The intricate structure of modern trolling motors includes various essential elements that ensure smooth operation and durability. Understanding the arrangement and function of each individual component can significantly improve both maintenance and performance. This section will guide you through a closer look at the vital mechanisms that contribute to the overall functionality.

By examining the internal layout, users can gain a clearer perspective on how different parts work together harmoniously to enhance efficiency. Proper knowledge of these elements not only helps in troubleshooting but also in prolonging the life of the equipment. In the following sections, we will delve deeper into the detailed arrangement of specific features and how they interact to provide optimal performance.

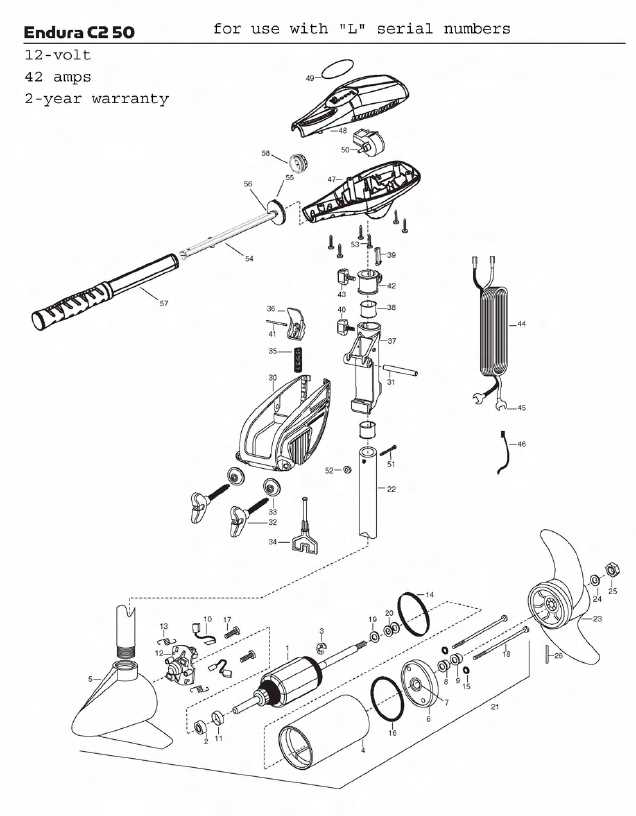

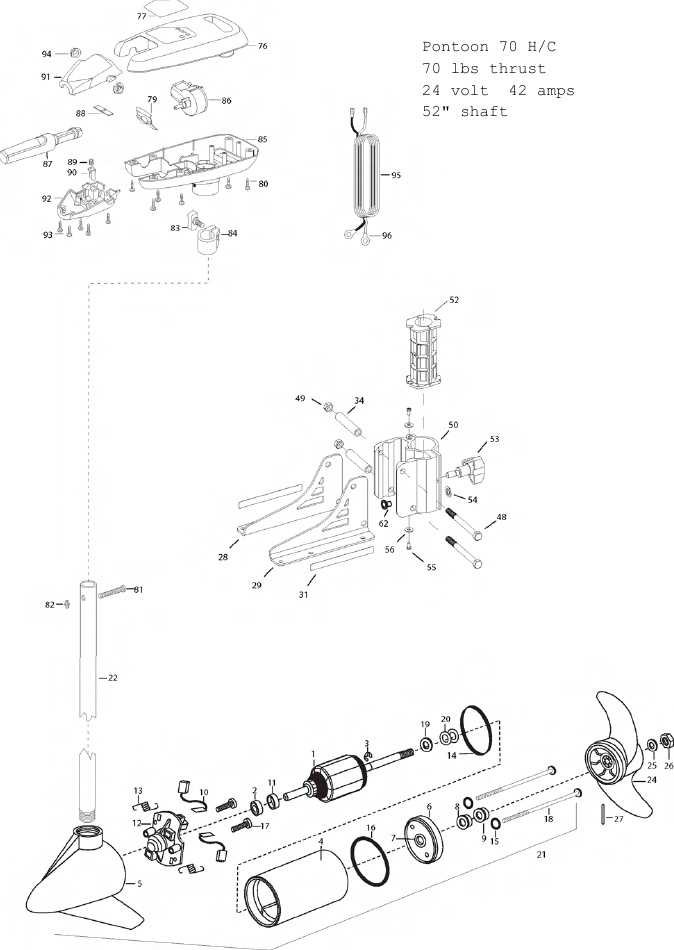

Complete Guide to Minn Kota Edge 70 Components

The purpose of this section is to provide a clear and comprehensive overview of the various elements that make up the performance and functionality of this popular motor model. Understanding how these components work together is key to maintaining efficiency and prolonging the life of your equipment.

Key Structural Elements

Several crucial elements are responsible for the reliable operation of this model. These include the mounting bracket, motor housing, and propeller system. Each part is designed to work seamlessly with the others, contributing to smooth navigation and control.

Performance and Electrical Features

Electrical components play a vital role in the functioning of the system. The control panel, wiring, and battery connections ensure that power is delivered effic

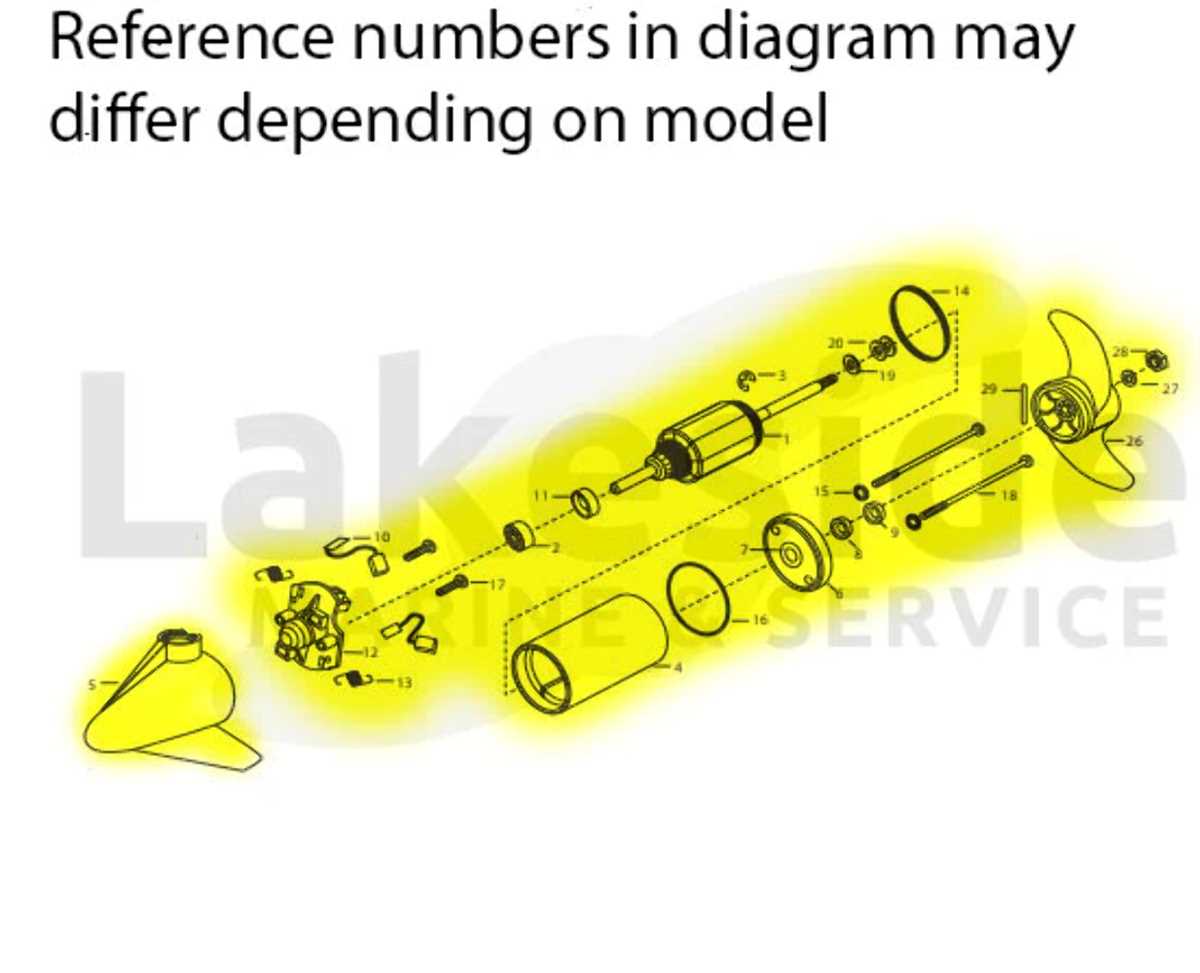

Understanding the Motor’s Internal Structure

The internal components of an electric motor play a crucial role in ensuring its efficient performance. By examining its structure, one can gain a deeper understanding of how various elements work together to generate power and control movement.

Key Components Inside the Motor

- Stator: A stationary part that helps create a magnetic field necessary for operation.

- Rotor: The moving section that spins and delivers the mechanical power output.

- Brushes: Elements that maintain electrical contact with the rotating parts.

- Windings: Coils that generate electromagnetic force when current flows through them.

- Power Source: Provides the necessary energy to operate the device. This could be a battery or another external source of electricity.

- Connectors: Serve as junction points where wires meet, ensuring a secure and efficient flow of current between components.

- Wiring Harness: A structured bundle of wires that efficiently distributes power to various parts of the system, often insulated for safety.

- Fuses: Protect the electrical circuit by breaking the connection if a short cir

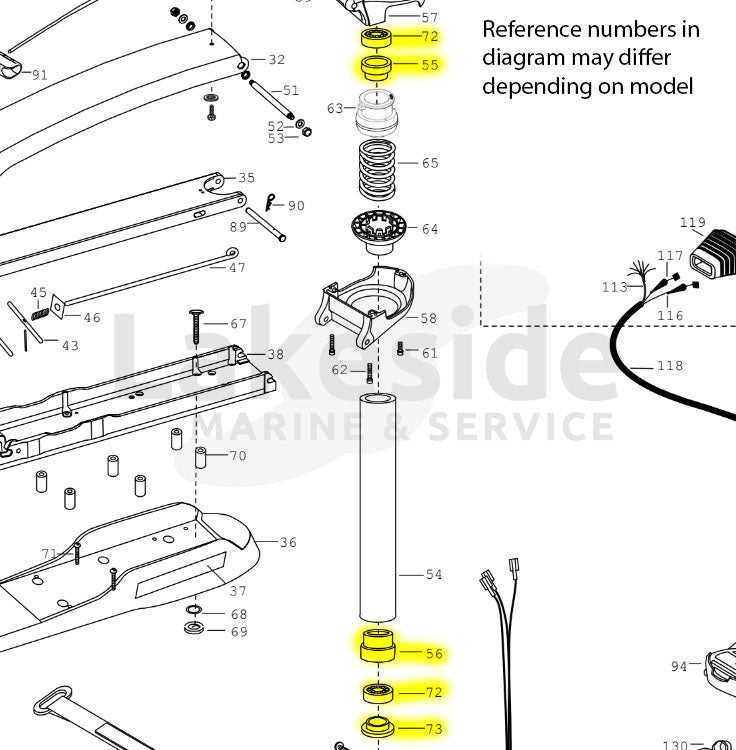

Mounting Bracket Features and Adjustments

The mounting bracket is a crucial component that ensures stability and flexibility during the installation of equipment. It allows for secure attachment and easy adjustments, adapting to different surfaces and environments. This section explores the key characteristics of the bracket and how it can be modified to meet various needs.

Durable Construction

Made from high-strength materials, the bracket is designed to withstand both regular use and harsh conditions. Its robust structure provides longevity and reliability, making it suitable for prolonged applications.

Adjustability for Precision

The bracket’s adjustment mechanism allows users to fine-tune the position of the equipment. This ensures optimal performance and alignment, whether on flat or

Control System and Cable Functions

This section provides an overview of the control mechanisms and the various cable functions that play a crucial role in the operation of the propulsion device. Understanding these components is essential for ensuring efficient performance and effective management of the system.

The control system serves as the brain of the operation, allowing users to manipulate various functions seamlessly. Key elements of the control system include:

- Throttle Control: Regulates the speed and direction of the motor.

- Steering Mechanism: Facilitates directional adjustments, ensuring precise navigation.

- Indicator Lights: Provide real-time feedback on system status and performance.

Cable functions are equally significant, as they establish vital connections between different components of the system. The following cables are integral to functionality:

- Power Cable: Supplies electrical energy to the motor.

- Control Cables: Link the control system to the motor, enabling communication of commands.

- Data Cables: Facilitate the transfer of information between various components for enhanced operation.

Proper maintenance and understanding of these systems contribute to the longevity and reliability of the propulsion device.

How to Replace Steering Parts Effectively

Maintaining proper control over your vessel is crucial for a safe and enjoyable experience on the water. This section focuses on the steps needed to effectively swap out steering components, ensuring optimal performance and responsiveness.

Identifying the Components

Before initiating the replacement process, it’s essential to identify which elements require attention. Common components that may need to be replaced include:

- Steering wheel

- Push rods

- Connector fittings

- Helm assembly

- Wiring harness

Step-by-Step Replacement Process

- Gather Tools: Collect necessary tools such as wrenches, screwdrivers, and pliers.

- Disconnect Power: Ensure that the power source is disconnected to avoid any electrical issues.

- Remove the Old Components: Carefully detach the existing steering elements, taking note of their arrangement.

- Install New Parts: Follow the manufacturer’s guidelines to install the new components, ensuring secure connections.

- Reconnect Power: Restore the power supply and check for any malfunctions.

- Test Functionality: Conduct a thorough test to ensure smooth operation of the steering system.

Essential Seals and Gaskets Overview

Seals and gaskets play a crucial role in ensuring the functionality and longevity of various mechanical systems. They serve as barriers to prevent fluid leakage and protect components from contaminants. Understanding their importance and characteristics can enhance the maintenance and performance of your equipment.

There are several types of seals and gaskets commonly used in mechanical assemblies:

- O-rings: These circular seals are designed to fit into grooves and provide a tight seal against pressure and fluid leaks.

- Flat gaskets: Made from various materials, these gaskets are placed between two mating surfaces to prevent leakage.

- Bellows: Flexible seals that allow for movement while maintaining a barrier against contaminants.

- Retaining rings: Used to secure components in place, preventing them from moving out of position.

Choosing the right materials for these components is vital for optimal performance. Factors such as temperature, pressure, and exposure to chemicals must be considered to ensure durability and effectiveness.

Regular inspection and replacement of worn or damaged seals and gaskets can prevent costly repairs and downtime, making them essential for reliable operation.

Diagnosing Common Motor Shaft Issues

Identifying frequent challenges with the motor shaft is crucial for maintaining optimal performance. Understanding these problems allows users to address issues promptly, ensuring the equipment operates smoothly. Below are some typical signs that may indicate a malfunctioning shaft.

Issue Symptoms Possible Solutions Excessive Noise Grinding or rattling sounds during operation. Inspect for debris or wear. Lubricate if necessary. Vibration Unusual shaking or wobbling while in use. Check for misalignment or damaged bearings. Rebalance if needed. Overheating Motor becomes excessively hot during use. Ensure proper ventilation and check for blockages. Inspect for electrical issues. Reduced Power Decreased performance or power output. Evaluate battery condition and connections. Examine for internal resistance. Foot Pedal Mechanics and Usage Tips

The foot control system is essential for smooth operation and maneuverability in various aquatic environments. Understanding its mechanics and optimal usage can enhance the overall experience while ensuring safety and efficiency. This section explores the fundamental aspects of foot pedals, providing insights into their functionality and practical advice for users.

Understanding the Mechanics

Foot pedals are designed to offer precise control over propulsion and steering. They typically operate through a series of interconnected components that translate foot movements into actionable responses. The primary elements include:

Component Function Foot Switch Activates propulsion or steering when pressed. Linkage System Transfers foot movements to the motor or steering mechanism. Control Cables Facilitates communication between the pedal and the motor. Usage Tips for Optimal Performance

To maximize the effectiveness of the foot control system, consider the following tips:

- Ensure the foot pedal is securely mounted and free from obstructions.

- Practice smooth and gradual pressure to maintain control.

- Regularly inspect the components for wear and tear.

Best Practices for Propeller Shaft Care

Maintaining the integrity of the propeller shaft is crucial for ensuring optimal performance and longevity of marine equipment. Proper care involves regular inspection, cleaning, and timely replacement of components to prevent corrosion and wear, thereby enhancing the overall functionality.

Here are some essential practices to follow for effective propeller shaft maintenance:

Practice Description Regular Inspection Check for signs of wear, rust, or damage frequently to address issues before they escalate. Cleaning Keep the shaft clean from debris, algae, and salt buildup to avoid performance degradation. Lubrication Apply appropriate marine-grade grease to moving parts to reduce friction and prevent wear. Corrosion Protection Use anti-corrosive coatings or paints to shield the shaft from harsh marine environments. Timely Replacement Replace worn or damaged components immediately to maintain efficiency and safety. Ide

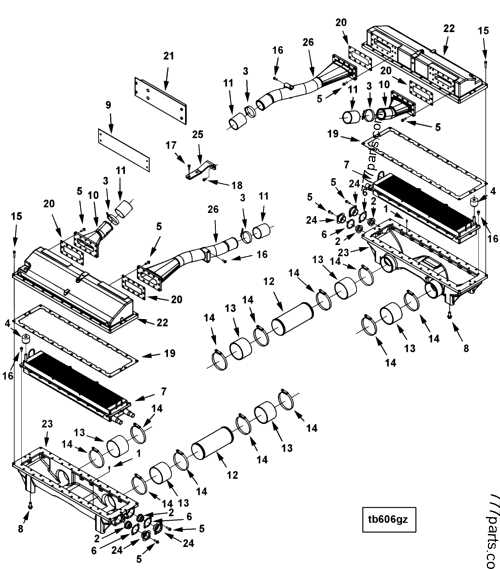

The concept revolves around understanding the essential components and their configurations for optimal functionality. This overview aims to shed light on how various elements interact within a system, enhancing performance and efficiency.

Exploring the key aspects of these components allows users to grasp the significance of each part in contributing to the overall effectiveness. By delving into the arrangement and connections, one can appreciate how improvements or modifications can lead to enhanced operation.

Additionally, familiarizing oneself with these configurations can empower individuals to make informed decisions regarding maintenance and upgrades, ensuring longevity and reliability in use.

Propeller Design and Maintenance Tips

The efficiency of a marine propulsion system largely depends on the design and upkeep of the propeller. A well-constructed propeller not only enhances performance but also ensures smooth operation and longevity. Regular inspections and proper care play a crucial role in maintaining optimal functionality, preventing damage, and improving overall efficiency on the water.

| Maintenance Tip | Description |

|---|---|

| Inspect for Damage | Regularly check the blades for cracks, chips, or bends that could affect performance. |

| Clean Thoroughly | Remove any debris or marine growth that could hinder smooth movement through water. |