The intricate design of a winter vehicle plays a crucial role in its performance and efficiency. Understanding the various elements that come together to create this machine is essential for anyone interested in its operation. Each component has a specific function that contributes to the overall functionality, ensuring a smooth ride over snow-covered landscapes.

Examining the layout of these elements provides valuable insights into how they interact and support one another. By gaining familiarity with these components, users can better appreciate the engineering behind the vehicle and its ability to navigate challenging terrains. Additionally, this knowledge can assist in maintenance and troubleshooting, enhancing the longevity and reliability of the machine.

Exploring the relationships between these elements not only deepens one’s understanding but also enriches the experience of operating such vehicles. As enthusiasts delve into the specifics, they uncover the complexity and ingenuity that characterize these winter machines, allowing for a greater appreciation of their capabilities.

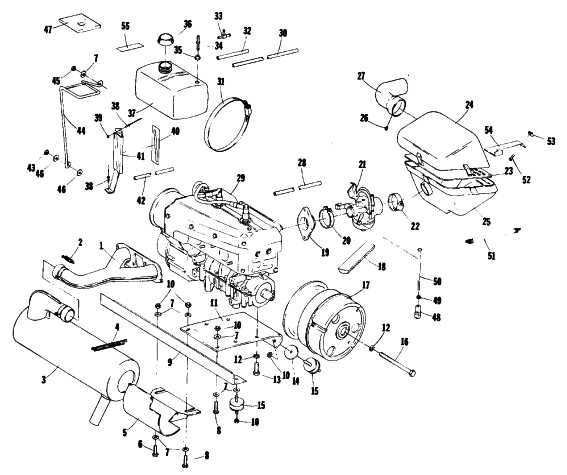

Snowmobile Engine Components Overview

This section provides a comprehensive look at the essential elements that power winter vehicles. Understanding these components is crucial for maintenance and performance optimization.

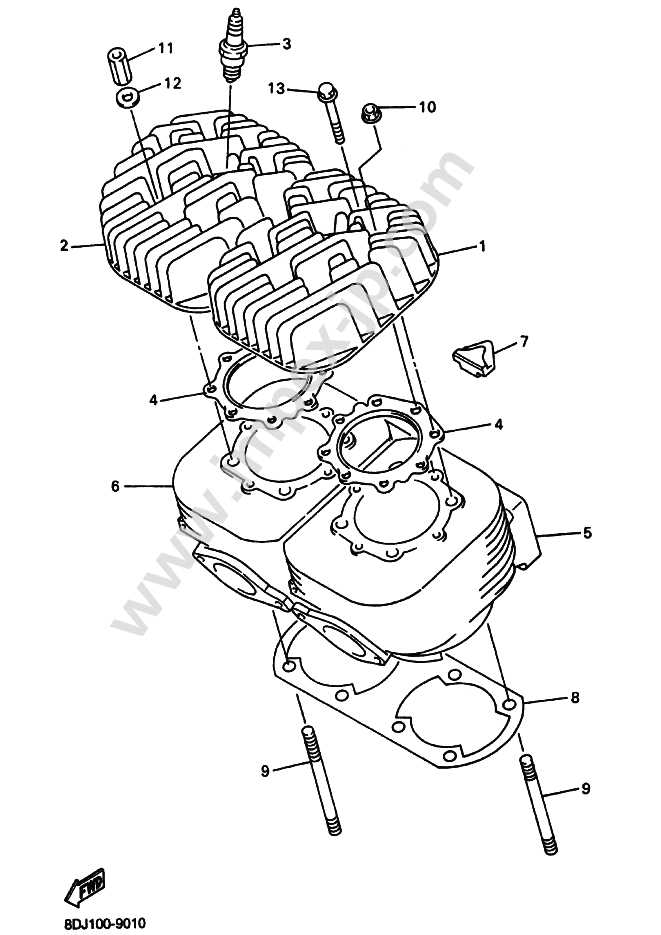

- Combustion Unit: The core mechanism responsible for energy production through fuel ignition.

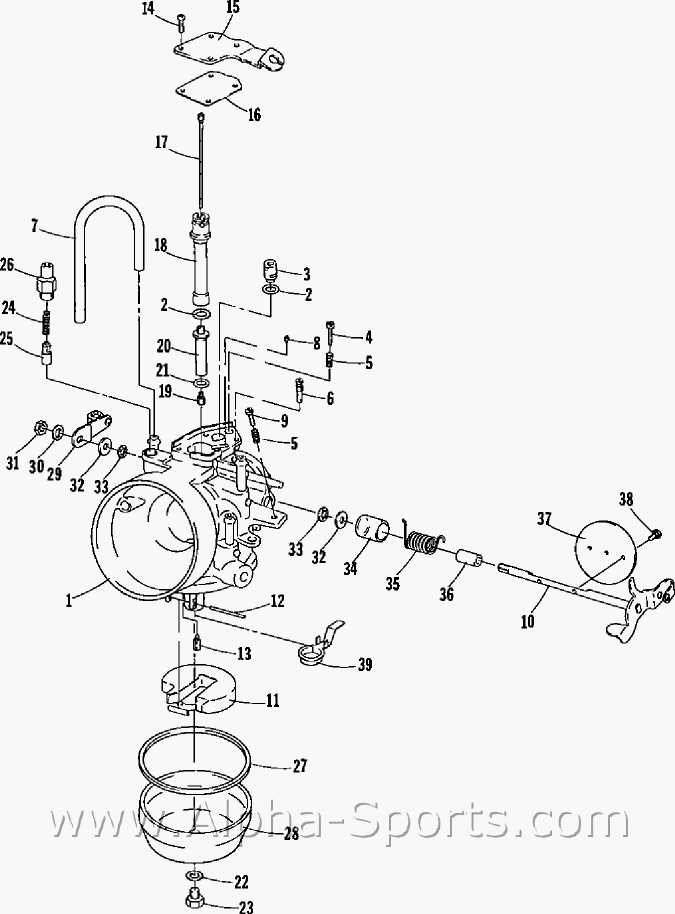

- Fuel Delivery System: Manages the transportation of fuel to the combustion unit for efficient operation.

- Cooling System: Maintains optimal temperature to prevent overheating during use.

- Exhaust Arrangement: Facilitates the removal of gases generated during the combustion process.

- Ignition Assembly: Initiates the combustion process to generate power.

- Lubrication Mechanism: Ensures smooth movement of moving components by reducing friction.

Each of these elements plays a vital role in the overall functionality of the vehicle, contributing to a seamless and enjoyable riding experience.

Understanding Engine Functionality

The inner workings of a propulsion unit are crucial for optimal performance and efficiency. This complex assembly consists of various components that work harmoniously to convert fuel into mechanical energy. Each element plays a distinct role in the overall process, contributing to the unit’s ability to operate smoothly under diverse conditions.

At the core of this assembly is the process of combustion, where fuel and air mix and ignite to produce power. This reaction generates the necessary force to drive the connected systems. Moreover, the coordination of moving elements ensures that the generated energy is effectively harnessed and transmitted to the desired locations, enabling a seamless experience for the user.

Understanding the interactions between these components is essential for maintenance and troubleshooting. By familiarizing oneself with how each part functions and contributes to the whole, one can make informed decisions regarding care and improvements, ultimately enhancing performance and longevity.

Key Parts of Snowmobile Engines

This section explores the essential components that contribute to the performance and functionality of a winter vehicle’s propulsion system. Understanding these elements is crucial for maintenance and optimal operation.

Core Components

- Power Source: The main element responsible for generating the necessary energy.

- Fuel Delivery System: Mechanism that ensures the efficient supply of energy source to the combustion area.

- Ignition System: Responsible for initiating the combustion process at the correct moment.

- Cooling Mechanism: Aids in regulating temperature to prevent overheating during operation.

Supportive Elements

- Exhaust System: Manages the release of byproducts resulting from combustion.

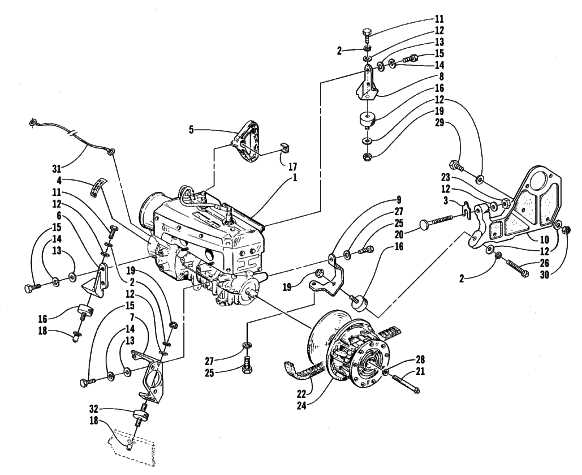

- Transmission: Transfers generated power to the track for movement.

- Lubrication System: Provides essential fluids to minimize friction and wear between moving parts.

- Chassis: The framework that houses and supports various components.

Importance of Each Component

Understanding the significance of individual elements within a machinery setup is crucial for optimal performance and longevity. Each segment plays a unique role, contributing to the overall functionality and efficiency of the system. Grasping the importance of these components enables users to identify potential issues and ensure smooth operation.

Fuel System: This aspect ensures a proper supply of energy, crucial for the operation. Any inconsistencies can lead to reduced performance.

Cooling Mechanism: Maintaining an appropriate temperature is vital. Overheating can cause significant damage, so this component must function effectively.

Lubrication System: Proper lubrication minimizes friction, enhancing the longevity of moving parts. Insufficient lubrication can lead to wear and tear, impacting overall efficiency.

Ignition System: This system initiates combustion, making it essential for starting and maintaining operations. A malfunction here can halt functionality entirely.

Transmission Assembly: This assembly transfers power from the source to the wheels, facilitating movement. Its efficiency directly affects speed and maneuverability.

Exhaust System: Properly channeling emissions is important for safety and environmental considerations. An ineffective exhaust system can lead to harmful buildup and operational issues.

In summary, recognizing the role of each component aids in effective maintenance and enhances overall performance, ensuring a seamless experience during use.

Common Issues with Engine Parts

Understanding the typical problems that arise with various components of a motorized unit can enhance maintenance and performance. Recognizing these common challenges allows for timely interventions, ensuring smooth operation and longevity.

| Issue | Description | Potential Solutions |

|---|---|---|

| Overheating | Excessive heat can cause components to warp or fail. | Check coolant levels and inspect the cooling system for blockages. |

| Unusual Noises | Strange sounds may indicate wear or damage. | Perform a thorough inspection and replace any worn components. |

| Difficulty Starting | Issues with ignition or fuel supply can hinder starting. | Examine the ignition system and fuel lines for obstructions. |

| Excessive Vibration | Vibrations can signify imbalances or loose fittings. | Ensure all connections are secure and consider balancing components. |

Maintenance Tips for Longevity

Ensuring the durability of your vehicle requires consistent care and attention. Implementing effective maintenance practices not only enhances performance but also extends the lifespan of essential components. Below are several key recommendations to keep in mind.

Regular Inspections

Conduct frequent evaluations of critical elements to identify potential issues early. Look for signs of wear, corrosion, or any irregularities that could lead to larger complications. Addressing minor concerns promptly can prevent more significant problems down the line.

Proper Lubrication

Maintaining appropriate lubrication is vital for reducing friction and wear between moving components. Use high-quality lubricants that are compatible with your machinery. Regularly check levels and replenish as needed to ensure smooth operation.

By following these maintenance tips, you can significantly enhance the reliability and performance of your vehicle, ultimately ensuring a longer and more enjoyable experience.

How to Identify Damaged Parts

Recognizing issues in mechanical components is crucial for maintaining optimal performance. Being able to spot wear and tear can prevent further complications and enhance longevity. This section outlines effective methods to detect faulty elements within the system.

Visual Inspection

Start by conducting a thorough visual check. Look for any signs of cracks, discoloration, or unusual wear patterns. Pay close attention to areas that experience high levels of stress, as these are more prone to damage. A comprehensive assessment will help you identify any potential problems early on.

Functional Testing

After the visual inspection, perform functional tests to assess the efficiency of the components. Listen for any irregular noises during operation, which could indicate underlying issues. Additionally, monitor for unexpected vibrations or performance inconsistencies that may signal malfunctioning parts.

Upgrading Engine Components Effectively

Enhancing the performance of your vehicle can significantly impact its overall efficiency and reliability. By focusing on specific elements within the system, you can achieve noticeable improvements that cater to your unique driving needs. This approach allows for tailored modifications, ensuring that every upgrade aligns with your expectations and enhances functionality.

Identifying Key Areas for Improvement

Before diving into enhancements, it’s crucial to assess which components will yield the most significant benefits. Prioritize elements that influence power output, fuel efficiency, and overall durability. Research and analysis of existing specifications can guide you in selecting the best options for upgrades that align with your performance goals.

Implementing Upgrades Wisely

Once you have identified the components for enhancement, the next step is to implement changes thoughtfully. Opt for high-quality replacements that meet or exceed original specifications. Additionally, consider consulting with experts or referring to reputable resources to ensure proper installation and compatibility. This will not only maximize the benefits of your upgrades but also help maintain the integrity of your vehicle’s systems.

Choosing Quality Replacement Parts

When it comes to maintaining performance and reliability, selecting superior components is crucial. The quality of these elements can significantly influence the overall functionality and longevity of your vehicle. Making informed choices ensures optimal operation and reduces the risk of future complications.

Here are some key factors to consider when selecting high-quality components:

- Material Quality: Look for components made from durable materials that can withstand wear and tear.

- Compatibility: Ensure that the replacement elements are designed to fit your specific model accurately.

- Manufacturer Reputation: Choose parts from reputable manufacturers known for their reliability and performance.

- Warranty: Opt for components that come with a warranty, indicating confidence in the product’s durability.

- Reviews and Ratings: Research customer feedback and ratings to gauge the performance of the replacement items.

By prioritizing these aspects, you can enhance the efficiency and dependability of your vehicle, ensuring a smoother and safer experience on the trails.

Engine Assembly and Disassembly Guide

This section provides an overview of the procedures for putting together and taking apart the various components of a power unit. Understanding the correct methods ensures efficiency and longevity of the machinery, while also facilitating repairs and maintenance. Following these steps can help in achieving optimal performance and reliability.

Before starting the process, it’s essential to have a comprehensive understanding of the elements involved. A well-organized workspace with all necessary tools is vital. This ensures that the procedure can be conducted smoothly and effectively.

| Step | Description |

|---|---|

| 1 | Gather all required tools and components. |

| 2 | Begin with the disassembly of the outer casing. |

| 3 | Carefully remove internal mechanisms, noting their arrangement. |

| 4 | Clean all components thoroughly before reassembly. |

| 5 | Assemble the unit in reverse order, ensuring all connections are secure. |

| 6 | Test the assembled unit to confirm proper functionality. |

Following these guidelines will help in successfully managing the assembly and disassembly process, allowing for better maintenance and increased operational efficiency of the system.

Tools Needed for Repairs

When it comes to maintaining and fixing mechanical systems, having the right instruments is crucial. Proper tools not only facilitate efficient work but also ensure that tasks are completed safely and effectively. From basic hand tools to specialized equipment, a well-equipped workspace can make a significant difference in repair outcomes.

Essential Hand Tools

Basic hand tools are indispensable for any repair job. Common items such as wrenches, screwdrivers, and pliers should be readily available. These tools allow for adjustments and replacements without requiring extensive technical knowledge. It’s important to choose high-quality options to ensure durability and performance.

Specialized Equipment

In addition to standard tools, specific tasks may necessitate specialized equipment. Items like torque wrenches and multimeters are vital for precise measurements and adjustments. Investing in these instruments can lead to better results and prolong the lifespan of the system being serviced. Understanding when to use these tools is key to successful maintenance.

Impact of Engine Parts on Performance

The efficiency and effectiveness of a power unit are significantly influenced by its components. Each element plays a crucial role in determining how well the system operates under various conditions. Understanding the relationship between these components and overall functionality is essential for optimizing performance and ensuring longevity.

Key Components and Their Roles

Every individual component contributes uniquely to the functionality of the whole system. Their interaction and harmony can lead to improved output and responsiveness. Here are some fundamental elements that impact overall capability:

| Component | Function | Impact on Performance |

|---|---|---|

| Piston | Moves within the cylinder to compress and ignite fuel | Increases power and efficiency when designed for optimal movement |

| Crankshaft | Converts linear motion of the piston into rotational motion | Enhances power delivery and reduces vibration |

| Valves | Control the flow of fuel and air into the combustion chamber | Improve air-fuel mixture for better combustion efficiency |

| Fuel Injector | Sprays fuel into the combustion chamber | Ensures precise fuel delivery for optimal combustion |

Conclusion

Each component within the power unit is integral to achieving high performance. Their design, quality, and interaction dictate the overall efficiency and effectiveness of the system. Therefore, investing in superior components and understanding their roles can lead to enhanced operational success.