The intricate composition of a V8 power unit consists of numerous elements that work together in harmony. Understanding the layout and function of each component is essential for anyone interested in high-performance vehicles. These interconnected elements are specifically designed to deliver both power and efficiency, making them vital for the overall function of the vehicle.

This guide will explore the key elements that make up the V8 configuration, providing insights into how they contribute to the system’s overall operation. Whether you’re a mechanic or an enthusiast, this breakdown will offer a clear perspective on the components within this powerful configuration.

In the following sections, we’ll delve into the various elements of the V8, explaining their roles and significance in detail. Each piece is integral to the smooth operation and longevity of the system, ensuring that it delivers optimal performance.

Understanding the V8 Engine Structure

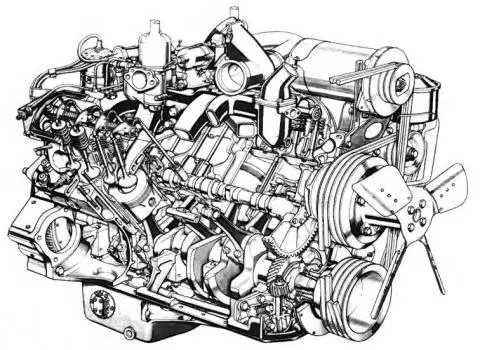

The V8 design is known for its efficiency and power, offering smooth performance and high output. Its layout involves eight chambers arranged in two sets of four, which allows for balanced operation. This setup is often preferred in vehicles that demand significant power while maintaining reliability and smooth running.

Each section of the system contributes to the overall performance, working in sync to deliver energy to the vehicle. The coordinated movement and careful balancing of the components allow the V8 design to stand out in both strength and durability, ensuring optimal functionality even under demanding conditions.

The configuration of this type of motor emphasizes synchronization and distribution of force, leading to better energy output. It’s a design that has been refined over the years, aiming to maximize efficiency while minimizing mechanical stress.

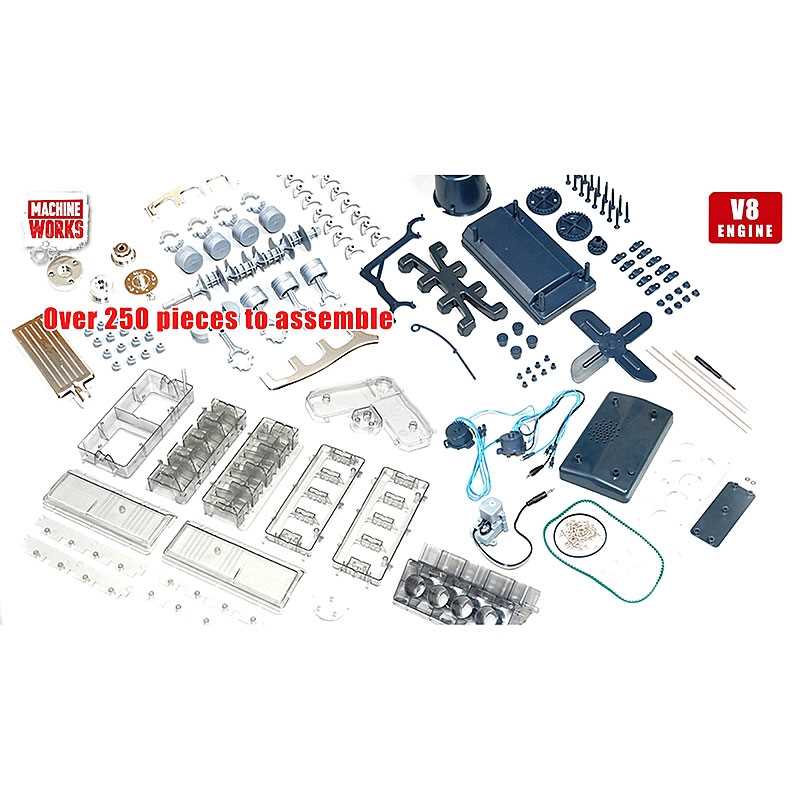

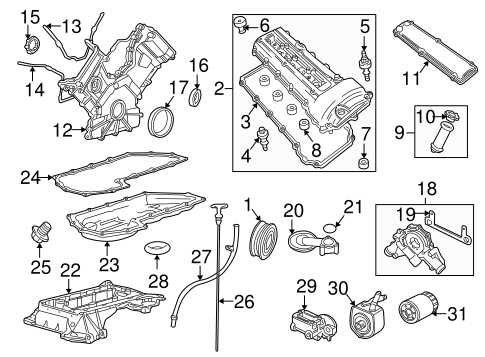

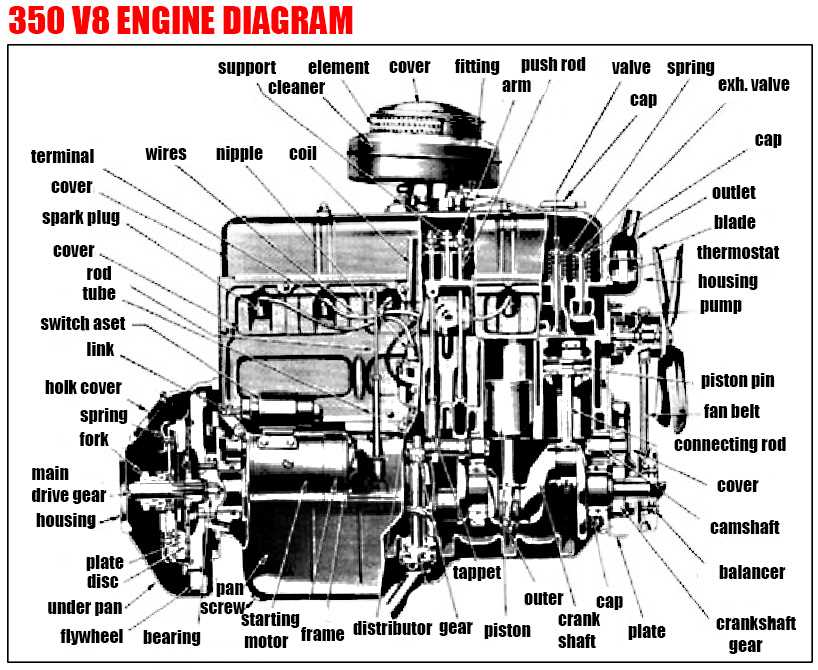

Main Components of a V8 Power Unit

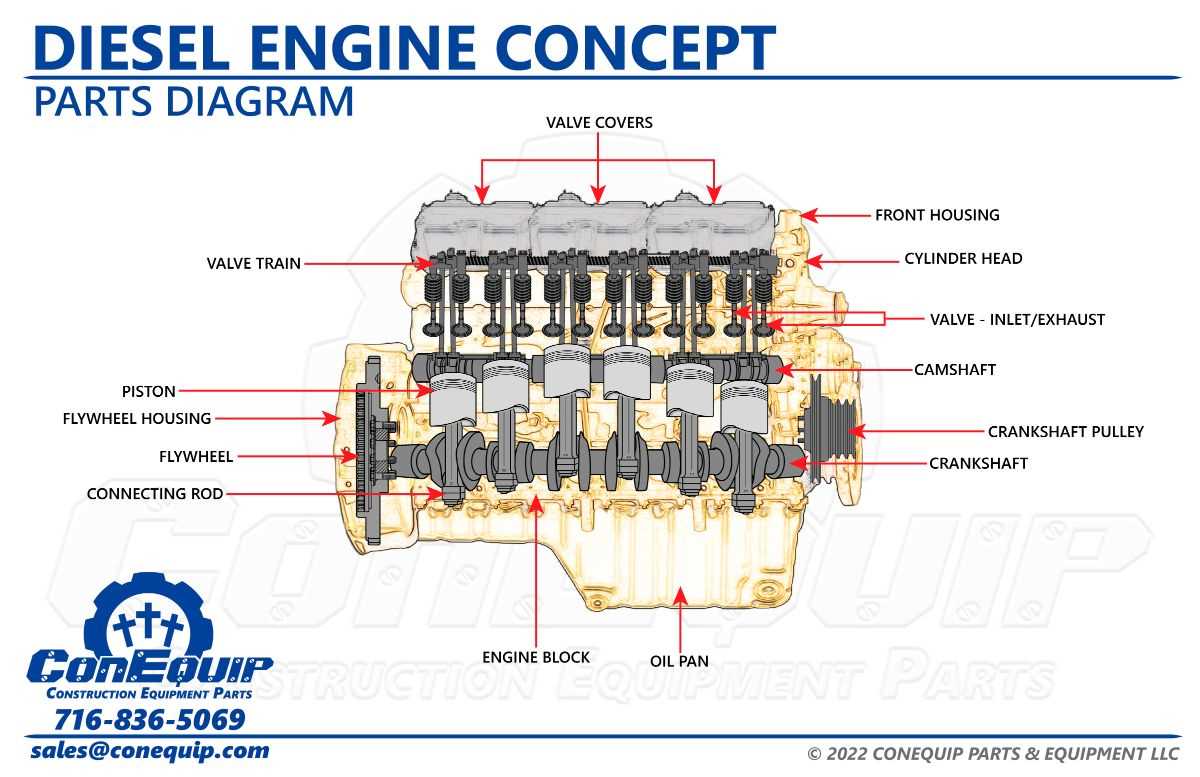

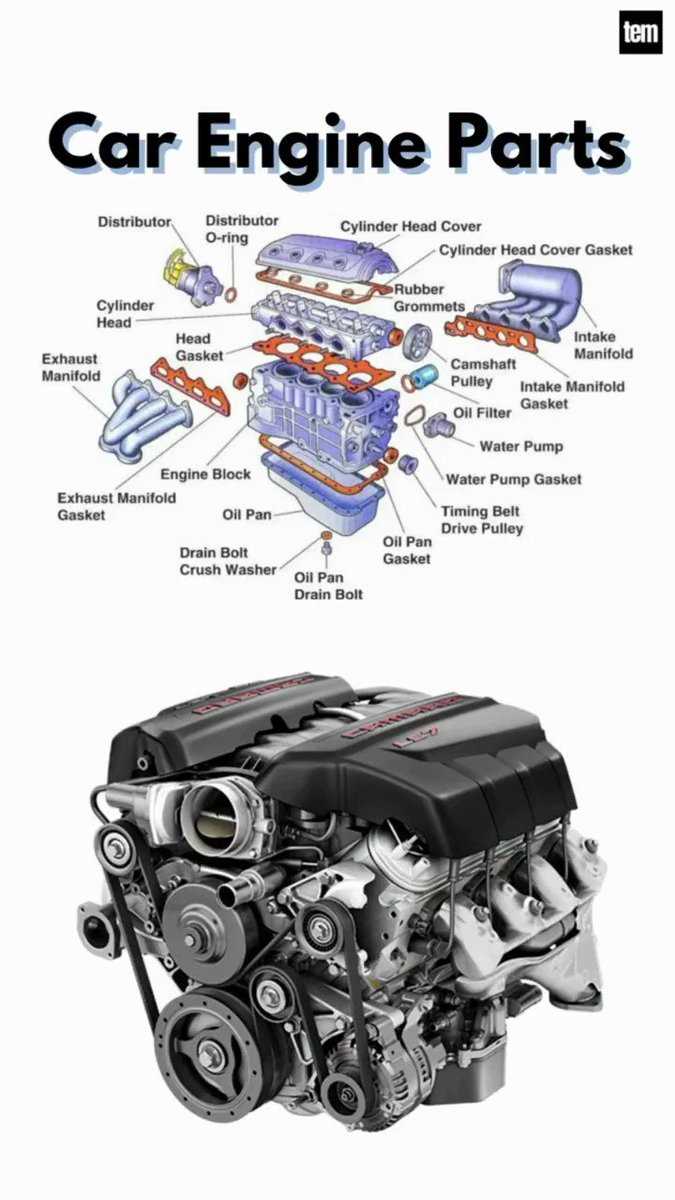

A V8 power unit consists of several interconnected elements that work in harmony to deliver efficient performance and power. These key elements are crucial for the smooth operation and optimal functionality of the unit, allowing it to handle a variety of demands from daily driving to high-performance scenarios. Below is an overview of the most important elements that form the core structure of this system.

| Component | Description | |||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

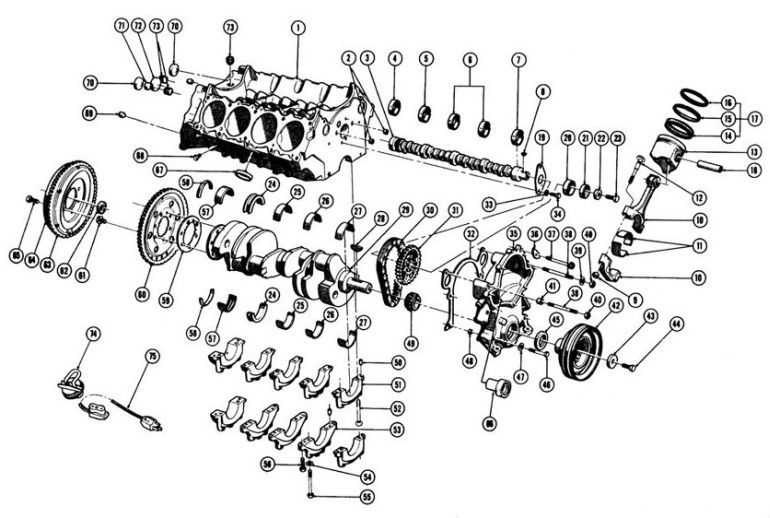

| Crankshaft | The central component that converts the linear motion of pistons into rotational motion, driving the system forward. | |||||||||||||||||||||||

| Cylinders | Eight chambers where fuel combustion occurs, providing the necessary power to move the pistons. | |||||||||||||||||||||||

| Pistons | Move up and down within the cylinders, driven by combustion, to transfer energy to the crankshaft. | |||||||||||||||||||||||

| Connecting Rods | Link the pistons to the crankshaft, transmitting the force generated by combustion. | |||||||||||||||||||||||

| Camshaft | Controls the timing of the intake and exhaust valves, ensuring precise opening and closing during operation. | |||||||||||||||||||||||

| Valves | Regulate the flow of air and exhaust gases in and out of the cylinders, critical for combustio

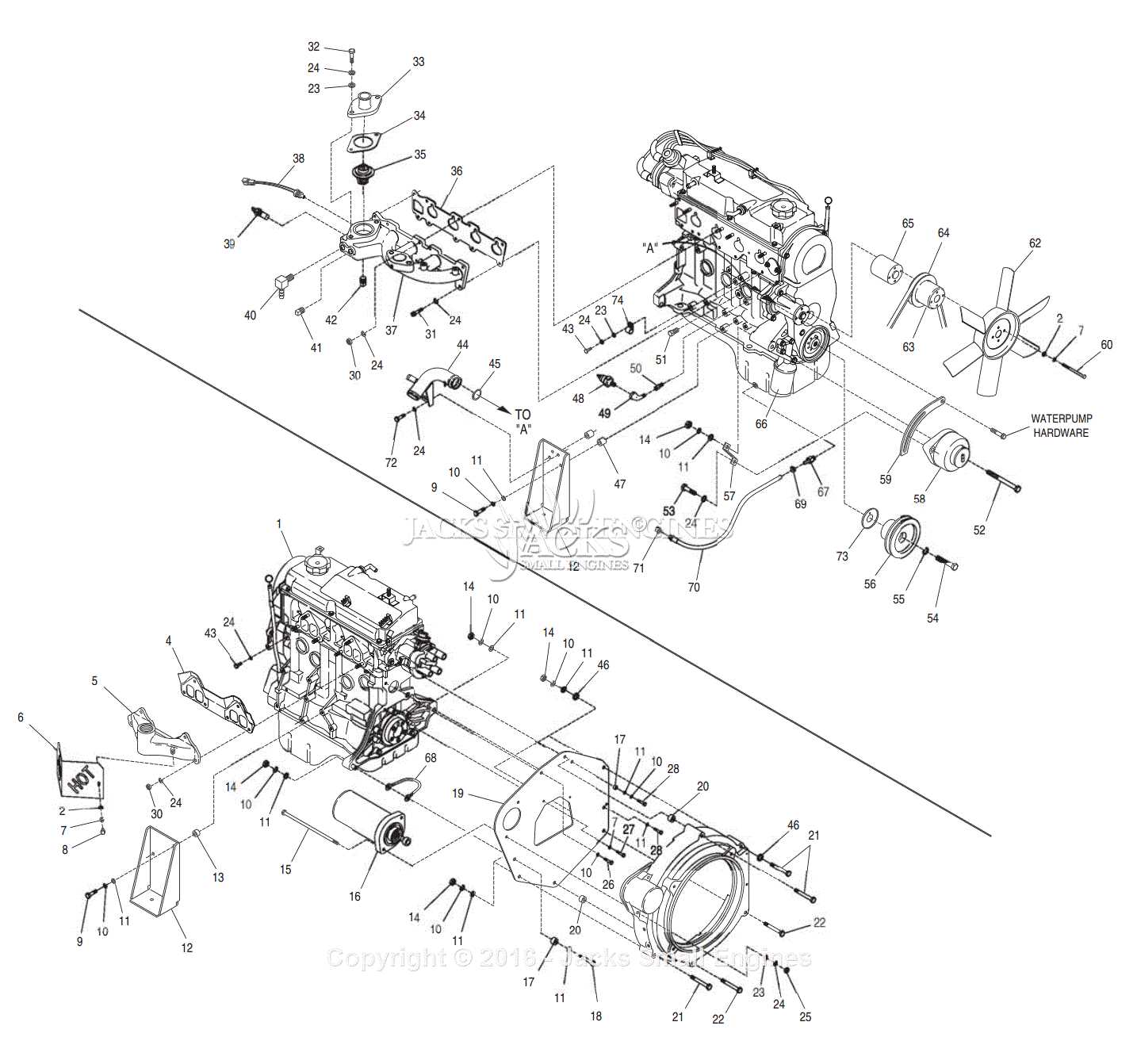

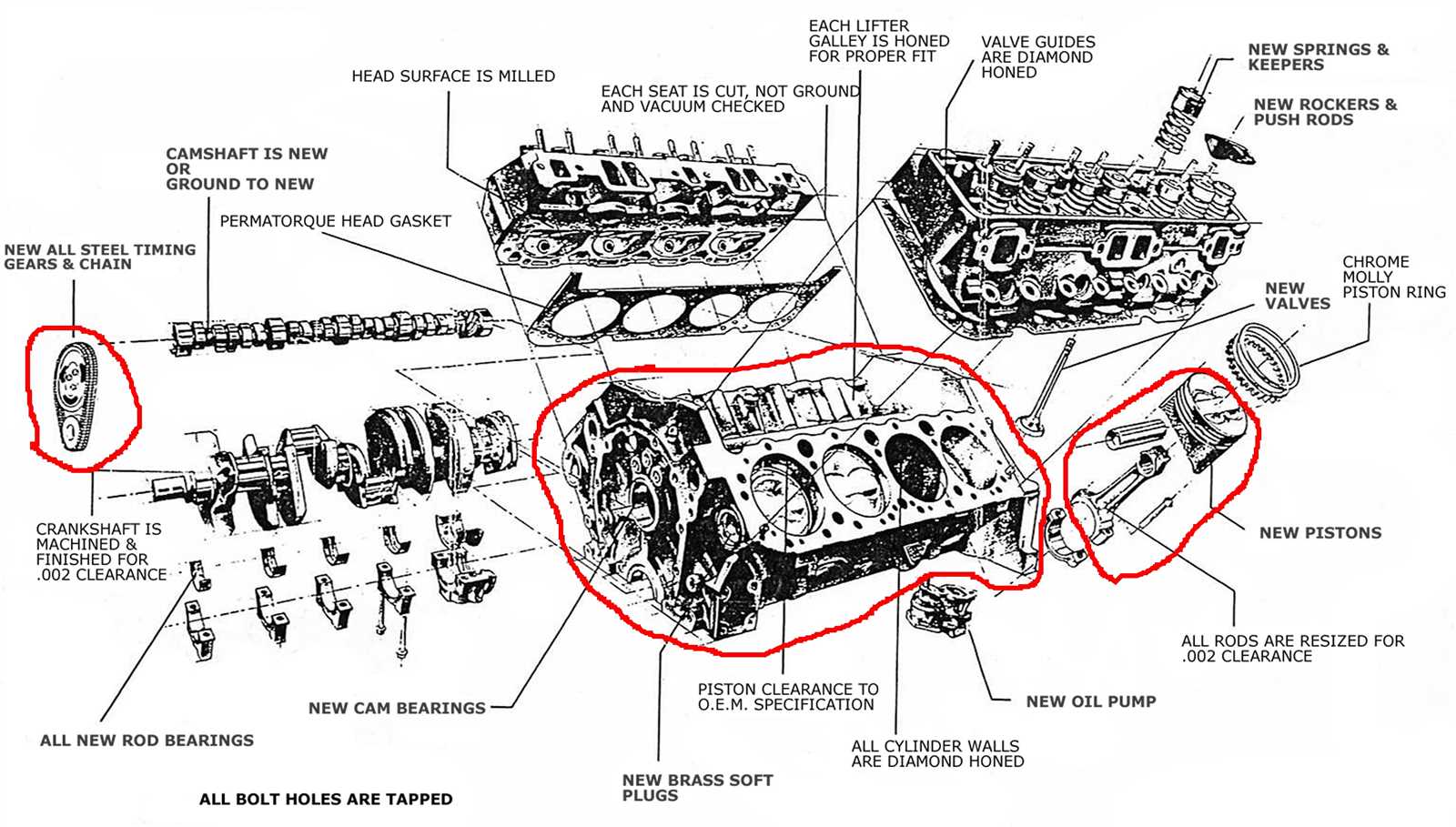

How Cylinders are Arranged in V8 Engines

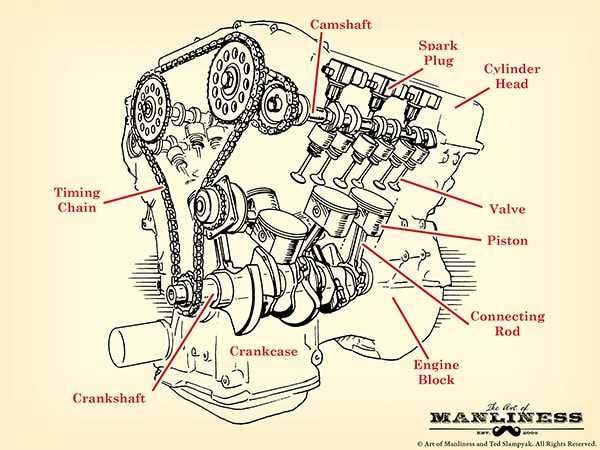

In this configuration, power-generating units are positioned to maximize efficiency and balance. The layout is designed to provide a smooth distribution of force and motion, ensuring high performance and stability during operation. By carefully placing these components, the structure achieves a balance that enhances the overall function of the system. The standard arrangement features two sets of four components placed in rows, with each set aligned opposite the other. This specific alignment creates a characteristic “V” shape, which is key to its name. The orientation of these units is meticulously crafted to ensure an even delivery of power, resulting in a powerful and reliable system. The symmetrical layout allows for an even distribution of movement between the rows, helping to maintain balance during function. This structure not only boosts overall performance but also contributes to a smoother, more controlled operation at high speeds. Crankshaft’s Role in V8 Operation

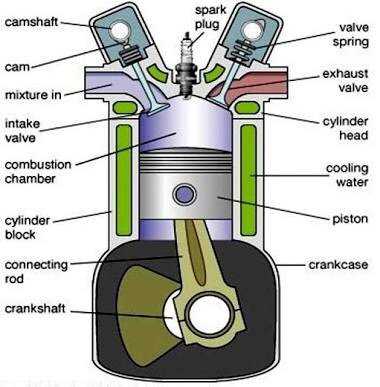

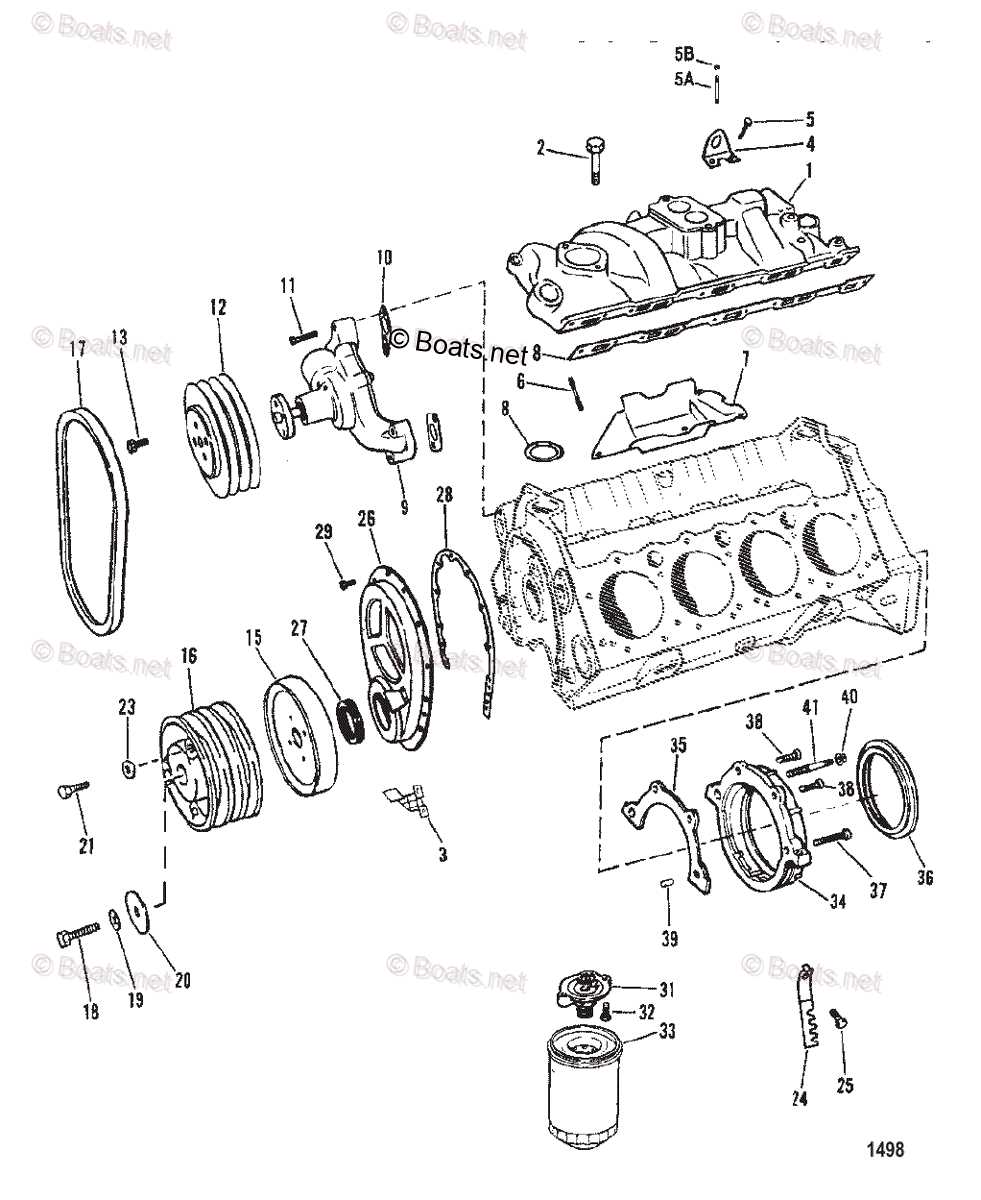

The crankshaft is at the heart of the V8’s functionality, converting the power produced into rotational movement. It transforms the linear force from the pistons into rotational energy, which is then directed to other components, ensuring smooth and efficient performance. This critical element operates in tandem with various systems to maintain a balanced and synchronized output. Balancing and Performance: Precision is vital for the crankshaft to handle the intense forces it encounters. Any imbalance can lead to vibrations, reducing overall performance and potentially causing damage. Special attention is paid to ensuring it remains properly aligned and weighted, keeping the entire assembly stable and optimized. Synchronization: The crankshaft plays a key role in timing, ensuring that the sequence of movements is perfectly coordinated. This precise coordination guarantees that the overall process runs smoothly, delivering power evenly and reliably. What Pistons Do in a V8 Engine

Pistons play a crucial role in the operation of any combustion system, particularly in a V8 configuration. These components are responsible for the conversion of energy generated by fuel combustion into mechanical motion. As they move up and down, they drive a sequence of processes that ultimately power the entire mechanism. Understanding how these elements function is essential to grasping the broader workings of this system. When the fuel ignites, the pistons begin their motion. This action creates a force that pushes downward, translating into rotational movement that is essential for overall performance. Without the continuous movement of these units, the entire structure would cease to function. They work in harmony with other moving parts, maintaining the balance required for smooth operation. Each stroke of the pistons contributes to a specific phase of the operation cycle, including intake, compression, combustion, and exhaust. The synchronized movement ensures that power is consistently generated, allowing the vehicle to run efficiently. In a V8, the unique arrangement of these components allows for a powerful yet balanced performance, making them an integral part of high-performance setups. Connecting Rod Functions in V8 Systems

The connecting rod plays a pivotal role in the performance and efficiency of V8 configurations. This critical component serves as a link between the crankshaft and the pistons, facilitating the transfer of force generated during combustion. Understanding its functions provides insight into the overall operation and mechanics of the system. One of the primary roles of the connecting rod is to convert the linear motion of the pistons into rotational motion for the crankshaft. This transformation is essential for maintaining the smooth operation of the entire system. Additionally, the connecting rod absorbs and mitigates the intense forces produced during combustion, ensuring stability and durability under high-stress conditions. Furthermore, the design of the connecting rod influences the overall performance characteristics, including acceleration and responsiveness. A well-engineered connecting rod contributes to reduced weight and improved strength, optimizing the system’s efficiency. The material composition and geometry are crucial in achieving the desired balance between flexibility and rigidity. In summary, the connecting rod is vital in the V8 configuration, directly impacting the power delivery and operational efficiency. Its ability to handle forces while facilitating motion underscores its significance in achieving optimal performance in modern vehicles. The Importance of V8 Camshafts

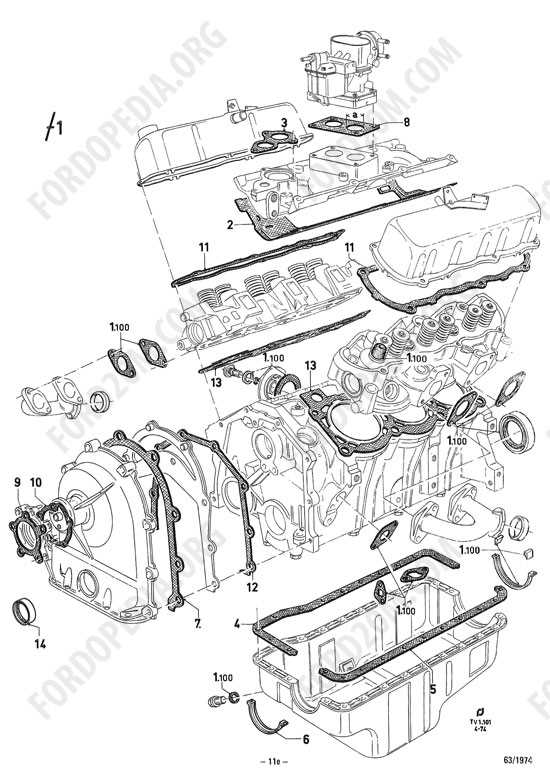

Camshafts play a pivotal role in the performance and efficiency of V8 configurations. They control the timing and duration of valve openings, directly influencing how air and fuel flow into the combustion chambers. This function is crucial for optimizing power output and overall operational smoothness. Precision in Timing: The accuracy of the camshaft’s rotation determines the precise moments at which valves open and close. This synchronization affects combustion efficiency, which can enhance torque and horsepower. A well-calibrated camshaft ensures that the engine breathes effectively, maximizing performance across various RPM ranges. Performance Tuning: Different camshaft profiles can dramatically alter the characteristics of a V8. For example, a camshaft designed for high-end power might prioritize valve lift and duration, while one aimed at low-end torque may focus on quicker response times. Choosing the right camshaft is essential for achieving specific performance goals. Additionally, the materials and design of camshafts contribute to durability and reliability. High-quality components reduce wear and tear, allowing for sustained performance under demanding conditions. Thus, investing in a premium camshaft can lead to long-term benefits and improved overall functionality. Fuel Injection Systems in V8 Engines

Fuel injection systems play a crucial role in optimizing performance and efficiency in V8 configurations. These systems are designed to precisely deliver the right amount of fuel to each cylinder, ensuring that combustion occurs efficiently. By controlling the fuel flow based on various parameters, these mechanisms enhance power output and reduce emissions, making them an essential component of modern automotive technology. Types of Fuel Injection Systems There are several types of fuel delivery systems commonly utilized in V8 configurations, each with its unique advantages. Sequential fuel injection offers precise control by injecting fuel into each cylinder individually, while multi-point injection supplies fuel to each intake port, promoting even distribution. In contrast, throttle body injection operates similarly to a carburetor, providing a simpler, yet effective method for fuel delivery. Benefits of Fuel Injection Implementing a fuel injection system in V8 setups results in improved throttle response, better fuel economy, and enhanced overall performance. Additionally, these systems contribute to lower emissions by ensuring a more complete combustion process. As automotive technology continues to evolve, the integration of advanced fuel injection systems remains pivotal in achieving higher efficiency standards. Conclusion In summary, fuel delivery mechanisms are fundamental to the operation of V8 configurations. By enabling precise control over fuel flow, these systems significantly enhance performance and sustainability, illustrating the importance of continuous innovation in automotive engineering. Exhaust System Design for V8 Engines

In the intricate orchestration of power and efficiency within high-performance V8 configurations, the pathway of exhaust gases presents a critical engineering challenge and opportunity. This section delves into the strategic design principles governing the route and optimization of exhaust flow. Optimizing Gas Flow Dynamics

Efficient expulsion of combustion byproducts necessitates meticulous planning to minimize backpressure and maximize scavenging effects. By carefully sculpting the pathways, engineers aim to enhance engine breathing, thereby augmenting overall performance without compromising environmental standards.

Integration with Vehicle DynamicsBeyond its functional role, the exhaust system’s design must harmonize with the vehicle’s overall dynamics, considering factors such as weight distribution, aerodynamics, and regulatory standards. This holistic approach ensures that performance enhancements align with safety and environmental imperatives. Cooling Mechanism in a V8 Power UnitIn high-performance automotive systems like the V8 power unit, ensuring optimal operating temperatures is critical for sustained efficiency and longevity. The cooling mechanism plays a pivotal role in maintaining thermal equilibrium within the intricate network of components. Heat Dissipation Strategy

The primary function involves managing thermal energy generated during operation through efficient dissipation techniques. This involves directing heat away from critical areas using specialized channels and conduits.

Coolant Circulation Dynamics

The cooling process involves the cyclic movement of coolant, which absorbs heat from the engine and carries it to the radiator for dissipation. This continuous flow is crucial for maintaining optimal operating temperatures under varying conditions. Ignition Systems in V8 Configurations

In V8 engines, the mechanism responsible for sparking the fuel-air mixture is critical for efficient combustion and engine performance. This essential system initiates the combustion process within the engine’s cylinders, utilizing advanced electronic components and precise timing to ensure optimal power delivery. Spark initiation in these configurations relies on sophisticated electronic controls that precisely time the ignition sequence, enhancing both fuel efficiency and power output. Electronic components such as ignition coils and control modules play pivotal roles in this process, ensuring reliable ignition across all cylinders. The timing of the spark, carefully synchronized with the engine’s rotation, is crucial for maximizing engine efficiency and minimizing emissions. This synchronization is managed by the engine control unit (ECU), which processes various sensor inputs to determine the ideal moment for each spark event. Overall, ignition systems in V8 engines exemplify the fusion of advanced electronics with mechanical precision, embodying decades of automotive engineering refinement aimed at optimizing performance and reliability. How V8 Valves Control Airflow

The functionality of the V8 configuration relies significantly on the intricate mechanisms that regulate the intake and exhaust of air and fuel. This system is crucial for maintaining optimal performance, efficiency, and power output. Understanding how these components interact can enhance knowledge of overall operation and maintenance. Role of Valves in Airflow Management

Valves are pivotal in determining the timing and quantity of the air-fuel mixture entering the combustion chambers and the exhaust gases exiting. The precise coordination of these elements allows for efficient combustion cycles, directly impacting the performance of the vehicle. Key factors include:

Types of Valves in V8 Configurations

Various types of valves serve different functions, contributing to the overall effectiveness of airflow management. Each type plays a unique role in enhancing the performance of the system:

In summary, the orchestration of these components is essential for achieving efficient airflow, significantly affecting overall vehicle performance. |