In the realm of warehouse operations, the efficient movement of goods relies heavily on specialized machinery. A clear understanding of the intricate elements that make up these devices is essential for maintenance and effective usage. Each component plays a vital role in ensuring smooth functionality and optimal performance.

To grasp the complexities of this machinery, it is important to explore a comprehensive visual representation of its elements. Such a breakdown not only aids technicians in identifying specific parts but also enhances the overall operational knowledge for users. This knowledge ultimately contributes to the longevity and reliability of the equipment.

By delving into the structure of these machines, one can uncover the ultimate insights needed for troubleshooting and repairs. Whether for routine maintenance or unexpected issues, familiarity with each segment empowers operators to handle their equipment with confidence and expertise.

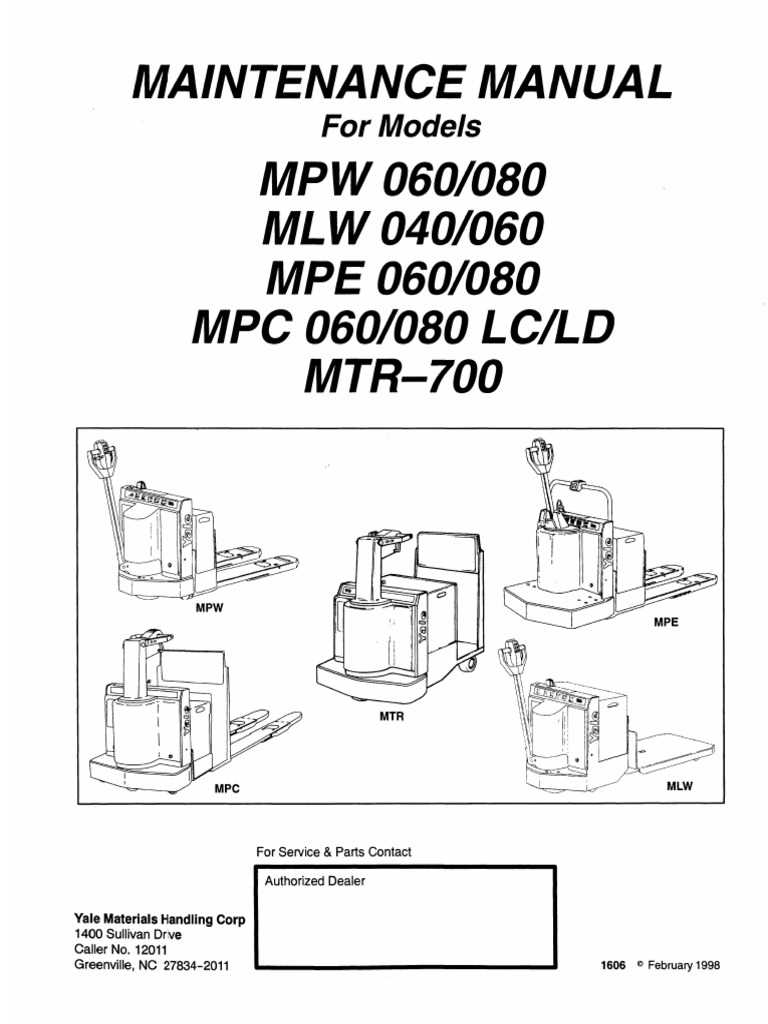

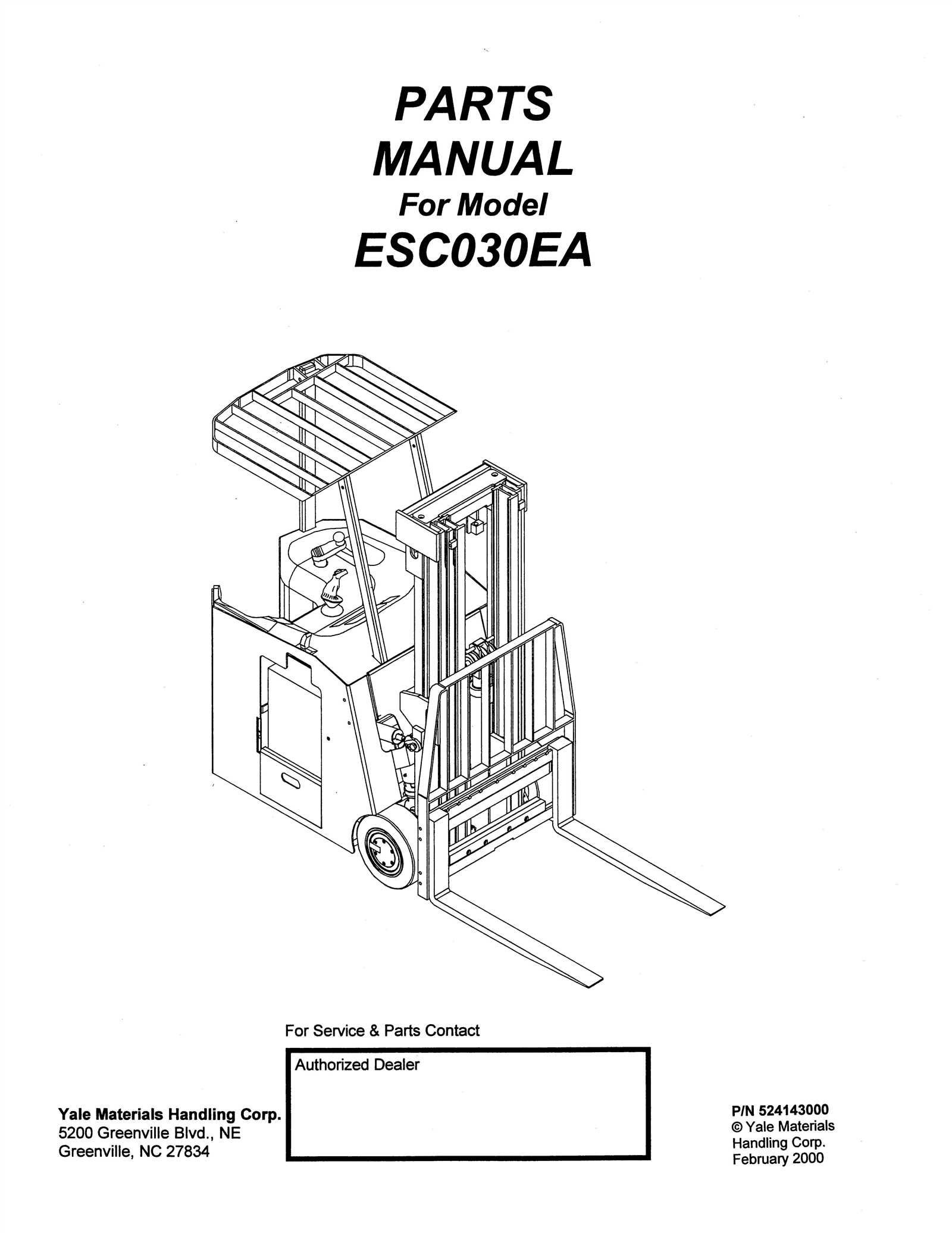

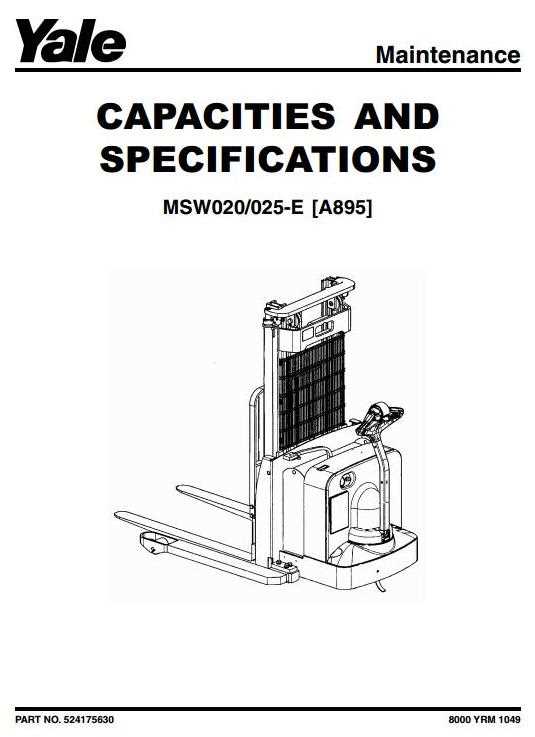

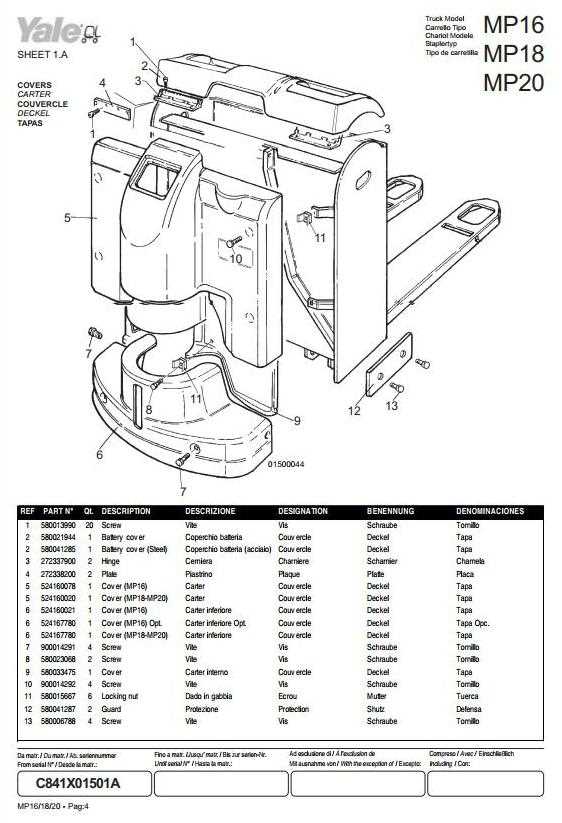

Understanding Yale Electric Pallet Jacks

This section provides insights into a specific type of material handling equipment widely used in warehouses and distribution centers. These machines are designed to facilitate the efficient movement of heavy loads, enhancing productivity and safety in various settings.

Key features of this equipment include:

- Robust construction for durability

- Ergonomic design for user comfort

- Powerful lifting mechanisms

- Compact size for maneuverability in tight spaces

When operating such machinery, understanding its components is crucial for effective usage and maintenance. Familiarity with each element can lead to:

- Improved operational efficiency

- Reduced risk of malfunctions

- Prolonged lifespan of the equipment

Proper knowledge also assists in troubleshooting issues that may arise, ensuring that any problems can be swiftly addressed. By prioritizing understanding, users can maximize the benefits of this essential tool in their daily operations.

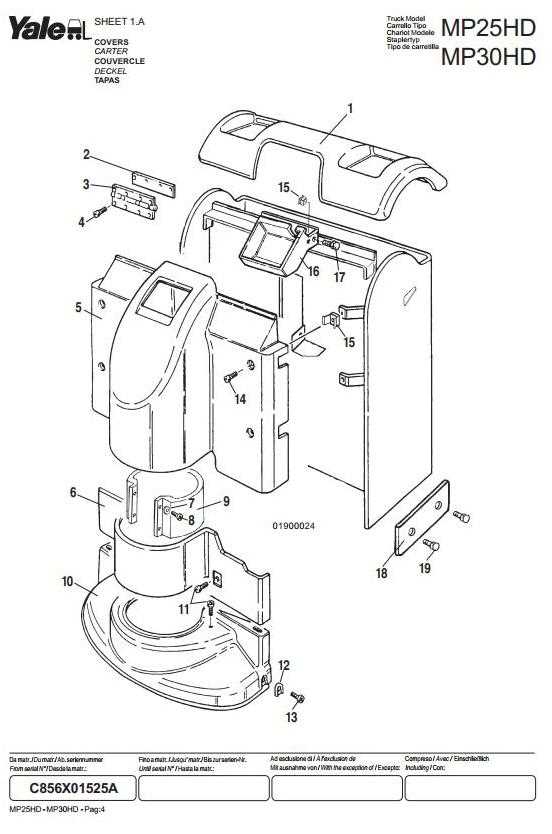

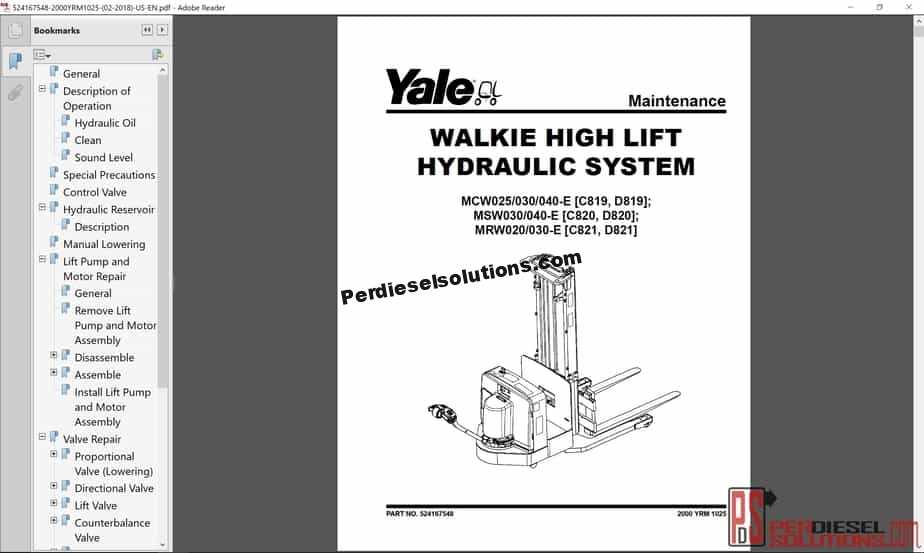

Importance of Parts Diagrams

Understanding the layout and components of machinery is crucial for effective maintenance and repair. Visual representations provide clarity and help users identify various elements, ensuring that technicians can troubleshoot issues efficiently. These illustrations serve as a vital resource for anyone involved in the upkeep of equipment.

Facilitating Communication is one of the key benefits of these visuals. When team members discuss repairs or modifications, having a common reference enhances collaboration. Clear depictions minimize misunderstandings, allowing for smoother workflows.

Enhancing Training opportunities is another significant advantage. New employees can familiarize themselves with the equipment quickly, learning about each component’s function through well-crafted visuals. This accelerates their ability to contribute effectively to the team.

Moreover, these references aid in streamlining repairs. When problems arise, technicians can pinpoint the affected areas rapidly, reducing downtime and improving overall productivity. Quick access to specific information ensures that repairs are carried out correctly and efficiently.

Lastly, maintaining accurate documentation is essential for compliance and future reference. A comprehensive visual guide not only supports immediate tasks but also serves as a valuable archive for future inspections or upgrades, safeguarding the longevity of the equipment.

Key Components of Electric Pallet Jacks

This section focuses on the essential elements that contribute to the functionality and efficiency of these crucial warehouse tools. Understanding these components is vital for optimal operation and maintenance.

Main Elements

The primary components include the control system, lifting mechanism, and support structure. Each part plays a significant role in ensuring safe and efficient movement of goods.

Functionality Overview

| Component | Function |

|---|---|

| Control System | Regulates movement and speed, enhancing user control. |

| Lifting Mechanism | Enables elevation of loads for stacking and transport. |

| Support Structure | Provides stability and strength to carry heavy items. |

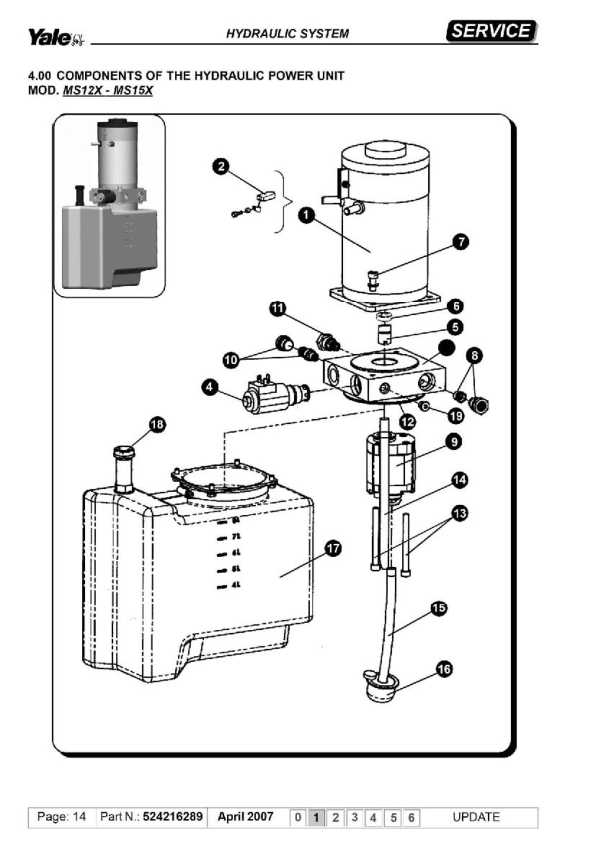

How to Read Parts Diagrams

Understanding schematic illustrations is crucial for efficient maintenance and repair. These visuals convey vital information about component arrangements, connections, and functions. Mastering the interpretation of these graphics can save time and enhance troubleshooting skills.

Identifying Symbols and Labels

Each illustration contains specific symbols representing various elements. Familiarize yourself with these icons and their corresponding labels to quickly locate items of interest. A clear understanding of these symbols simplifies the process of finding replacement components.

Interpreting Connections

Pay close attention to the lines and arrows indicating how different components are linked. These connections reveal how parts interact and function together, providing insight into the overall system. Recognizing these relationships is essential for effective repairs.

Common Issues with Yale Pallet Jacks

When operating material handling equipment, several challenges may arise that can affect efficiency and safety. Understanding these frequent concerns is essential for maintaining optimal functionality and prolonging the lifespan of the equipment.

Mechanical Failures

One of the most prevalent problems involves mechanical components, which can wear down over time. Issues such as broken wheels or malfunctioning steering mechanisms often lead to operational difficulties. Regular maintenance can help identify these issues early.

Electrical Malfunctions

Another significant concern involves the electrical systems. Problems like faulty batteries or wiring issues can result in performance drops. Ensuring that electrical components are routinely checked and serviced is vital for avoiding unexpected downtimes.

Replacement Parts Overview

Understanding the essential components that ensure optimal functionality is crucial for maintaining equipment efficiency. This section provides insights into various elements that can be replaced to enhance performance and prolong the lifespan of your machinery. Regular assessment and timely substitutions can prevent operational downtime and improve overall reliability.

Here is a summary of common components that may require attention:

| Component | Description | Importance |

|---|---|---|

| Battery | Power source for operation. | Critical for energy supply and efficiency. |

| Forks | Attachments for lifting loads. | Essential for handling various materials safely. |

| Wheels | Facilitate movement and stability. | Vital for maneuverability and ease of transport. |

| Controller | Regulates operation and functionality. | Key for performance management and safety. |

| Chassis | Main structure supporting all components. | Fundamental for overall integrity and strength. |

By ensuring these elements are well-maintained and replaced as necessary, operators can achieve seamless functionality and enhance the productivity of their equipment.

Maintaining Your Electric Pallet Jack

Proper upkeep of your material handling equipment is essential for ensuring longevity and optimal performance. Regular checks and maintenance can prevent costly repairs and enhance safety in your operations.

Start by inspecting the battery regularly. Ensure it’s charged and free of corrosion. Clean the terminals and check for any leaks. Additionally, monitor the wheels for wear and tear, replacing them when necessary to maintain maneuverability.

Lubricate moving components to reduce friction and avoid premature wear. Ensure that all fasteners are tight and secure, as loose parts can lead to instability during operation.

Lastly, review the operator manual for specific guidelines tailored to your model, as adhering to manufacturer recommendations is vital for effective maintenance.

Finding Genuine Yale Parts

When maintaining your machinery, ensuring the use of authentic components is crucial for optimal performance and longevity. Genuine items are designed specifically for your equipment, providing a perfect fit and reliability that aftermarket alternatives often lack.

Why Choose Authentic Components?

Opting for original pieces offers several advantages:

- Quality Assurance: These items undergo rigorous testing to meet industry standards.

- Perfect Compatibility: Designed to integrate seamlessly with your equipment, reducing the risk of malfunctions.

- Long-Term Savings: Investing in authentic parts can prevent costly repairs and replacements down the line.

Where to Find Genuine Items

Locating authentic components can be straightforward if you know where to look:

- Authorized Dealers: Always check with certified distributors who offer genuine items.

- Manufacturer Websites: Many manufacturers provide online catalogs where you can purchase directly.

- Industry Trade Shows: Attending events can connect you with trusted vendors.

By prioritizing original components, you ensure the reliability and efficiency of your machinery for years to come.

DIY Repairs for Pallet Jacks

Taking on repairs yourself can be a rewarding experience that saves time and money. Understanding the components and common issues allows users to troubleshoot effectively and perform maintenance when needed.

Identifying Problems: Start by observing any irregularities in performance. Common symptoms include unusual noises, difficulty in movement, or uneven lifting. Documenting these issues will guide your repair efforts.

Essential Tools: Having the right tools on hand is crucial. Basic tools like wrenches, screwdrivers, and pliers can help with most repairs. A multimeter is also beneficial for electrical troubleshooting.

Common Repairs: Many repairs involve checking for wear on wheels, inspecting hydraulic systems, or replacing worn-out seals. Regular maintenance can prevent major issues, so keep an eye on fluid levels and ensure components are free from debris.

Safety First: Always prioritize safety when working on machinery. Disconnect power sources and ensure the area is clear before starting any repairs. Wearing protective gear is also advisable to prevent injuries.

When to Seek Professional Help

Understanding the limits of your knowledge and skills is crucial when dealing with machinery. Certain situations demand expertise beyond basic troubleshooting or maintenance tasks. Recognizing when to consult a professional can save time, reduce costs, and ensure safety.

Here are some key indicators that it may be time to seek assistance:

- Persistent Issues: If a problem continues after your attempts to fix it, this may indicate a deeper underlying issue.

- Complex Repairs: Tasks requiring specialized tools or knowledge should be handled by experienced technicians.

- Safety Concerns: If you feel uncertain about the safety of operating the equipment, it’s best to call an expert.

- Warranty Considerations: Attempting repairs on equipment still under warranty might void it; consult a professional to protect your investment.

- Performance Decline: Noticeable drops in efficiency or functionality suggest that expert evaluation is necessary.

In these scenarios, contacting a qualified technician can ensure that issues are resolved effectively, maintaining the integrity of your machinery and ensuring operational safety.

Safety Features in Yale Models

When it comes to material handling equipment, safety is paramount. The design of these machines incorporates numerous mechanisms aimed at minimizing risks during operation. From built-in alarms to ergonomic controls, each feature plays a critical role in ensuring operator safety and efficiency.

Emergency Stop Functionality: One of the most essential elements is the emergency stop button, which allows for immediate cessation of operations in case of unforeseen circumstances. This feature can prevent accidents and injuries effectively.

Stability Enhancements: Advanced engineering ensures that the equipment remains stable, even when transporting heavy loads. Features like low centers of gravity and wide bases contribute to reducing tipping risks.

Operator Presence Sensors: Many models are equipped with sensors that detect the operator’s presence. If the operator steps away or loses control, the equipment automatically slows down or stops, providing an additional layer of protection.

Training and Awareness: Regular training programs are essential for operators to understand the safety features and their proper usage, ensuring that safety protocols are always followed.

Upgrades and Accessories Available

Enhancements and supplementary tools can significantly improve the efficiency and functionality of your material handling equipment. These additions not only boost performance but also ensure longevity and adaptability to various tasks.

Popular Enhancements

- Improved battery options for extended use

- Enhanced control systems for better maneuverability

- Load management features for increased safety

Essential Accessories

- Fork extensions for handling larger loads

- Protective covers to shield against environmental factors

- Toolboxes for convenient storage of necessary items

Resources for Further Information

Accessing comprehensive materials can greatly enhance your understanding and maintenance of various equipment types. Numerous platforms offer valuable insights, including user manuals, troubleshooting guides, and maintenance tips that cater to a wide audience, from beginners to experienced operators.

Online forums and communities are excellent venues for exchanging knowledge and experiences with fellow users. These platforms often provide real-time assistance and recommendations, helping you resolve specific issues effectively.

Manufacturer websites typically host extensive libraries of technical documents and FAQs. Here, you can find detailed specifications, safety guidelines, and maintenance protocols that are crucial for the proper functioning of your machinery.

Additionally, instructional videos on popular platforms can serve as visual aids, demonstrating repair techniques and operational best practices. These resources can be invaluable for both hands-on learners and those seeking to troubleshoot problems independently.