. The spark plug generates the necessary spark to ignite the fuel-air mixture, while the ignition coil transforms the battery voltage into a higher voltage. Additionally, the flywheel plays a crucial role in creating the magnetic field required for spark generation, making it an indispensable element of the system.

Understanding the Functionality

The functionality of the ignition mechanism revolves around a series of coordinated actions. When the engine is started, the coil receives electrical energy and produces a high-voltage spark at the appropriate moment. This spark travels through the ignition wire to the spark plug, where it ignites the fuel mixture, leading to engine operation. Proper synchronization of these components is essential for optimal performance and efficiency.

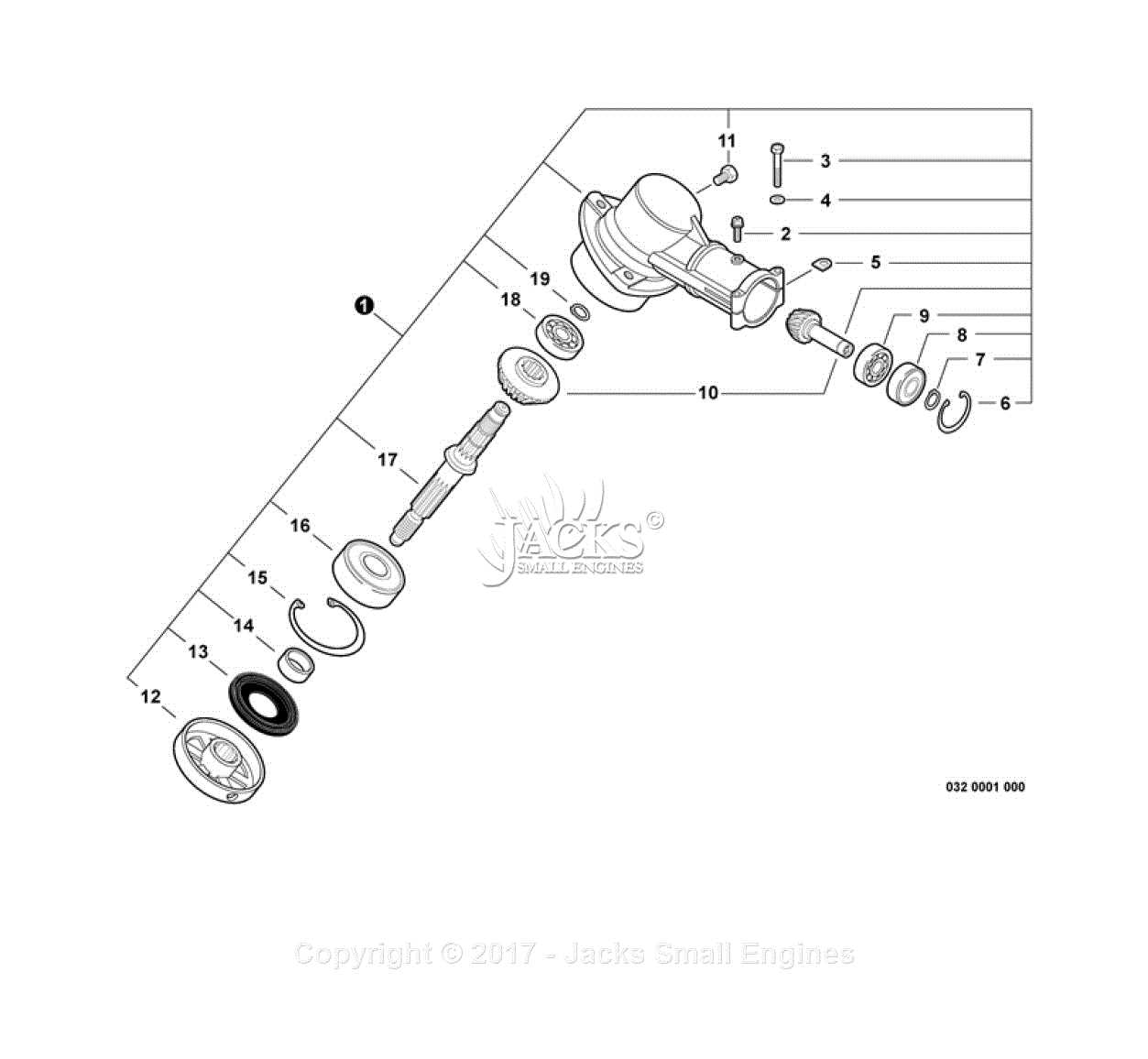

Drive Shaft and Cutting Head Assembly

The assembly of the transmission shaft and cutting mechanism is crucial for the effective operation of trimming devices. This component ensures the transfer of power from the engine to the cutting head, allowing for efficient grass and weed management.

The drive shaft serves as a vital link, converting rotational motion into usable energy for the cutting head. Its design typically includes robust materials that withstand the stresses of continuous operation. Proper alignment and secure attachment of this assembly are essential for optimal performance and longevity.

Incorporating various types of cutting heads enhances versatility, enabling users to tackle different vegetation types. These cutting attachments may include blades or nylon lines, tailored for specific tasks. Regular maintenance of both the drive shaft and cutting head assembly is recommended to prevent wear and ensure consistent functionality.

Troubleshooting Common Part Failures

When operating outdoor power equipment, understanding how to identify and resolve frequent component malfunctions can significantly enhance performance and longevity. This section aims to provide practical insights into diagnosing issues and implementing effective solutions for typical failures that may arise during use.

Common symptoms of component failures often include irregular operation, excessive noise, or lack of power. By systematically examining these indicators, users can pinpoint the underlying issues and take appropriate corrective actions. The following table outlines typical problems, their potential causes, and suggested remedies:

| Symptom | Potential Cause | Suggested Remedy |

|---|---|---|

| Difficulty starting | Clogged fuel filter | Replace the fuel filter |

| Engine stalling | Worn spark plug | Replace the spark plug |

| Reduced power output | Dirty air filter | Clean or replace the air filter |

| Unusual vibrations | Loose components | Tighten all loose parts |

| Excessive smoke | Oil leakage | Inspect and seal oil leaks |

By following these guidelines, users can effectively manage common issues, ensuring their equipment operates smoothly and reliably.