The efficient operation of a high-performance power unit relies on a myriad of essential components working in harmony. Familiarity with these elements not only enhances maintenance practices but also aids in troubleshooting potential issues that may arise during operation. Each part plays a significant role in the overall functionality, contributing to the unit’s reliability and effectiveness.

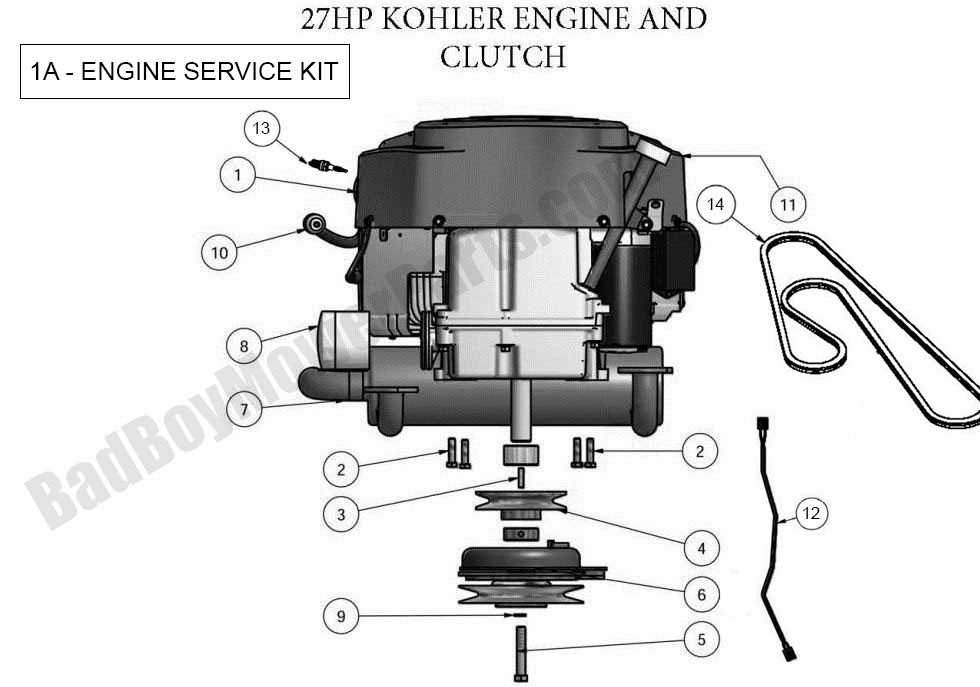

In this section, we will explore the various elements that comprise a 22 HP power system. From the core assembly that generates mechanical energy to the auxiliary components that facilitate optimal performance, understanding their arrangement and purpose is crucial for any operator. Knowledge of these elements empowers users to make informed decisions regarding repairs and upgrades.

Furthermore, grasping the relationships between different components can lead to improved longevity and performance. This insight is especially valuable for those involved in routine maintenance or seeking to enhance their unit’s efficiency. Whether for personal use or professional applications, a thorough comprehension of these intricacies will ensure a more seamless and productive experience.

This section delves into the essential elements that contribute to the functionality and performance of the power unit. Understanding these components provides valuable insight into how each part works together to ensure optimal operation and efficiency.

Primary Elements

- Crankshaft: This crucial part converts the linear motion of the pistons into rotational movement, driving the output shaft.

- Piston: This component moves up and down within the cylinder, creating the necessary compression for fuel ignition.

- Camshaft: Responsible for controlling the timing of the intake and exhaust valves, allowing air and fuel to enter and exhaust gases to exit.

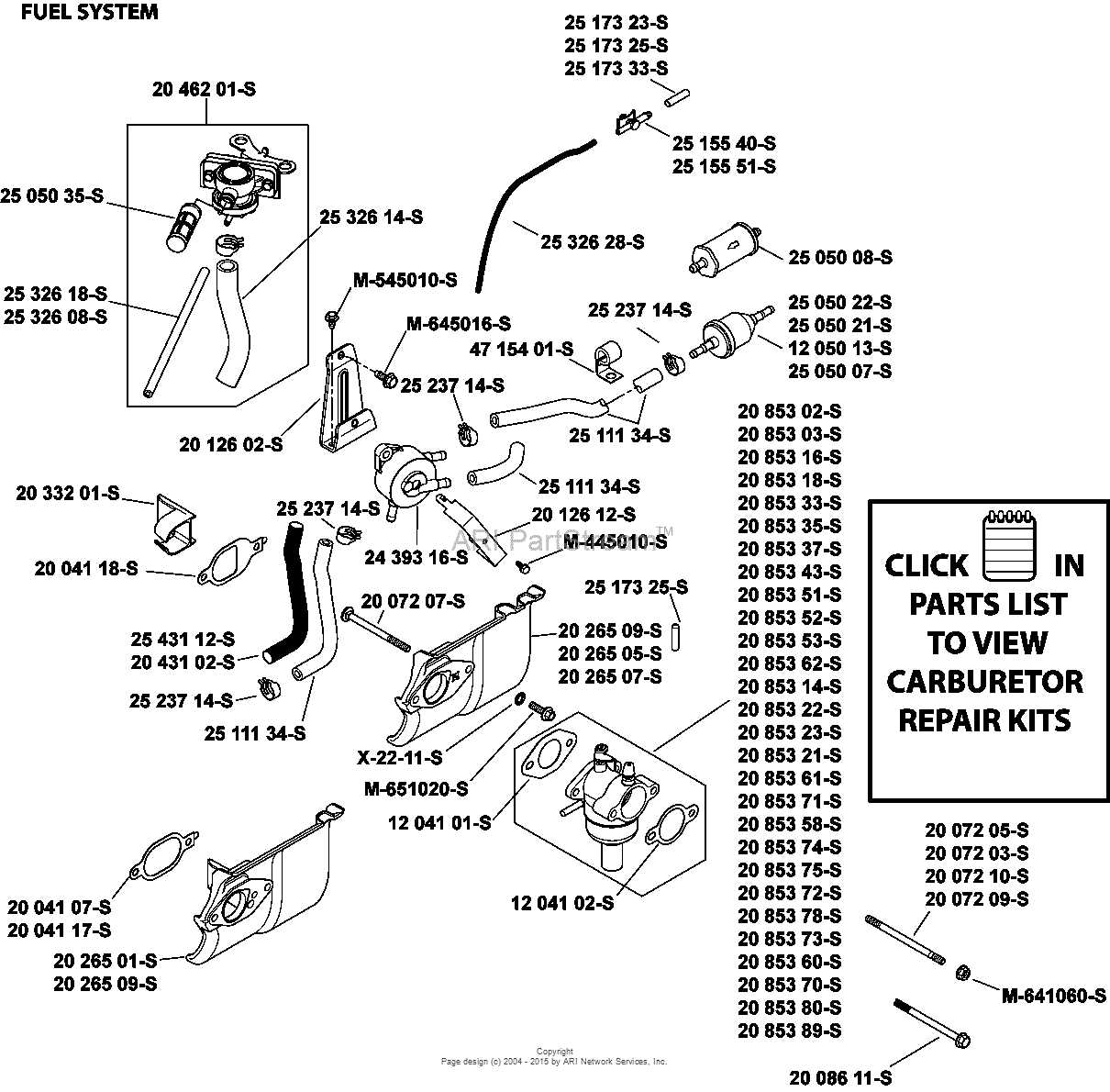

- Fuel System: This includes the carburetor or fuel injector, which mixes the right amount of fuel with air for combustion.

Supporting Structures

- Cooling System: Ensures that the internal temperature remains within safe limits, preventing overheating and maintaining performance.

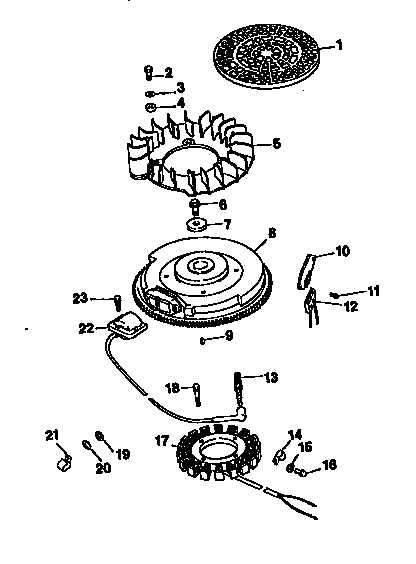

- Ignition System: Generates the spark needed for combustion, typically involving a spark plug and ignition coil.

- Lubrication System: Provides necessary oil flow to reduce friction between moving parts, enhancing longevity and efficiency.

- Exhaust System: Directs exhaust gases away from the unit, helping to maintain optimal performance and reduce emissions.

Understanding Engine Functionality

Grasping the mechanisms behind a power source’s operation is essential for effective maintenance and troubleshooting. This knowledge allows users to recognize how various components interact to produce motion and energy, ensuring optimal performance.

At its core, a power-generating unit transforms fuel into mechanical work through a series of synchronized processes. These processes involve intake, compression, combustion, and exhaust, each critical for the overall efficiency of the system. Understanding these stages helps in identifying issues that may arise during operation.

| Process | Description |

|---|---|

| Intake | Air and fuel mixture enters the chamber. |

| Compression | The mixture is compressed, increasing its temperature and pressure. |

| Combustion | The spark ignites the compressed mixture, creating an explosion that drives the piston. |

| Exhaust | Burned gases are expelled from the chamber, making way for a new cycle. |

By comprehensively understanding these functions, users can enhance the longevity and reliability of their equipment while ensuring it operates smoothly and efficiently.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the extended lifespan and optimal performance of your machinery. Regular care not only enhances efficiency but also minimizes the risk of unexpected failures. Implementing a structured maintenance routine will help in preserving functionality and reliability over time.

Regular Inspection

Frequent checks of key components can prevent minor issues from escalating into major problems. Focus on identifying wear and tear, as well as any signs of leakage or abnormal noise. Keeping a log of inspections can also be beneficial for tracking changes over time.

Fluid Changes

Maintaining clean and adequate levels of all fluids is crucial for smooth operation. Regularly changing the oil, coolant, and fuel filters can enhance performance and reduce wear. Refer to the manufacturer’s recommendations for the appropriate intervals for fluid changes.

| Maintenance Task | Frequency |

|---|---|

| Oil Change | Every 50 hours |

| Air Filter Check | Every 25 hours |

| Spark Plug Replacement | Every 100 hours |

| Fuel Filter Replacement | Every 200 hours |

| Coolant Level Check | Every 50 hours |

Identifying Common Issues

Understanding frequent problems that can arise in small power sources is essential for effective maintenance and operation. Recognizing these issues early can prevent more significant failures and ensure optimal functionality.

One prevalent concern is inadequate performance, often manifesting as reduced power output or sluggish operation. This can stem from various factors, including fuel quality, air intake blockages, or issues within the ignition system.

Another common difficulty involves unusual noises, which may indicate wear or malfunction of internal components. Regular inspection of moving parts and their lubrication can help mitigate this risk.

Additionally, overheating can pose a serious threat to longevity. Ensuring proper cooling systems are functioning and checking coolant levels are critical steps to avoid this problem.

Lastly, leaks from gaskets or seals should not be overlooked. Regularly examining these areas can help identify potential leaks before they lead to more extensive damage.

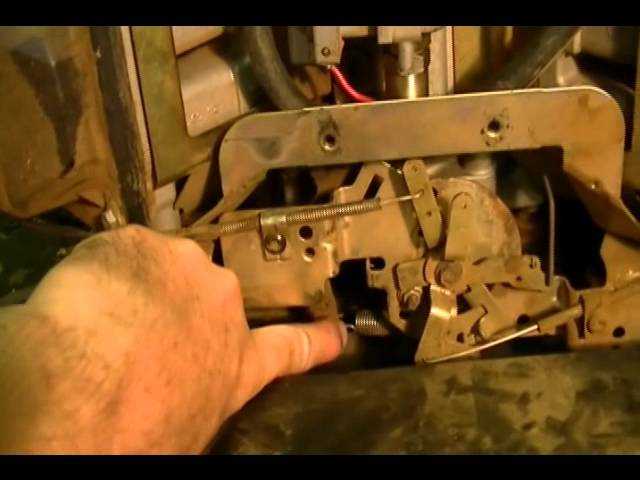

Parts Replacement Procedures

Maintaining optimal performance requires periodic updates of various components. Following specific guidelines can ensure the longevity and efficiency of the machinery. This section outlines essential steps for effectively swapping out worn or malfunctioning items, emphasizing safety and precision.

Preparation Steps

Before starting any replacement task, gather necessary tools and ensure a clean workspace. It is crucial to refer to the user manual for particular specifications and recommendations regarding compatible components. Disconnect power sources to avoid accidents and ensure personal safety throughout the process.

Replacement Process

Follow these sequential steps to ensure a successful replacement:

| Step | Action | Notes |

|---|---|---|

| 1 | Identify the component that requires replacement. | Inspect for wear, damage, or inefficiency. |

| 2 | Remove any obstructions or coverings. | Ensure easy access to the target item. |

| 3 | Detach the faulty component carefully. | Use appropriate tools to avoid damage. |

| 4 | Install the new component securely. | Follow torque specifications if applicable. |

| 5 | Reassemble any removed parts. | Double-check connections and placements. |

| 6 | Reconnect the power source and test functionality. | Monitor for unusual noises or performance issues. |

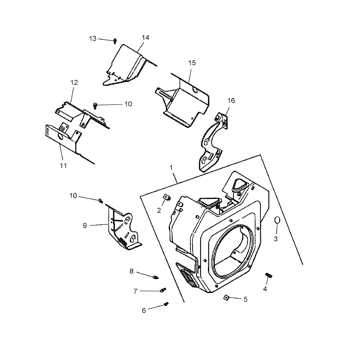

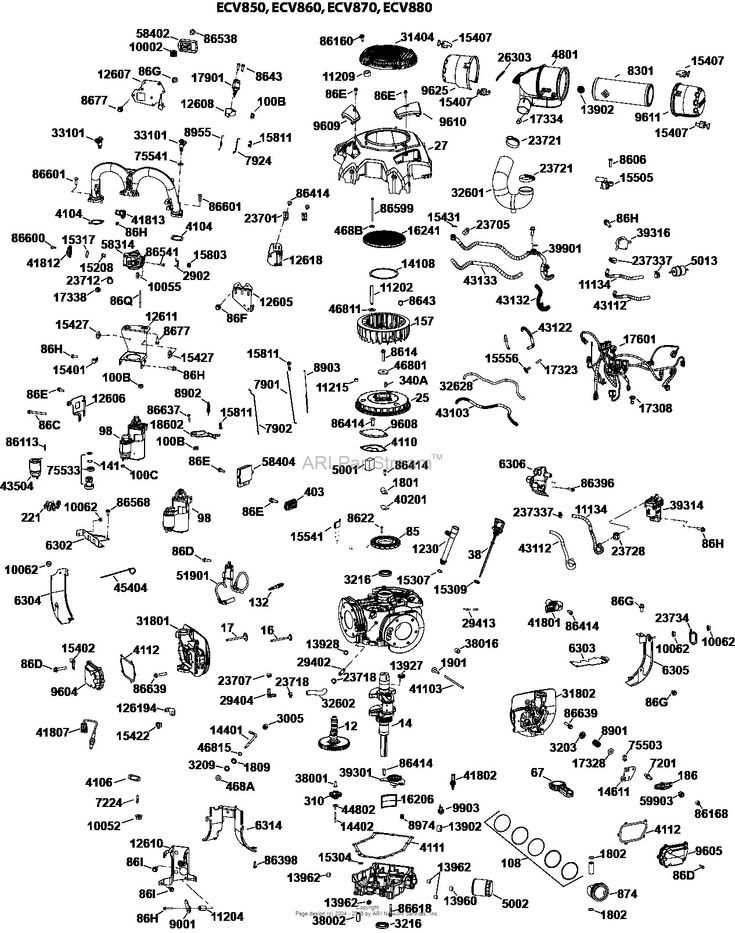

Diagram Interpretation Guide

This section aims to provide insights into effectively understanding visual representations of mechanical assemblies. Familiarizing yourself with these illustrations can significantly enhance your ability to identify components and their relationships within the system.

When examining a visual representation, focus on the symbols and lines that indicate how various elements connect and interact. Labels often accompany these visuals, offering specific names or functions for each component. Pay close attention to any color coding or patterns that may signify different types of parts or their operational roles.

Additionally, consider the scale and orientation of the illustration. A well-structured visual will clearly indicate the perspective from which the components are viewed. Understanding this context is crucial for correctly interpreting the layout and function of the individual pieces.

Finally, cross-referencing the visual with an accompanying list or glossary can provide further clarity. This approach will enable you to gain a comprehensive understanding of the assembly, facilitating maintenance, troubleshooting, or upgrades as necessary.

Recommended Tools for Repairs

Having the right equipment is essential for performing maintenance and fixes effectively. A well-equipped workspace not only speeds up the process but also ensures precision and safety during tasks. Below are some recommended implements that can assist in various repair jobs.

Basic Hand Tools

- Wrenches: A set of adjustable and fixed wrenches will accommodate various sizes of bolts and nuts.

- Screwdrivers: Phillips and flathead screwdrivers in different sizes are vital for loosening or tightening screws.

- Pliers: Needle-nose and slip-joint pliers are useful for gripping, twisting, and cutting wires or small components.

Specialized Equipment

- Torque Wrench: Ensures that bolts are tightened to the manufacturer’s specifications.

- Multimeter: Essential for diagnosing electrical issues and testing voltages.

- Mechanic’s Creeper: Provides comfort and ease of movement while working underneath components.

Having these tools readily available can significantly enhance your repair experience, allowing for more efficient and effective work. Proper maintenance is key to prolonging the life of any machinery, and the right tools make all the difference.

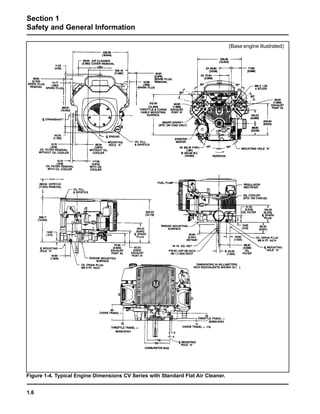

Engine Specifications and Features

This section provides an overview of the essential characteristics and capabilities of a specific power unit designed for high-performance applications. Understanding these specifications is crucial for those looking to maintain, repair, or upgrade their machinery, ensuring optimal functionality and efficiency.

Technical Details

The unit is a reliable four-stroke power source with a displacement of 22 horsepower, making it suitable for various demanding tasks. It operates using a horizontal shaft design, enabling seamless integration with numerous attachments. Additionally, its air-cooled configuration helps maintain optimal temperatures during operation, prolonging lifespan and performance.

Operational Features

Equipped with a cast-iron cylinder and a high-capacity fuel system, this power unit ensures consistent performance under heavy loads. The integrated ignition system guarantees quick starts, while the durable construction minimizes maintenance needs. Furthermore, the design includes features that enhance fuel efficiency, making it an economical choice for users.

Where to Find Replacement Parts

Finding high-quality components for your small power unit is crucial for maintaining its performance and longevity. Fortunately, there are various avenues to explore when searching for suitable replacements. Here’s a guide to help you locate the necessary components efficiently.

Authorized Dealers and Retailers

One of the most reliable sources for obtaining components is through authorized dealers and retailers. They typically stock genuine items that meet the manufacturer’s specifications.

- Visit local dealers in your area.

- Check online platforms for authorized distributors.

- Inquire about warranties and return policies to ensure satisfaction.

Online Marketplaces

The internet provides a plethora of options for sourcing quality replacements. Numerous online marketplaces cater to various needs and budgets.

- Amazon and eBay often have listings for new and used components.

- Specialized websites focus on outdoor equipment and machinery parts.

- Read customer reviews to gauge the reliability of sellers.

By exploring these options, you can find the necessary items to keep your power unit operating smoothly.

Understanding Warranty Options

When investing in machinery, it is essential to comprehend the coverage provided for your purchase. Warranty plans are designed to safeguard your investment by offering repair or replacement services under specific conditions. Familiarizing yourself with these options can enhance your experience and ensure that you receive the necessary support should any issues arise.

Most warranty options vary in terms of duration and the scope of coverage. Some plans may offer comprehensive protection against defects in materials and workmanship, while others might be more limited. It is crucial to evaluate the details of each warranty to determine what is included and what might incur additional costs.

Moreover, understanding the claims process is vital. Knowing how to initiate a claim and what documentation is required can save time and reduce stress if repairs are needed. Keep in mind that warranties may also have specific maintenance requirements that must be adhered to in order to remain valid.

Ultimately, selecting a warranty option that aligns with your usage expectations and maintenance capabilities will provide peace of mind. Thoroughly reviewing the terms and conditions can help you make an informed decision, ensuring your machinery remains in optimal condition for years to come.