In the world of fishing and recreational boating, maintaining optimal performance of your equipment is essential. Every component plays a crucial role in ensuring smooth operation and enhancing the overall experience on the water. Familiarizing yourself with the various elements of a motor can greatly improve efficiency and longevity.

For enthusiasts and professionals alike, a comprehensive breakdown of these mechanisms not only aids in troubleshooting but also empowers users to make informed decisions regarding repairs and upgrades. Knowledge of each section allows for a deeper appreciation of the technology that supports your aquatic adventures.

Whether you are looking to replace worn-out sections or simply wish to enhance your understanding, exploring the intricacies of these mechanisms will ultimately lead to more enjoyable and successful outings. Let’s delve into the essential components that keep your motor running smoothly.

Overview

This section provides a comprehensive look at a popular trolling motor model, renowned for its reliability and performance on the water. Designed for anglers and boating enthusiasts, it combines innovative technology with user-friendly features, making it a preferred choice for many.

The motor is engineered to deliver efficient thrust while ensuring minimal noise, allowing for stealthy maneuvers during fishing trips. Its construction emphasizes durability, capable of withstanding harsh marine environments. Additionally, it offers various speed settings, enabling precise control over navigation.

One of the standout characteristics is its intuitive deployment mechanism, which facilitates easy handling and setup. Users appreciate the ergonomic design that enhances comfort during operation. Overall, this model exemplifies a balance of power and convenience, catering to both novice and seasoned users.

Key Features:

- Durable materials for extended longevity.

- Multiple speed options for enhanced control.

- Quiet operation to avoid disturbing aquatic life.

- User-friendly deployment for hassle-free use.

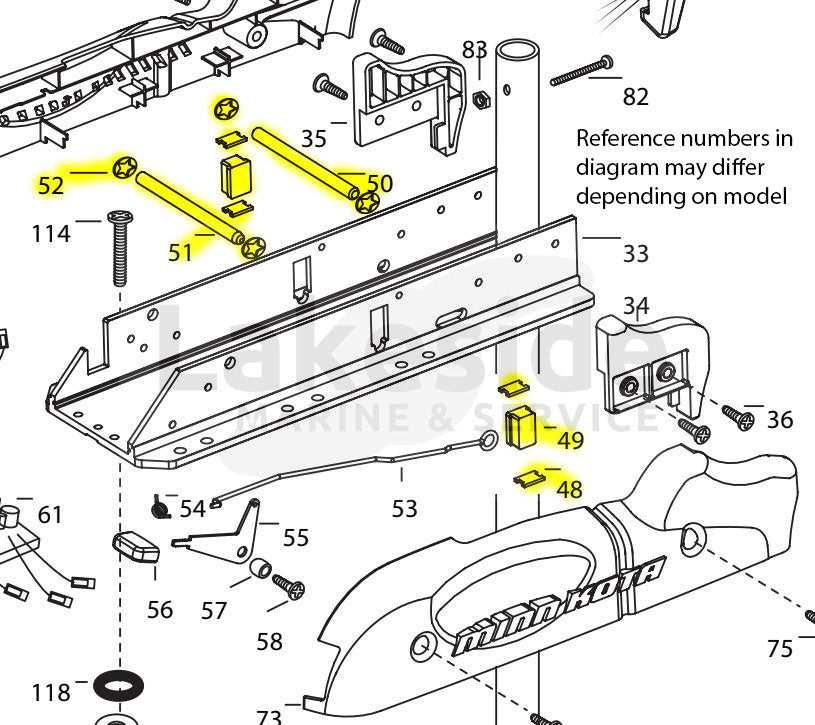

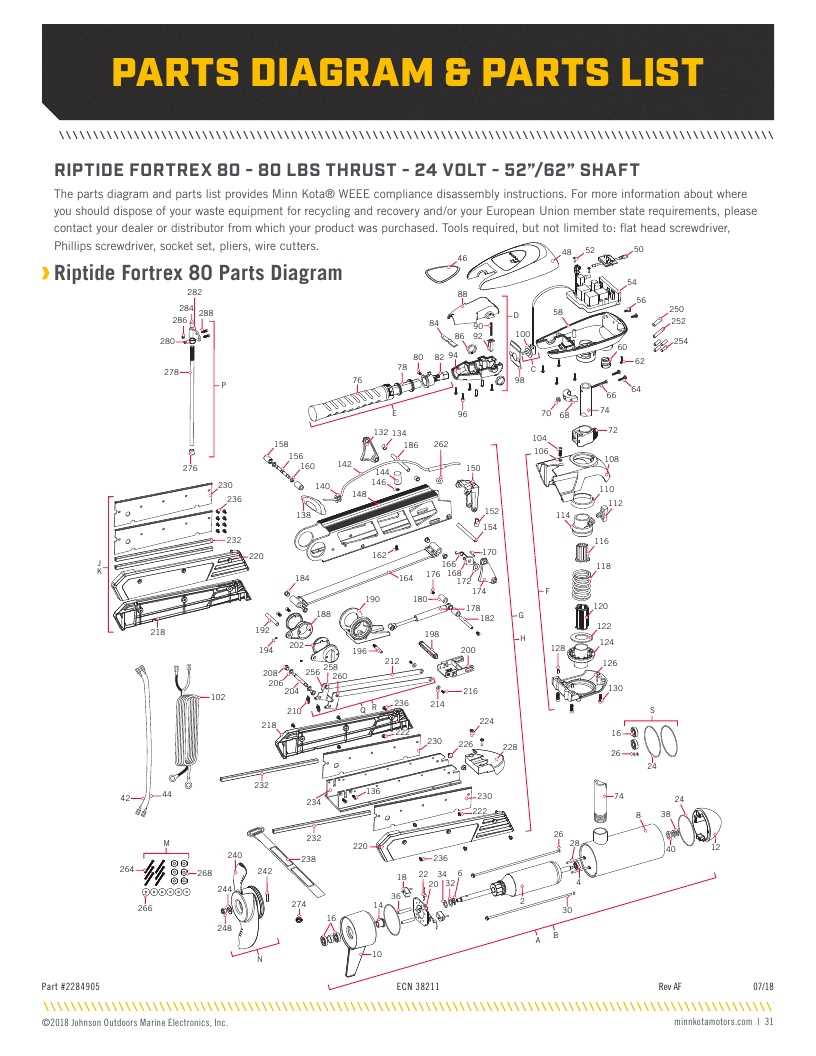

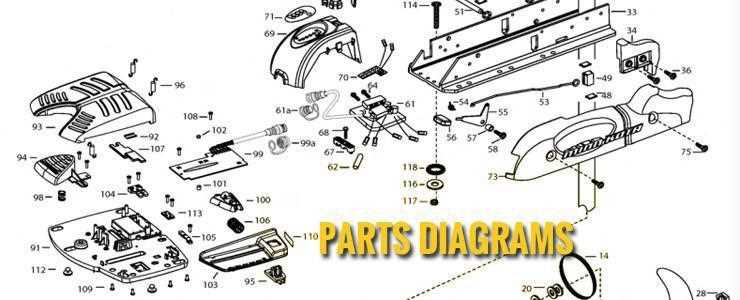

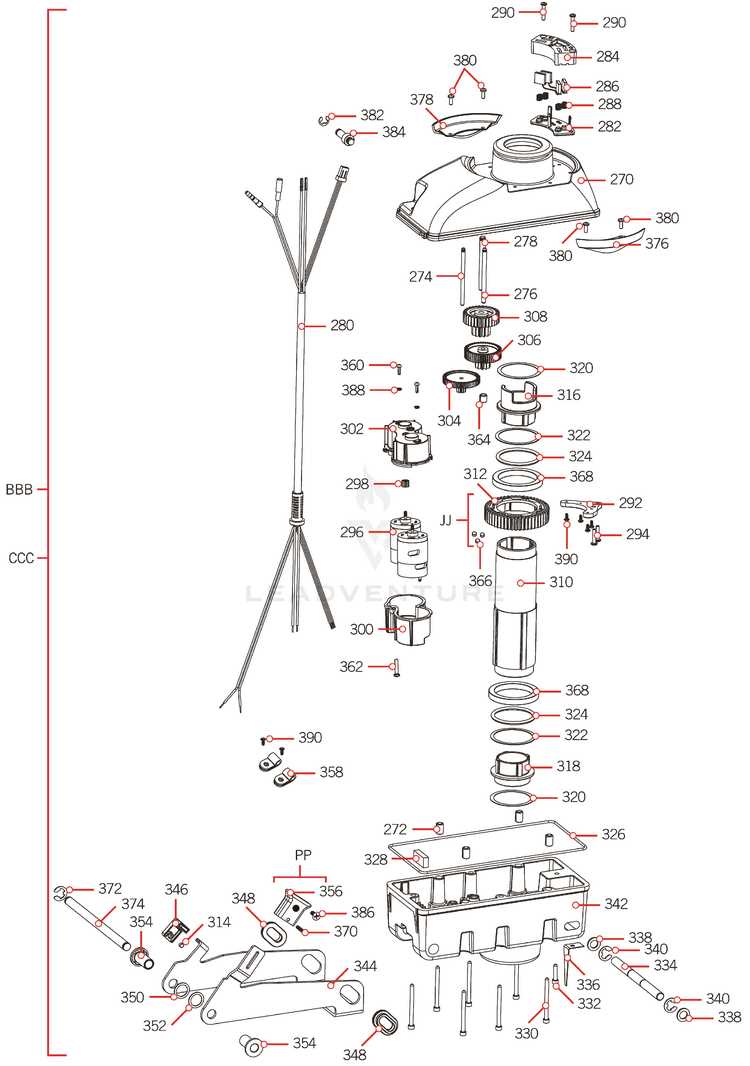

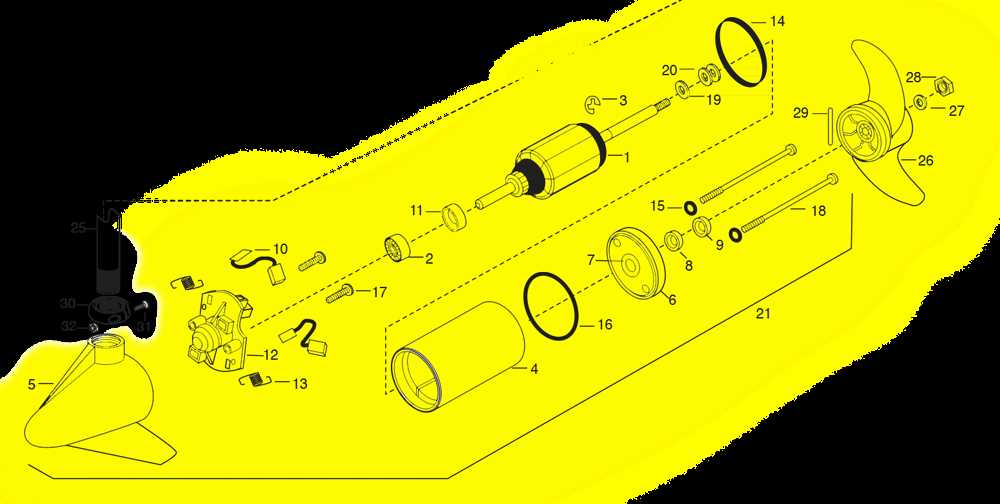

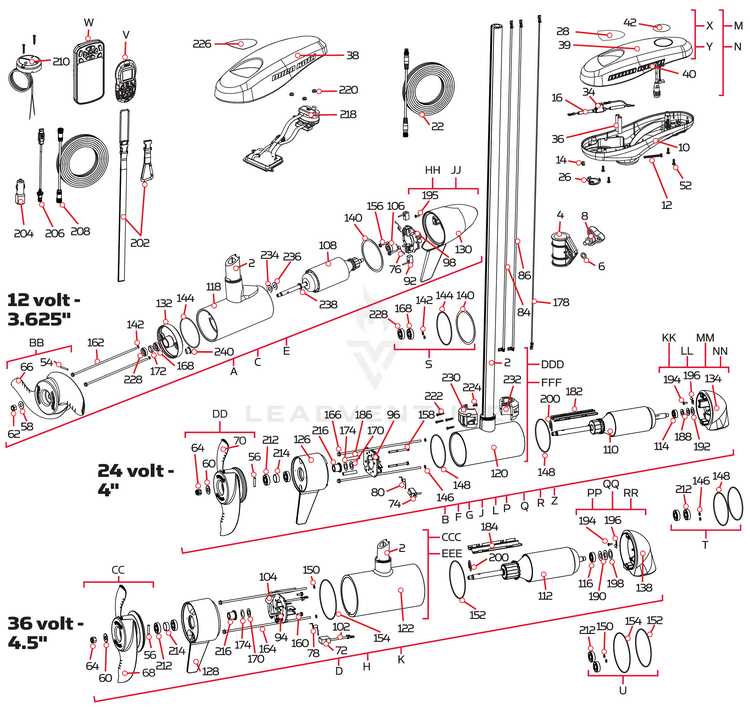

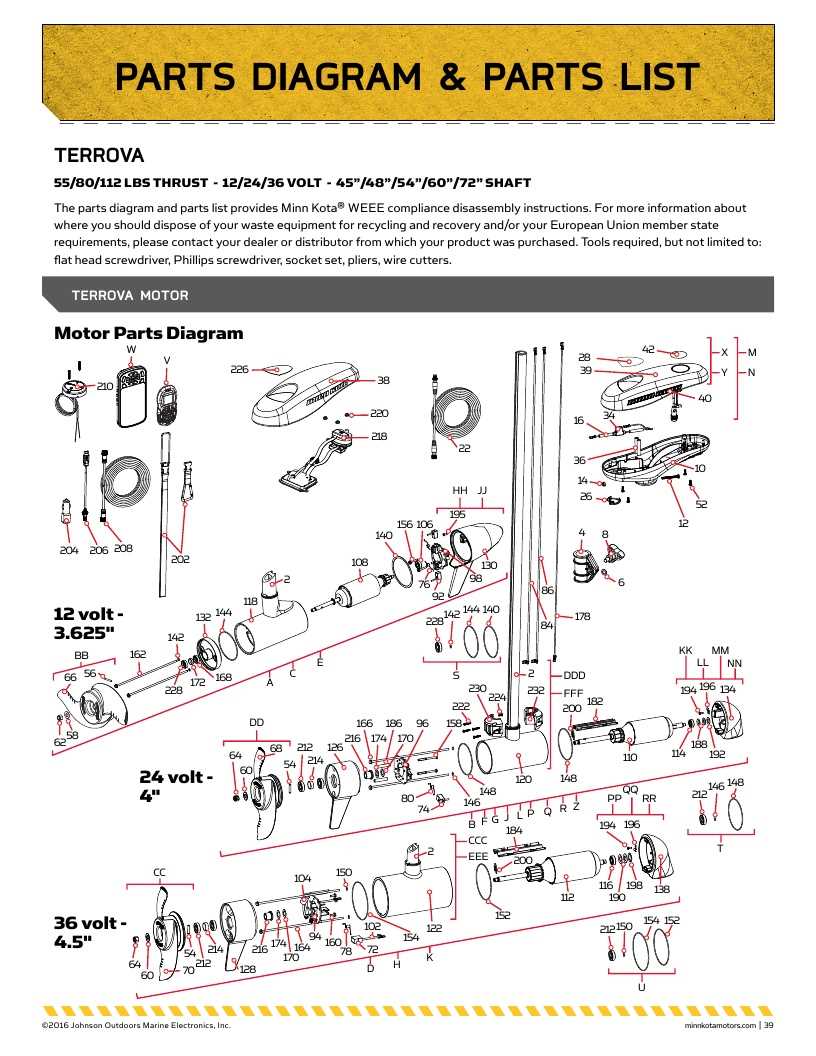

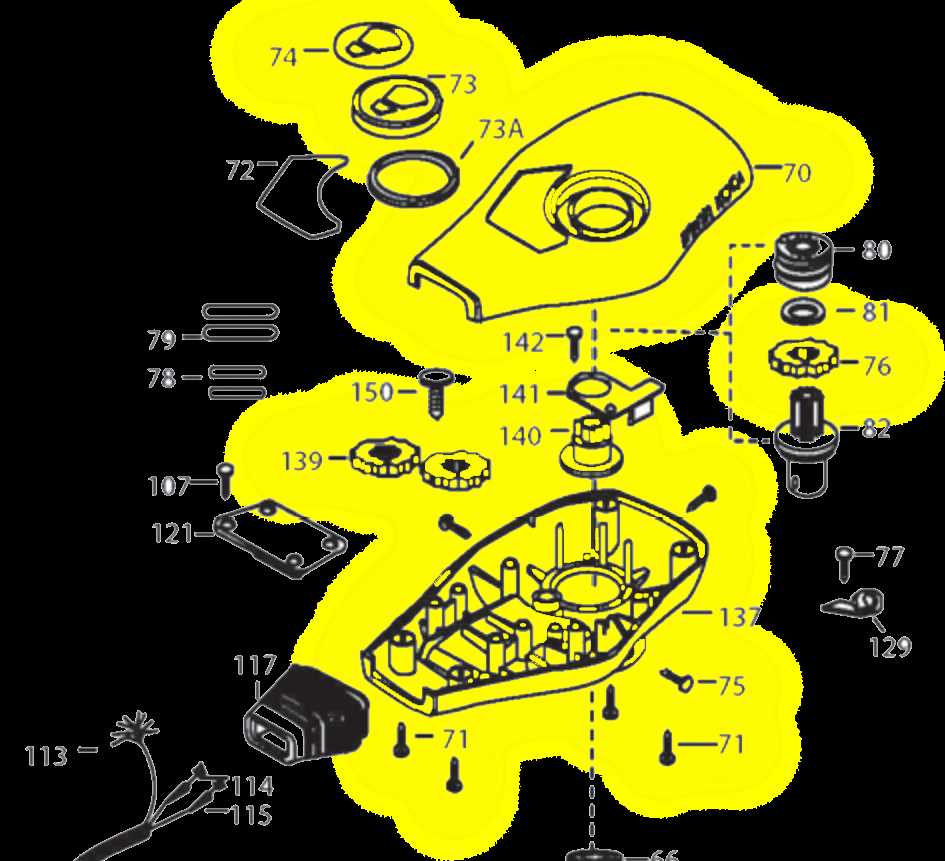

Understanding the Parts Diagram

Comprehending the schematic representation of components is essential for effective maintenance and repair. This visual tool offers insights into the arrangement and functionality of each element, enabling users to identify necessary replacements and perform troubleshooting with greater ease.

Key Components Explained

Each section of the schematic highlights specific items, illustrating their position and interconnections. By examining these elements, users can gain a deeper understanding of how they work together to ensure optimal performance. Recognizing these individual parts can simplify the repair process and enhance overall efficiency.

Benefits of Familiarity

Being well-versed in the layout of components not only aids in quick identification but also fosters confidence in handling repairs. Users who take the time to study the schematic will find themselves better equipped to tackle issues, ultimately prolonging the lifespan of their equipment and improving functionality.

Key Components of the Edge Model

This section explores the essential elements that define the functionality and efficiency of a specific model designed for aquatic navigation. Understanding these crucial components enhances the overall user experience and ensures optimal performance during use.

Motor Assembly

The motor assembly serves as the powerhouse of the system, delivering the necessary thrust and control. This component is engineered for durability and responsiveness, making it vital for maneuverability in various water conditions.

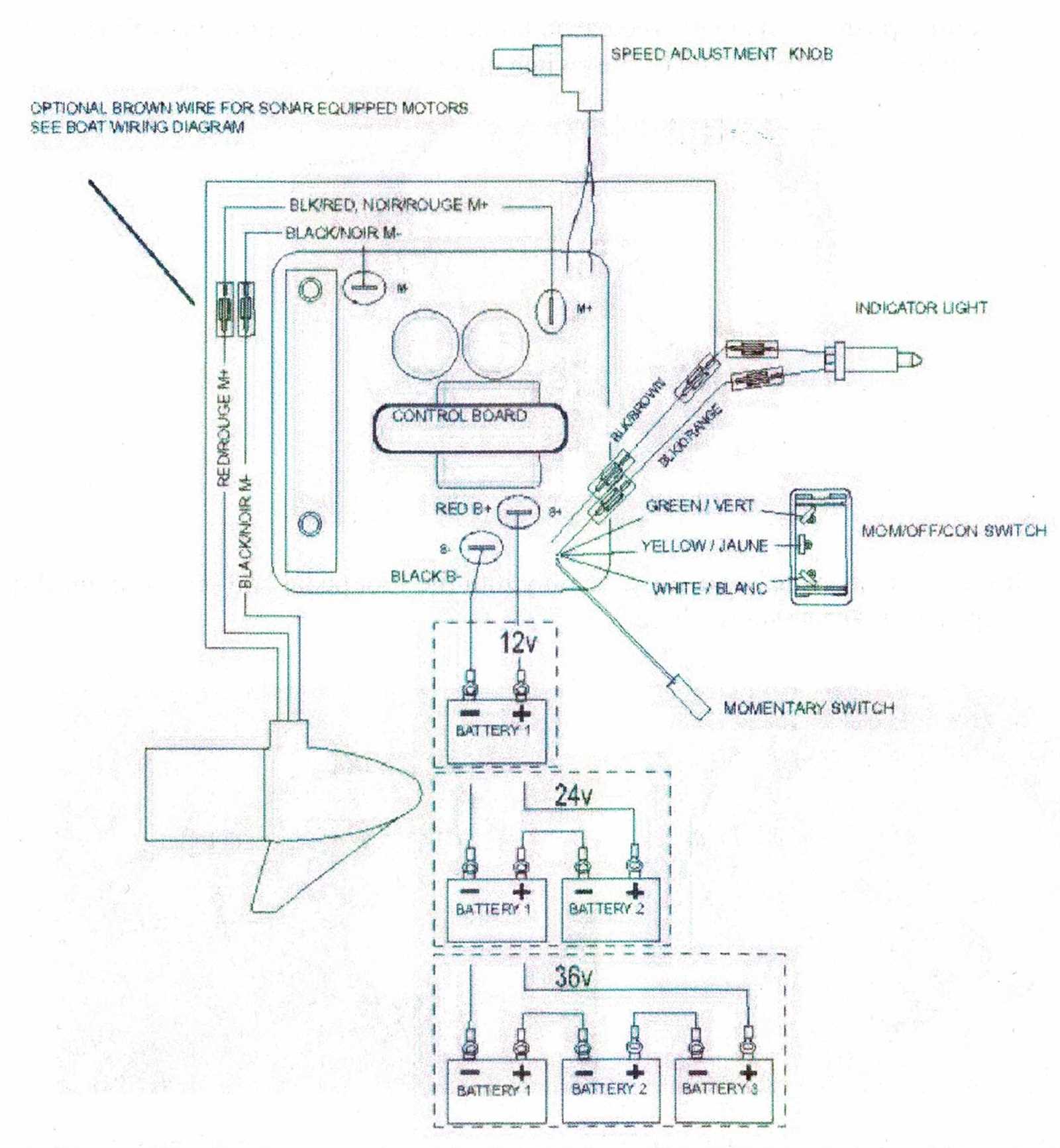

Control Mechanism

The control mechanism is integral for adjusting speed and direction. With intuitive design and ergonomic features, it allows users to operate the equipment with precision, ultimately enhancing navigation experiences on the water.

Importance of Proper Maintenance

Regular upkeep of equipment is crucial for ensuring optimal performance and longevity. Neglecting maintenance can lead to a range of issues, from minor inconveniences to significant failures. By dedicating time to proper care, users can not only enhance the efficiency of their devices but also prevent costly repairs in the long run.

Enhancing Performance

Consistent maintenance activities help in identifying potential problems before they escalate. This proactive approach ensures that machinery operates at peak efficiency, providing users with reliable service. Regular checks can improve functionality and minimize the risk of unexpected breakdowns, ultimately leading to a smoother experience.

Extending Lifespan

Incorporating a routine maintenance schedule significantly contributes to the lifespan of equipment. By addressing wear and tear promptly and replacing worn components, users can enjoy prolonged use of their devices. Moreover, well-maintained machinery often retains its resale value, making it a wise investment in the long term.

In summary, committing to regular maintenance is essential for achieving both enhanced performance and extended lifespan of equipment. A little effort can yield substantial rewards in reliability and efficiency.

Common Issues and Troubleshooting Tips

Understanding potential malfunctions and their solutions is key to maintaining a smoothly functioning system. Recognizing symptoms early can help prevent long-term damage and ensure optimal performance. This section provides guidance on identifying common problems and offers practical troubleshooting advice.

| Problem | Possible Cause | Solution | ||||||

|---|---|---|---|---|---|---|---|---|

| Device doesn’t power on | Battery connection issues | Check and secure all wiring connections; ensure the battery is fully charged. | ||||||

| Inconsistent speed control | Loose control unit connections | Tighten or replace any loose or damaged connections; inspect control unit for faults. | ||||||

| Unusual noises during operation | Worn-out or obstructed components | Inspect moving parts for wear or obstructions; clean an

Replacing Worn-Out PartsOver time, various components of any equipment can deteriorate due to regular use. Identifying these worn elements early and replacing them is essential to ensure smooth operation and extend the lifespan of your device. Whether it’s mechanical or electrical, addressing the issue promptly prevents more significant damage and maintains peak performance. Signs of Wear and TearRecognizing the indicators of degradation is the first step in ensuring timely maintenance. Common signs include unusual noises, decreased efficiency, and visible damage to components. These symptoms suggest that replacement is necessary to avoid potential malfunctions. Steps for Replacing Essential Elements

Begin by carefully inspecting the affected areas and identifying the components that need to be replaced. Make sure to acquire compatible replacements and follow the manufacturer’s guidelines to ensure proper installation. If unsure, consulting a professional can guarantee safe and accurate replacement. Keeping a regular maintenance schedule will also help to prevent future wear. Tools Required for RepairsWhen performing maintenance or fixing mechanical issues, having the correct set of instruments is essential for efficient and safe repairs. Using the appropriate tools ensures precision, reduces the risk of damage, and helps achieve optimal results in less time. Basic Equipment

Specialized Instruments

Ensure these to How to Read the Diagram

Understanding the structure of a schematic can greatly assist in identifying key components and their connections. By carefully examining the layout, you can trace the flow of each part, ensuring all elements are correctly aligned. The visual representation provides a roadmap for analyzing how each section interacts with the others, allowing for a clear understanding of the system’s functionality. Start by locating the major sections, typically positioned for easy identification. From there, follow the connection lines to observe how different units relate to one another. Ensure to pay attention to any labels or symbols, as they often provide crucial insights into the functionality of specific components. Familiarizing yourself with these markings is essential for successful navigation of the schematic. When reviewing the layout, focus on Frequently Asked Questions

This section provides answers to the most common inquiries regarding the functionality, setup, and troubleshooting of mechanical components. The goal is to offer clear guidance on frequently encountered issues and general maintenance tips.

|